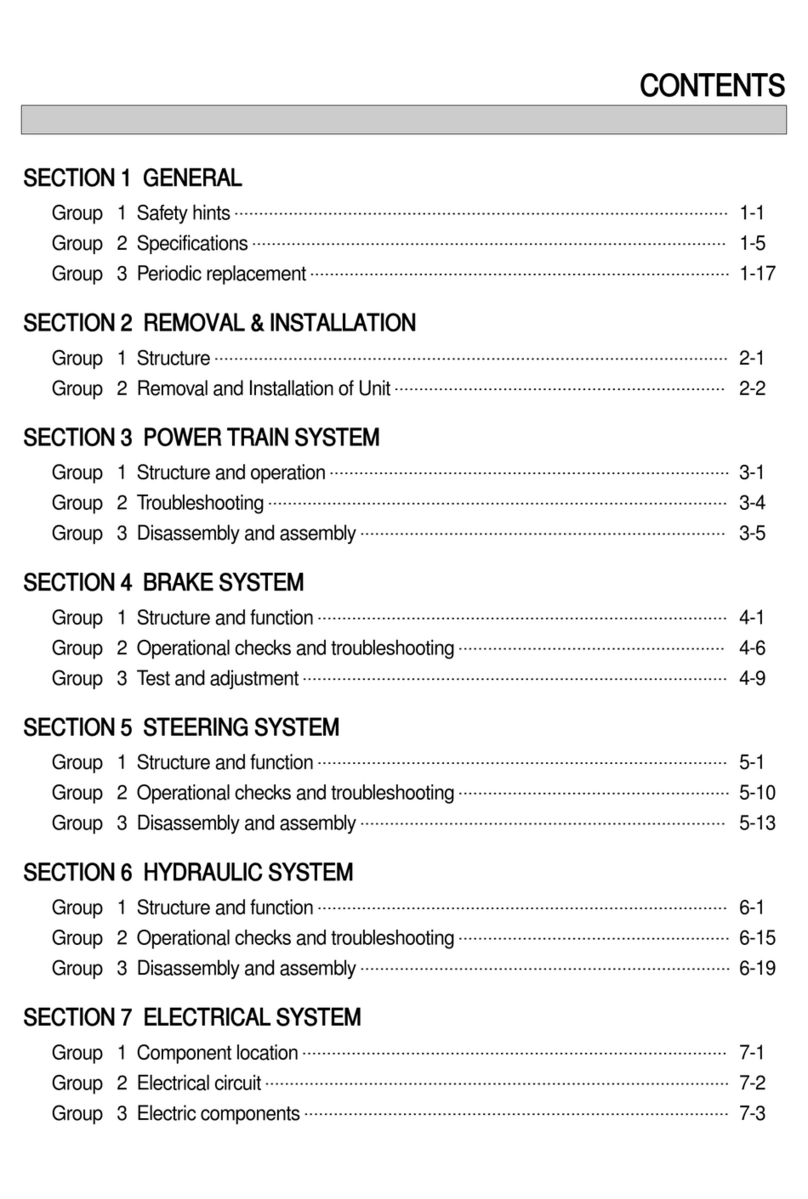

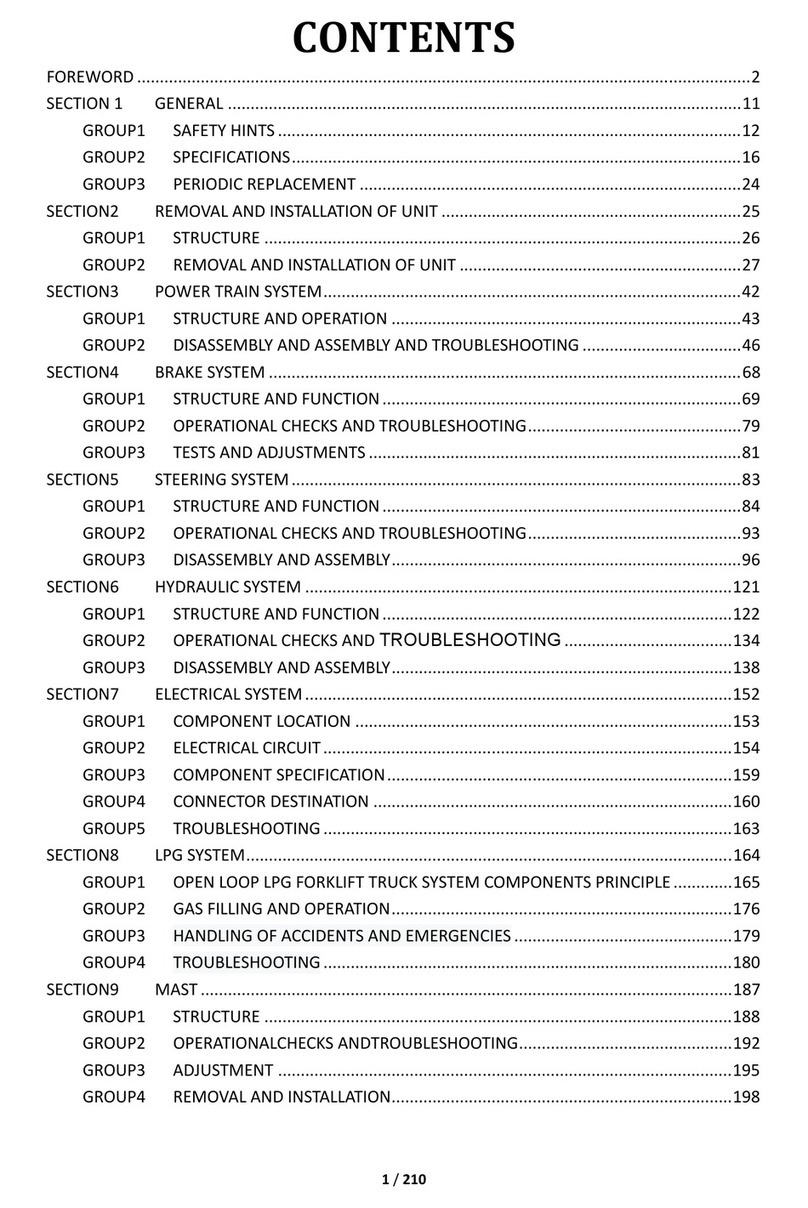

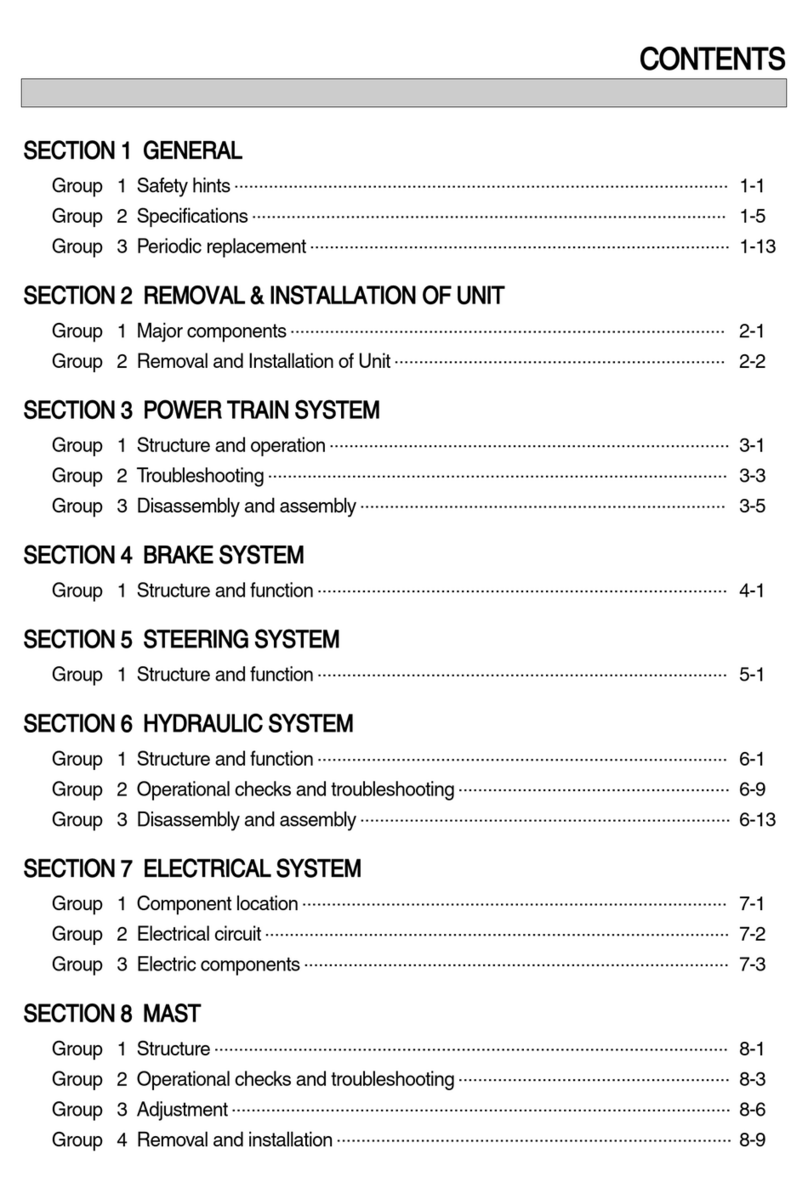

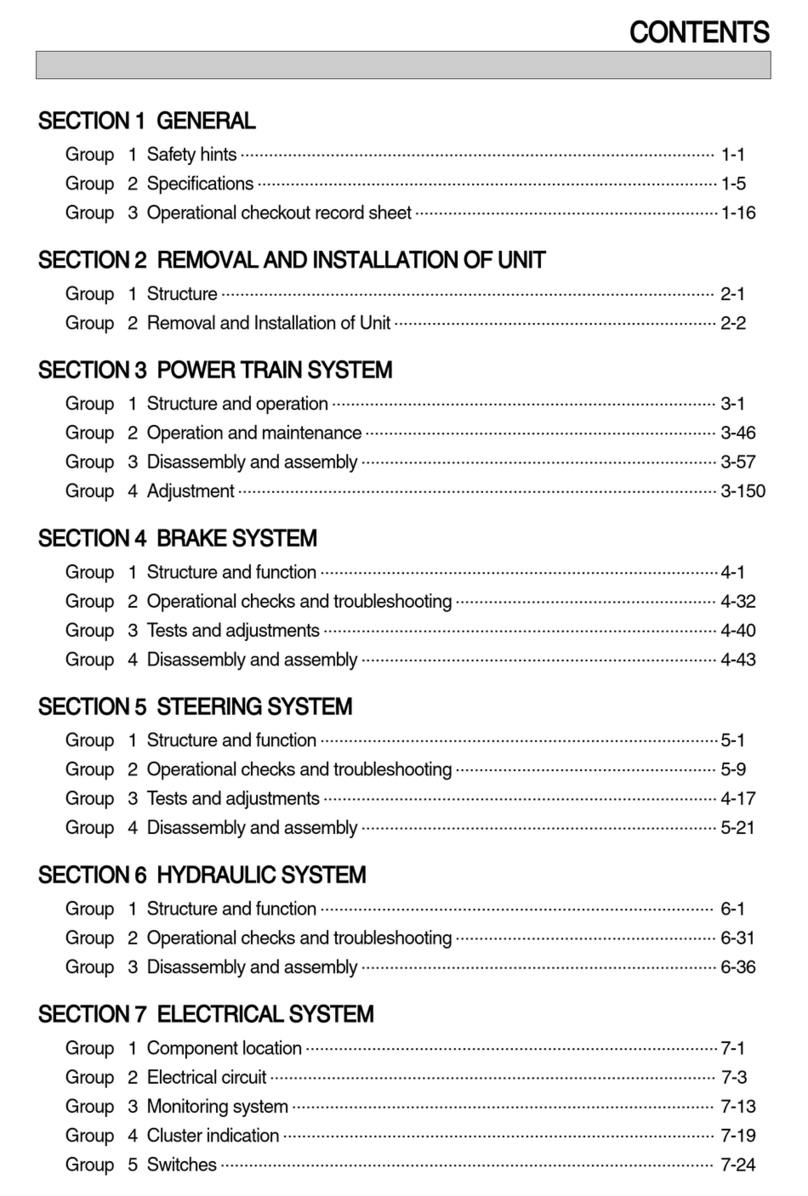

CONTENTS

SECTION 1 GENERAL

Group 1 Safety Hints

----------------------------------------------------------------------------------------------------

1-1

Group 2 Specifications

-------------------------------------------------------------------------------------------------

1-5

Group 3 Periodic Replacement

------------------------------------------------------------------------------------

1-13

SECTION 2 REMOVAL AND INSTALLATION OF UNIT

Group 1 Structure

---------------------------------------------------------------------------------------------------------

2-1

Group 2 Removal and Installation of Unit

--------------------------------------------------------------------

2-2

SECTION 3 POWER TRAIN SYSTEM

<OLD Transmission and drive axle>

Group 1 Structure and Operation

---------------------------------------------------------------------------------

3-1

Group 2 Troubleshooting

----------------------------------------------------------------------------------------------

3-21

Group 3 Disassembly and Assembly

---------------------------------------------------------------------------

3-25

<NEW Transmission and drive axle>

Group 1 Structure and Operation

--------------------------------------------------------------------------------

3-76

Group 2 Troubleshooting

----------------------------------------------------------------------------------------------

3-94

Group 3 Disassembly and Assembly

---------------------------------------------------------------------------

3-100

SECTION 4 BRAKE SYSTEM

Group 1 Structure and Function

-----------------------------------------------------------------------------------

4-1

Group 2 Operational Checks and Troubleshooting

------------------------------------------------------

4-8

Group 3 Tests and Adjustments

-----------------------------------------------------------------------------------

4-10

SECTION 5 STEERING SYSTEM

Group 1 Structure and Function

-----------------------------------------------------------------------------------

5-1

Group 2 Operational Checks and Troubleshooting

------------------------------------------------------

5-10

Group 3 Disassembly and Assembly

---------------------------------------------------------------------------

5-12

SECTION 6 HYDRAULIC SYSTEM

Group 1 Structure and Function

-----------------------------------------------------------------------------------

6-1

Group 2 Operational Checks and Troubleshooting

------------------------------------------------------

6-18

Group 3 Disassembly and Assembly

---------------------------------------------------------------------------

6-22

SECTION 7 ELECTRICAL SYSTEM

Group 1 Component Location

--------------------------------------------------------------------------------------

7-1

Group 2 Electrical Circuit

----------------------------------------------------------------------------------------------

7-2