1. KNOW YOUR UNIT—Read owners manual carefully. Learn its

applications, limitations, capabilities and proper use.

2. HAZARDOUS LOCATIONS—Use hazardous duty motor in

locations where fire or explosion hazards may exist due to

flammable gases or vapors. Use air motor in a dust environment.

Use stainless steel pump for flammable liquids.

3. KEEP WORK AREA CLEAN—Cluttered areas and benches invite

accidents.

4. AVOID DANGEROUS ENVIRONMENT—As with any electric

power tool, don’t expose the unit to rain.

5. KEEP BYSTANDERS AWAY—All visitors and unauthorized

persons should be kept a safe distance from work areas.

6. STORE PROPERLY—As with any power tool, when not in use,

unit should be cleaned and stored in a dry place away from

unauthorized personnel.

7. DON’T FORCE TOOL—Do not use pump to break ice in drums or

break up sludge masses. Rapid wear and/or damage will occur

when pumping abrasives or thick materials.

8. WEAR PROPER APPAREL—No loose clothing or jewelry to get

caught on hoses or cords. Rubber gloves, aprons and footwear

are recommended.

9. USE SAFETY GLASSES— The operation of

any power tool can result in foreign objects

(splashing) being thrown into the eyes, which

can result in severe eye damage. Always wear

safety glasses with eye shields before com-

mencing power tool operation. We recommend

Wide Vision Safety Mask for use over

spectacles, or safety glasses.

10. DON’T ABUSE CORD—Never carry tool by

cord or yank it to

disconnect from receptacle. Keep cord from heat

and sharp edges

.

11.SECURE PUMP AND HOSE—When not pumping from a drum,

secure pump to prevent accidental immersion into tanks. Secure

discharge end of hose to prevent “whipping” of hose.

Secure hose clamp tight.

12.DO NOT IMMERSE—pump into fluid above pump discharge.

Do not immerse motor in any fluid.

13. DON’T OVERREACH—Keep proper footing and balance at all times

.

14.MAINTAIN EQUIPMENT with care — Keep pump clean for best

performance. Follow maintenance instructions.

15. DISCONNECT MOTOR—when not in use and before servicing,

remove plug from power supply.

16. AVOID ACCIDENTAL STARTING—Don’t carry plugged-in tool

with finger on switch. Be sure switch is off when plugging in.

17. KEEP HANDS AND FINGERS FROM IMPELLER.

18. KEEP FACE AWAY—Don’t look into hose, pump discharge or

suction.

19. REVIEW MATERIAL SAFETY DATE SHEET OF THE PRODUCT

TO BE PUMPED

.

INTRODUCTION

DOUBLE INSULATION is a concept in safety, in electric power tools,

which eliminates the need for the usual three wire grounded power

cord and grounded supply system. Wherever there is electric current

in the tool there are two complete sets of insulation to protect the user.

All exposed metal parts are isolated from the internal metal motor

components with protecting insulation.

IMPORTANT — Servicing of a motor with double insulation requires

extreme care and knowledge of the system and should be performed

only by a qualified service technician. For service, we recommend

returning your motor to Sethco.

HAZARDOUS DUTY MOTOR — When service is required, return to

factory. NOTE: This motor is equipped with a thermal overload sen-

sor. When activated the pump will stop and re-start automatically

when the motor cools.

Problem: Pump capacity reduced

1.

Worn impeller and/or suction intake

1. Replace

2. Low voltage 1. Check outlet

3. Thick fluids 1. Consult factory

4. Hose crimped 1. Straighten

5. Pump bearings worn 1. Replace

6. Motor bearing worn 1. Return to factory

7. Suction partially clogged 1. Unplug motor and clean

8. Discharge line restricted 1. Unplug motor and clear

CAUTION: Read rules for safe operation and instructions carefully

WEAR YOUR

SAFETY GLASSES

SWITCH

The standard 115V & 230V electric P90 motor is equipped with a

rocker switch located in the upper part of the handle. Press the upper

part of the rocker to start and the opposite half to stop. The switch

has a built in circuit breaker which will trip the switch in the event of

an overload. Be sure switch is in the “off” position before connecting

to power supply.

SWITCH

The hazardous duty motor is equipped with a rotary switch. Make sure

the switch is in the “off” position before connecting to power supply.

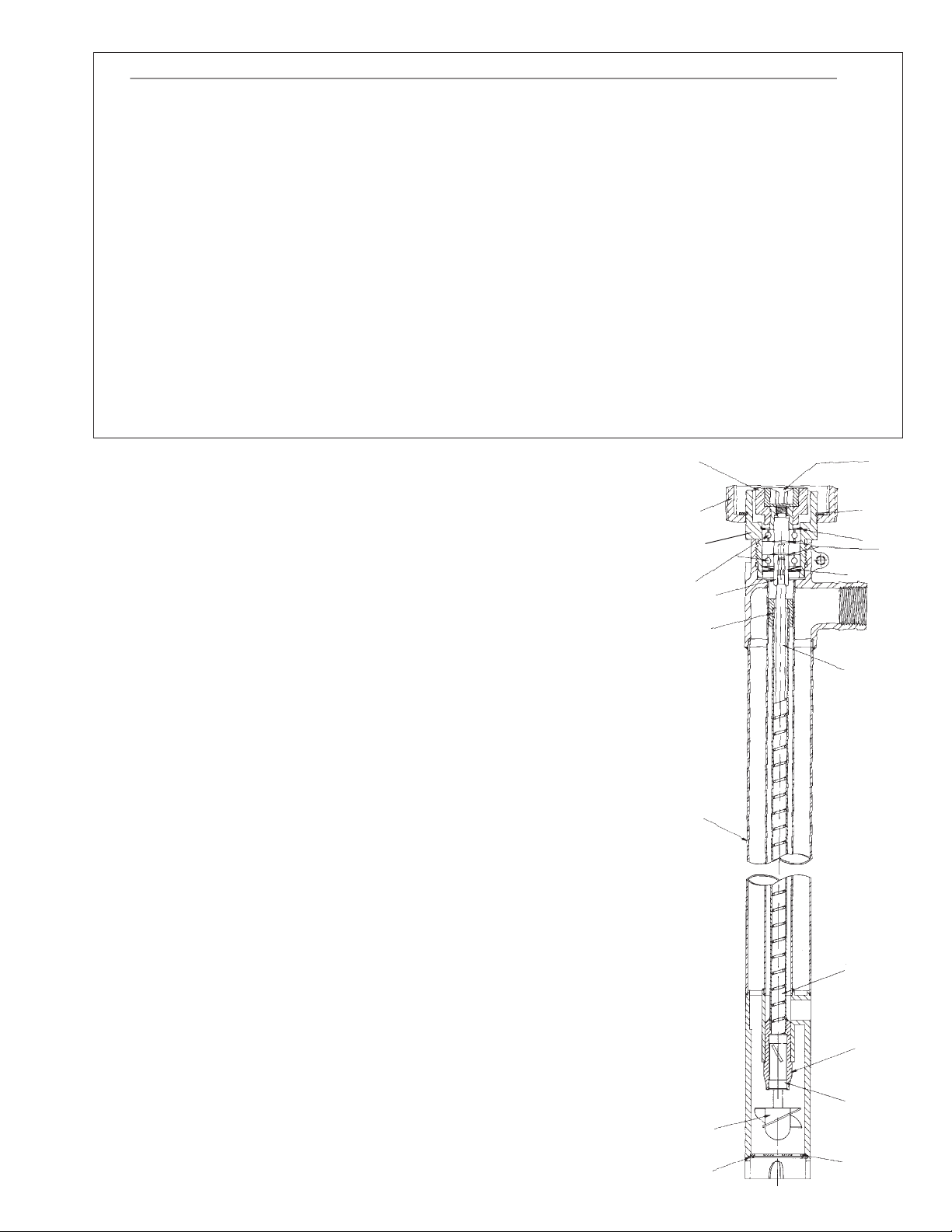

OPERATION

1. Align coupling splines and motor spline.

2. Align motor key and pump head.

3. Insert pump head into motor and secure with collar (1).

4. Slip hose clamp over hose end.

5. Slip hose onto pump discharge. Push hose onto full length of

discharge nipple. (1-1/8 inches).

6. Align hose clamp between discharge nipple “barbs”.

7. Tighten hose clamp.

START-UP (CAUTION — OBSERVE SAFETY RULES)

1. Insert pump into drum. 2. Control or secure discharge hose.

3. Plug in motor. 4. Switch unit on.

STOPPING

1. Switch unit off. 2. Unplug motor.

3. Lift pump from fluid slowly; allowing pump to drain.

STORAGE

1. Run pump in a rinsing solution for 30 seconds with discharge hose

open and 30 seconds with discharge hose closed.

2. Allow pump to drain.

3. Store in a secure area to prevent unauthorized use.

MAINTENANCE

When servicing, replace with original factory quality parts only. Only

the parts shown in the materials list are intended to be replaced by

the customer. The standard 115V & 230V motor is equipped with a

“DOUBLE INSULATION” system and should be serviced only by a

qualified service technician.

STAINLESS STEEL P90 DRUM PUMPS - SAFETY RULES