Nobili TB 151 User manual

OPERATOR'S

MANUAL

SHREDDERS

TB 151/181/211

Cod. mum-TB_G

- English - 04-2006

Dear Owner 1

TB 151/181/211

Shredders

$DEAR OWNER

In buying a Nobili machine you have chosen wisely. Into it have gone years of thought, research and

improvements. You will find, as have thousands of owners all over the world, that you have the best that

engineering skill and actual field testing can produce. You have purchased a dependable machine, but only by

proper care and operation can you expect to receive the performance and long service built into it.

This manual contains all the necessary information for you to receive full efficiency from your machine. The

performance you get from this machine is largely dependent on how well you read and understand this manual

and apply this knowledge. Please DO NOT ASSUME YOU KNOW HOW TO OPERATE AND MAINTAIN YOUR

MACHINE before reading this manual carefully. KEEP THIS MANUAL AVAILABLE FOR REFERENCE. Pass

it on to the next owner if you re-sell the machine.

Your dealer can offer a complete line of original manufacturer service parts. These parts are manufactured and

carefully inspected in the same factory that builds the machine to assure high quality and accurate fitting of any

necessary replacements.

About improvements

We are continually striving to improve our products. It therefore reserves the right to make improvements or

changes when it becomes practical to do so, without incurring any obligations to make changes or additions to

the equipment sold previously.

Designated use of the machine

The TB151/181/211 shredders must be used exclusively for the work for which they have been designed:

upkeep of verges, road sides, canals, ditches, lawns and parks.

2Contents

TB 151/181/211

Shredders

$CONTENTS

Dear Owner..................................................................................................................... 1

Contents.......................................................................................................................... 2

Identification of the machine ........................................................................................ 4

Front view ......................................................................................................................................... 4

Rear view .......................................................................................................................................... 4

Model identification plate................................................................................................................ 5

Optional equipment ......................................................................................................................... 5

Safety .............................................................................................................................. 6

Description of symbols used in this document ............................................................................ 6

Safety instructions........................................................................................................................... 7

Location and description of safety decals on the machine....................................................... 15

Machine specifications................................................................................................ 21

Description and glossary .............................................................................................................. 21

Technical specifications................................................................................................................ 22

Sound levels................................................................................................................................... 22

Putting into service...................................................................................................... 23

Coupling and uncoupling.............................................................................................................. 23

Instructions for transport............................................................................................ 30

Putting the machine into transport position ............................................................................... 30

Conformity with the road regulations .......................................................................................... 31

Contents 3

TB 151/181/211

Shredders

Instructions for work....................................................................................................32

Putting the machine into work position ...................................................................................... 32

Adjustments in working position .................................................................................................33

Machine use ................................................................................................................................... 34

Optional equipment......................................................................................................36

Cable controls................................................................................................................................ 36

Double skinned plate..................................................................................................................... 36

Movable bottom land roller........................................................................................................... 37

Rounded skids............................................................................................................................... 38

Antishock unit arm ........................................................................................................................ 39

Constant velocity double joint ..................................................................................................... 39

Maintenance and storage ............................................................................................40

Frequency chart............................................................................................................................. 40

Cleaning the machine.................................................................................................................... 41

Lubrication ..................................................................................................................................... 41

Rimessaggio .................................................................................................................................. 50

Limited warranty...........................................................................................................53

4Identification of the machine

TB 151/181/211

Shredders

$IDENTIFICATION OF THE MACHINE

1. Front view

2. Rear view

Identification of the machine 5

TB 151/181/211

Shredders

3. Model identification plate

Please write below the type and serial number of the

machine. This information is to be indicated to the dealer

for all spare parts orders.

Type: TB 151

No:

Type: TB 181

No:

Type: TB 211

No:

4. Optional equipment

Tick box corresponding to the equipment fitted on your

machine:

Kit no. 001732: Cable controls.

Kit no. 400794: Double skinned plate (TB 151).

Kit no. 400793: Double skinned plate (TB 181).

Kit no. 400796: Double skinned plate (TB 211).

Kit no. 400336: Movable bottom land roller (TB 151).

Kit no. 400337: Movable bottom land roller (TB 181).

Kit no. 400338: Movable bottom land roller (TB 211).

Kit no. 401269: Rounded skids.

Kit no. 400889: Antishock unit arm (TB 151).

Kit no. 400730: Antishock unit arm (TB 181-211).

Kit no. 000548: Constant velocity double joint.

6Safety

TB 151/181/211

Shredders

$SAFETY

1. Description of symbols used in this

document

This symbol indicates a potentially hazardous situation

that if not avoided, could result in serious bodily injury.

This symbol is used to identify special instructions or

procedures which, if not followed strictly, could result in

machinery damage.

This symbol is used to communicate technical

information of particular interest.

Safety 7

TB 151/181/211

Shredders

2. Safety instructions

-

Read and follow the safety instructions

Before using the machine, carefully read all the safety

instructions in this manual and the warnings placed on

the machine.

Before starting work, the operator must be familiar with

all machine controls, handling devices and their

functions. It is too late to learn once work has been

started!

Never let anyone operate the machine who is not trained

to do so.

Should you have any difficulties in understanding certain

parts in this manual, please contact your NOBILI dealer.

Precautions to be taken before carrying out

any operations on the machine

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Introduction

The machine must only be operated, maintained and repaired by competent persons who are familiar with

machine specifications and operation and aware of safety regulations for preventing accidents.

The operator must imperatively respect safety instructions in this manual and in the warnings posted on the

machine. The operator is also obliged to respect current legislation concerning accident prevention, work safety

and public traffic circulation.

Designated use of the machine also means following operation, maintenance and repair recommendations

given by the manufacturer, and using only genuine spare parts, equipment and accessories, as recommended

by the manufacturer.

The manufacturer is not held liable for any damage resulting from machine applications other than those

specified by the manufacturer. Any use other than the designated operation is at the risk and responsibility of

the operator.

The manufacturer is not held liable for any damage or accidents resulting from machine modifications carried

out by the operator himself or by a third party without previous written agreement from the manufacturer.

0018650

8Safety

TB 151/181/211

Shredders

Precautions to take before using the

machine

Do not wear loose clothing which could become caught

up in moving parts.

Wear the appropriate protective clothing for the work in

hand (gloves, shoes, goggles, helmet, ear-protectors,

etc.).

Make sure that all operating controls (ropes, cables,

rods, etc) are placed so that they cannot be set off

accidentally, risking accident or damage.

Before operating the machine, check tightness of nuts

and bolts, particularly on fixing elements (tines, forks,

blades, knives, etc). Retighten if necessary.

Before operating the machine, ensure that all the safety

guards are firmly in place and in good condition.

Immediately replace any worn or damaged guard.

Precautions when driving

Precision steering, tractor adherence, road holding and

efficient braking are influenced by the type of implement,

weight, ballast of front axle, ground or road conditions. It

is therefore of the utmost importance to be cautious in

every given situation.

Groundspeed must be adapted to ground conditions as

well as to roads and paths. Always avoid abrupt changes

of direction.

Be particularly cautious when turning corners, paying

attention to machine overhang, length, height and

weight.

Never use a narrow track tractor on very uneven or

steeply sloping ground.

Never leave the tractor seat while the machine is

operating.

Carrying people or animals on the machine when

working or in transport is strictly forbidden.

Safety 9

TB 151/181/211

Shredders

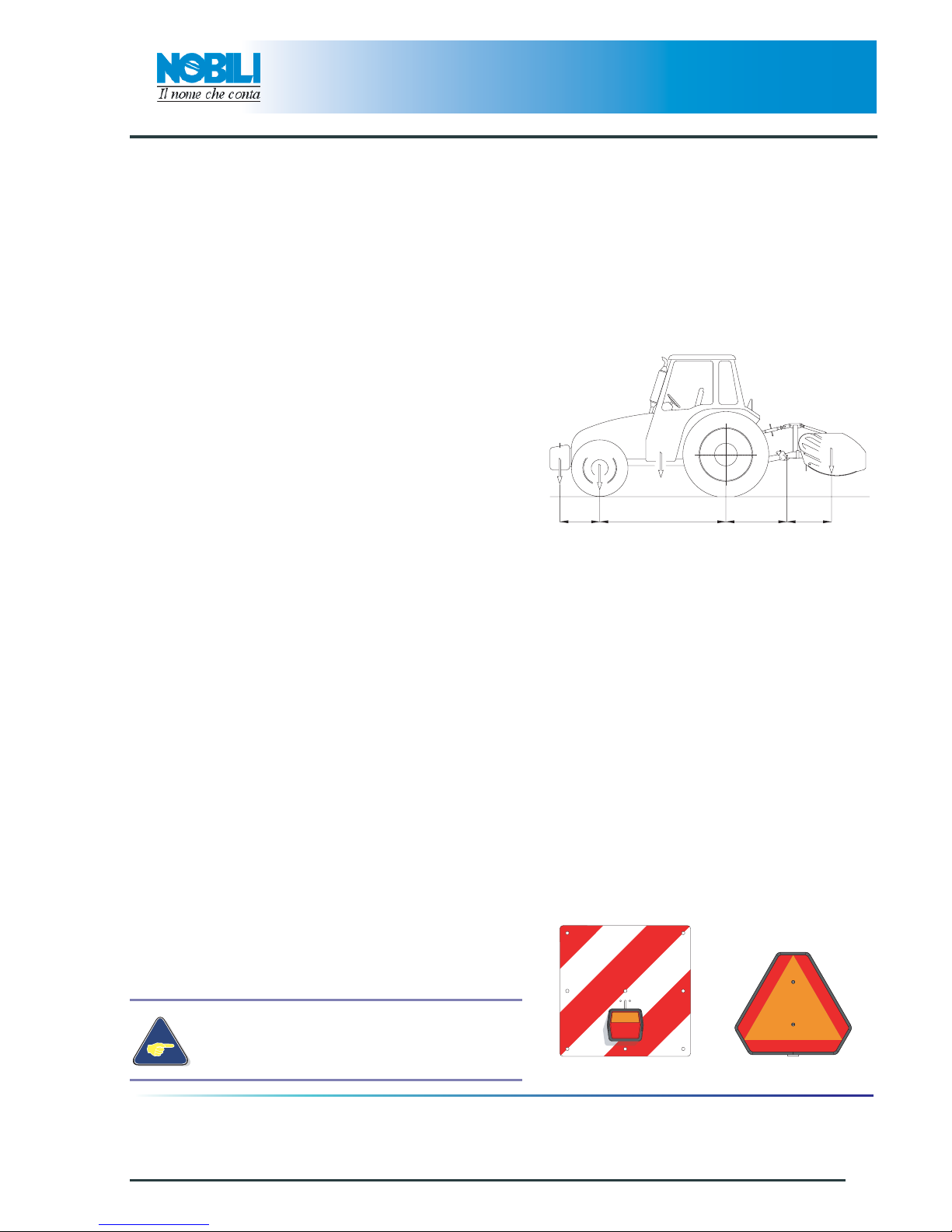

Precautions when driving on public roads

Dimensions

Depending on the dimensions of the machine, contact

the relevant authorities to ensure that it can be legally

transported on public roads.

If the machine is over the maximum legal size, follow the

local regulations for special transports of oversize

equipment.

Gross weight and weight per axle

Check that the tractor's authorized gross weight as well

as its lift capacity and maximum weight per axle are not

surpassed.

If necessary, add ballast weights to the front or to the

rear to preserve the steering and braking efficiency.

Always make sure that following ratio is fulfilled:

M x (S1 + S2) < 0.2 x T x i + Z x (d + i)

- i = Tractor wheel wheelbase.

- d = Distance of the front axle from ballast.

- S1 = Distance of the ball joints of lift lower links from

tractor rear axle.

- S2 = Distance of the lower couplings from machine

barycentre (see technical specifications).

- T = Tractor weight + operator (75 Kg).

- Z = Ballast weight.

- M = Operating machine weight.

Transport position

Before transporting the machine on public roads, place

the machine into its transport position, according to the

instructions in this manual.

Lightings and signallings

Before transporting the machine on public roads, ensure

that all legally required lightings and signallings are in

place.

Ensure that lightings and signallings are clean and in

good working order. Replace any missing or broken

equipment.

Always obey current regulations for driving

on roads.

T

0.2 T

M

Z

diS1 S2

10 Safety

TB 151/181/211

Shredders

Maximum speed

Always keep to the legal speed limit for driving a tractor-

machine assembly on public roads.

Precautions when coupling

Before attaching the machine, make sure that it cannot

accidentally start moving (chock the wheels) and that the

parking stand is in the right position.

The machine must only be attached to the hitch points

provided for this purpose.

Never stand between the tractor and the machine when

operating the rear remote control lever of the three point

linkage.

Do not stand between the tractor and the machine

without ensuring that the parking brake is applied.

Hydraulic circuit

Beware! The hydraulic circuit is under pressure.

Maximum pressure at work: 200 bar.

Before connecting hoses to the tractor hydraulics,

ensure that tractor and machine circuits are not under

pressure. Before disconnecting a hose, depressurize the

hydraulic circuit.

To avoid making wrong connections, mark hydraulic

couplers and corresponding hoses with colours.

WARNING! Functions could be reversed (for example:

lift/lower) and cause accidents.

Regularly check the hydraulic hoses. In case of normal

wear, replace the hydraulic hoses every 5 years.

Damaged or worn hoses must immediately be replaced.

When replacing the hydraulic hoses, make sure to use

hoses with the specifications and quality recommended

by the manufacturer of the machine.

To locate a leak, use appropriate means. Protect body

and hands from liquid under pressure.

Any liquid under pressure (particularly oil from

hydraulics) can penetrate the skin and cause severe

injury. If injured, see a doctor immediately, there could

be danger of infection.

Before any adjustments, maintenance or repairs are

carried out, lower the machine on the ground,

depressurize the hydraulics, turn off the engine, remove

ignition key and wait until all moving parts have come to

a complete stop.

Before connecting the PTO shaft, ensure that the PTO

Safety 11

TB 151/181/211

Shredders

speed (rotational frequency) and directions of rotation

are in line with manufacturer's recommendations.

Before engaging the PTO drive, make sure all people

and animals are clear from the machine. Never engage

the PTO drive when the tractor engine is stopped.

When uncoupling the machine, rest the PTO shaft on the

support specially provided, and replace protective cover

on the PTO stub of the tractor.

Read and follow the instructions in the operator's manual

provided with the PTO shaft.

Precautions during manoeuvres

When moving the machine from the transport position to

the working position and vice versa, make sure that

nobody is within the machine pivoting area.

Remote controlled components

Danger of crushing and shearing can exist when

components are operated by hydraulic or pneumatic

controls. Keep away from these danger zones.

Safety decals

Safety warning decals to respect, are placed in pictorial

form on various parts of the machine. They are there to

warn you of potential dangers and to tell you how to

avoid accidents.

Always keep the safety decals clean and readable, and

replace them when they are worn, damaged, missing or

illegible.

12 Safety

TB 151/181/211

Shredders

Waste disposal

Respect the environment! Never spill pollutants (oil,

grease, filters etc.) on the ground neither pour them

down the drain or discard them in any other place where

they could pollute the environment. Never throw away or

burn a tire. Always take waste to specialized recycling or

waste disposal centers.

Precautions for maintenance and repair

work

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Rest the machine on the ground, release the pressure

from the hydraulic circuit and leave the machine to cool

down.

Make sure that the parts of the machine that need to be

lifted for maintenance or repair work are firmly propped

up.

Before any work is done on the electric circuit or before

any electric welding is carried out on the attached

machine, disconnect the machine from the tractor

electrical circuit. Also disconnect alternator and battery

terminals.

Repairs on elements under pressure or tension (springs,

pressure accumulators, etc.) must only be carried out by

competent persons with regulation equipment.

Wear the appropriate protective clothing for the work in

hand (gloves, shoes, goggles, helmet, ear-protectors,

etc.).

Do not solder, weld or use a blow torch near fluids under

pressure or inflammable products.

For your own safety and for correct machine operation,

only use original manufacturer parts.

It is strongly recommended to have your machine

serviced by your NOBILI dealer after each season,

especially cutting elements and their fixing elements.

Safety 13

TB 151/181/211

Shredders

Projection of stones and foreign objects

For driver safety, always use a tractor equipped with a

cab.

Keep the ground to be mown or shredded free from

foreign objects.

Avoid using the shredder on stony or rocky ground. If this

is not possible, take extra safety precautions, such as:

- Fit polycarbonate screens inside the tractor cab's side

and rear windows, or install narrow mesh guards on

their exterior.

- Increase the cutting height to avoid contact with

stones or rocks.

- Never start the shredder when there are people

nearby.

Even when the machine is used in accordance with its

purpose, objects may be projected. Stones and other

foreign objects projected by the moving parts can travel

a considerable distance. Keep all persons and animals

away from the danger zone.

Guards on the machine help reduce the risks of

projection. Therefore, make sure that all shredder

protection devices are in place and good condition prior

to using the machine.

Check the guards regularly. Immediately replace any

damaged or missing protection.

14 Safety

TB 151/181/211

Shredders

Precautions for machine use

Before using the shredder, inspect cutting tools (knives,

hammers, flails) and their attachment hardware in

accordance with the instructions given in the present

manual. Immediately replace any worn, damaged or

missing cutting tool or element. For your safety, only use

genuine parts !.

Check the guards regularly. Immediately replace any

damaged or missing element.

Before engaging the PTO drive, lower the machine on

the ground. Make sure all the guards are in place. Keep

all persons and animals away from the danger zone.

Stay a safe distance from the machine when the cutting

tools are in movement.

Never work in reverse.

After the power source has stopped, the rotors can

continue turning for a time. Stay away from the machine

until all moving parts have come to a complete standstill.

If an obstacle is hit, disengage the PTO drive, stop the

tractor engine, remove the ignition key and wait for all

moving parts to come to a complete standstill. Check the

entire machine for any damage before resuming work.

Precautions to take to prevent rotor from

clogging

Foreign bodies in the field (wire,...) can cause clogging.

Avoid shredding close to roads, dumps or inert material

dumps.

To eliminate cloggings, take the following safety

measures:

- Switch off the engine.

- Lift the machine using the tractor's lift linkage.

- Put on gloves and protective glasses.

- Wait until all rotating parts have come to a complete

stop.

- Checked concerned parts for overheating.

- Prop up frame using trestles.

- Remove foreign body with adequate equipment(lever

and pliers).

Safety 15

TB 151/181/211

Shredders

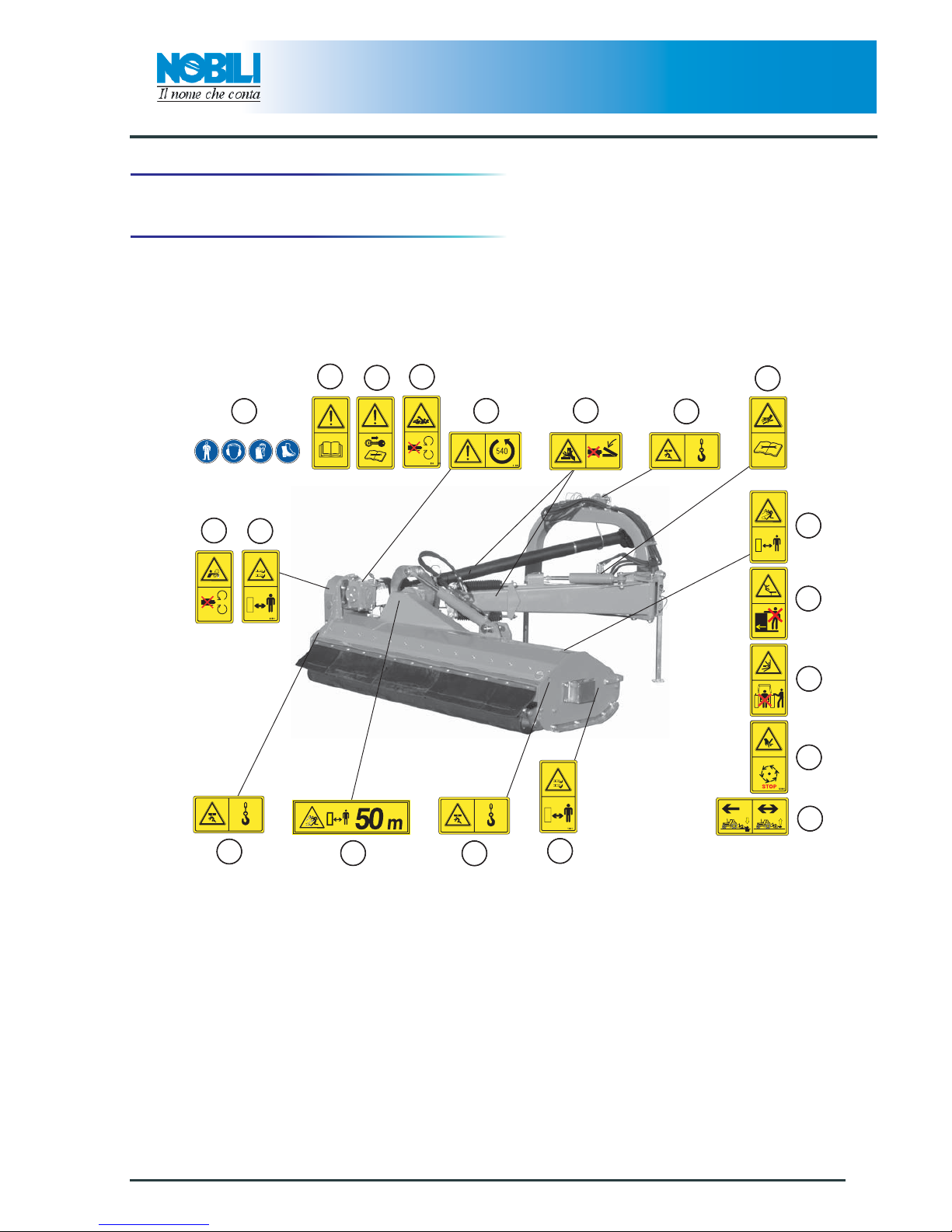

3. Location and description of safety

decals on the machine

Location of safety decals

10

4

10

10

6

16

9

11

5

1

4

0018642

0018661

0018661

0018661

3

0018645

0018658

133047

0018647

8

134384

2

0018650

12

136009

7

136010

13

136007

15

14

16 Safety

TB 151/181/211

Shredders

Description of safety decals

Operating instructions (1)

The operator's manual contains all the information

necessary for using the machine safely. It is imperative

to read and comply with all instructions.

Working on the machine (2)

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Projections (3)

Stones and other debris projected by the moving parts

can travel a long distance. The protection covers must

always be in position and in good condition. Always stay

at a safe distance from the machine.

0018642

0018650

0018645

Safety 17

TB 151/181/211

Shredders

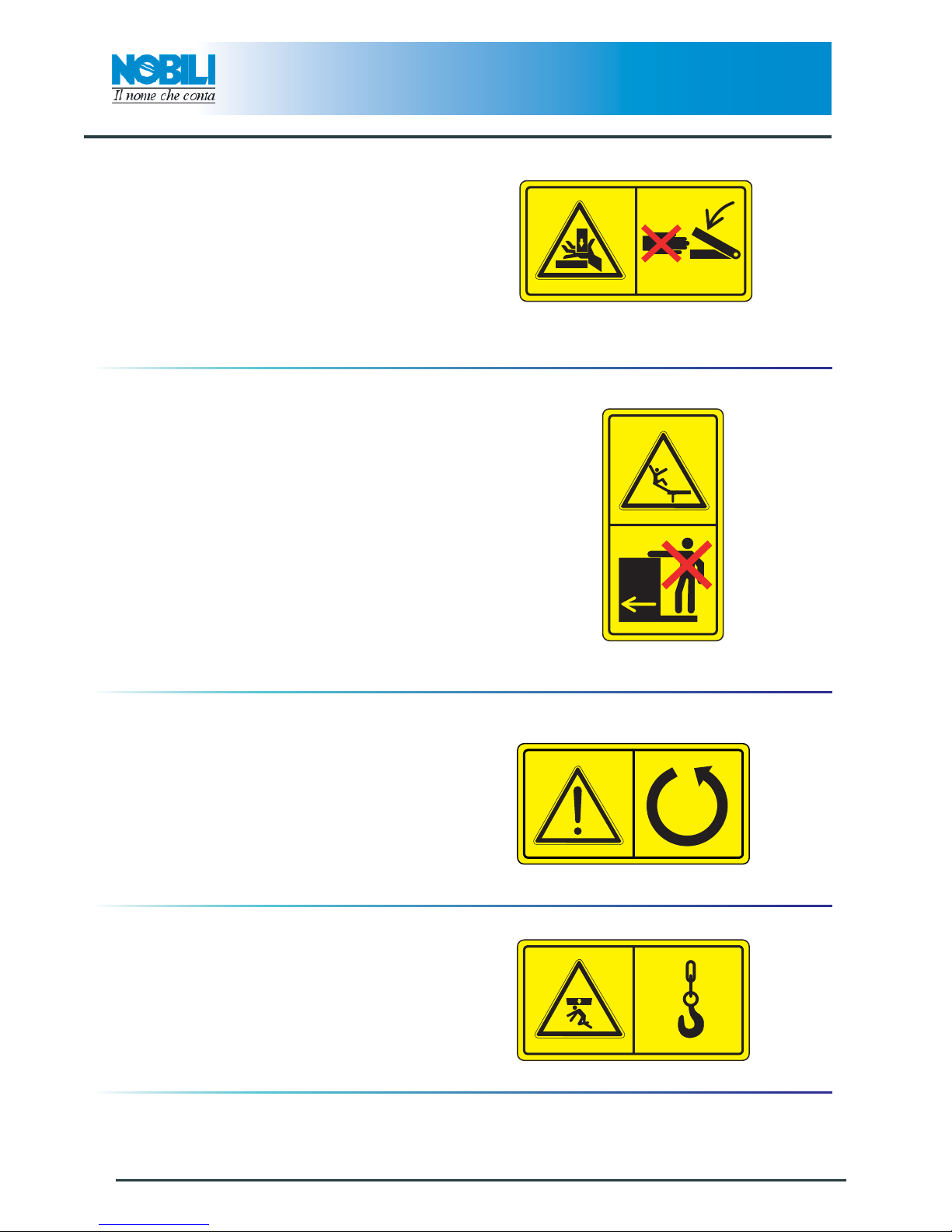

Rotating cutting tools (4)

Keep away from the mower knives all the time the engine

is running, the PTO drive engaged and the moving parts

have not come to a complete stop.

Moving elements (5)

Do not open or remove guards when the engine is on.

Support wheels (6)

At work, the support wheels must rest on the

ground. During manoeuvres, raise the machine to lift the

wheels off the ground.

133047

0018658

18 Safety

TB 151/181/211

Shredders

Crushing area (7)

Never operate in an area where there is a crushing risk

before all moving parts have come to a complete stop .

Danger of falling (8)

Do not ride on the machine.

Power requirement (9)

Machine preset for a 540 drive.

Anchoring point ((10))

Indicates anchoring points for handling the machine.

136010

134384

540

134389

0018661

This manual suits for next models

2

Table of contents

Other Nobili Paper Shredder manuals