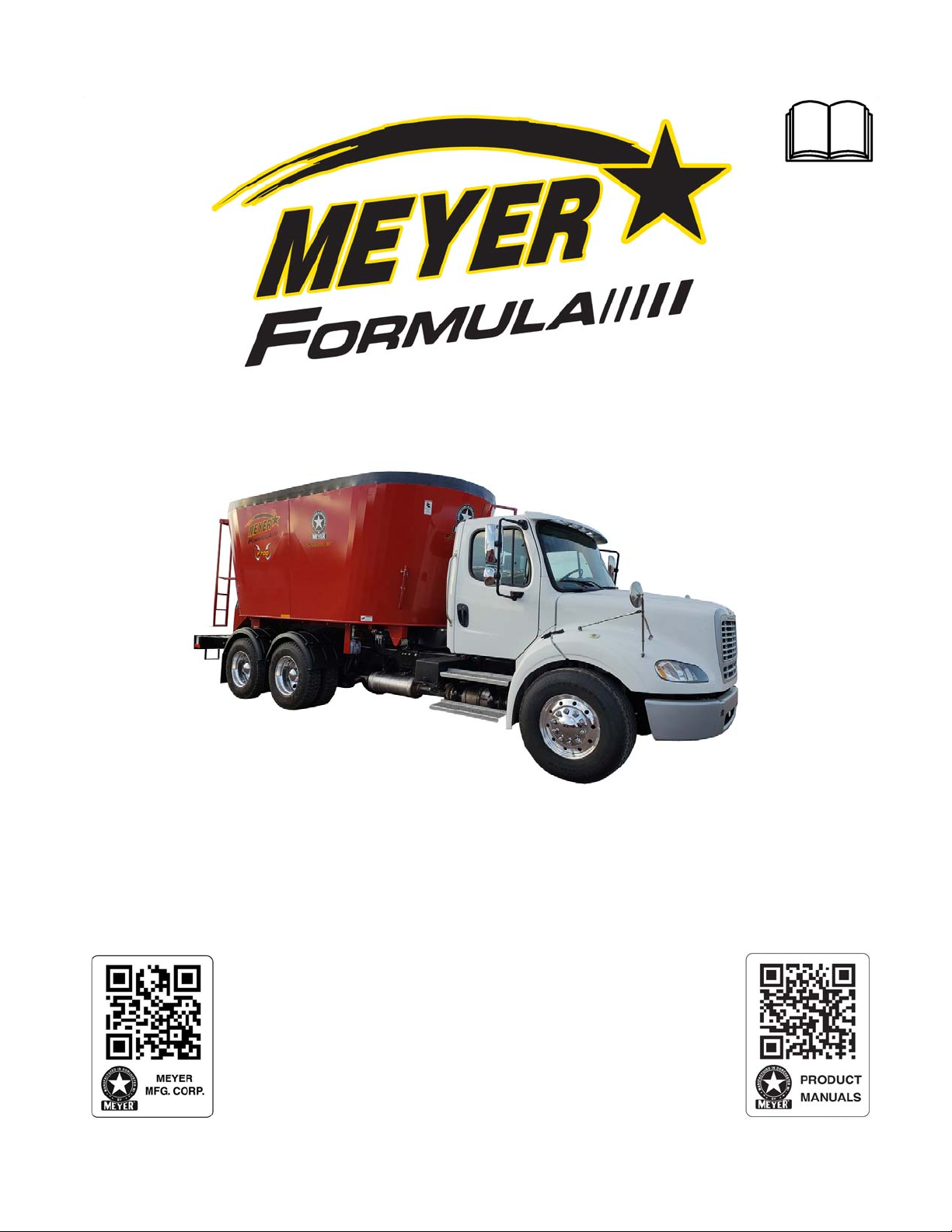

Meyer Formula Owner's manual

6990633 (1-13) Printed in U.S.A. © Bobcat Company 2013

FORMULA MIXER

Models F585 • F700

Mechanical Truck Mount

Owner / Operator’s Manual

& Parts Book

2018 Model Year & Later

PB-MIXER-TR-MECH

1 / 2020

Meyer Manufacturing Corporation - 2 -

1.0 IMPORTANT INFORMATION

The mixer serial number plate is located on the front left hand side of the mixing tub.

Please enter the model, serial number and additional information in the space provided for future reference.

Always use your serial number when requesting information or when ordering parts.

HOW TO READ YOUR SERIAL NUMBER

Meyer Manufacturing Corporation

674 W. Business Cty Rd A

Dorchester, WI 54425

Phone: 1-800-325-9103

Fax: 715-654-5513

Email: sales@meyermfg.com

Website: www.meyermfg.com

Model No.

Mixer Serial No.

Date of Purchase

Dealership

Dealership Phone No.

Mixer Body

Serial Number

Model Year / Vertical Mixer / Model / Sequence Of Build

VM 0700 201

18

MIXER

EXAMPLE: 18VM0700201

1-800-325-9103

Formula Mixer Check List - 3 - www.meyermfg.com

2.0 PRE-DELIVERY & DELIVERY CHECK LIST

This Pre-Delivery & Delivery Check List must be gone through by the Selling Party and the Customer to validate the

Owner’s Registration Form.

Meyer Manufacturing Corporation

Phone: 715-654-5132 • Toll-Free: 1-800-325-9103 • P.O. Box 405 • Dorchester, WI 54425

PB Mixer Check List

All shields and guards are in place and securely

fastened.

All PTO shields turn freely.

All bolts and other fasteners are secure and tight.

All mechanisms operate trouble free.

All grease fittings have been lubricated, gear

boxes filled to proper levels, and all roller chains

are oiled. See “Lubrication” section of this

manual.

All decals are in place and legible.

All stop/tail/turn lights work properly.

PRE-DELIVERY CHECK LIST

After the New Meyer Mixer has been completely set-up,

check to be certain it is in correct running order before

delivering it to the customer.

The following is a list of points to inspect:

Check off each item as you have made the proper

adjustments and found the item operating

satisfactorily. Any adjustments made, MUST be

according to specifications defined in this manual.

DELIVERY CHECK LIST

The following check list is an important reminder of

valuable information that MUST be passed on to the

customer at the time the unit is delivered.

Check off each item as you explain it to the

customer.

Explain to the customer that pre-delivery check

list was fully completed.

Give customer the Owner & Operator’s Manual.

Instruct to read and completely understand its

contents BEFORE attempting to operate the

mixer.

Explain and review with customer the New Meyer

mixer manufacturer’s warranty.

Show the customer where to find the serial

number on the implement.

Explain and review with the customer “Safety

Precautions” section of this manual.

Explain and review with customer the proper

“Start-up and Operating Procedures” sections of

this manual.

Explain and review with customer the

recommended loading and unloading

procedures.

Demonstrate the start-up and shutdown controls.

Explain that regular lubrication and proper

adjustments are required for continued proper

operation and long life of the mixer. Review with

the customer the “Lubrication” and “Adjustments”

sections of this manual.

Fully complete this “PRE-DELIVERY &

DELIVERY CHECK LIST” with the customer.

Meyer Manufacturing Corporation - 4 - Formula Mixer Check List

Meyer Manufacturing Corporation

674 W. Business Cty Rd A

Dorchester, WI 54425

Phone: 1-800-325-9103

Fax: 715-654-5513

Email: sales@meyermfg.com

Website: www.meyermfg.com

1-800-325-9103

PB-MIXER-TR-MECH - 5 - www.meyermfg.com

3.0 INTRODUCTION

Congratulations on your purchase of a new Meyer farm equipment product. Undoubtedly you have given

much consideration to your purchase and we’re proud that you have selected Meyer. Pride in craftsmanship,

engineering and customer service have made Meyer products the finest in the farm equipment industry today.

There is no substitute for quality. That is why thousands of people like you have purchased Meyer farm

equipment. They felt it was the best equipment to serve their farming needs, now and in years to come. We

ask that you follow our policy of “safety first”, and we strongly suggest that you read through the Operator’s

& Parts manual before operating your Meyer farm equipment. Meyer Manufacturing Corporation wants to

thank you for not compromising quality. We are determined to offer excellence in customer service as well as

provide you with the very best value for your dollar.

Sincerely,

All Employees of

MEYER MANUFACTURING CORPORATION

When the PTO is referred to, it means power takeoff from the truck.

This manual is to be used in conjunction with your truck/chassis manual.

The formula mixer may be referred to as mixer, implement, equipment or machine in this manual.

Manufacturer’s Statement: Meyer Manufacturing Corporation reserves the right to make improvements in design, or

changes in specifications at any time, without incurring any obligation to owners of units previously sold. This supersedes

all previous published instructions.

IMPORTANT: You are urged to study this manual and follow the instructions carefully. Your efforts will be

repaid in better operation and service as well as a savings in time and repair expense. Failure to read this

manual and understand the machine could lead to serious injury. If you do not understand instructions in

this manual, contact either your dealer or Meyer Manufacturing Corp. at Dorchester, WI 54425.

WARRANTY: At the front of this manual is the Owner’s Registration Form. Be sure your dealer has

completed this form and promptly forwarded a copy to Meyer Manufacturing to validate the manufacturer’s

warranty. The product model and serial number are recorded on this form and on the inside of the front

cover for proper identification of your Meyer equipment by your dealer and the manufacturer when

ordering repair parts. The serial number is stamped in the front left-hand side of the mixing tub.

Meyer Manufacturing Corporation - 6 - PB-MIXER-TR-MECH

FEATURES

OPTIONS

DESCRIPTION F585 F700

Twin Mixing Augers STD STD

Replaceable Scrapers STD STD

Hardened Knives STD STD

Hay Stops STD STD

Ladder STD STD

Torque Disconnect PTO’s STD STD

2-Speed (Electric Shift) STD STD

Straight Drive STD STD

Heavy -Duty Gearboxes STD STD

DESCRIPTION F585 F700

Side Discharge Door Right/Left OPT OPT

Rear Discharge Door OPT OPT

Slide Tray OPT OPT

Magnets OPT OPT

Hay-Retention Ring OPT OPT

Capacity Belt Extension OPT OPT

Hardened Knives (Additional) OPT OPT

Tank Liner OPT OPT

Baffle Liner OPT OPT

1-800-325-9103

PB-MIXER-TR-MECH - 7 - www.meyermfg.com

TABLE OF CONTENTS

1.0 IMPORTANT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2.0 PRE-DELIVERY & DELIVERY CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.0 MANUFACTURER’S WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.0 SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 SAFETY SIGNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5.3 SHUTOFF & LOCKOUT POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3.1 Shutoff & Lockout Power Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.0 PRE-OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 STATIC INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 TRUCK MOUNT SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3 PTO DRIVELINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

6.4 START-UP AND SHUT-DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.4.1 Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

6.4.2 Shut-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6.5 OPERATIONAL CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6.5.1 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

6.6 TRANSPORTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.6.1 Brake Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.7 OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.7.1 Digital Scale Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.0 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1.1 Cutout Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

7.1.2 Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

7.2 LOADING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2.1 Loading Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.3 MIXING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.4 UNLOADING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.5 MIXER TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Meyer Manufacturing Corporation - 8 - PB-MIXER-TR-MECH

8.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

8.1 LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

8.1.1 Daily or every 8-10 loads: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

8.1.2 Monthly: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

8.1.3 Every 40 hours: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

8.1.4 50 hours: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

8.1.5 Annually or Every 500 hours (Whichever Is First): . . . . . . . . . . . . . . . . . . . . . . . . .35

8.1.6 Annually or Every 2000 hours (Whichever Is First): . . . . . . . . . . . . . . . . . . . . . . . .36

8.1.7 Every 5000 hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

8.1.8 Gearbox Oil Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

8.1.8.1 Planetary Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

8.1.8.2 2-Speed Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

8.1.8.3 Superior & Benzi Front Driveline Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

8.2 ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

8.2.1 Auger Scraper Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

8.2.2 Auger Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

8.2.3 PTO Cutout Clutch Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

8.2.4 Knives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

8.2.4.1 Knife Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

8.2.4.2 Adding Knives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

8.2.4.3 Knife Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

8.2.4.4 Knife Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

8.2.4.5 Replacing Damaged or Worn Knives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

8.2.5 Hay Stop Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

8.2.5.1 Hay Stop Lock Bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

8.3 STORING THE MIXER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

8.4 RETURNING THE MIXER TO SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

8.5 REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

9.0 PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

TAIL LIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

SCALE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

2-SPEED ELECTRICAL SYSTEM PRIOR TO SN 18VM(0585235, 0700212) . . . . . . . .48

2-SPEED ELECTRICAL SYSTEM SN 18VM(0585235, 0700212) & LATER . . . . . . . . .50

HYDRAULIC POWER PACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

HYDRAULIC POWER PACK TO VALVE BANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

MIXER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

REAR BUMPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

DOOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

OPTIONAL REAR OR REAR SIDE DOOR HYDRAULIC SCHEMATIC . . . . . . . . . . . . . . . . .60

1-800-325-9103

PB-MIXER-TR-MECH - 9 - www.meyermfg.com

DOOR HYDRAULIC SCHEMATIC

LEFT DOOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

AUGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

DRIVELINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

RIGHT SIDE PTO GEARBOX DRIVELINE MOUNT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

LEFT SIDE PTO GEARBOX DRIVELINE MOUNT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

LOWER GEARBOX PRIOR TO SN 18VM0585230 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

UPPER GEARBOX PRIOR TO SN 18VM0585230 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

LOWER GEARBOX SN 18VM(0585230, 0700212) & LATER . . . . . . . . . . . . . . . . . . . . . . . . 72

UPPER GEARBOX SN 18VM(0585230, 0700212) & LATER . . . . . . . . . . . . . . . . . . . . . . . . . 74

1800 SERIES PLANETARY (119-18-13.92-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

HOSE FITTING HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

HAY RETAINING RING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

8” CAPACITY EXTENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

SIDE DISCHARGE SLIDE TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

SLIDE TRAY HYDRAULIC SCHEMATIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

DUAL SLIDE TRAY HYDRAULIC SCHEMATIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

REMOTE SCALE MOUNT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

TANK MAGNET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

10.0 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

10.1 MODELS F585, F700 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

MAINTENANCE RECORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Meyer Manufacturing Corporation - 10 - PB-MIXER-TR-MECH

1-800-325-9103

PB-MIXER-TR-MECH - 11 - www.meyermfg.com

4.0 MANUFACTURER’S WARRANTY

MEYER FORMULA MIXER 4/2014

I. The “Owner’s Registration Form” must be completed in full and promptly returned to Meyer Mfg. Corp. for this

warranty to become both valid and effective. All warranties on New Meyer Mixers shall apply only to the

original retail customer from an authorized Meyer Mfg. Corp. dealership.

II. This warranty shall not apply to any Meyer Mixer which has been subjected to misuse, negligence, alteration,

accident, incorrect operating procedures, has been used for an application not designed for or pre-authorized

by Meyer in writing, has had the serial numbers altered, or which shall have been repaired with parts other

than those obtained through Meyer Mfg. Corp. Meyer is not responsible for the following: Depreciation or

damage caused by normal wear, lack of reasonable and proper maintenance, failure to follow the operator's

manual recommendations or normal maintenance parts and service. Meyer is not responsible for rental of

replacement equipment during warranty repairs, damage to a power unit (including but not limited to a truck

or tractor), loss of earnings due to equipment down time, or damage to equipment while in transit to or from

the factory or dealer.

III. Meyer Mfg. Corp. warrants New Meyer Mixer to be free from defects in material and workmanship under

recommended use and maintenance service, as stated in the operator’s and parts manuals, as follows:

A. Meyer Mfg. Corp. will repair or replace F.O.B. Dorchester, WI, as Meyer Mfg. Corp. elects, any

part of a new Meyer Mixer which is defective in material or workmanship:

i. Without charge for either parts or labor during the first (1) year from purchase date to the

original retail customer.

B. In addition to the above basic warranty, Meyer Mfg. Corp. will repair or replace F.O.B. Dorchester,

WI as Meyer Mfg. Corp. elects:

i. Any part of the following which is defective in material or workmanship (not neglect to

recommended use and service) with a “pro-rated” charge for parts only (not labor) during

the stated time period from date of purchase to the original retail customer. 1st year

100%, 2nd year 100%, 3rd year 50%, 4th year 25%, 5th year 10%

a. The Formula Mixer Planetary Gearbox. Meyer Part # 119-18-13.92-1.

IV. COMMERCIAL USE: Coverage as in paragraph III.A.i. only, except warranty coverage is for (90) days for parts

and labor to the original commercial retail customer.

V. Repairs eligible for labor warranty must be made by Meyer Mfg. Corp. or an authorized Meyer dealership. The

original retail customer is responsible for any service call and/or transportation of the mixer to the dealership or

the factory for warranty service.

VI. Except as stated above, Meyer Mfg. Corp. shall not be liable for injuries or damages of any kind or nature,

direct, consequential, or contingent, to persons or property. This warranty does not extend to loss of crop or for

any other reasons.

VII. No person is authorized to give any other warranties or to assume any other obligation on Meyer Mfg. Corp.’s.

behalf unless made or assumed in writing by Meyer Mfg. Corp. This warranty is the sole and exclusive warranty

which is applicable in connection with the manufacture and sale of this product and Meyer Mfg. Corp.’s

responsibility is limited accordingly.

Purchased Product Warranty:

This warranty does not apply to component parts not manufactured by Meyer such as but not limited to wheels, tires,

tubes, PTO shafts, clutches, hydraulic cylinders, scales, etc.

Meyer Manufacturing Corporation - 12 - PB-MIXER-TR-MECH

1-800-325-9103

PB-MIXER-TR-MECH - 13 - www.meyermfg.com

5.0 SAFETY

Meyer Mfg. Corp. equipment is manufactured with operator safety in mind. Located on the equipment are various safety

signs to aid in operation and warn of hazardous areas. Pay close attention to all safety signs on the equipment.

Carefully follow the operating and maintenance instructions in this manual and all applicable safety laws. Failure to follow

all safety procedures may result in serious injury or death.

Before attempting to operate this equipment, read and study the following safety information. In addition, make

sure that every individual who operates or works with the equipment, whether family member or employee, is

familiar with these safety precautions.

Meyer Mfg. Corp. provides guards for exposed moving parts for the operator’s protection; however, some areas

cannot be guarded or shielded in order to assure proper operation. The operator’s manual and safety signs on

the equipment itself warn you of hazards and must be read and observed closely!

Danger, Warning, Caution, and instructional decals and plates are placed on the equipment to protect anyone working on

or around this equipment, as well as the components of the equipment. All personnel operating or maintaining this

equipment must familiarize themselves with all Danger, Warning, Caution, and instructional decals and plates.

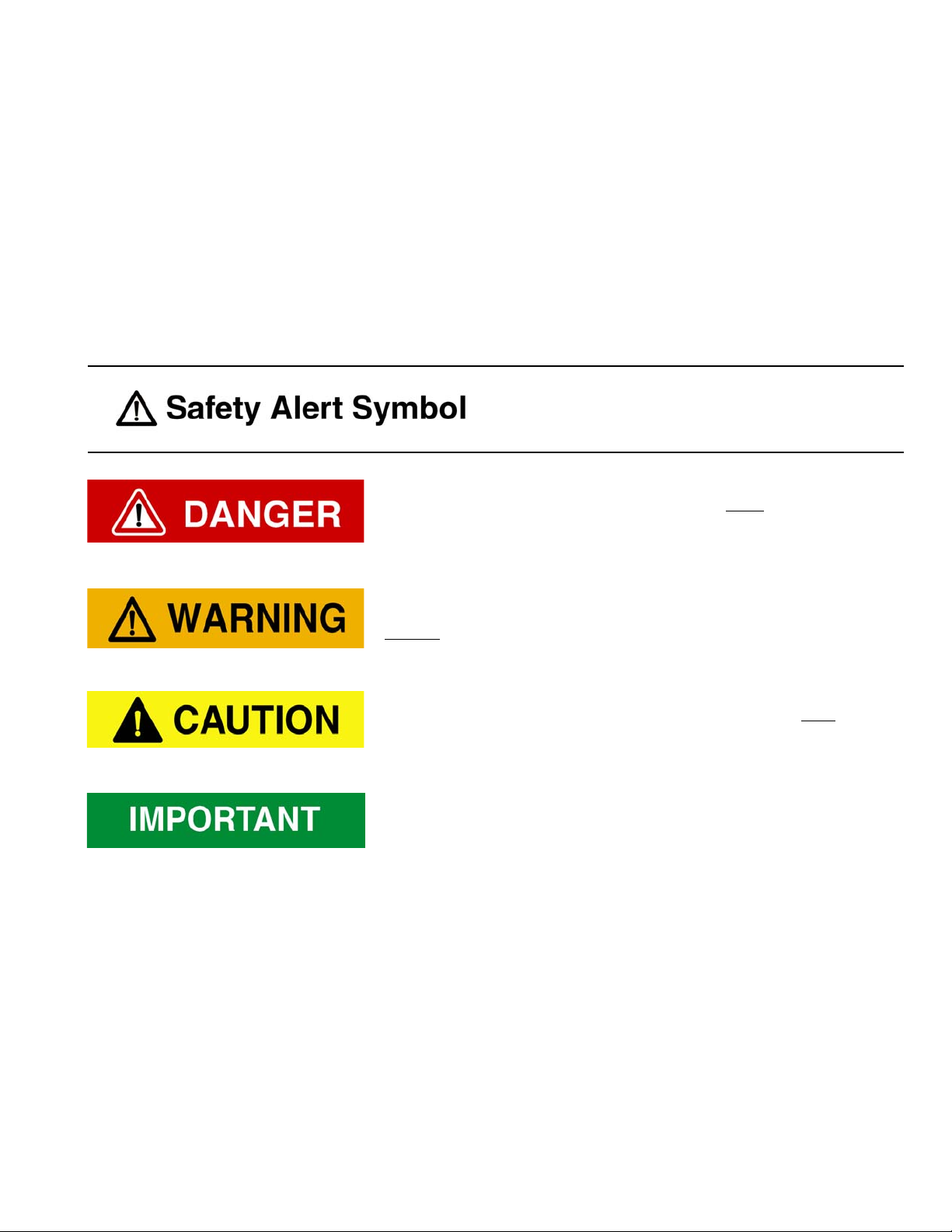

This symbol is used to call attention to instructions

concerning personal safety. Be sure to observe and

follow these instructions. Take time to be careful!

The signal word DANGER on the machine and in the manual identifies

a hazardous situation which, if not avoided, WILL result in death or

serious injury.

The signal word WARNING on the machine and in the manual

indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

The signal word CAUTION on the machine and in the manual indicates

a potentially hazardous situation which, if not avoided, MAY result in

minor or moderate injury. It may also be used to alert against unsafe

practices.

This notice identifies procedures which must be followed to avoid

damage to the machine.

Meyer Manufacturing Corporation - 14 - PB-MIXER-TR-MECH

5.1 SAFETY PRECAUTIONS

• The truck/chassis owner's operator's manual should be used in conjunction with this manual.

• DO NOT allow anyone to operate, service, inspect or otherwise handle this equipment until all operators have read

and understood all of the instructional materials in this Operator’s And Parts Manual and have been properly trained

in its intended usage.

• For an operator to be qualified, he or she must not use drugs or alcohol which impair alertness or coordination while

working. An operator who is taking prescription drugs must get medical advice to determine if he or she can safely

operate a machine and the equipment.

• Make sure all personnel can READ and UNDERSTAND all safety signs.

• DO NOT allow minors (children) or inexperienced persons to operate this equipment.

• DO NOT operate until all shields and guards are in place and securely fastened.

• DO NOT step up on any part of the equipment that is not designated as a ladder or viewing platform at any time.

• DO NOT adjust, clean or lubricate while the equipment is in motion.

• Inspect when first delivered and regularly thereafter; that all connections and bolts are tight and secure before

operating.

• Know how to stop operation of the equipment before starting it!

• Make certain everyone is clear of the equipment before applying power.

• Keep hands, feet and clothing away from moving parts. Loose or floppy clothing should not be worn by the operator.

• Observe all applicable traffic laws when transporting on public roadways (where legal to do so). Check local laws for

all highway lighting and marking requirements.

• Shut off and lock out power before adjusting, servicing, maintaining or clearing an obstruction from this machine. (See

5.3 SHUTOFF & LOCKOUT POWER on page 20.)

• Always enter curves or drive up or down hills at a low speed and at a gradual steering angle.

• Never allow riders on either truck or equipment.

• Keep truck in a lower gear at all times when traveling down steep grades.

• Stay away from overhead power lines. Electrocution can occur without direct contact.

• Use only properly rated undercarriage and tires.

All individuals who will operate this equipment must read

and completely understand this Operator’s And Parts

Manual. Operator must have instructions before operating

the machine. Untrained operators can cause injury or death.

1-800-325-9103

PB-MIXER-TR-MECH - 15 - www.meyermfg.com

Safety Precautions For Truck Mounted Units:

• Comply with state and local laws governing highway safety and movement of machinery on roadways.

Safety Precautions For Hydraulic System:

• Check hydraulic tubes, hoses and fittings for damage and leakage. Never use hands to check for leaks. Hydraulic

tubes and hoses must be properly routed and have adequate support and secure clamps. Tighten or replace any parts

that show leakage.

• Always clean fluid spills. Do not use gasoline or diesel fuel for cleaning parts. Use commercial nonflammable solvents.

Meyer Manufacturing Corporation - 16 - PB-MIXER-TR-MECH

5.2 SAFETY SIGNS

Read all safety signs on the equipment and in this manual. Keep all

safety signs clean and replace any damaged or missing safety signs

before operating the equipment. Do Not remove any safety signs.

Safety signs are for operator protection and information.

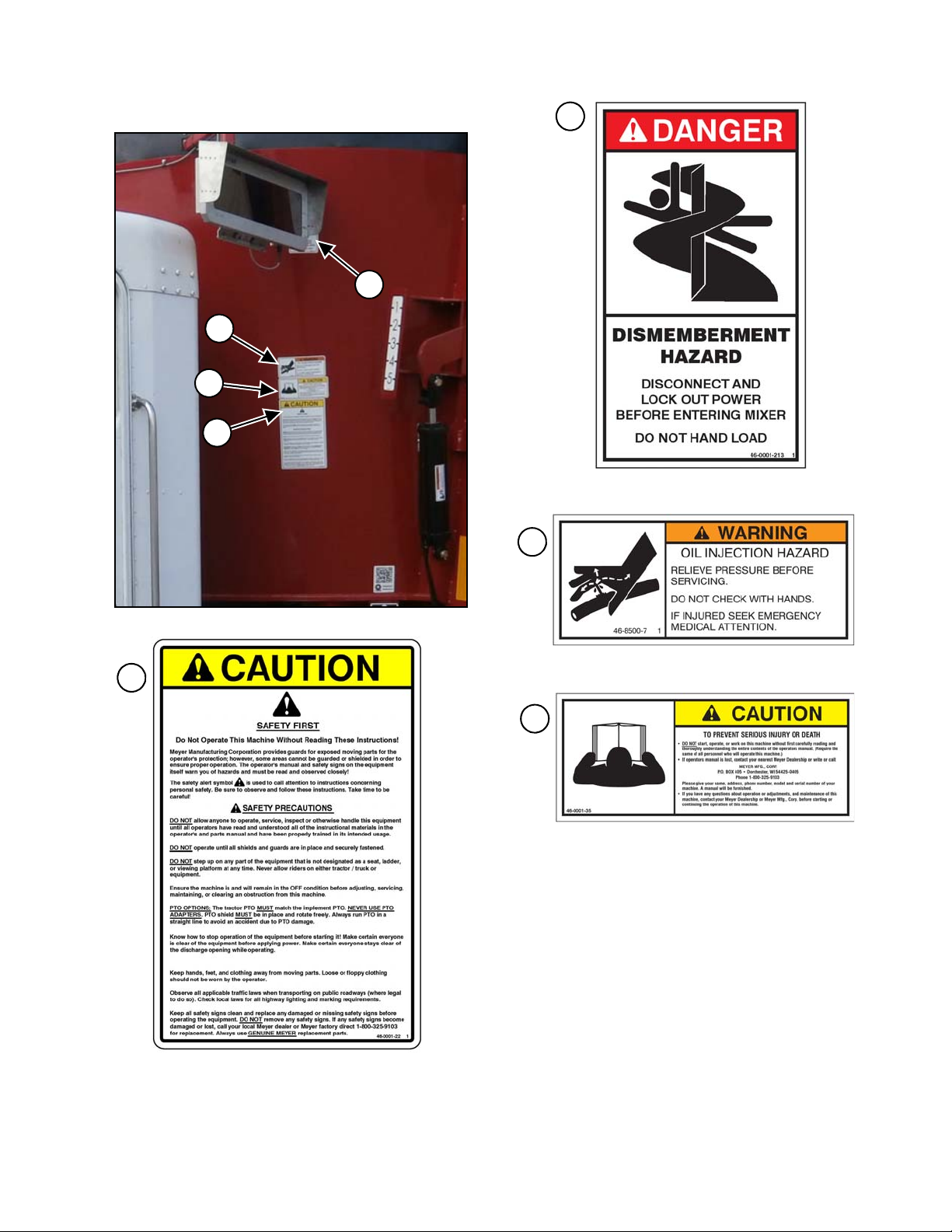

FRONT OF MIXER

PART NO. 46-0001-211

1

1

1-800-325-9103

PB-MIXER-TR-MECH - 17 - www.meyermfg.com

FRONT OF MIXER

1

2

3

4

PART NO. 46-0001-213

1

PART NO. 46-8500-7

2

3

PART NO. 46-0001-35

4

PART NO. 46-0001-22

Meyer Manufacturing Corporation - 18 - PB-MIXER-TR-MECH

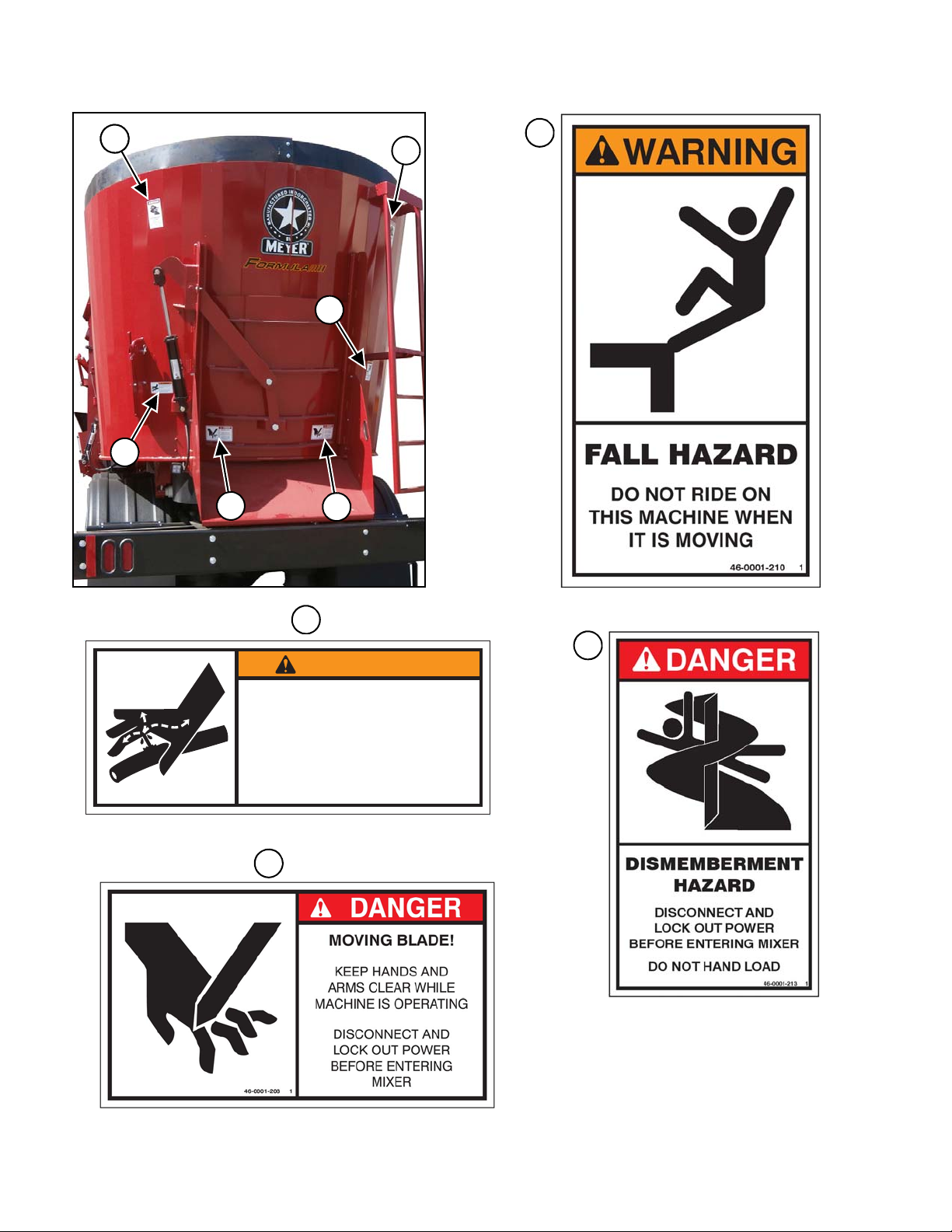

REAR OF MIXER

1

2

33

4 4

PART NO. 46-0001-210

1

PART NO. 46-0001-213

3

WARNING

OIL INJECTION HAZARD

RELIEVE PRESSURE BEFORE

SERVICING.

DO NOT CHECK WITH HANDS.

IF INJURED SEEK EMERGENCY

MEDICAL ATTENTION.

46-8500-7 1

PART NO. 46-8500-7

2

4

PART NO. 46-0001-208

1-800-325-9103

PB-MIXER-TR-MECH - 19 - www.meyermfg.com

1

PART NO. 46-0001-211

1

UNDER MIXER

PART NO. 46-0001-212

(Located under mixing tub)

(Located under mixer belting)

Meyer Manufacturing Corporation - 20 - PB-MIXER-TR-MECH

5.3 SHUTOFF & LOCKOUT POWER

5.3.1 Shutoff & Lockout Power Recommendations

1. Think, Plan and Check

a. Think through the entire procedure and identify all the steps that are required.

b. Plan what personnel will be involved, what needs to be shut down, what guards / shields need to be removed, and

how the equipment will be restarted.

c. Check the machine over to verify all power sources and stored energy have been identified including engines,

hydraulic and pneumatic systems, springs and accumulators, and suspended loads.

2. Communicate - Let everyone involved, including those working on or around this machine, that work is being done

which involves keeping this machine safely “OFF”.

3. Power Sources

a. LOCKOUT - Shut off engines and take the key, or physically lock the start/on switch or control. Disconnect any

power sources which are meant to be disconnected (i.e. electrical, hydraulic, and PTO of pull-type units).

b. TAGOUT - Place a tag on the machine noting the reason for the power source being tagged out and what work is

being done. This is particularly important if the power source is not within your sight and/or will need to be isolated

for a longer period of time.

4. Stored Energy - Neutralize all stored energy from its power source. Ensure that this machine is level, set the parking

brake, and chock the wheels. Disconnect electricity, block moveable parts, release or block spring energy, release

pressure from hydraulic and pneumatic lines, and lower suspended parts to a resting position.

5. Test - Do a complete test and personally double check all of the above steps to verify that all of the power sources are

actually disconnected and locked out.

6. Restore Power - When the work has been completed, follow the same basic procedures, ensuring that all individuals

working on or around this machine are safely clear of the machine before locks and tags are removed and power is

restored.

It is important that everyone who works on this equipment is properly trained to help ensure that they are

familiar with this procedure and that they follow the steps outlined above. THIS MANUAL WILL REMIND YOU

WHEN TO SHUTOFF & LOCKOUT POWER.

Any individual that will be adjusting, servicing, maintaining, or

clearing an obstruction from this machine needs to ensure that this

machine stays safely “OFF” until the adjustment, service, or

maintenance has been completed, or when the obstruction has been

cleared, and that all guards, shields, and covers have been restored

to their original position. The safety of all individuals working on or

around this machine, including family members, are affected. The

following procedure will be referred to throughout this manual, so be

familiar with the following steps.

This manual suits for next models

2

Table of contents

Other Meyer Mixer manuals

Popular Mixer manuals by other brands

Assistent ORIGINAL

Assistent ORIGINAL 920 900 023 instructions

Hans Grohe

Hans Grohe Ecostat Comfort HQ Instructions for use/assembly instructions

Saturn

Saturn ST-FP1022 manual

Behringer

Behringer Europower PMP1680S user manual

Varimixer

Varimixer AR100 VL-1L operating instructions

Bravetti

Bravetti 300 WATT POWER MIXER EP545 Use and care instructions