Noblift LPT22 User manual

NOBLELIFT EQUIPMENT

Service & Maintenance Manual

LPT22 Power Pallet Truck

V-LPT22-01.00 Date: 2011-02-26

1

CONTENTS

FOREWORD............................................................................................................................................2

1. GENERAL.........................................................................................................................................3

1.1 INTRODUCTION – MAINTENANCE SAFETY PRECAUTIONS..............................................3

1.2 MEASUREMENT CONVERSIONS..........................................................................................7

2. SPECIFICATION.............................................................................................................................11

2.1 LOCATION OF COMPONENTS ............................................................................................11

2.2 SPECIFICATION SHEETS.....................................................................................................12

2.3 LUBRICATION.......................................................................................................................13

3. ELECTRICAL SYSTEM..................................................................................................................14

3.1 ELECTRICAL DIAGRAM.......................................................................................................14

3.2 INSTALLATION OF ELECTRIC.............................................................................................17

3.3 DRIVE WHEEL.......................................................................................................................19

3.4 POWER UNIT.........................................................................................................................19

3.5 BATTERY...............................................................................................................................19

3.6 CHARGER .............................................................................................................................24

3.7 CURTIS CONTROLLER ........................................................................................................29

3.8 BATTERY INDICATOR..........................................................................................................36

3.9 REPLACING THE ELECTRIC PARTS ..................................................................................38

3.10 TOOL FOR REPAIRING THE PIN OF ELECTRICAL PLUG .................................................43

4. HYDRAULIC SYSTEM....................................................................................................................44

4.1 HYDRAULIC FLOW DIAGRAM .........................................................................................44

4.2 INSTALLATION OF HYDRAULIC SYSTEM........................................................................44

4.3 REPLACING THE POWER UNIT ........................................................................................45

4.4 REPLACING THE CYLINDER.............................................................................................46

4.5 CLEANING OIL TANK AND FILTER...................................................................................47

4.6 TROUBLE DIAGNOSTICS ..................................................................................................48

5. DRIVE WHEEL................................................................................................................................50

5.1 REPLACING THE DRIVE SYSTEM AND WHEEL..............................................................51

5.2 REPLACING THE CARBON BRUSH KIT...........................................................................52

5.3 REPLACING THE BRAKE...................................................................................................52

5.4 THE BRAKE CLEARANCE ADJUSTMENT........................................................................52

6. CONTROL HANDLE.......................................................................................................................54

6.1 REPLACING THE CONTROL HANDLE................................................................................55

6.2 REPLACING THE AIR SPRING AND MICRO SWITCH........................................................57

7. CASTER WHEEL............................................................................................................................58

7.1 REPLACING OF THE CASTER WHEEL...............................................................................58

7.2 ADJUSTING THE PRESSURE FOR THE DRIVE WHEEL ...................................................58

8. TROUBLE DIAGNOSTICS.............................................................................................................59

8.1 MAINTENANCE LIST ............................................................................................................59

8.2 TROUBLE SHOOT.................................................................................................................60

2

FOREWORD

Proper operation, maintenance, troubleshooting and repairs are necessary to preserve the performance

of the pallet truck over along period of time and ensure that fault and breakdowns do not occur. The

object of this service manual is to provide the information necessary especially in connection with the

performance of inspections and repairs mainly in the maintenance areas.

The majority of this pallet truck consists of steel, it can be completely recycled. Waste

material in conjunction with repairs, maintenance, cleaning or scrapping, must be collected and disposed

of in an environment-friendly way and in accordance with the directives of respective countries. Such

work must be carried out in areas intended for this purpose. Recyclable material should be taken care of

by specialized authorities. Environmentally hazardous waste, such as oil filters, batteries and electronics,

will have a negative effect on the environment, or health, if handled incorrectly.

All of the information reported herein is based on data available at the moment of

printing. Our products are constantly being developed and renewed, we reserves the right to modify our

own products at any moment without prior notice and incurring in any sanction. So, it is suggested to

always verify possible updates.

3

1. GENERAL

1.1 INTRODUCTION – MAINTENANCE SAFETY PRECAUTIONS

Careless performing of the easy work may cause injuries. Take care to always perform work safely, at

least observing the following. It is of utmost importance that maintenance personnel pay strict attention

to these warnings and precautions to avoid possible injury to themselves or others, or damage to the

equipment. A maintenance program must be followed to ensure that the machine is safe to operate.

The specific precautions to be observed during maintenance are inserted at the appropriate point in the

manual. These precautions are those that apply when servicing hydraulic and larger machine

component parts.

MODIFICATION OF THE MACHINE WITHOUT CERTIFICATION BY A

RESPONSIBLE AUTHORITY THAT THE MACHINE IS AT LEAST AS SAFE AS ORIGINALLY

MANUFACTURED, IS A SAFETY VIOLATION.

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CONTROL OVER THE

FIELD INSPECTION AND MAINTENANCE, SAFETY IN THIS AREA RESPONSIBILITY OF THE

OWNER OR OPERATOR.

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LlSTED IN THIS SECTION

MAY RESULT IN MACHINE DAMAGE, PERSONNEL INJURY OR DEATH AND IS A SAFETY

VIOLATION.

When carrying out any operation or maintenance, have trained and experienced personnel carry out

the work.

When carrying out any operation or maintenance, carefully read out Operation and Maintenance

Manual.

Read all the precautions given on the decals which are fixed to the machine.

Be sure you fully understand the contents of the operation. It is important to prepare necessary tools

and parts and to keep the machine.

Your safety, and that of others , is the first consideration when

engaging in the maintenance of equipment. Always be conscious of

weight. Never attempt to move heavy parts without the aid of a

mechanical device. Do not allow heavy objects to rest in an

unstable position. When raising a portion of the equipment, ensure

that adequate support is provided.

4

It should be noted that the machines hydraulic systems operate at

extremely high potentially dangerous pressures. Every effort should

be made to relieve any system pressure prior to disconnecting or

removing any portion of the system. Relieve system pressure by

cycling the applicable control lowering button several times with the

motor stopped and ignition on, to direct any line pressure back into

the reservoir. Pressure feed lines to system components can then

be disconnected with minimal fluid loss.

Remove all rings, watches and jewelery when performing any maintenance.

Wear well-fitting helmet, safety shoes and working Clothes When

drilling grinding or hammering always. Wear protective goggles.

Always do up safety clothes properly so that they do. Not catch on

protruding parts of machines. Do not wear oily clothes. When

checking, always release battery plug. DO NOT WEAR LONG

HAIR UNRESTRAINED, OR LOOSE-FITTING CLOTHING AND

NECKTIES WHICH ARE APT TO BECOME CAUGHT ON OR

ENTANGLED IN EQUIPMENT.

During maintenance do not allow any unauthorized person, to

stand near the machine.

Flames should never be used instead of lamps. Never use a buring

flame to check leaks or the level of oil or electrolyte.

Immediately remove any oil or grease on the floor of the operator’s

compartment or on the handrail. It is very dangerous if someone slips

while on the machine.

Always use the recommended pure oil or grease, and be sure to use clean containers.

Oil is a dangerous substance. Never handle oil, grease or oily

clothes in places where there is any fire or flame. As

preparation for use of fire extinguishers and other fire- fighting

equipment.

Keep the battery away from fire hazards. The generated gases

are explosive.

Store all the oils in a specified place.

Keep the flammable things away from the machine. Do not

smoke in the working site.

Battery should always be disconnected during replacement of electrical components.

5

Always use the grades of grease and oil recommended by NOBLELIFT choose the viscosity

specified for the ambient temperature.

Exhaust gas is dangerous provide ventilation when working in a closed

space.

Avoid breathing dust that may be generated when handling components

containing asbestos fibers. Wear a gas mask if necessary.

When working on top of the machine, be careful not to lose your balance

and fall.

Hand a caution sign in the operator’s compartment (for example “Do not

start” of “Maintenance in progress”). This will prevent anyone from

starting or moving the machine by mistake.

When welding on the machine or working on the electical system,

ALWAYS turn the key switch OFF and remove the battery plug

from the battery. Park the machine on firm, flat ground. Lower the

fork to the min. height and stop the motor.

Sulfuric acid in battery electrolyte is poisonous. Ist is strong

enough to burn skin and eat holes in clothing. If you spill acid on

your clothes or skin, immediately flush it with large quantities of

water.

When working on the battery, wear goggles or safety glasses. If

splashed into the eyes, flush with water and get medical attention

immediately.

Battery terminals touched by metal objects can cause short circuit

and burn you. Keep tools away from the terminals.

When disassembling and assembling the battery, make sure that

the battery terminals (+, –) are correctly connected.

If water gets into the electrical system, abnormal operation or

failure can result. Do not use water or steam on sensors, connectors

and instruments in the cab.

Do not handle electrical equipment while wearing wet gloves, or in wet

places, as this can cause electric shock.

When working with others, choose a group leader and work according to his instructions. Do not

perform any maintenance beyond the agreed work.

Unless you have special instructions to the contrary, maintenance should always be carried out with

the motor stopped. If maintenance is carried out with the motor running, there must be two men

present : one operating the pallet truck and the other one performing the maintenance. In such a

case, never touch any moving part.

6

Before making adjustment, lubricating or performing any other maintenance, shut off all power

controls.

When removing parts containing O-ring Gaskets or seal. Make sure clean the mounting surface and

replace with new sealing parts.

Thoroughly clean the machine. In particular, be careful to clean the grease fittings and the area

around the dipsticks. Be careful not to let any dirt or dust into the system.

Use only approved, nonflammable cleaning solvents.

When changing the oil or fitter, check the drained oil and filter for any signs of excessive metal

particles or other foreign materials.

Always use NOBLELIFT genuine parts for replacement. ENSURE REPLACEMENT PARTS OR

COMPONENTS ARE IDENTICAL OR EQUIVALENT TO ORIGINAL PARTS OR COMPONENTS.

When checking an open gear case, there is a risk of dripping things in. Before removing the covers

to inspect such cases, empty everything from your pockets. Be particularly careful to remove

wrenches and nuts.

7

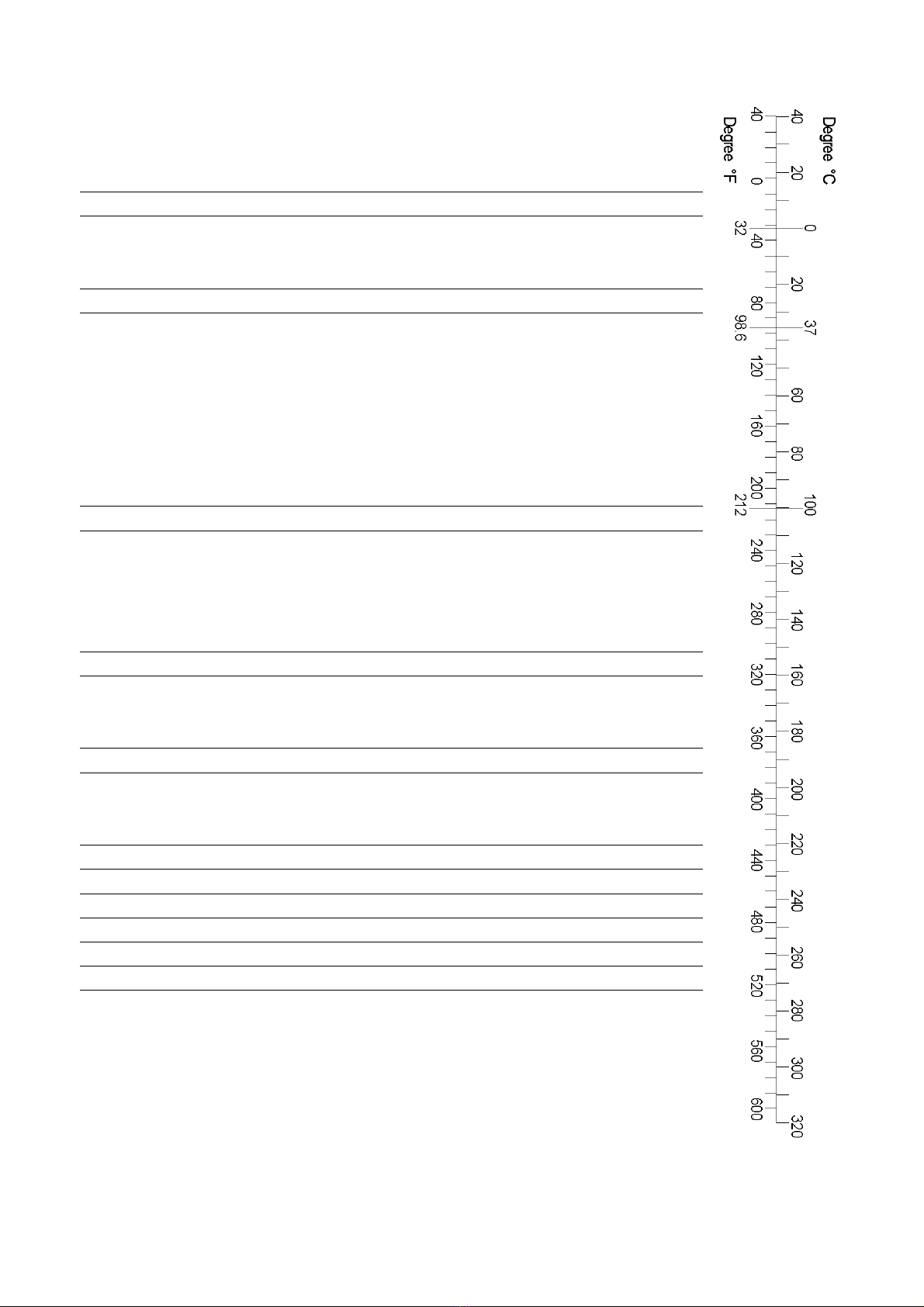

1.2 MEASUREMENT CONVERSIONS

Length

Unit cm m km in ft yd mile

cm 1 0.01 0.00001 0.3937 0.03281 0.01094 0.000006

m 100 1 0.001 39.37 3.2808 1.0936 0.00062

km 100000 1000 1 39370.7 3280.8 1093.6 0.62137

in 2.54 0.0254 0.000025 1 0.08333 0.02777 0.000015

ft 30.48 0.3048 0.000304 12 1 0.3333 0.000189

yd 91.44 0.9144 0.000914 36 3 1 0.000568

mile 160930 1609.3 1.6093 63360 5280 1760 1

1mm=0.1cm, 1m=0.001mm

Area

Unit cm2 m2 km2 a ft2 yd2 in2

cm2 1 0.0001 – 0.000001 0.001076 0.000012 0.155000

m2 10000 1 0.000001 0.01 10.764 1.1958 1550.000

km2 – 1000000 1 10000 1076400 1195800 –

a 0.01 100 0.0001 1 1076.4 119.58 –

ft2 – 0.092903 – 0.000929 1 0.1111 144.000

yd2 – 0.83613 – 0.008361 9 1 1296.00

in2 6.4516 0.000645 – – 0.006943 0.000771 1

1ha=100a, 1mile2=259ha=2.59km2

Volume

Unit cm3 = cc m3 l in3 ft3 yd3

cm3 = m l 1 0.000001 0.001 0.061024 0.000035 0.000001

m3 1000000 1 1000 61024 35.315 1.30796

l 1000 0.001 1 61.024 0.035315 0.001308

in3 16.387 0.000016 0.01638 1 0.000578 0.000021

ft3 28316.8 0.028317 28.317 1728 1 0.03704

yd3 764529.8 0.76453 764.53 46656 27 1

1gal(US)=3785.41 cm3=231 in3=0.83267gal(US)

Weight

Unit g kg t oz lb

g 1 0.001 0.000001 0.03527 0.0022

kg 1000 1 0.001 35.273 2.20459

t 1000000 1000 1 35273 2204.59

oz 28.3495 0.02835 0.000028 1 0.0625

lb 453.592 0.45359 0.000454 16 1

1 tonne(metric)=1.1023 ton(US)=0.9842 ton(UK)

8

Pressure

Unit kgf/cm2 bar Pa=N/m2 kPa lbf/in2 lbf/ft2

kgf/cm2 1 0.98067 98066.5 98.0665 14.2233 2048.16

bar 1.01972 1 100000 100 14.5037 2088.6

Pa=N/m2 0.00001 0.00001 1 0.001 0.00015 0.02086

kPa 0.01020 0.01 1000 1 0.14504 20.886

lbf/in2 0.07032 0.0689 6894.76 6.89476 1 144

lbf/ft2 0.00047 0.00047 47.88028 0.04788 0.00694 1

kgf/cm2=735.56 Torr(mmHg)=0.96784atm

Standard torque

The following charts give the standard torque specification of bolts and nuts.

Exceptions are given in the sections of “Disassembly and Assembly”

METER TABLE

Classification 4T, 5T 10T

Bolt type

Bolt size Torque kgf · m (lbf · ft) Torque kgf · m (lbf · ft)

M4 0.2 ± 0.02 0.4 ± 0.04

M5 0.3 ± 0.03 0.8 ± 0.08

M6 0.5 ± 0.05 1.4 ± 0.14

M8 1.2 ± 0.12 3.3 ± 0.3

M10 2.3 ± 0.23 6.5 ± 0.7

M12 4.0 ± 0.4 11.3 ± 1.1

M14 6.4 ± 0.6 17.9 ± 1.8

M16 9.5 ± 0.9 26.7 ± 2.7

M18 13.5 ± 1.4 38.0 ± 3.8

M20 18.6 ± 1.9 52.2 ± 5.2

M22 24.7 ± 2.5 69.4 ± 6.9

M24 32.1 ± 3.2 90.2 ± 9.0

M30 62.6 ± 6.3 176.1 ± 17.6

M36 108.2 ± 10.8 304.3 ± 30.4

M42 171.8 ± 17.2 483.2 ± 48.3

M45 211.3 ± 21.1 594.3 ± 50.4

10.9

9

INCH TABLE

4T, 5T 10T

Classification Bolt type

Bolt size Torque kgf · m (lbf · ft) Torque kgf · m (lbf · ft)

1/4 0.6 ± 0.06 1.7 ± 0.2

5/16 1.2 ± 0.12 3.0 ± 0.3

3/8 2.0 ± 0.20 5.6 ± 0.5

7/16 3.2 ± 0.32 8.9 ± 0.9

1/2 4.7 ± 0.47 13.4 ± 1.3

9/16 6.8 ± 0.68 19.0 ± 1.9

5/8 9.3 ± 0.93 26.1 ± 2.6

3/4 16.0 ± 1.60 45.1 ± 4.5

7/8 25.5 ± 2.55 71.6 ± 7.2

1 38.0 ± 3.80 106.9 ± 10.7

1-1/8 54.1 ± 5.41 152.2 ± 15.2

1-1/4 74.2 ± 7.42 208.9 ± 20.9

1-3/4 98.8 ± 9.88 277.8 ± 27.8

1-1/2 128.2 ± 12.82 360.7 ± 36.1

The torque specifications in above table shall not be applied to the bolts with nylon packings and nonferrous

metal washers, or the ones with specifically designated torque and standard.

H Newton meter : 1 N·m = 0.1kgf·m

TIGHTENING TORQUE OF SPLIT FLANGE BOLTS

The following torque shall be applied to the split flange bolts.

TorqueDiameter

(mm)

Flat width

(mm) kgf·m N·m

10 14 6.7 ± 0.7 66.7 ± 6.8

12 17 11.5 ± 1 112 ± 9.8

16 22 28.5 ± 3 279 ± 29

10

APPROXIMATE CONVERSIONS

SI Conv Non–SI Conv SI

Unit Factor Unit Factor Unit

Torque

newton meter (N·m) ×8.9 = ln·in ×0.113 = N·m

newton meter (N·m) ×0.74 = lb·ft. ×1.36 = N·m

newton meter (N·m) ×0.102 = kg·m ×7.22 = lb·ft.*

Pressure (Pa = N/m2)

kilopascal (kPa) ×4.0 = in. H2O ×0.249 = kPa

kilopascal (kPa) ×0.30 = in. Hg ×3.38 = kPa

kilopascal (kPa) ×0.145 = psi ×6.89 = kPa

(bar) ×14.5 = psi ×0.069 = bar*

(kg/cm2) ×14.22 = psi ×0.070 =

kf/

2

*

newton/mm2×145.04 = psi ×0.069 = bar*

megapascal (MPa) ×145 = psi ×0.00689 = MPa

(Pa=N·m2)

Power r (W = J/s)

kilowatt(kW) ×1.36 = PS (cv) ×0.736 = kW

kilowatt(kW) ×1.34 = HP ×0.746 = kW

kilowatt(kW) ×0.948 = Btu/s ×1.055 = kW

watt(W) ×0.74 = ft·lb/s ×1.36 = W

(W=J/s)

Energy (J = N·m)

kilojoule(kJ) ×0.948 = Btu ×1.055 = kJ

j

oule(J) ×0.239 = calorie ×4.19 = J

(J=N·m)

Velocity and Acceleration

meter per sec2(m/s2) ×3.28 = ft/s2×0.305 = m/s2

meter per sec (m/s) ×3.28 = ft/s ×0.305 = m/s

kilometer per hour (km/h) ×0.62 = mph ×1.61 = km/h

Horse Power/Torque

BHP ×5252 R.P.M. = TQ (lb·ft) TQ Z R.P.M. 5252 = B.H.P.

Temperature

°C = (°F–32) ÷ 1.8 °F= (°C Z 1.8) + 32

Flow Rate

liter/min (dm3/min) ×0.264 = US gal/minZ3.785 = l/min

Note : ( ) Non–SI Unit

11

2. SPECIFICATIONS

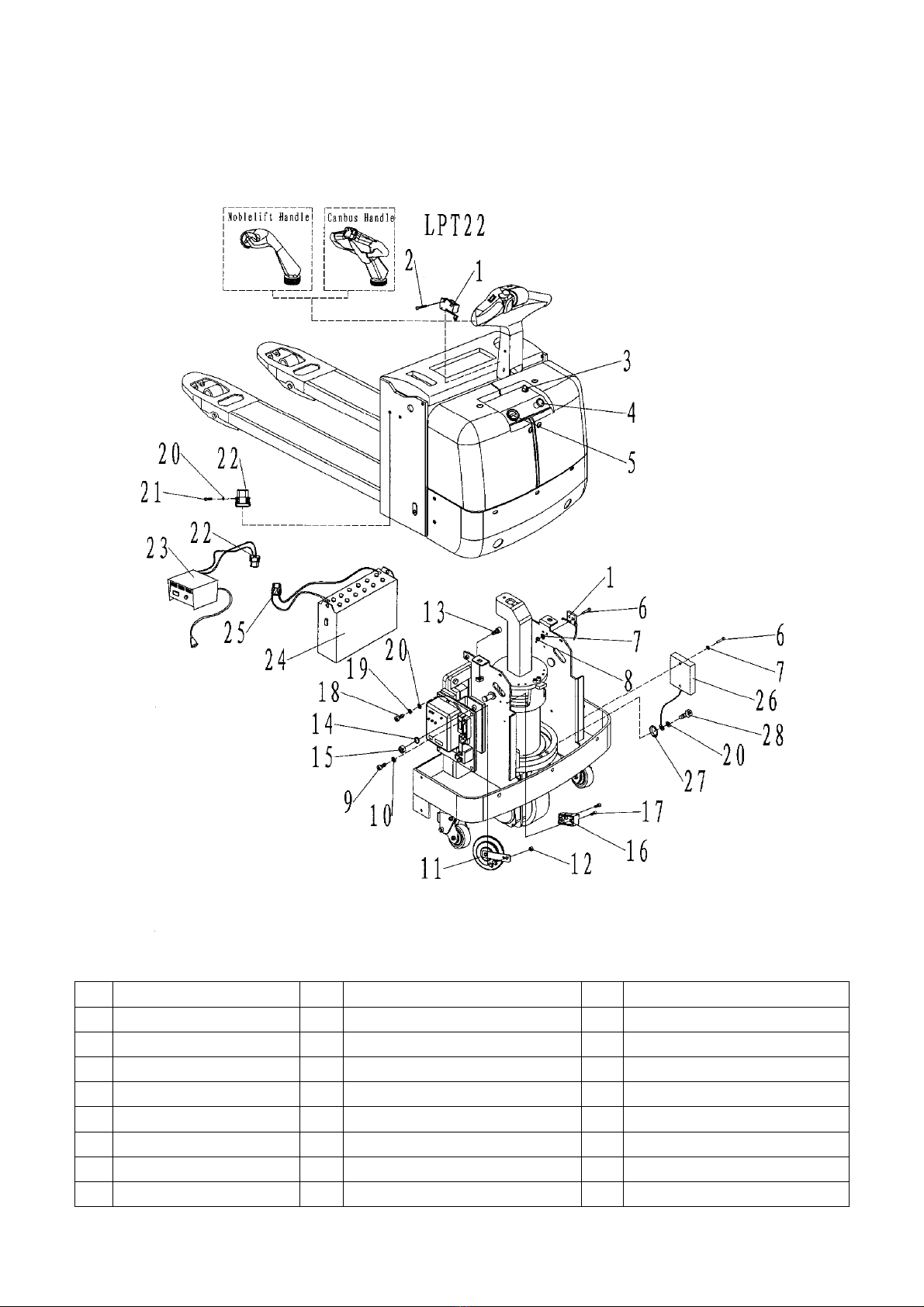

2.1 LOCATION OF COMPONENTS

1. Control Handle 7. Stabilizing Caster (Inside The Cover)

2. Key Switch (ON/ OFF) 8. Pump Unit (Inside The Cover)

3. Emergency Stop Button Or Kill Switch 9. Lift Cylinder

4. Battery Indicator CURTIS 803 10. Battery (Inside The Cover)

5. Controller assembly 11. Load Roller

6. Drive Wheel (Inside The Cover)

CONTROL HANDLE

1. Raise/Lower buttons – Rocker switches

adjusting fork height.

2. FWD/BWD/REV travel button –Control

variable speed by turning knob

3. Emergency Reverse button – Emergency

reverse button or commonly known as the belly

button switch

4. Horn button

5. Indicator light – Indicates high/low speed

status. Green indicates high speed, red

indicates slow speed.

6. Shift button – Shift button for high speed and

low speed

12

2.2 SPECIFICATION SHEETS

1.2 Model of manufacture LPT22

1.3 Power supply (electric, diesel, petrol, gas, mains Electric

1.4 Type of operation (hand, pedestrian, stand on, rider Pedestrian

1.5 Capacity / rated load Q KGs 2200

1.6 Load center distance C mm 600

1.8 Load distance X mm 963/1033

Characteristics

1.9 Wheelbase Y mm 1368

2.1 Weight (including battery) KGs 512

2.2 Axle loadings laden drive end / load end KGs 1082/1630

2.3 Axle loadings unloaded drive end / load end KGs 399/113

Weight

3.1 Tyres (rubber, Vulkollan, pneumatic, polyurethane) Polyurethane

3.2 Tyre size Dia. x width drive end mm Φ230x75

3.3 Tyre size Dia. x width load end mm 2 xΦ84x70/Φ84x93

3.4 Castor wheels (dimensions) mm 2xΦ100x40

3.5 Wheels, number(x=drive wheel) 1x -2/ 2/ 1x -2/ 4

3.6 Track width (front) drive end b10 mm 500

Wheels types

3.7 Trackwidth(rear) loadend b11 mm 380/525

4.4 Lift height h3 mm 120

4.9 Tiller height in neutrality position h14 mm 1323

4.15 Fork height lowered h13 mm 85

4.19 Overall length l1 mm 1725/1795

4.20 Length to front face of fork l2 mm 575

4.21 Overall width b1 mm 726

4.22 Fork dimensions s/e/l mm 60/160/1150(1220)

4.25 Overall fork width b5 mm 540/685

4.32 Floor clearance, center of wheelbase m2 mm 25

4.34 Working aisle with 800x1200 pallet lengthwise Ast mm 2305/2344

Dimensions

4.35 turning radius Wa mm 1640/1710

5.1 Travel Speed laden / unloaded mph 5.2 / 5.5

5.2 Lifting speed laden / unloaded mm/s 19 / 35

5.3 Lowering speed laden / unloaded mm/s 30 / 27

5.8 Gradeability laden / unloaded % 9/15

Performance

5.10 Brakes Electric-magnetic

6.1 Drive motor kw 1.5(AC)

6.2 Lifting motor kw 0.8

6.4 Battery voltage, normal capacity K5 V/Ah 24/210

6.5 Battery weight +/-5% KGs 185

6.6 Battery dimensions l /w / h mm 645/196/570

Electric motor

8.1 Type of drive control MOSFET Control

8.4 Sound level at driver’s ears dB(A) <70

Other

Turning angle °180

13

2.3 LUBRICATION

Hydraulic oil

Hydraulic oil must have anti-wear qualities at least. It is not advisable to mix oils of

different brands or types, as they may not contain the same required additives or be of

comparable viscosities.

Name: Thickened hydraulic oil.

ISO Viscosity Grade #40 #30

Characteristics unit

At 40OC 57 48

Viscosity At 50OC mm2/s 40 30

Viscosity index ≥150 ≥150

Flash point, Cleveland open cup OC ≥160 ≥160

Pour point, Max OC ≤-35 ≤-35

Density at 15 OC kg/m3861.5

Copper corrosion(100OC, 3h) degree ≤1 ≤1

Foaming (93.5 OC) ml / ml

≤30/0 ≤30/0

Vickers vane pump test, loss of mass (on vanes after 100h) mg ≤100 15.3

Diameter of wear spot, 1200 r/min, 294N, 30min, 75 OC mm ≤0.5 ≤0.5

The oil for gear box

Name: Extreme pressure lithium-based grease, 1#.

Characteristics unit

Worked Penetration, 0.1mm 310--340

Dropping point, OC ≥170

Extreme pressure (Timken OK) N ≥177

Similar viscosity (-10 OC, 10s-1) Pa.s ≤250

Corrosion preventive properties (52 OC, 48h) Grade 1

Wire points oil (100 OC, 24h) % ≤10

14

3. ELECTRICAL SYSTEM

3.1 ELECTRICAL DIAGRAM

WIRING DIAGRAM

15

CONNECTION DIAGRAM

16

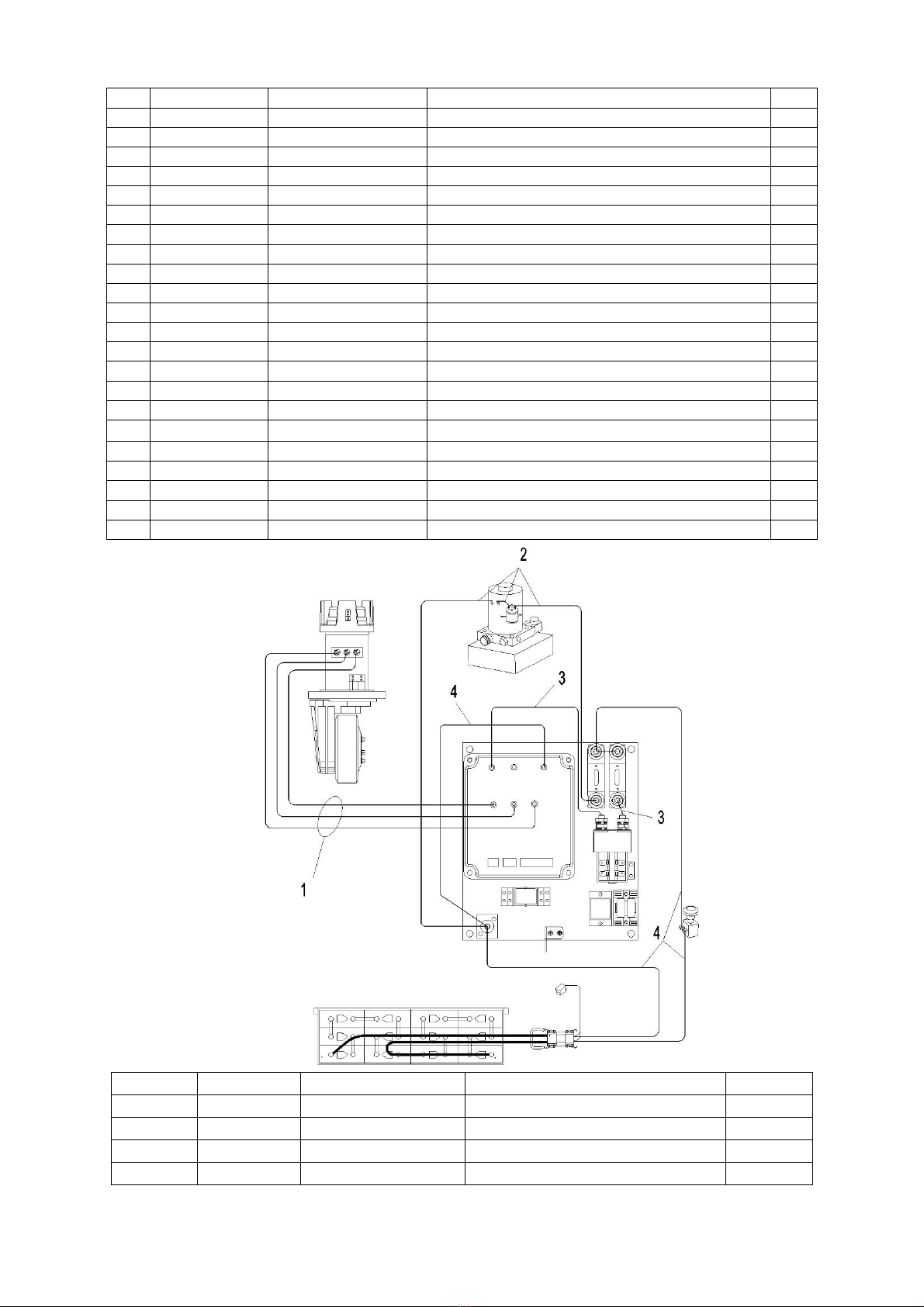

No. Code NL. Drawing No. Description Qty.

1 GB CS1232.6.1 Battery – 24V/210Ah 1

2 FU01 DQ-38 Fuse, 80A 1

3 Mp WG-19-1 Motor for pump, DC24V/0.8kw 1

4 KMp WG-19-2 Relay for motor of pump, DC24V 1

5 YV WG-19-3 Lower magnet valve, DC24V 1

6 Mt WG-54-1 Motor for traction, DC16V/1.3kw 1

7 YB WG-55-1 Brake, DC24V 1

8 KM DQ-3 Main relay C100/120 DC24V 1

9 Kr DQ-2-1 Thermal protection BD-W135/110 1

10 FU02 DQ-17 Fuse, 150A 1

11 Et DQ-19 Controller CURTIS 1243C-2405 1

12 VD DQ-10 Diodes 1N5408 1

13 FU1 DQ-9 Fuse,10A 1

14 S DQ-48 Emergency button ZDK31-250 1

15 SY DQ-26-1 Lock LKS-101A 1

16 P DQ-27 Battery Indicator CURTIS 803 1

17 B WG-5 Control handle (94300-00)1

18 SA, SU DQ-23 Micro switch Z-15GW2 1

19 K DQ-14 Relay ARL2F DC24V 1

20 HA DQ-22 Horn DC24V 1

21 VD DQ-10 Diodes 1N5408 1

22 F DQ-34-2 Discharger protection, PC802 1

Master cable system drawing

Serial Part No NL. Drawing No. Description Quantity

1 102043301 DQ-LPT22-X1 Drive motor cable 1

2 102043301 DQ-LPT22-X2 Pump motor cable 1

3 102043301 DQ-LPT22-X3 Main contactor cable 1

4 102043301 DQ-LPT22-X4 Controller power cable 1

17

CANBUS handle cable drawing

Serial No Part No NL. Drawing No. Description Quantity

1 1020433019 DQ-LPT22-X6 Controller cable 1

18

3.2 INSTALLATION OF ELECTRIC

1. Micro switch 10. Washer Φ8 19. Elastic washer 6

2. Screw M4×20 11. Horn 125 24V 20. Washer Φ6

3. Key switch 12. Locking nut M8 21. Screw M6×30

4. Emergency button 13. Screw M10X25 22. Plug

5. Battery indicator 803 14. Elastic washer 10 23. Charger 24V/30A

6. Screw M4×25 15. Nut M10 24. Battery

7. Washer Φ4 16. Cable clip 25. Socket

8. Locking nut M4 17. screw M6X30

9. Screw M8X25 18. Screw M6X16

19

3.3 DRIVE WHEEL

Type: 3EL-DC-0.75

Drive Motor

Model YDQ1.3-4BT

Rate voltage 16V AC

R.P.M 3200rpm

Rate output 1.3kw

Rate hour 60min.

Rated current 76.2A

Amperager rating- max 110.7HZ

Amperager rating- min H class

Insulation class YDQ1.3-4BT

Electromagnetic Brake

Model G072-REB0510(20)P-R

Rate voltage DC 24V

Rate Power 30W

Output Torque 16N·M

Gear Box

transmission ratio i=1:30

3.4 PUMP UNIT

Type: MR2-B-V1B-F4.5-PCMAV1Y-TK05C-F2

Item Specification

Rated voltage 24V

Rated output 0.8 kw

R.P.M 2500 rpm

Rated current 60 A

Rated hour 1.8 min.

Insulation class F class

IP Code IP54

Displacement 0.7cc/rec

Max. operating pressure 250bar

3.5 BATTERY

Rate Specification

Rated voltage 24V

Capacity (5 hours) 210Ah

Overall size (L*W*H) 677mm*196mm*555mm

Initial charge

When the battery is charged for the first time, you should prepare the exclusive sulfuric acid and

excluslve water of lead acids (lf no excusive water is present in local areas, distilled water can be

Table of contents

Other Noblift Forklift manuals

Popular Forklift manuals by other brands

Hyster

Hyster G001 Repair manual

maximal

maximal FD80T operation & maintenance

Presto Lifts

Presto Lifts Power Stak PPS3000-125FS Installation, operation and service manual

Presto Lifts

Presto Lifts PPS1100-62-CB owner's manual

Manitou

Manitou MHT-X 780 T-E3 Operator's manual

Hyster

Hyster H2.00XMS Service & repair manual