Norcros Triton Shower tower User manual

INSTALLERS PLEASE NOTE THESE INSTRUCTIONS ARE TO BE LEFT WITH THE USER

2180363B Feb 2003

Shower Tower

manual mixer

Installation and

Operating

Instructions

Shower tower

CONTENTS Page

Introduction 1

Safety warnings 1

Main components 2

Site requirements 3

Typical installations 4 - 5

Preparing the mixer valve 6

Siting of shower 6

Installation 6 - 8

Using the mixer control lever 9

Using the diverter valves 9

Adjusting the sprayhead 10

Maintenance 10

Spare parts 11

Fault finding 12 - 13

Guarantee, service policy, etc. rear cover

UKAS

QUALITY

MANAGEMENT

003

Shower tower

1

INTRODUCTION

This book contains all the necessary fitting and

operating instructions for your Triton Shower

Tower manual mixer shower. Please read them

carefully.

Read through the whole of this book before

beginning your installation.

The shower installation must be carried out by a

suitably competent person and in sequence of

this instruction book.

Care taken during the installation will ensure a

long and trouble free life from your shower.

This shower tower is designed to operate on

the higher pressure systems found in the UK up

to a maximum of 6 bar running pressure.

The shower MUST NOT be subjected to water

temperatures above 80°C.

This mixer shower is suitable for fully

modulating type combination boilers and multi-

point hot water heaters. It is also suitable for

thermal storage, unvented systems and

pumped gravity systems.

Important: Before installing with a gas

instantaneous water heater, ensure it is

capable of delivering hot water at a

minimum switch-on flow rate of 3 litres per

minute. At flow rates between 3 and 8 litres

per minute, the appliance must be capable of

raising the water temperature to a minimum

of 52°C. Water temperature at the inlet to

the mixer must remain relatively constant

when flowrate adjustments are made (refer to

the water heater operating manual to confirm

compatibility with this shower tower).

This shower tower is supplied with an integral

single check valve and integral large area filter

in each inlet elbow. Inlet connections are by

braid hoses having 1/2” BSP unions.

SAFETY WARNINGS

a Layout and sizing of pipework must be such

that when other services are used, pressures

at the shower control inlets DO NOT fall

below the recommended minimum.

b DO NOT choose a position where the

shower could become frozen.

c DO NOT connect this mixer shower to any

form of tap or fitting not recommended by

the manufacturer.

d The sprayhead must be regularly cleaned to

remove scale and debris.

e Conveniently situated isolating valves in

each inlet supply must be fitted as an

independent method of isolating the

shower should maintenance or servicing be

necessary.

f If it is intended to operate the shower in

areas of hard water (above 200 ppm

temporary hardness), a scale inhibitor may

have to be fitted. For advice on the Triton

scale inhibitor, please contact Customer

Service.

g Do not operate the shower outside the

guidelines as laid out in ‘site requirements’.

Replacement parts can be ordered from Triton

Customer Service. See ‘spare parts’ for details

and part numbers.

Due to continuous improvement and updating,

specification may be altered without prior notice.

To ensure the product suitability for

commercial and multiple installations, please

contact Triton’s specification advisory service

prior to installation.

Telephone: (024) 7632 5491

Facsimile: (024) 7632 4564

Shower tower

2

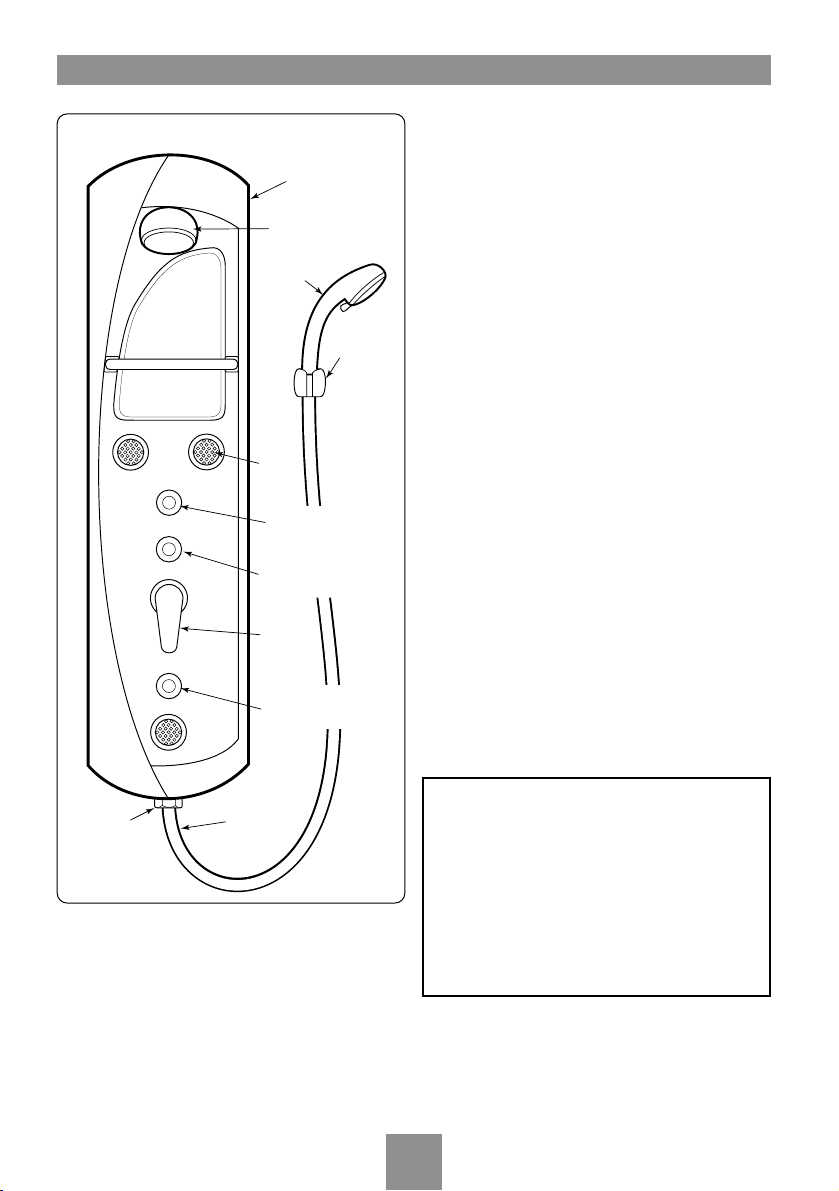

MAIN COMPONENTS

Thank you for purchasing our high quality

product. Check components and quantity

before installation. In the unlikely event of

anything being amiss, please contact Triton

Customer Service.

Pack contents

Showertower body - 1 off

Fixed head - 1 off

Handset and hose - 1 off

Manual mixer valve control lever - 1 off

Diverter valves - 3 off

Body jets - 3 off

Elbows with filters and check valves - 2 off

Hanging brackets - 2 off

Screws and wall plugs - 4 off

Guarantee.

Important notes before you start

This product has passed a factory control test

before reaching you. Do not attempt to

dismantle or modify it.

●Ensure there are no hidden service pipes and

cables where you intend to drill.

●Ensure the hot and cold supply pipes are

flushed out before final connection to the unit.

●The working pressure of this product is 0.5

bar – 6 bar. (7 bar static)

●Please be aware of your safety while drilling

and installing.

Showertower

body

Fixed head

Body

jets

Diverter valve

(fixed head)

Diverter valve

(body jets)

Diverter valve

(handset)

Mixer

control

lever

Handset

Handset

hose

Handset

bracket

Outlet

connector

Fig.2

WARNING!

The shower tower mixer valve is NOT

thermostatic and will NOT prevent

water flowing from the spray outlets

should there be a loss of one supply to

the inlets.

This product is NOT suitable for low

pressure gravity fed supplies unless a

suitable pump is also installed.

Shower tower

3

SITE REQUIREMENTS

The installation must be in accordance with

Water Regulations and Byelaws.

Minimum running water pressure: 0.5 bar

Maximum running water pressure: 6 bar

Maximum static water pressure: 7 bar

For otimum performance an operating

pressure of 3 bar running is required.

Both hot and cold supplies should be at

nominally equal pressures with a minimum flow

rate of 8 litres per minute to both inlets.

While the shower tower is operational (open

outlet), inlet pressures must not be capable of

exceeding 6 bar. For effective operation of the

internal seals, the maximum static pressure

must not be exceeded.

Note: On sites where the running pressure is

above 6 bar, the use of a suitably sized pressure

reducing valve fitted in the cold mains supply

pipework can provide nominally equal pressures

at the showertower.

For a satisfactory performance from the shower

tower both cold and hot inlet supplies must be

from a balanced supply.

Additional isolating valves must be fitted as an

independent means of isolating the water

supplies should maintenance be necessary.

The pipework should be installed such that the

flow is not significantly affected by other taps

and appliances being operated elsewhere on

the premises.

Note: Where thermal store systems and

instantaneous gas water heaters are used, if

excessive draw offs take place the boiler may

not be able to maintain an adequate output

temperature. This could result in the

showertower temperature becoming noticeably

cooler.

DO NOT use jointing compounds on pipework.

Water temperature requirements

Recommended maximum 65°C.

BS6700 recommends the temperature of stored

water should never exceed 65°C.

A stored water temperature of 60°C is

considered sufficient to meet all normal

requirements and will minimise the effects of

scale in hard water areas.

Temperature adjustment range

The mixed water temperature can be adjusted

from cold through to the temperature of hot

water available from the hot water appliance.

Flow rate performance

For all systems, the ability to use showerheads

and body jets simultaneously is dependent on

domestic hot water pressures and flow rates.

Table of contents

Popular Bathroom Fixture manuals by other brands

Kohler

Kohler Mira Sport Max J03G Installation and user guide

Moen

Moen 186117 Series installation guide

Hans Grohe

Hans Grohe Raindance Showerpipe 27235000 Instructions for use/assembly instructions

Signature Hardware

Signature Hardware ROUND SWIVEL BODY SPRAY 948942 Install

fine fixtures

fine fixtures AC3TH installation manual

LIXIL

LIXIL HP50 Series quick start guide