Nobili BNE Series Specification sheet

Shredder

type: BNE

04.09.2009

AGRICULTURAL MACHINERY MANUFACTURERS

2

04.09.2009

CORRECT USE OF THE MACHINE

WARNING: Before using the machine it is necessary to check the following points:

1°) The machine should be included in the weight and overall dimension limits mentioned in the

tractor use manual, regarding the equipped tools

2°) In case of rear coupling, with the machine raised from the ground, check that on the tractor front

axle (steering) there is a residual weight not lower than 20% of total weight.

EXAMPLE

Total weight = Tractor weight + Machine weight = 2500 Kg + 800 Kg = 3300 Kg

Residual weight on the steering axle = 20% di 3300 Kg = 660 Kg

IT IS NOT ALLOWED:

• Working on stony or uneven grounds.

• Transporting persons, animals, or things.

• Towing cars or equipment.

• Working near houses or roads.

• Fitting other equipment which may change the machine's characteristics.

• Machine tools must NEVER touch the ground.

INTENDED USE

NOBILI S.p.A. - Agricultural Machinery Manufactures - wishes first of all to thank you for the wise choice you have

made in purchasing one of its machines, whilst assuring you that the maximum efforts have been put into making

the machine as advanced and practical as possible.

In order to get the best use out of the machine and prolong its working life, NOBILI S.p.A. has decided to give a

few practical hints to help you use it to its full potential and to help you avoid those problems that are due, in the

majority of cases, not to manufacturing defects, but mainly to negligence and carelessness.

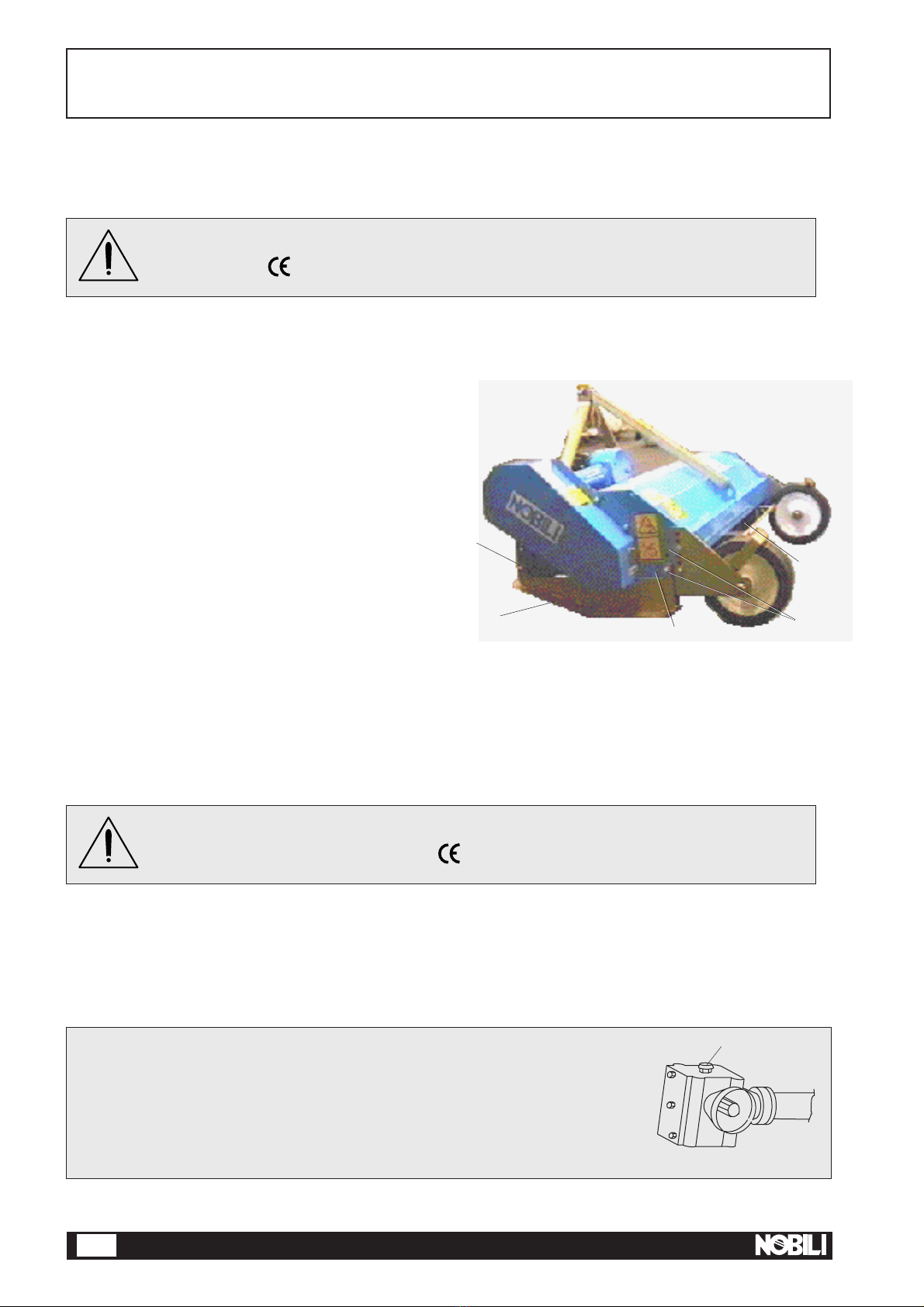

NOBILI BNE multivalent shredders have been designed for the following activities: care of grassland and public

parks, shredding of thin wood, vine sarments, and potato leaves.

Machine tools - blades or rams - must NEVER touch the ground.

The correct use of the machine includes:

- following carefully manufacture's instructions regarding use, maintenance and care of your machine.

- using original spare parts only, as well as original or approved units and accessories.

The use of the machine, its maintenance and repairs are reserved to specialized people, who are familiar with the

technical data and features of these machines.

WARNING! THIS SYMBOL, USED THROUGHOUT THIS MANUAL, MARKS

INSTRUCTIONS THAT MAY AFFECT YOUR SAFETY, OTHER PEOPLE'S SAFETY, AND

THE EFFICIENT WORKING OF THE MACHINE. ALWAYS FOLLOW THE SAFETY

INSTRUCTIONS SCRUPULOUSLY.

AGRICULTURAL MACHINERY MANUFACTURERS 3

04.09.2009

USER'S MANUAL No. AO 917

SHREDDERS: BNE 100 - 120 - 150 - 180 - 210

CONTENTS

INTENDED USE ....................................................................................................................... Page 2

MARKS AND MACHINE IDENTIFICATION ............................................................................ Page 4

Declaration of conformity .......................................................................................................... Page 4

Characteristics and machine identification ............................................................................... Page 5

Decals regarding: Safety- Use - Maintenance .......................................................................... Page 6-7-8

SAFETY PRECAUTIONS......................................................................................................... Page 9

Hoisting the machine and transport .......................................................................................... Page10

Dangerous areas ...................................................................................................................... Page 11

Recommandations for use ........................................................................................................ Page 12

Checking tools and corresponding locking pins ....................................................................... Page 13

STARTING AND STOPPING THE MACHINE

INFORMATION REGARDING USE AND ADJUSTMENT

..........................................................

Page 14

Assembly of skids, roller, wheels and corresponding guards................................................... Page 14

Coupling to the tractor .............................................................................................................. Page 15

Connecting the propeller shaft.................................................................................................. Page 16

Working height adjustment ....................................................................................................... Page 17

How to displace fixed drawbar .................................................................................................. Page 18

Parking position ........................................................................................................................ Page 19

INFORMATION REGARDING ACOUSTIC PRESSURE ......................................................... Page 20

Air noise emitted ....................................................................................................................... Page 20

INFORMATION REGARDING MAINTENANCE ...................................................................... Page 21

Lubrication ................................................................................................................................ Page 21

Belt tension ............................................................................................................................... Page 22

Tool replacement and balancing ............................................................................................... Page 23

ACCESSORIES: DRAWBARS WITH LATERAL SHIFTING ................................................... Page 24

Assembly and adjustments of drawbars with lateral shifting .................................................... Page 24

Warning signs ........................................................................................................................... Page 25

Overall dimensions ................................................................................................................... Page 25

TROUBLESHOOTING.............................................................................................................. Page 26

WARRANTY ............................................................................................................................. Page 27

AGRICULTURAL MACHINERY MANUFACTURERS

4

04.09.2009

F A C - S I M I L E

S.p.A.

Via Circonvallazione Sud, 46 40062 MOLINELLA (BO)

Declaration de conformité

à la directive "machines"

(Directive 89/392/CEE modifiée)

et aux réglementations prises pour sa transposition

Le fabricant:

EC declaration of conformity

(conforming to directive

89/392/EEC amended)

The manufacturer:

EG-Konformitätserklärung

(entsprechend der EG-Richtlinie

89/392/EWG und deren Änderungen).

Der Hersteller:

Dichiarazione di Conformità

ai sensi della direttiva CEE 89/392

e successive modificazioni.

Il costruttore:

declares that the product

described hereafter:

déclare que la machine

désignée ci-dessous

:

erklärt in alleiniger

Verantwortung, daß das

Produkt:

dichiara che la macchina

sotto descritta:

Tipo - Type

Type - Typ:

......................................

N°- N°

No - Nr.:

......................................

.

In caso di vendita della macchina, la presente dichiarazione deve essere consegnata all'acquirente.

En cas de revente de la machine, la présente déclaration de conformité est a remettre à l'acheteur.

In the case of resale of the machine, this declaration of conformity is to be passed on to the buyer.

Bei Weiterverkauf dieser Maschine ist diese Konformitätserklärung dem Käufer zu übergeben.

Molinella (BO) Li-Le-Date-Den:................

-est conforme aux dispositions de la directive

européenne

89/392/CEE

modifiée ainsi qu'à celles de la directive:

86/188/CEE.

-est conforme aux dispositions des normes

européennes harmonisées suivantes:

EN 294 EN

349

-est égalment conforme aux normes nationales et

aux dispositions techniques suivantes:

auf das sich diese Erklärung bezieht, den

einschlägigen grundlegenden Scherheits- und

Gsundheitsanforderungen der EG-Richtlinie

89/392/EWG und deren Änderungen, sowie den

Anforderungen der einschlägigen EG-Richtlinie

86/188/EWG entspricht.

Zur sachgerechten Umsetzung der in den

EG-Richtlinien genannten Sicherheits- und

Gesundheitsanforderungen wurden die

harmonisierten Normen:

EN 294 EN 349

sowie die nationalen Normen und techischen

Spezifikationen:

herangezogen.

to which this declaration applies, conforms to the

essential health and safety requirements of

European Council Directive 89/392 CEE amended

and conforms also to the requirements of Directive

86/188/EEC.

-to conform to these essential health and safety

requirements, the provisions of following

harmonized standards were particularly considered:

EN 294 EN 349

-the provision of following national standards and

specifications were also considered:

è conforme ai Requisiti essenziali di Sicurezza e di

Tutela della Salute di cui alla Direttiva CEE 89/392 e

sue successive modificazioni, nonché ai Requisiti di

cui alle seguenti Direttive CEE:

86 /188 /CEE

Per la verifica della Conformità di cui alle Direttive

sopra menzionate, sono state consultate le seguenti:

Norme Armonizzate:

EN 294 EN 349

Norme e specifiche Tecniche:

Responsabile della Sicurezza -- Responsable Sécurité et Homologations -- Safety Officer--Beauftragter für Gerätesicherheit

.

.............................................................

Barilani Andrea

TRINCIA

BROYEUR

SHREDDER

MULCHGERÄT

DECLARATION OF CONFORMITY

AGRICULTURAL MACHINERY MANUFACTURERS 5

04.09.2009

540 r.p.m.

Machine power input:

BNE 100 11 Kw 15 HP

BNE 120 15 Kw 20 HP

BNE 150 18 Kw 25 HP

BNE 180 22 Kw 30 HP

BNE 210 29 Kw 40 HP

TECHNICAL CHARACTERISTICS

BNE 1

TECHNICAL CHARACTERISTICS BNE 100 BNE 120 BNE 150 BNE 180 BNE 210

Tractor coupling Range 1°1°1°1°1°

P.T.O. speed r.p.m. 540 540 540 540 540

Required power Kw 11 15 18 22 29

Transport position Transversal

Max. transport width mm 1245 1445 1730 2015 2300

Weight for standard version Kg 180 190 210 240 270

Working position central or on the right -- -- 370 370 370

Working components Blades Y N°28 32 40 48 56

Vanes N°14 16 20 24 28

Rams N°14 16 20 24 28

Swivelling blades N°28 32 40 48 56

Working width mm 978* 1177* 1460* 1745* 2030*

Cutting rim speed m\sec 48,5 48,5 47,9 47,9 47,9

Rotor speed r.p.m. 2230 2230 2207 2207 2207

Main drive Bevel Gear Pair

Secondary drive Belt type: B 46 Belt type: SPBX

n°3 belts n°3 belts

Cutting height adjustment Manual

Lateral shifting adjustment Manual or hydraulic

ACCESSORIES

Sliding drawbar, hydraulic No No Yes Yes Yes

Parallelogram drawbar, hydraulic No No Yes Yes Yes

Rear wheels N°22222

Rear roller Yes Yes Yes Yes Yes

* Dimension with rams 06

MARCATURA E RICONOSCIMENTO DELLA MACCHINA

TARGHETTA FISSATA AL TELAIO (Vedi Pag. 6)

SERIE E TIPO

MACCHINA

NUMERO DI

MATRICOLA

ANNO DI

COSTRUZIONE

MASSA IN

VERSIONE

COMPLETA DI

ACCESSORI

NOME ED INDIRIZZO DEL COSTRUTTORE

TRINCE

BROYEURS

TRITURATOR

MULCHER

LUBRIC. ACONSEJADOS - RECOMMENDED LUBRICANTS

EMPFOHLENE OELE/FETTE - LUBRIFIANTS CONSEILLES

LUBRIFICANTI CONSIGLIATI

Mod.

Num.

Data

Massa Kg :

:

:

:

BLASIA 460

(ISO 460)

MU / EP2

SUPERTRACTOR

UNIVERSAL

COSTRUZIONI

MECCANICHE

PER L’AGRICOLTURA

R

AGRICULTURAL MACHINERY MANUFACTURERS

6

04.09.2009

ADHESIVE LABELS REGARDING SAFETY

AND PROPER OPERATION

7

2

A

B

CB

11

8

4

5

10

12

1

1

4

13 CB

CR

CR

A ) Machine identification metal plate.

B ) Type and model of the machine

CB) White reflectors

CR) Red reflectors

Safety labels are located on the machine according to the pictures below.

Decals have been designed for your safety and for other people's safety.

The machine's owner or the person in charge must be sure the operator has read the Instruction Manual carefully.

Keep decals in good conditions and replace the damaged ones.

The adhesive labels N°6 - 7 - 12 - 14 are not applied on the BNE series machine.

AGRICULTURAL MACHINERY MANUFACTURERS 7

04.09.2009

READ THE INSTRUCTION

MANUAL BEFORE

STARTING THE MACHINE

DANGER!

THROWN OBJECTS.

STAND OFF.

DO NOT WORK NEAR

BUILDINGS OR ROADS

1

3

GREASE EVERY 4 WORKING HOURS

GREASE EVERY 50 WORKING HOURS

MACHINE SET FOR

POWER INPUT AT 1000 r.p.m.

6

5

7

MACHINE SET FOR

POWER INPUT AT 540 r.p.m.

DO NOT REMOVE

GUARDS UNTIL ALL

ROTATING PARTS

ARE IDLE

TURN OFF THE

TRACTOR ENGINE AND

TAKE THE KEY OFF

BEFORE SERVICING

OR ADJUSTING THE

MACHINE

ADHESIVE LABELS

2

4

8

0018646 0018642

0018650 0018645

50 h.

AGRICULTURAL MACHINERY MANUFACTURERS

8

04.09.2009

ADHESIVE LABELS

10 11

12

LIFT THE

MACHINE FROM

THE GROUND

BEFORE GOING

INTO REVERSE

OR TURNING

SHARPLY.

14

15

INDICATION OF THE HOOKING

POINTS FOR LIFTING THE

MACHINE.

13

0018658

AGRICULTURAL MACHINERY MANUFACTURERS 9

04.09.2009

SAFETY PRECAUTIONS

MANY INDUSTRIAL INJURIES ARE DUE TO THE LACK OF

RESPECT OF THE MOST ELEMENTARY SAFETY PRECAUTIONS.

• Thus it is necessary that whoever needs to work or to carry out the maintenance of the machine,

knows the safety precautions described in the manual or on the decals.

• Before any cleaning or maintenance operations, it is necessary to lay the machine horizontally on the

ground or on strong supports, stop the tractor engine and remove the propeller shaft.

• Before beginning work, check: tightening of bolts, integrity and efficiency of guards, right position of

safety pins.

• Be sure that the tractor meets the CHARACTERISTICS REQUIRED BY THE MACHINE USED.

• Keep persons and animals away from the machine before its starting.

• Do not leave the machine running without surveillance.

• Do not wear clothes which can get entangled.

• Do not transport persons or animals on the machines.

• Check that the PROPELLER SHAFT IS MARKED AND THAT, DURING ASSEMBLY,THE GUARDS

ARE PROTECTED AGAINST ROTATION with the appropriate chains.

• Be particularly careful when you work on cat’s backs or ditches.

• Be particularly careful when you work on cat’s backs or ditches.

The uneven ground can make the guards temporarily inefficient and allow the projection of stones or

fragments in a wide range (See page 11).

• Be particularly prudent during the road-transport of the machine.

The user must be sure that the transport complies with the highway Code of the Country where it is

CARRIED OUT.

AGRICULTURAL MACHINERY MANUFACTURERS

10

04.09.2009

USE HOISTING EQUIPMENT ACCORDING TO THE RULES IN FORCE AND RIGHT

FOR THE MACHINE WEIGHT.

WARNING: BE CAREFUL AS ACCESSORIES AFFECT MACHINE BALANCE.

NEVER LIFT UNBALANCED LOADS.

HOISTING THE MACHINE

Available hitch points:

1) ø 20 holes, on the machine sides

2) hitch pin, 3rd point

ENIHCAM THGIEW

gK

001ENB 081

021ENB 091

051ENB 012

081ENB 042

012ENB 072

AGRICULTURAL MACHINERY MANUFACTURERS 11

04.09.2009

DANGEROUS AREAS

Before shredding: Keep all persons and animals away from the machine

danger zone. This zone is defined by a radius (R) of 50 m (164') around the

working line of the machine.

The use of the machine hood must be only destined to maintenance

operations.

Before maintaining the machine, stop the tractor motor, turn off the engine,

remove ignition key and wait until all moving parts have come to a

complete stop.

It is strictly forbidden to leave the hood open when the machine is operating

and its parts are moving.

The misuse of the machine may cause involuntary projection of stones and

other foreign objects, and consequently damages to persons, things and

animals.

AGRICULTURAL MACHINERY MANUFACTURERS

12

04.09.2009

RECOMMENDATIONS FOR USE

ALWAYS STOP THE TRACTOR ENGINE BEFORE CARRYING OUT ANY WORK OF

ADJUSTMENT OR CLEANING ON THE MACHINE.

BEFORE STARTING THE ADVANCING OF THE MACHINE, WAIT THAT THE ROTOR REACHES THE R.P.M.

WORK ONLY ON STRAIGHT LINE, LIFT THE MACHINE FROM THE GROUND BEFORE CHANGING

DIRECTION.

DO NOT ACTIVATE THE SIDE DISPLACEMENT WITHOUT LIFTING THE MACHINE.

IF DURING THE LIFTING FROM THE GROUND, THE JOINTS OF THE PROPELLER SHAFT ARE BENT TO

MORE THAN 40°(STILL P.T.O.) REMOVE THE SHAFT OF THE TRACTOR P.T.O.

DURING WORK, BLADES OR RAMS SHOULD NOT TOUCH THE GROUND.

DAILY CHECK THE WEAR OF BLADES OR RAMS.

IN CASE OF IRREGULAR CONSUMPTIONS OR BREAKS, IMMEDIATELY SUBSTITUTE THE DAMAGED

PARTS. USE ONLY ORIGINAL SPARE PARTS.

AFTER THE FIRST HOURS OF WORK (3 HOURS) CHECK THETENSION OF THE BELTS, DAILY CONTROL

THE TIGHTENING OF ALL NUTS AND BOLTS AND THE TENSION OF THE BELTS.

VERIFY SPECIALLY THE TIGHTENING OF BLADE BOLTS (See page 13).

CHECK THAT THE SAFETY CHAINS OF PINS AND THE ANTIROTATION CHAINS OF THE PROPELLER

SHAFT GUARDS ARE INTACT AND COUPLED UP.

CLEAN, WASH, GREASE THE INSIDE AND OUTSIDE OF THE MACHINE AT REGULAR INTERVALS.

SPECIALLY REMOVE THE MATERIAL SETTLED ON THE ROTOR AND BLADE SUPPORTS.

BEFORE A LONG PERIOD OF INACTIVITY THE MACHINE SHOULD BE CLEANED AND GREASED. PUT

IN A PLACE PROTECTED FROM BAD WEATHER.

THE USER IS COMPLETELY RESPONSIBLE OF ROAD-TRANSPORT.HE MUST CHECK THE COMPLIANCE

WITH THE HIGHWAY CODE IN FORCE IN HIS COUNTRY.

IF ATRACTOR WITHOUT SOUNDPROOF AND PRESSURIZED CABIN IS USED, IT IS NECESSARYTHAT

THE OPERATOR USES INDIVIDUAL PROTECTION SYSTEMS:

1) PROTECTION EARPIECES FOR NOISE, IF STANDARD EXPOSURE LEVELS ARE

EXCEEDED.

2) DUST MASK, IF A GREAT QUANTITY OF DUST IS RAISED BECAUSE OF EITHER THE

KIND OF PRODUCT WORKED OR VERY DRY GROUND OR USE OF OPEN MACHINE.

IF DURING WORK YOU NOTICE UNUSUAL VIBRATIONS OF THE MACHINE, STOP IMMEDIATELY AND

CHECK THE INTEGRITY OF ROTOR AND BLADES OR RAMS.

EXCESSIVE VIBRATIONS CAN CAUSE PHYSICAL DAMAGES TO THE DRIVER.

THE MANUFACTURER DISCLAIMS ALL RESPONSIBILITY IN CASE OF DAMAGES OR ACCIDENTS

CAUSED BY AN INAPPROPRIATE USE OR NON-OBSERVANCE OF RECOMMENDATIONS INCLUDED IN

THE USE AND MAINTENANCE MANUAL.

AGRICULTURAL MACHINERY MANUFACTURERS 13

04.09.2009

BNE 4

BNE 5

Shredding quality, machine integrity and safety depend on the care which will be devoted to these elements.

They must be replaced immediately if damaged.

Normal wear (specially rapid on sandy grounds or working with the machine too low) and bumps against obstacles

can cause distortions or cracks in the blades or rams, which can lead to:

• Worsening in the work quality,

• Increase in vibrations and consequent mechanical damages in the machine,

• Total or partial break of the blades and rams with consequent projection of fragments at high speed.

CHECK BLADES OR RAMS AND THEIR

FASTENING ELEMENTS

F

F

F

F

L

L

L

L

S

H

Worn blades or rams:

The hole (F)of the pin should not be ovalized over 2mm from the

original diameter.

The length (L) of the blade or ram should not be reduced over 20

mm.

The pin fixing can be carried out with split pins or nuts,

according to the model of the machine.

Pins should be replaced if:

They are clearly bent or damaged in the thread: in particular check

(if welded) the welding integrity of the plate (S).

The tracking made by the wear of the blade or ram (H) is greater of

2 mm.

During assembly:

The selflocking split pins or nuts should be changed every time.

Torque wrench setting for M16 nut: 100 Nm

Torque wrench setting for M20 nut: 250 Nm

Check that the pin with tooth or the pin with hexagonal head, CANNOT rotate in their seat on

the support, because this could cause an abnormal consumption.

Blades or rams: to be checked always before using the machine

to be checked immediately after an obstacle

ENIHCAM EKVDKVKVENB

RKVUMW KNGNBUNB

FORETEMAIDLAITINI

ELOHEHT "36.0"1

RETEMAIDMUMIXAM

DETTIMDA "17.0"70.1

FOHTGNE

LLAITINI

REMMAHROEDALB "33.4"90.7

HTGNELMUMINIM

ELBATPECCA "45.3"29.5

AGRICULTURAL MACHINERY MANUFACTURERS

14

04.09.2009

INSTRUCTIONS

FOR SKIDS, ROLLER,WHEELS ASSEMBLY

Whenever the machine is delivered with skids, roller and wheels not mounted because of shipping

requirements.

Before connecting the machine to the tractor, make sure the transmission unit

is equipped with oil drain plug (T).

For shipping requirements the machine may be shipped in vertical position; in

such a case, a blind plug is fitted on the transmission unit

so as to avoid oil overflow.

Therefore, replace the fitted plug with the drain plug contained in the proper

packing joined to the machine.

BNE 6

T

In order to use the machine with roller or wheels, mount side guards (SL),

according to rules.

Skids assembly:

Make use of holes (A) on the lateral sides.

On the skids, select the proper holes so as to get up

the machine from the ground, at the height required.

See page 17.

Mount the safety bar (B) on the rear side.

Roller assembly:

Make use of the pair of holes (V) on the lateral sides.

On the roller support, select the proper holes so as

to get up the machine from the ground, at the height

required. See page 17.

Mount guards (SL) on the lateral sides.

Wheel unit assembly:

Make use of the pair of holes (V) on the lateral sides.

On the wheel support, select the proper holes so as

to get up the machine from the ground, at the height

required. See page 17.

Mount guards (SL) on the lateral sides.

Mount the safety bar (B) on the rear side.

In order to use the machine with skids or wheels, mount the bar (B) which determines

the rear safety distance required by rules.

A

V

Wheels herein described are

mounted laterally and are not

steering: therefore, track can not be

controlled.

SL

A

B

AGRICULTURAL MACHINERY MANUFACTURERS 15

04.09.2009

45°

BNE 7

COUPLING TO THE TRACTOR

THE MACHINE HAS BEEN DESIGNED FOR COUPLING TO THE TRACTOR PROVIDED

WITH REAR ELEVATOR.

WARNING: IN THE THREE-POINT HITCH AREA YOU MAY RUN THE RISK OF HARMING

YOURSELF.

WARNING: GET OUT OF THE THREE-POINT HITCH AREA WHILE THE ELEVATOR IS

RUNNING!

PB

SECURE ALL PINS WITH SAFETY PINS

REPLACE LOCKS IF DAMAGED

BNE 8

BNE 9

SS

Machines type BNE 150 - 180 - 210 are provided

with two different hitch positions; select between

the central position and the lateral one.

See page 18.

Before coupling the machine to the tractor, make

sure the drawbar is in the required position.

Check the elevator links are at the same height

from the ground, and fit them into the connecting

pins (D).

Fit safety pins (S).

Connect the 3rd point tie rod (P) to the connecting

rod (B) by the proper pin; adjust the length of the

3rd point tie rod so as to make the connecting rod

(B) reach a 45°angle when the machine is in the

working position.

If you run the machine without

connecting rod, or with connecting rod

blocked, the warranty will be voided,

as the roller or wheel supports could

have been damaged irreparably by

such operations.

Get up the machine from the ground and adjust cutting height (please see: working height adjustment on

page 17).

Raise foot and secure it.

Adjust machine and elevator attitude by placing the machine horizontally or slightly higher on the rear side so as

to make material infeed easier.

DS

AGRICULTURAL MACHINERY MANUFACTURERS

16

04.09.2009

Measure the minimum distance (A) between

the notch of the tractor P.T.O. and that of the

shredder, when they are on the same axis.

CONNECTING THE PROPELLER SHAFT

TP

A

THE TRACTOR ENGINE SHOULD NOT RUN, THE MACHINE SHOULD BE CORRECTLY

CONNECTED TO THE TRACTOR (See page 15).

IT IS FUNDAMENTAL TO HAVE A PROPELLER SHAFT OF APPROPRIATE LENGTH.

1/3 L

L

MAXIMUM 20°- running

MAXIMUM 40°- still

BLOCK THE ROTATION OF THE CARDAN JOINT PROTECTION WITH THE APPROPRIATE

CHAINS.

B = A- 25 mm

BNE 10

BNE 11

25 mm

Measure the distance of the propeller shaft, in the position of minimum

extension (all closed).

The measure Bshould be smaller than Aof at least 25 mm.

During work both inside that outside plastic pipes should not bump

against heads.

If the propeller shaft is too long, before cutting metal pipes and guards,

it is necessary to check that, when it is in the maximum extension position,

inside metal pipes remain overlapped at least of 1/3 of the length (L).

If the overlapping is smaller, there is too much difference between

the minimum and maximum position of the transmission.

If this occurs, it is necessary to ask for longer lower connecting

arm to space more the machine from the tractor.

Be careful to cut surface: trim the cut inside and outside, clean for

eliminating chips and dirt, and grease with lithium grease.

Always check that the shaft is dimensioned according to the power of

the machine declared.

Check that the propeller shaft does not take angles over the value

admitted.

Check that the machine cannot be raised over the maximum dimension

allowed by the shaft length: it could come out.

If the machine is connected to a tractor provided with

tracks or without double clutch, a cardan shaft with free-

wheel should be used to avoid the inertia of the shredder

rotor stopping quickly the tractor-machine unit.

BNE 12

BNE 13

MAX 20°

AGRICULTURAL MACHINERY MANUFACTURERS 17

04.09.2009

VERSION WITH SKIDS:

RAISE THE MACHINE SLIGHTLY FROM THE GROUND

Remove bolts (A, B, C) which secure skid (SL), to the

machine and to guard (P).

On the skid (SL) select holes according to the height

required, fit bolts (A and B)and screw them.

Fit bolt (C) into the guard hole (P), keeping the guard parallel

to the lower edge of the side part.

Screw and tighten all bolts.

VERSION WITH ROLLER:

RAISE THE MACHINE SLIGHTLY FROM THE GROUND

Loosen bolts (OS) on one side, unscrew and remove bolts

(OD) on the other side.

On the support select the holes right for the height desired,

then fit bolts (OD)and screw nuts but do not tighten them.

Remove bolts (OS) and fit them into the holes corresponding

to those selected on the other side.

Screw and tighten all bolts.

VERSION WITH WHEELS:

RAISE THE MACHINE SLIGHTLY FROM THE GROUND

Loosen bolts (OS) and on the support select the holes right

for the height desired, then fit and tighten bolts (OS).

PERFORM THE SAME OPERATION AT THE OTHER.

BLADES MUST NEVER TOUCH THE GROUND!

LEAVE AT LEAST 40 MM.

WORKING HEIGHT ADJUSTMENT

OD

BNE 14

SL

P

C

B

A

OD

AGRICULTURAL MACHINERY MANUFACTURERS

18

04.09.2009

BNE 150 - 180 - 210

If you need to change the working position with respect to the tractor track.

(With the machine already attached)

DISCONNECT TRACTOR P.T.O.

TURN OFF TRACTOR ENGINE.

TAKE THE KEY OFF THE DASHBOARD.

MAKE SURE ALL MOVING PARTS ARE IDLE.

1 ) Remove the machine from the tractor (See page 15).

2 ) In order to adjust drawbar (A),remove bolts fixing drawbar to connections (P1, P3, F1), as well as the supporting

foot.

3 ) Remove drawbar and fit it by means of connections (P2, P4, F2).

4 ) Remove supporting foot and fit it by means of connection (P3).

5 ) Tighten bolts properly.

6 ) Attach the machine to the tractor (See page 15).

HOW TO DISPLACE THE FIXED DRAWBAR

A

F2

F1

P1

P2

P3

P4

AGRICULTURAL MACHINERY MANUFACTURERS 19

04.09.2009

PARKING POSITION

DISCONNECT TRACTOR P.T.O.

TURN OFF TRACTOR ENGINE WHEN THE MACHINE

IS RAISED FROM THE GROUND.

TAKE THE KEY OFF THE DASHBOARD.

MAKE SURE ALL MOVING PARTS ARE IDLE.

CHOOSE A STABLE, FLAT GROUND TO PERFORM THE FOLLOWING OPERATIONS

Lower foot (P).

Lower the elevator until the machine rests on the ground.

Disconnect propeller shaft from tractor P.T.O. and secure it to the suitable hook (G), so as to avoid damaging the

guard.

Extract pins and move away the tractor.

Make sure the machine is slightly tilted forward so as to prevent backwater on flat parts when the machine is

parked in the open.

INTERVENTIONS AT THE END OF SEASON

Before garaging the machine in a dry and protected place, some maintenance operations should be

carried out:

1) Remove the Cardan shaft and carry out the maintenance separately (see Instruction handbook of the Cardan

joint).

2) Wash carefully the machine, in particular inner parts, being sure to have removed completely every rests of

earth or grass. Check the protections of the rotor and roller bearings.

3) Grease the rotor bearings, rotating the rotor manually, until the exceeding grease comes out from the inner

part of the bearing supports cleaning inside.

4) Disassemble the roller supports, cleaning and greasing the bearings and spacers and checking that the

bearing protections are intact.

5) Put a grease film on all parts where the paint or galvanization has been removed.

6) Remove the protection guard of the belts and clean inside.

7) Disassemble and check the knives and blades and their fastening elements.

8) Check the integrity of the protection straps and pin safety laces.

LOCK THE PIN WITH THE SUITABLE SAFETY PINS

REPLACE LOCKS IF DAMAGED.

P

G

BNE 8

S

AGRICULTURAL MACHINERY MANUFACTURERS

20

04.09.2009

BNE 100

AIR NOISE EMITTED

Data taken according to the following rules:

UNI 7712

AFNOR S 31-069

NF S 31-027

BNE 120

BNE 150

80.7 78.8 84.3 79.1

107.1 108.4

BNE 180

80.7 78.8 84.3 79.1

107.1 108.4

80.7 78.8 84.3 79.1

107.1 108.4

80.7 78.8 84.3 79.1

107.1 108.4

BNE 15

BNE 210

80.7 78.8 84.3 79.1

107.1 108.4

AIR NOISE EMITTED

TRACTOR 60 CV

TRACTOR+ MACHINE

CLOSED

MACHINE:

Tractor cab

Level of acoustic pressure:

operator place dB(A)

Level of acoustic power:

dB(A)

TRACTOR ONLY

OPEN CLOSED OPEN

TRACTOR+ MACHINE

CLOSED

MACHINE:

Tractor cab

Level of acoustic pressure:

operator place dB(A)

Level of acoustic power:

dB(A)

TRACTOR ONLY

OPEN CLOSED OPEN

TRACTOR+ MACHINE

CLOSED

MACHINE:

Tractor cab

Level of acoustic pressure:

operator place dB(A)

Level of acoustic power:

dB(A)

TRACTOR ONLY

OPEN CLOSED OPEN

TRACTOR+ MACHINE

CLOSED

MACHINE:

Tractor cab

Level of acoustic pressure:

operator place dB(A)

Level of acoustic power:

dB(A)

TRACTOR ONLY

OPEN CLOSED OPEN

TRACTOR+ MACHINE

CLOSED

MACHINE:

Tractor cab

Level of acoustic pressure:

operator place dB(A)

Level of acoustic power:

dB(A)

TRACTOR ONLY

OPEN CLOSED OPEN

When determining the noise value within the limit of 85 dB, take into consideration the acoustic pressure level.

This manual suits for next models

5

Table of contents

Other Nobili Paper Shredder manuals

Popular Paper Shredder manuals by other brands

Dahle

Dahle PaperSAFE manual

Royal Sovereign

Royal Sovereign RDS-905X owner's manual

Royal Sovereign

Royal Sovereign AFS-800 owner's manual

HSM

HSM HSM 411.2 operating instructions

KRUG+PRIESTER

KRUG+PRIESTER IDEAL 2465 CC JUMBO operating instructions

KRUG+PRIESTER

KRUG+PRIESTER EBA 2127 S operating instructions