Nobilium Ticonium Colloid-Saver 3.5 User manual

Owner’s Manual

NOBILIUM

TM

TM

Special Features

Description: Colloid-Saver 3.5 duplicator

Part #: 40811

Capacity: 3.5 allons (13.2 Liters)

Electrical: 115 Volt, 60 Hz, 12 Amps

Height: 26” (66 cm)

Width: 17 1/2” (44.5 cm)

Depth: 18 3/4” (47.6 cm)

Weight: 90 Lbs (40.8 Kg)

Shipping Weight: 96 Lbs (43.5 Kg)

Colloid-Saver™3.5 Duplicator

• Intelli-Heat™ computer-controlled

heating system prevents over-heating

and eliminates chunks of colloid

• Altitude setting for precision

temperature control

• SmartCycle™ stirring cycle activated

only when needed, minimizing colloid

breakdown

• High volume, no-drip, no-clog

dispensing nozzle

• Pre-set programs for virtually any

colloid

• Fully programmable

• Flexible capacity: Use 1 to 3.5 gallons

• USB port for future software upgrades

• Lighted work area with laser

sight-line

• Extra large easy-to-fill tank

• Corrosion-proof front panel

• Air-Cooled, no water or drain required

• Optional extension for continuous

dispensing

Special Features

Specifications

Fully Automatic

& Computer Controlled

Helps to extend colloid life!

Designed & Manufactured

in our Albany, NY Factory

2

Congratulat ons!

ou have just purchased a quality piece of CMP Dental Laboratory

Equipment. It’s quality has been carefully controlled and thoroughly

tested for optimum performance and durability.

If you have any questions regarding CMP’s quality line of dental laboratory

equipment and supplies, please call toll-free: 800-833-2343 or 518-434-3147

(Fax: 518-434-1288) between the hours of 8:00 AM and 4:30 PM Eastern

Time. Or, if you prefer, visit us at our web site: www.cmpindustries.com . . .

we will be pleased to assist you.

This manual may be available in other languages. Please check our website.

Special Features

It is important to thoroughly review this

manual and test your new duplicator prior

to loading with duplicating material.

I. Receiving & Unpacking

We have made every effort to test your

equipment and inspect it for damages prior

to packing for shipment. However, once the

equipment leaves our factory, the shipping

company accepts the equipment and the

responsibility becomes theirs for its safe and

undamaged delivery.

When you unpack your shipment, keep all

the packing materials until you are confident

that the equipment is in good working

condition and functions properly. If there

is any concealed damage, the shipping

company may need to examine the container

when a claim is filed.

If there is damage, the carrier should be

contacted as soon as possible. The claim

for damages must be filed with the carrier.

We are not in a position to assist you with

replacement, repair or warranty issues until

the carrier has completed their investigation.

If no damage has been found, place the

duplicator on a level bench where it will be

used. It is best to locate the unit adjacent

to the area where the duplicate models

will be cooled. Do not block the exhaust fan.

II. Electrical Connection

The Colloid-Saver 3.5 duplicator requires

only a standard 115V–60 Hz outlet to

operate. Before plugging-in the duplicator,

be sure to identify the electrical specifica-

tions of the outlet. A dedicated circuit

should be used as the Colloid-Saver 3.5

duplicator draws about 12 amps at 115 volts.

As with any electrical device, take extra care

when handling liquids around electrical

connections to avoid accidental shock.

It is important to carefully read and follow

the instructions in the next section

prior to actually plugging-in the duplicator.

III. Testing & Inspection

This is a very important step in the installa-

tion of your new Colloid-Saver 3.5 duplicator.

Even though your unit was fully tested and

inspected before leaving our factory, it may

have suffered damage during transit. For this

reason the following testing and inspection

steps are very important.

Note: The parts list located in the back of this

manual will help in the proper identification of the

items described below.

1. DO NOT insert the power cord.

Remove the rear panel and inspect

internal components visually. Look for

loose connections and parts.

2. Replace rear panel after inspection.

3. Remove the top cover by rotating it

clockwise and check inside the tank to

be sure there are no interferences with

the stirrer. Make sure stirrer knob is tight.

4. Replace top cover and rotate it

counter-clockwise to engage it with the

locking pins in the tank. Make sure cover

handle is facing forward.

5. Check to be sure the duplicator’s

identification plate voltage agrees with

the electrical voltage of the outlet. If unsure,

test voltage or contact a qualified electrician.

If these two items are compatible, plug

duplicator into the electrical outlet.

Note: The Colloid-Saver 3.5 duplicator (115V)

draws about 12 amps and should be on its own

dedicated circuit.

3

6. Flip the main power switch to the On (I)

position. The main power switch is located

on the right side of the unit, adjacent to the

electrical cord (Figure A).

7. Press the red POWER button located on

the front display panel to start the duplicator

(Figure C).

The display panel should illuminate and

shows the PROCESS temperature (actual

temperature reading of the tank) and the

hold temperature SET POINT. The unit is

now in “Standby Mode” (no heating lights

illuminated).

8. The Colloid-Saver 3.5 duplicator has been

pre-programmed for use with Nobilium,

Ticonium or Niranium colloids at sea level.

If the duplicator will not be used at sea level,

or other colloids will be used, you must

make setting adjustments as shown in

section VI.

IV. Colloid Loading & Cook-Down

1. Remove the top cover by rotating it

clockwise, then fill duplicator with 1 to 3 ½

gallons (4 to 13 liters) of colloid material.

Note: Colloid material must be chopped into small

(2 to 5 cm) chunks. Using larger chunks of material

may cause the stirrer mechanism to fail.

Do not fill the tank more than 3/4 full

initially. To maximize the volume of material

in the tank, wait 5 minutes after cook-down

begins, then remove the top cover and add

remaining material until the tank is full.

Make sure to add any liquid that may be in

the bottom of colloid container. The liquid

contains ingredients which extend the life

of the colloid. Replace

top cover and rotate it

counter-clockwise to

engage it with the

locking pins in the

tank (Figure B). As a

safety measure, the

top cover must be fully

rotated into a locked position

before the motor will function.

2. Press the ENTER button on the front

display panel. (The display will indicate

“Cook”).

3. Press the V arrow once (the display will

indicate “Hold”). Select either cook or hold

and press the ENTER button.

4. The stirring motor will start and the

display panel will indicate the PROCESS

temperature (actual temperature reading

of the tank) and the cook-down temperature

SET POINT.

5. All three heating lights will illuminate.

Heating will continue until the cook-down

temperature is reached. Then the duplicator

fan will activate until the unit reaches the

hold temperature. This cook-down process

takes 2 to 3 hours. (To suspend or restart

the cook-down process, press the ENTER

button).

6. The material is ready when the controller

display blinks “READY” (Figure C) and an

audible “beep”sounds. Turn off the audible

“beep” by pressing the SET button.

Note: The ready display and sound can be

turned off in the profile setup.

V. Operation

Cook-Down

It is best to cook-down in late afternoon.This

allows the cool-down cycle to occur in the

evening when the duplicator is not in use.

4

(Figure A)

(Figure B)

5

Colloid Storage

Please follow these procedures when storing

used material that will be re-melted.

1. After removing the colloid from the

duplicating flask, rinse with water to remove

any foreign material clinging to the colloid.

Pieces of gypsum or investment that remain

in the colloid can permanently damage the

tank and/or stirrer, as they will be dragged

around inside the tank during the cook-down

cycle.

2. ently shake-off excess water.

3. Store colloid in a clean, covered

container. Keep container covered so

moisture is not lost.

4. When ready to cook-down, cut colloid

molds in quarters, then load duplicator.

5. If re-melted colloid is difficult to

dispense due to high viscosity, add small

amounts of water until the viscosity is

reduced.

Changing Duplicating Material

When the tank is virtually empty, press

the red POWER button on the front panel to

turn-off the duplicator. To remove the colloid

at the very bottom of the tank, simply allow

it to cool then peel it out.

Preventive Maintenance & Cleaning

1. Clean Colloid-Saver 3.5 duplicator

approximately once a month or when

new duplicating material is added. Your

frequency of cleaning may vary with usage.

Scrub inside wall of tank and cover assembly

with a non-abrasive pot scrubber.

2. Inspect stirrer for wear and distortion.

Clean with non-abrasive pot scrubber.

3. Remove back panel and inspect the

bearing. If any colloid is leaking from this

area, the bearing must be replaced.

4. Be very careful not to spill liquids on

the duplicator! Liquids can damage the

control panel and circuit boards. If a spill

occurs, unplug the duplicator immediately

and clean thoroughly.

5. Clean fan air filter regularly to maintain

proper air flow.

Calibration

Calibration of the Colloid-Saver 3.5

duplicator is not necessary. The computer

controller is self-calibrating.

Continuous Dispensing (Emptying)

The Colloid-Saver 3.5 duplicator

can be used to fill flasks in a continuous

line using the optional Dispensing

Extender shown in (Figure D).

(Figure D)

Dispensing

Extender

Attributes

PROFILE A 15-100% On/Off 199°F (93°C) 133°F (56°C) 30 mins. F° 0 “Sea Level”

PROFILE B 15-100% On/Off 207°F (97°C) 131°F (55°C) 30 mins. F° 0 “Sea Level”

PROFILE C 15-100% On/Off 204°F (96°C) 134°F (57°C) 20 mins. F° 0 “Sea Level”

PROFILE D 15-100% On/Off 207°F (97°C) 131°F (55°C) 15 mins. F° 0 “Sea Level

Power Supply Interruption

In the event of a power interruption

(example: electrical outage due to weather),

the computer-controller will remember the

heating cycle and will continue with the

same cycle if the power supply comes

back online within 15 minutes. If the

colloid material is not solid, start a normal

cook-down cycle by turning the unit on and

pressing the ENTER button. If the power

supply is off for more than 15 minutes and

the colloid material is completely solid,

select the cold start cook-down cycle by

following these steps: With the power on,

press the SET button then the “ ” button

then the SET button twice (display will flash

“DONE”), then press ENTER twice.

VI. Settings

The factory default profile “A” is set-up

for Nobilium, Ticonium or Niranium colloid

products used at sea level. If the duplicator

will not be used at sea-level, the altitude

setting must be adjusted. Failure to set

the Altitude could cause the duplicator to

deliver poor quality colloid.

Select Pre-Programmed Setting

If not using Nobilium, Ticonium or Niranium

colloid products, review the requirements

of the duplicating material to be used and

match them to one of the pre-programmed

profile settings below. To select a specific

profile, the duplicator must be in “Standby

Mode” (power on but no heating lights illu-

minated). Press the SET button twice. The

display will show the first option on the set-

tings menu which is the present profile.

Press the “^” (UP) button to find the profile

to be changed. Press the SET button again

to select the profile. Press the ENTER button

to exit the settings menu.

Develop Custom Settings

If none of the pre-programmed settings

match the requirements of the duplicating

material, then develop a custom profile.

To develop custom profile settings, the

duplicator must be in “Standby Mode”

(power on but no heating lights illuminated).

Press the SET button once. Then press the

“^” button to find the attribute to be

changed. When the desired attribute is

displayed, press the SET button to select it.

Then press the “^” or “ ” button to change

the setting. Press the SET button to confirm

the change. Press the ENTER button to exit

the settings menu. The attribute setting

options are presented below along with their

maximum and minimum values.

To reset the duplicator to factory defaults,

scroll through the menu options until the

display reads “SET DEF.” Press the SET

button to return all settings to factory default

settings and “DONE” will be displayed. To

abort changes, press the Enter button to

re-enter the “Stanby Mode.” Other

attributes (KP, KI, KD) cannot be edited.

6

Stirrer Ready Cook-Down Temp. Hold Temp. Cook Dwell F° or C° Altitude

Max. 100% On/Off 207°F or (97°C) 140°F or 60°C 60 Minutes F°/C° +255' x 100

Min. 15% On/Off 190°F or (88°C) 125°F or 52°C 1 Minute F°/C° – 14' x 100

(+ 25,500')

(–1,400')

^

^

Display “STR” “RDY” “SCT” “SHT” “SCD” “DE ” “ALT”

*

* Default settings

7

If manufacturer- recommended

specifications for the colloid to be

used are unavailable, follow these steps:

1. Cook-Down Temperature – Select a

profile and edit the cook-down temperature

as described on page 6. Start with

Cook-Down temperature of 200°F (93°C).

If the colloid is fully melted after 30 minutes,

then reduce the next cook-down tempera-

ture by increments of 2°F (1°C). Continue

the process until the colloid is not fully melt-

ed. Use the lowest cook-down temperature

that will yield usable material in order to

maximize colloid life.

2. Hold Temperature – Select a profile

and edit the hold temperature as described

on page 6. Start with a Hold Temperature of

140°F (60°C) then gradually lower the hold

temperature as performed above. Use the

lowest hold temperature that will yield

usable material in order to maximize

colloid life.

VII. Troubleshooting

1. Colloid-Saver 3.5 duplicator will not turn on.

A. Check wall outlet for power.

B. Check if power cord is connected to

duplicator.

C. Check if the main power supply is

turned to the On (O) position.

D. Check if back panel is secure.

E. Check 15 amp circuit breaker on right

side rear. (Press to reset)

2. Duplicator front panel display is working,

but duplicator does not heat.

A. Check heater connections on terminal

board, relay & controller.

3. Motor will not run.

A. Check 1 amp circuit breaker on right

side rear. (Press to reset)

B. Check top cover. It must be fully

rotated into a locked position.

C. Check motor connections on terminal

board, relay & controller.

4. Fan does not turn on.

A. Check fan connections on terminal

board, relay & controller.

5. Top cover will not open.

A. Top cover is designed to resist opening

during the advanced stage of the cook-down

cycle. This is a safety measure to prevent the

addition of colloid during the advanced

stages of the cook-down cycle which may

result in splash of hot colloid material.

8

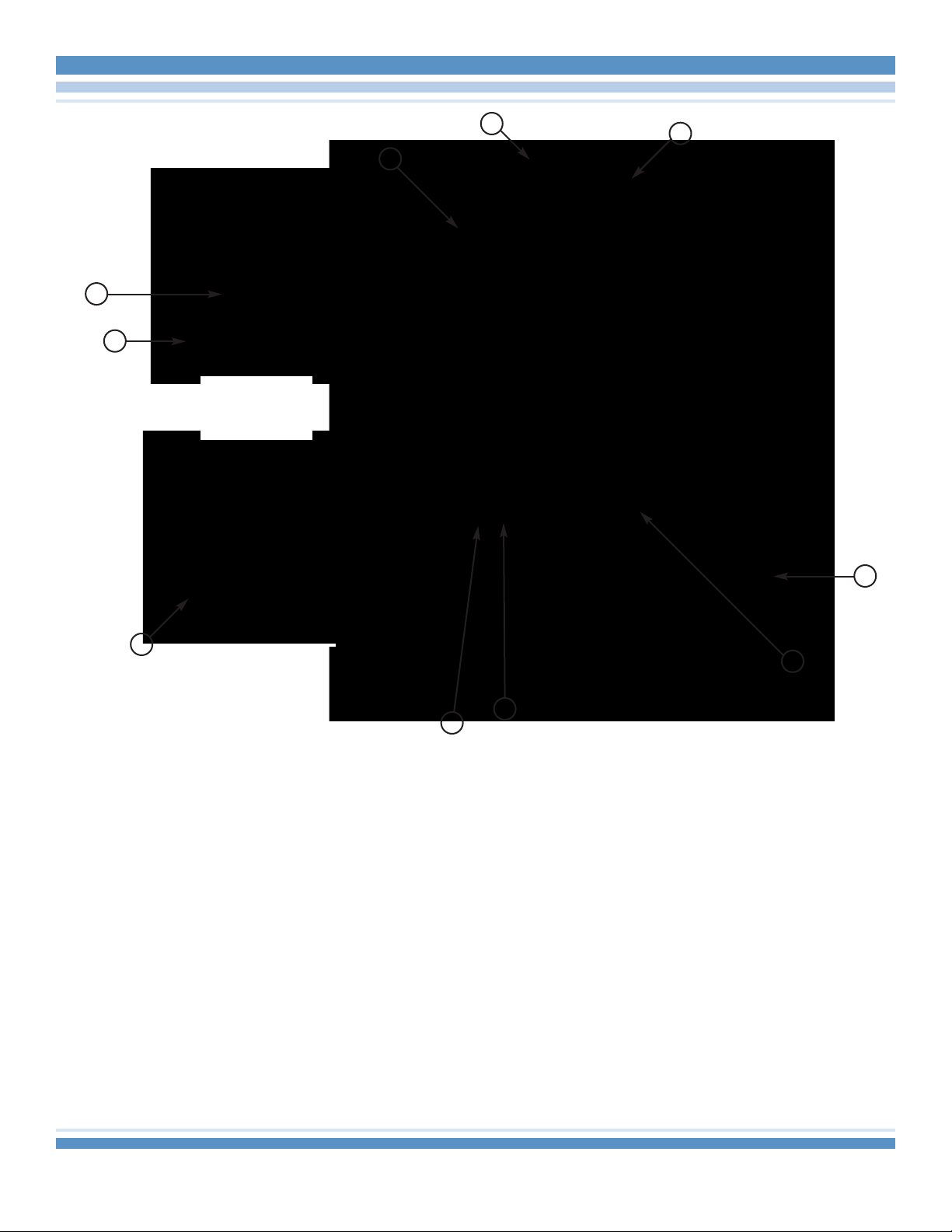

Front V ew w th Top Cover

ITEM & DESCRIPTION PART NUMBER

1. Front Panel Control 40811P37

2. Precision Laser 40811P48

3. LED Light 40811P38

4. Power Entry Module 40811P20

5. Cover Lock 40811P44

6. Poly Cover 40811P1

7. Cover Interlock 40811P45

8. Cover Handle 40811P43

9. Power Cord Assembly 40811P61

10. Mold Form Front Panel 40811P27

1

10

4

5

3

2

9

8

7

6

Underside

of Top Cover

9

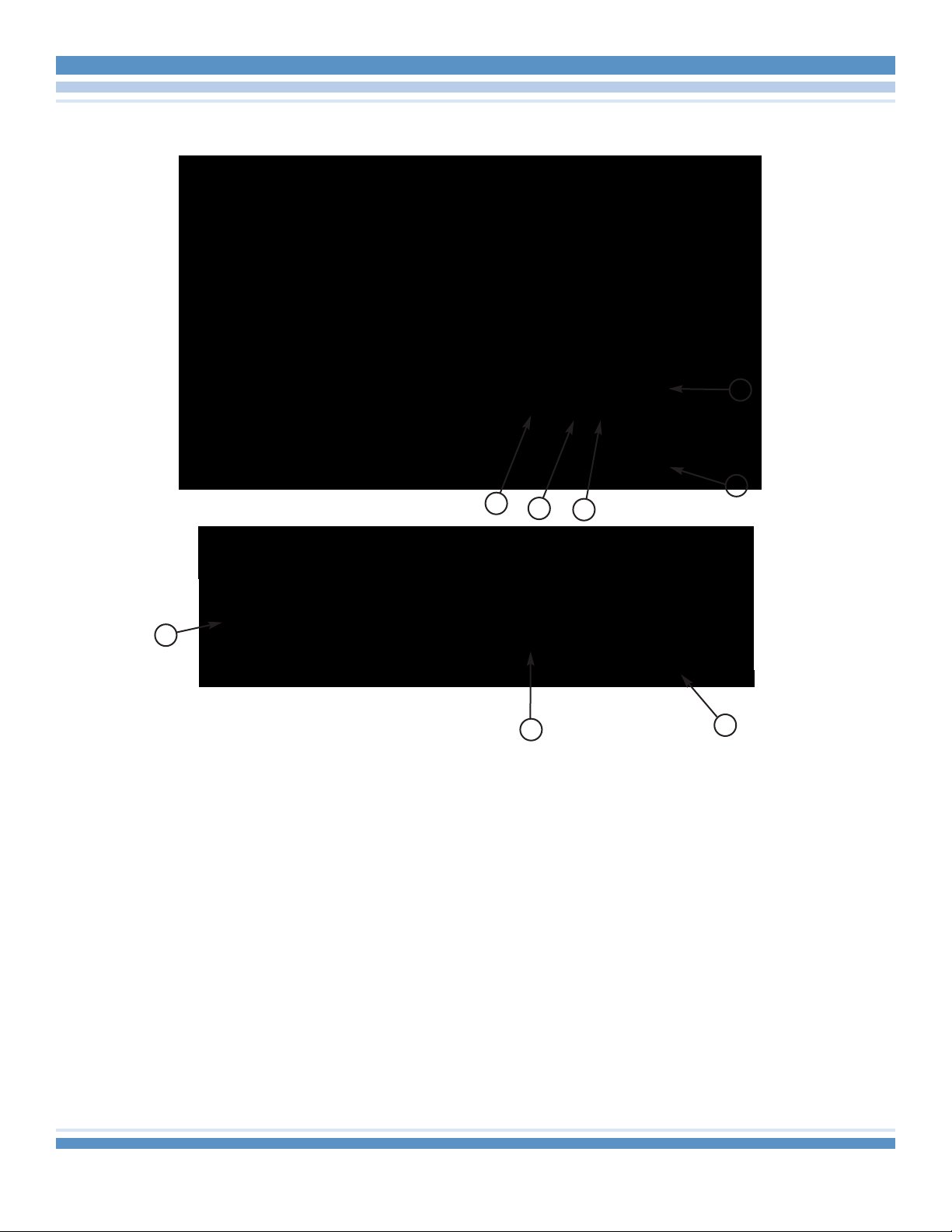

S de V ew & Valve

ITEM & DESCRIPTION PART NUMBER

1. USB Port Connector 40811P39

2. 1 Amp Motor Circuit Breaker 65383P7

3. 15 Amp Main Breaker 65383P6

4. Power Entry Module 40811P20

5. Rubber Feet 40811P19

6. Knob 40811P2

7. Valve Body 40811P7

8. Locking Nut 40811P11

123

4

5

6

78

10

Ins de V ew

(S de)

ITEM & DESCRIPTION PART NUMBER

1. Fan 36081R

2. Fan uard 40811P22

3. Fan Air Filter 40811P22A

4. Side Heater 40811P33

5. Controller 40811P34

6. Drawer Slide 40811P12

7. Solid State Relay 41984P18

8. Handle 40811P26

9. 2-Pin Connector 40811P51

10. 8-Pin Connector (X2) 40811P50

11. 14-Pin Terminal Block 40811P52

12. Flat Cable 40811P53

13. Relay 5V 40811P49

14. USB Port Connector 40811P39

1 2 3

8

4

7

9

10

11

13

6

5

12

14

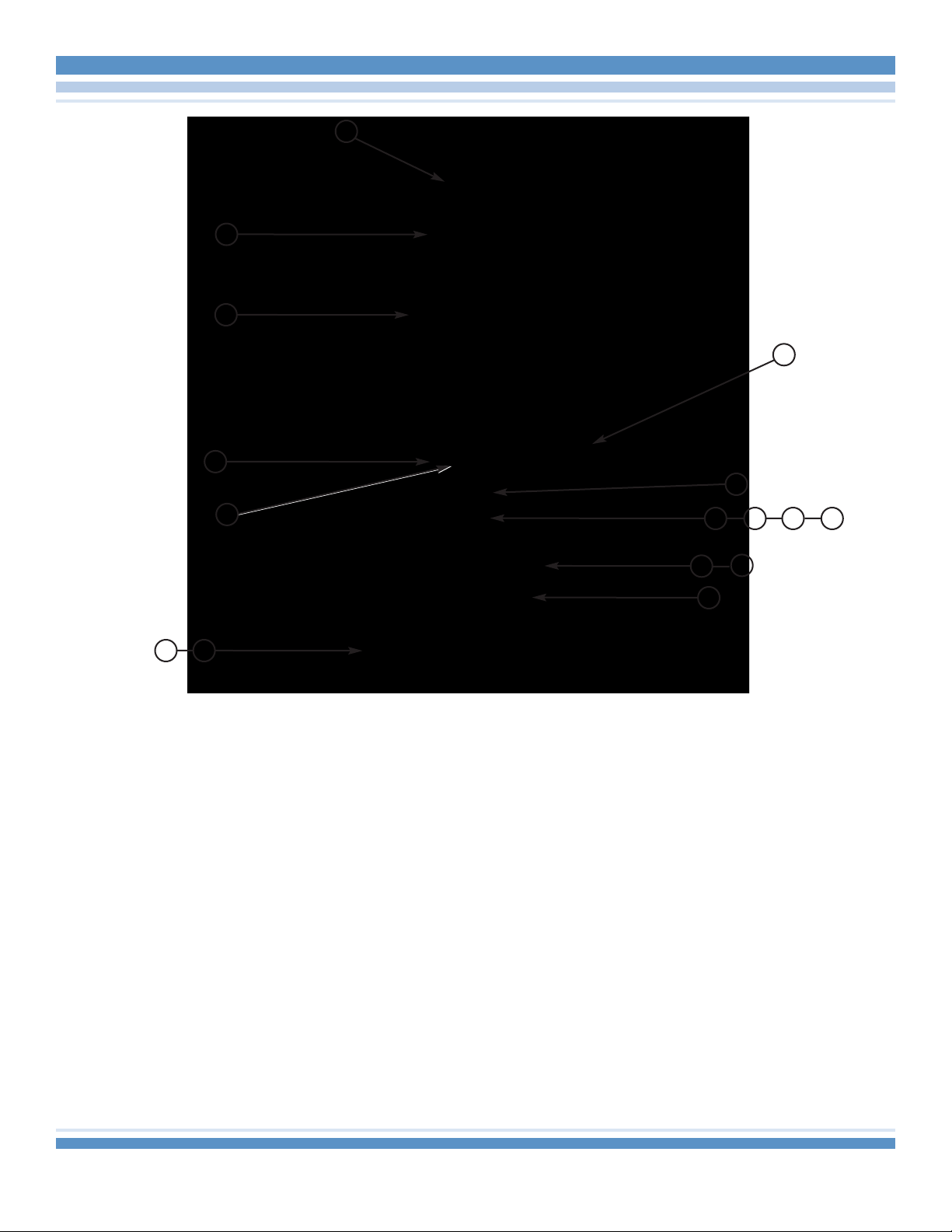

Ins de V ew (Back)

ITEM & DESCRIPTION PART NUMBER

1. Coupling Hub 5/8 40811P23

2. Coupling Hub 3/4 40811P24

3. Coupling Spider 40811P25

4. Keyed Drive Shaft 40811P30

5. Shaft Collar 40811P35

6. Motor 40811P31

7. earhead 40811P31A

8. Power Supply 40811P40

9. Thermistors 120C 40811P28

10. Tank Assembly 40811 3

11. Bottom Heater 4081132

12. Cover Interlock Bracket 40811P46

13. Panel Safety Switch 40811P47

14. Panel Safety Switch Bracket 40811P60

15. Bottom Heater Bracket 40811P17

16. Tank Support Bracket 40811P36

12

2 3 4

13

7

10

9

11

15

14

6

8

16

1

11

5

12

Ins de Tank & St rrer

ITEM & DESCRIPTION PART NUMBER

1. Thermocouple K-Type 10980

2. Main Shaft 40811P13

3. Bearing 40811P29

4. Seal 40811P41

5. Stirrer Assembly 40811 2

6. Stirrer Knob 40811P18

4

3

2

5

1

Inside View of Tank

6

13

Accessor es

ITEM & DESCRIPTION PART NUMBER

1. Dispensing Extender 40811P58

1

413 North Pearl Street •Albany, New York •12207 •USA

Toll-Free: 800 833-2343 •USA: 518 434-3147 •Fax: 518 434-1288

Website: www.cmpindustries.com

Form 40811

NOBILIUM

TM

TM

Table of contents