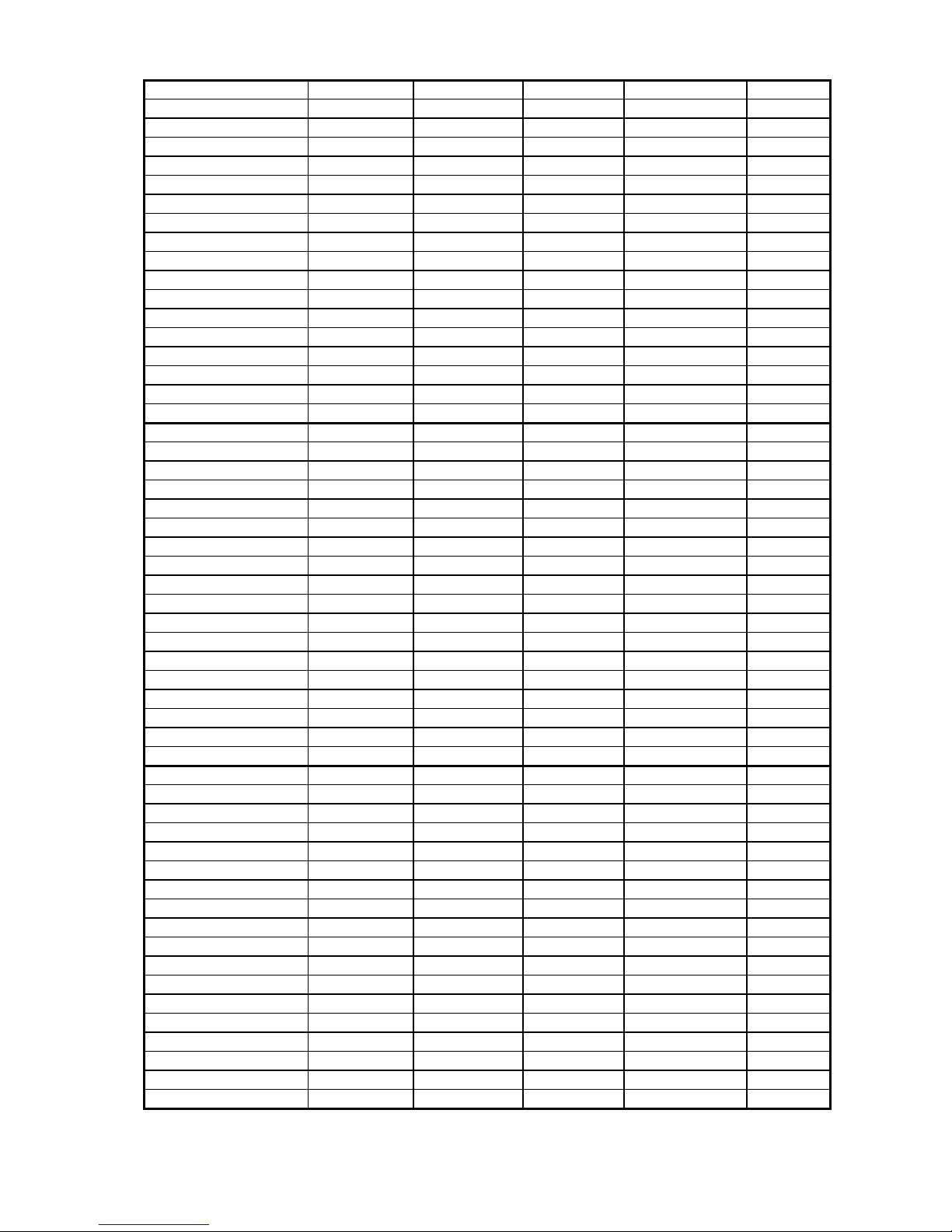

4

Time Table For Sync. Signal

Mode No. 1 2 3 4 Unit

Resolution 720 x 400 640 x 480 640 x 480 800 x 600

Horizontal Frequency 31.468 31.469 43.269 37.879 KHz

(A)Horizontal 31.774 31.778 23.11 26.4 usec

(B ) Horizontal Pulse 3.813 3.813 1.556 3.2 usec

(C ) Horizontal Back Porch 1.907 1.907 2.222 2.2 usec

(D) Horizontal Active Area 25.423 25.422 17.778 20 usec

(E) Horizontal Front Porch 0.325 0.636 1.554 1 usec

(F) H. Sync. Polarity - - - +

Vertical Frequency 70 59.94 85.008 60.317 Hz

(O) Vertical Period 14.286 16.683 11.764 16.570 msec

(P) Vertical Pulse Width 0.063 0.064 0.069 0.106 msec

(Q) Vertical Back Porch 1.143 1.049 0.578 0.607 msec

(R )Vertical Active Area 12.698 15.253 11.093 15.840 msec

(S) Vertical Front Porch 0.382 0.317 0.024 0.026 msec

(T) V. Sync. Polarity + - - +

(U) Interlaced No No No No

Mode No. 5 6 7 8 Unit

Resolution 800 x 600 832 x 624 1024 x 768 1024 x 768

Horizontal Frequency 53.674 49.725 48.363 68.677 KHz

(A)Horizontal 18.631 20.113 20.677 14.561 usec

(B) Horizontal Pulse Width 1,138 1.117 2.092 1.016 usec

(C) Horizontal Back Porch 2.702 3.911 2.462 2.201 usec

(D) Horizontal Active Area 14.222 14.522 15.754 10.836 usec

(E) Horizontal Front Porch 0.569 0.558 0.561 0.508 usec

(F) H. Sync. Polarity + - - +

Vertical Frequency 85.061 74.5 60.024 84.989 Hz

(O) Vertical Period 11.756 13.416 16.660 11.765 Msec

(P) Vertical Pulse Width 0.056 0.060 0.124 0.044 Msec

(Q) Vertical Back Porch 0.503 0.784 0.600 0.524 Msec

(R ) Vertical Active Area 11.199 12.551 15.880 11.183 Msec

(S) Vertical Front Porch 0.019 0.021 0.062 0.014 Msec

(T) V. Sync. Polarity + - - +

(U) Interlaced No No No No No

Mode No. 9 10 Unit

Resolution 1152 x 864 1280 x 1024

Horizontal Frequency 67.5 69.095 KHz

(A)Horizontal 14.815 14.473 usec

(B) Horizontal Pulse Width 1.185 1.160 usec

( C) Horizontal Back Porch 2.370 2.219 usec

(D) Horizontal Active Area 10.667 10.758 usec

(E) Horizontal Front Porch 0.593 0.33 usec

(F) H. Sync. Polarity + +

Vertical Frequency 75 65 Hz

(O) Vertical Period 13.333 15.385 msec

(P) Vertical Pulse Width 0.044 0.043 msec

(Q) Vertical Back Porch 0.474 0.567 msec

(R ) Vertical Active Area 12.8 14.82 msec

(S) Vertical Front Porch 0.015 0.041 msec

(T) V. Sync. Polarity + +

(U) Interlaced No No