Norden EBS-1 User manual

Read, Understand, and Follow this manual which provides information

and procedures to safely operate and maintain the attachment.

Euro Bale Spear

Owner Manual

MADE IN THE USA

EBS-1

Euro Bale Spear 3 Norden Mfg. LLC (877) 296-5851

CONTENTS

1. INTRODUCTION ..........................4

1.1 Intended Usage .......................4

1.2 Operator Orientation....................4

1.3 Specications .........................4

1.3.1 EBS-1Specications.............4

1.4 Serial Number Location .................4

1.5 Product Improvements ..................5

1.6 Disposal of Equipment at End of Useful Life . 5

1.7 Unanswered Questions .................5

2. SAFETY .................................6

2.1 General..............................6

2.2 Safety Alert Symbol ....................6

2.3 Safety Icons Nomenclature ..............7

2.3.1 Personal Protection /

Important Information ............7

2.3.2 Prohibited Actions ...............7

2.3.3 Hazard Avoidance ...............7

2.4 General Safety ........................8

2.5 Machine Related Safety .................8

2.6 Safety decals .........................8

2.7 Operation Safety ......................8

2.8 Transporting Safety ....................8

2.9 Storage Safety . . . . . . . . . . . . . . . . . . . . . . . . 8

2.10 Maintenance Safety . . . . . . . . . . . . . . . . . . . . 8

2.11 Training .............................8

2.12 Authorization/TrainingSign-OForm .....9

3. SAFETY DECALS AND LABELS ...........11

3.1 General Information . . . . . . . . . . . . . . . . . . . 11

3.2 Contact Information ...................11

3.3 How to Install Replacement Safety Decals . 11

3.4 Safety Decal Locations.................12

3.5 Safety decals ........................12

4. NOMENCLATURE .......................13

5. ASSEMBLY AND SETUP ..................14

6. USAGE .................................15

6.1 User Safety..........................15

6.1.1 Machine Operation Recommendations

15

6.1.2 Machine Requirements ..........15

6.2 MachineSpecications.................16

6.3 Attaching to Machine ..................16

6.4 Pre-Operation Checklist ...............17

6.5 Usage..............................17

6.5.1 Picking Up a Bale ..............18

6.5.2 Moving with a Bale .............18

6.5.3 Placing the Bale ...............19

6.6 Detaching from Machine ...............19

7. TRANSPORTING.........................20

7.1 Highway and Transport Safety ...........20

7.2 Pre-transport Checklist.................20

8. STORAGE...............................21

8.1 Placing in Storage ....................21

8.2 Removing from Storage ................21

9. MAINTENANCE ..........................22

9.1 Maintenance Safety . . . . . . . . . . . . . . . . . . . 22

9.2 Practice Safe Service Procedures . . . . . . . . 22

9.3 Bolt Torque Requirements ..............23

9.4 Welding Repairs ......................23

9.5 Service Record ......................24

10. PARTS SECTION.........................25

10.1 Ordering Parts .......................25

10.2 Contact Information ...................25

10.3 Safety Decals and Instructional Labels ....25

10.4 EBS-1 Parts Detail ....................26

Norden Mfg. LLC (877) 296-5851 4 Euro Bale Spear

1. Introduction

The Norden Euro Bale Spear is an attachment that

mounts to a utility tractor equipped with a loader

having the ability to quick attach to attachments

following ISO 2326. It is designed specically to

move large bales of hay or straw.

Note: Thespecicterm“Attachment”willbe

referredtosimplyas“balespear”or

“attachment”throughouttherestofthis

manual and may refer to any of the models

covered by this manual. The term utility

tractorwillbereferredtoas“machine”

throughout this manual.

Read, understand, and follow the manual carefully

to become familiar with your new Norden bale spear.

Ultimately it is our desire that you will be operating

your bale spear as a seasoned professional in very

little time!

1.1 Intended Usage

Do not use this bale spear for any other purpose

than its intended use of moving large bales of hay

and straw.

Note: Do not use an oversized machine; the

attachment is intended to be used on

machines rated up to 120 HP or a 3500 pound

operating capacity.

1.2 Operator Orientation

The directions left, right, front, and rear, as

mentioned throughout this manual, are as seen from

the operator’s seat, facing in the direction of travel.

1.3 Specifications

Specifications subject to change without notice.

1.3.1 EBS-1 Specifications

Overall Width 42"

Overall Length 50.25"

Overall Height 20.1”

Overall Approximate Weight

120.8 lb.

Bale Spear Length and Quantity

49”x1

Bale Spear Socket

Conus 2

Bale Spear Rating (Each)

Frontofsockettoloadpointis19.68”

4,046 lbs.

Anti-Rotation Spikes - 1” Dia.

2

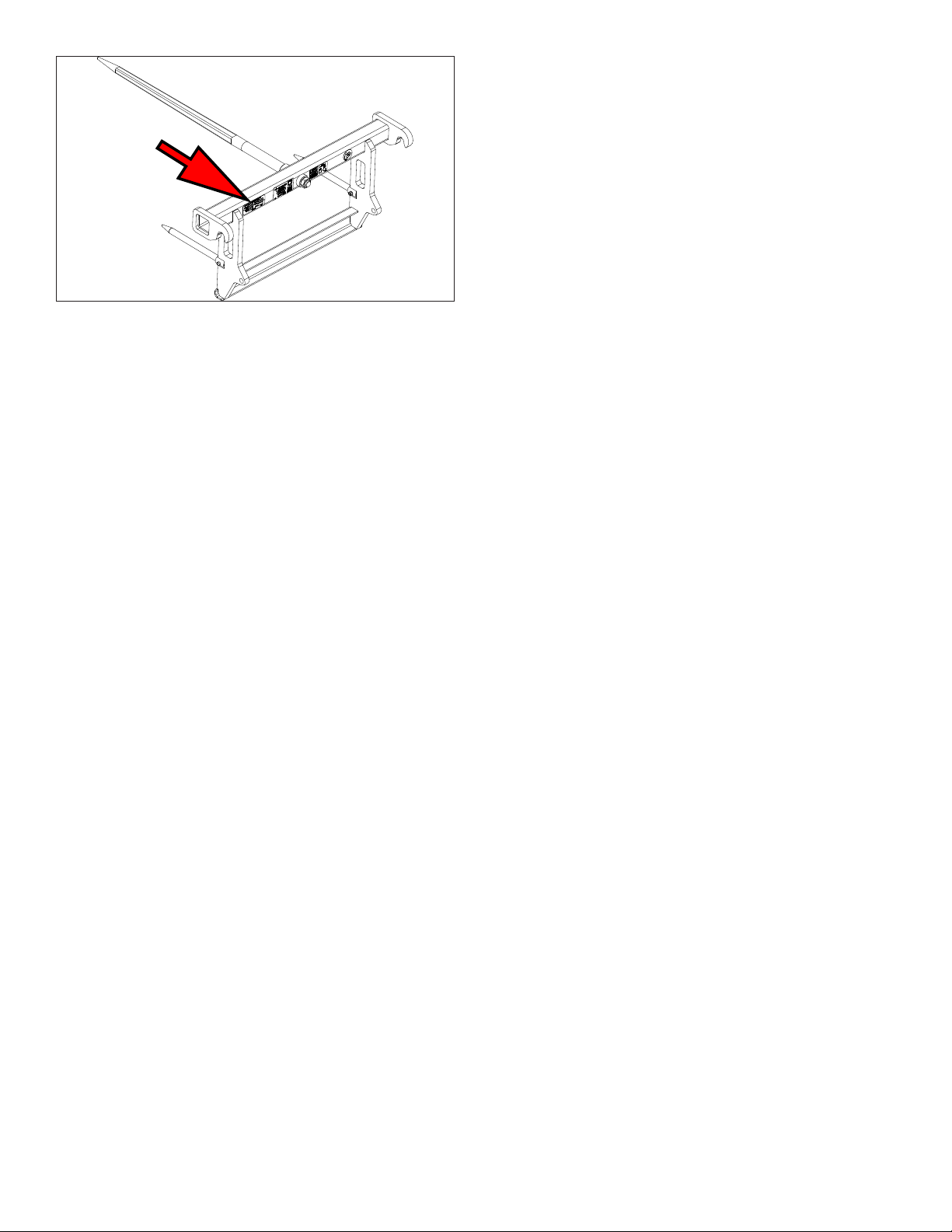

1.4 Serial Number Location

The bale spear’s serial number and model number

decal (1) is located on the back of the bale spear

frame. Please use these numbers when requesting

service, seeking information, or ordering parts.

1.

4210 Kinsman Rd NW, North Bloomeld, OH 44450

www.nordenmfg.com - (877) 296-5851

Made in USA

Serial Number

Mfg Date

Model Number/Rev

Max Hyd. Pressure

Load Rating

Approx. Weight

Part Number

1027460

Euro Bale Spear 5 Norden Mfg. LLC (877) 296-5851

EBS-1

Record the serial and model numbers as well as

the date of purchase in the space provided for easy

reference when contacting Norden Mfg LLC with

questions.

Model Number _____________________________

Serial Number ______________________________

Date of Purchase ___________________________

1.5 Product Improvements

Because Norden Mfg LLC maintains an ongoing

program of product improvement, we reserve the

right to make improvements in design or changes

inspecicationswithoutincurringanyobligationto

install them on attachments previously sold.

1.6 Disposal of Equipment at End of Useful

Life

The Norden Mfg LLC bale spears are designed

forthespecicpurposeofmovinglargebalesof

hay and straw. When this bale spear is no longer

capable of performing its intended use, it should be

dismantled and scrapped. Do not use any materials

or components from this bale spear for any other

purpose.

1.7 Unanswered Questions

If you have any questions not answered in this

manual, require additional copies, or the manual is

damaged, please contact your dealer or:

Norden Mfg LLC

4210 Kinsman Road NW

North Bloomfield, OH 44450

Phone: (877) 296-5851

Fax:(440)693-4336

E-mail: [email protected]

The manual is also available for download at:

www.nordenmfg.com

Norden Mfg. LLC (877) 296-5851 6 Euro Bale Spear

2. Safety

2.1 General

Most work-related accidents are caused by failure

to observe basic safety rules or precautions. An

accident can often be avoided by recognizing

potentially hazardous situations before an accident

occurs. As you use and maintain the bale spear you

must be alert to potential hazards.

Improper use and/or maintenance of this bale spear

could cause a dangerous situation that results in

property damage, personal injury, or death.

WARNING

Do not use the bale spear until you read,

understand, and follow the information

contained in this manual and all related

equipment manuals. Do not use the bale spear

for anything other than its intended purpose.

Safety precautions and warnings are

provided in this manual and on the bale

spear. If these precautions and warnings are not

followed, bodily injury or death could occur to

you or to other persons.

Norden Mfg LLC cannot anticipate every possible

circumstance that might involve a potential hazard.

The warnings in this manual and on the product are,

therefore, not all-inclusive. If a method of operation

notspecicallyrecommendedbyusisused,you

must satisfy yourself that it is safe for you and for

others. You should also ensure that the attachment

will not be damaged or be made unsafe by the use

or maintenance methods that you choose.

Theinformation,specications,andillustrationsin

this manual are based on the information that was

available at the time this material was written and

can change at any time.

2.2 Safety Alert Symbol

This is the safety alert symbol. It is used to

alert you to potential personal injury

hazards. The symbol is followed by a

signalwordsuchas“WARNING”or

“CAUTION”dependingontheseverityofthe

potential hazard. Obey all safety messages that

follow this symbol to avoid possible injury or death.

This manual contains WARNINGS, CAUTIONS,

NOTICES,SAFETYINSTRUCTIONS,andNOTES.

Warnings, Cautions, and Safety Instructions must be

followed to prevent the possibility of personal injury

or death due to improper operation. Notices and

Notes help prevent bale spear or property damage.

WARNING

Indicates a potentially hazardous situation

which, if not avoided, COULD result in death or

serious injury.

CAUTION

Indicates a potentially hazardous situation

which, if not avoided, MAY result in minor or

moderate injury.

NOTICE

Indicates that bale spear or property damage

can result if instructions are not followed.

SAFETY

INSTRUCTIONS

Indicates specific safety-related instructions or

procedures.

Note: Contains additional information important to

operation or a procedure.

Euro Bale Spear 7 Norden Mfg. LLC (877) 296-5851

2.3 Safety Icons Nomenclature

This manual and the bale spear has numerous

safety icons. These safety icons provide important

operating instructions which alert you to potential

personal injury hazards

2.3.1 Personal Protection /

Important Information

Read the manual

Maintenance procedure

Eye protection

Hearing protection

Hand protection

Foot protection

First aid kit

Use proper tools

OEMOEM

Use OEM parts

Use ROPS and seat belt

Maintain safety decals

Place in park

Remove key

STOP

Stop engine

Visibility - slow moving vehicle (SMV)

Set parking brake

2.3.2 Prohibited Actions

Do not alter or modify

Do not leave out tools

Do not weld

No riders

No children

No alcohol

No drugs

2.3.3 Hazard Avoidance

Crushing hazard

Crushing hazard

Slipping hazard

Tripping hazard

Falling hazard

Safety alert symbol

Defective or broken part

Falling hazard

Maintain safe distance

Pinch point hazard

Crush hazard

Rollover hazard

Not a lifting device

Entanglement hazard

Norden Mfg. LLC (877) 296-5851 8 Euro Bale Spear

2.4 General Safety

WARNING

Read, Understand, and Follow

Manual

To prevent personal injury or even death, be

sure you read, understand, and follow all of the

instructions in this manual and other related

OEM equipment manuals! This bale spear was

designed for a specific application; DO NOT

modify or use this bale spear for any application

other than that for which it was designed.

Attachments used improperly or by untrained

personnel can be dangerous! Inexperienced

operators should receive instruction from

someone familiar with the bale spear and the

machine before being allowed to operate the

bale spear.

Do Not Operate

Do not use the attachment if it is in

need of repair. If you believe the bale spear has

a defect which could cause injury or death, you

should immediately stop using the bale spear.

Fall Hazard

Do not use the attachment as a platform

for standing. Do not stand on top of the

attachment at any time. Do not hang on the

attachment or allow others to hang on it.

Pinch Point Hazard

Keep hands and feet away from

the attachment to prevent them from getting

pinched or crushed.

2.5 Machine Related Safety

Impaired User Hazard

Do not attempt to use or maintain

the attachment under the influence of drugs

or alcohol. Consult your doctor before using

the bale spear while taking prescription

medications.

Falling Hazard

Do not allow riders on the machine

or attachment at any time. Falling can result in

severe injuries or death.

WARNING

Stay Clear

Clear the area of people, especially

small children, before using the attachment.

Under no circumstances should young children

be allowed to work with or around the bale

spear.

Not A Lifting Device

Do not use the bale spear to lift other

objects.

2.6 Safety decals

Refertosection“3.SafetyDecalsandLabels”on

page 11 for safety recommendations related to

using the bale spear.

2.7 Operation Safety

Refertosection“6.1UserSafety”onpage15for

safety recommendations related to using the bale

spear. All applicable safety recommendations in

other sections should also be followed.

2.8 Transporting Safety

Referto“7.Transporting”onpage20forsafety

recommendations related to traveling with a

machine and attachment on a public roadway. All

applicable safety recommendations in other sections

should also be followed.

2.9 Storage Safety

Refertosection“8.Storage”onpage21for

safety recommendations related to storing the bale

spear. All applicable safety recommendations in

other sections should also be followed.

2.10 Maintenance Safety

Refertosection“9.Maintenance”onpage22for

safety recommendations related to maintaining the

bale spear. All applicable safety recommendations in

other sections should also be followed.

2.11 Training

Norden Mfg LLC follows the general Safety

StandardsspeciedbytheFarmEquipment

ManufacturersAssociation(F.E.M.A.),andthe

American National Standards Institute (ANSI).

Anyone who will be using and/or maintaining the

bale spear must read and clearly understand ALL

safety, operation, and maintenance information

presented in this manual, other related OEM

Euro Bale Spear 9 Norden Mfg. LLC (877) 296-5851

machine manuals, and the safety decals.

If you do not understand any information in this

manual, see your dealer or contact Norden Mfg LLC

before proceeding.

Do not use or allow anyone else to use this

attachment until all information has been reviewed.

Annually review this manual before the season start-

up.

MakeperiodicreviewsofSAFETYandOPERATION

a standard practice. An untrained operator is not

qualiedtousethisbalespear.

2.12 Authorization / Training Sign-Off Form

Theauthorizationandtrainingsign-oformis

provided for your records to show that all personnel

who will be working with the attachment have read

and understand the information in this Operator

Manual and have been trained in the operation of

the machine the attachment is connected to. The

user and the owner should both sign and date the

form to indicate acceptance of the risk of using the

bale spear.

Norden Mfg. LLC (877) 296-5851 10 Euro Bale Spear

Authorization / Training Sign-O Form

Date User’s Signature Owner’s Signature

Euro Bale Spear 11 Norden Mfg. LLC (877) 296-5851

3. Safety Decals and Labels

3.1 General Information

The types of safety decals (hazard labels) and

instructional labels, along with their locations on the

bale spear, are shown in the following illustrations.

Good safety practices require that you familiarize

yourself with the various safety decals, the type

of warning, and the area or particular operation

relatedtothatareathatrequiresyourSAFETY

AWARENESS.

THINK

SAFETY!

Think SAFETY!

Work SAFELY!

Pay close attention to the safety decals and

instructional labels attached to the machine and bale

spear.Thesafetydecalsaxedtothebalespear

are reproduced in this section. If the bale spear is

missing a label or one is unreadable, replace the

label before using the bale spear.

SAFETY

INSTRUCTIONS

Safety Decals and Instructional Labels

1. Keep safety decals or instructional labels

clean and legible at all times. Use a clean,

damp cloth to clean safety decals.

2. Replace any missing or hard-to-read safety

decals or instructional labels.

3. Use care when washing or cleaning the bale

spear not to remove or damage the decals.

When using a pressure washer to clean

the bale spear, avoid spraying too close

to decals; high-pressure water can enter

through very small scratches or under edges

of decals causing them to peel or come off.

4. Locations for the decals and replacement

part numbers are shown in this section.

5. Replacement parts must have replacement

decals attached before the bale spear is

used.

6. Decals are available from your authorized

dealer or from Norden Mfg LLC at no charge.

3.2 Contact Information

Forreplacementdecals,contact:

Norden Mfg LLC

4210 Kinsman Road NW

North Bloomfield, OH 44450

Phone: 877-296-5851

Fax:440-693-4336

E-mail: [email protected]

3.3 How to Install Replacement Safety

Decals

1. Clean and dry the installation area.

Note: Do not install the signs if the temperature is

below50°F.

2. Determinetheexactpositionbeforeyouremove

the backing paper.

3. Remove the backing paper.

4. Align the safety decal or instructional label over

thespeciedareaandcarefullypressthesignto

the part/frame.

Note: Small air pockets can be pierced with a pin

and smoothed out using the piece of backing

paper or plastic card.

Norden Mfg. LLC (877) 296-5851 12 Euro Bale Spear

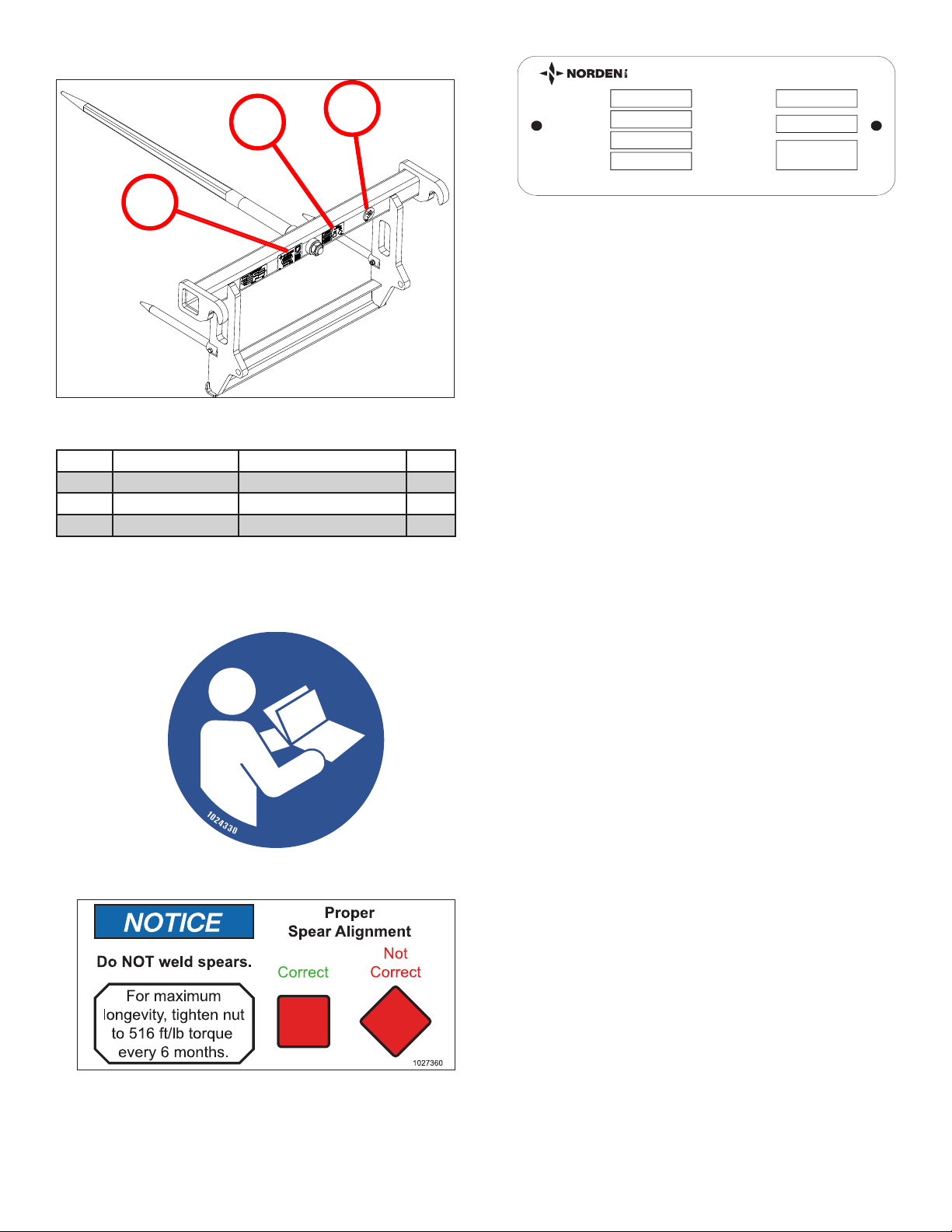

3.4 Safety Decal Locations

1

2

3

Item Type Description Qty.

1INFORMATIONAL Read the Manual 1

2 NOTICE Spear Orientation 1

3INFORMATIONAL Mfg Placard 1

3.5 Safety decals

1.

INFORMATIONAL — Read the Manual

2.

NOTICE — Spear Orientation

3.

4210 Kinsman Rd NW, North Bloomeld, OH 44450

www.nordenmfg.com - (877) 296-5851

Made in USA

Serial Number

Mfg Date

Model Number/Rev

Max Hyd. Pressure

Load Rating

Approx. Weight

Part Number

1027460

INFORMATIONAL — Manufacturer Placard

Euro Bale Spear 13 Norden Mfg. LLC (877) 296-5851

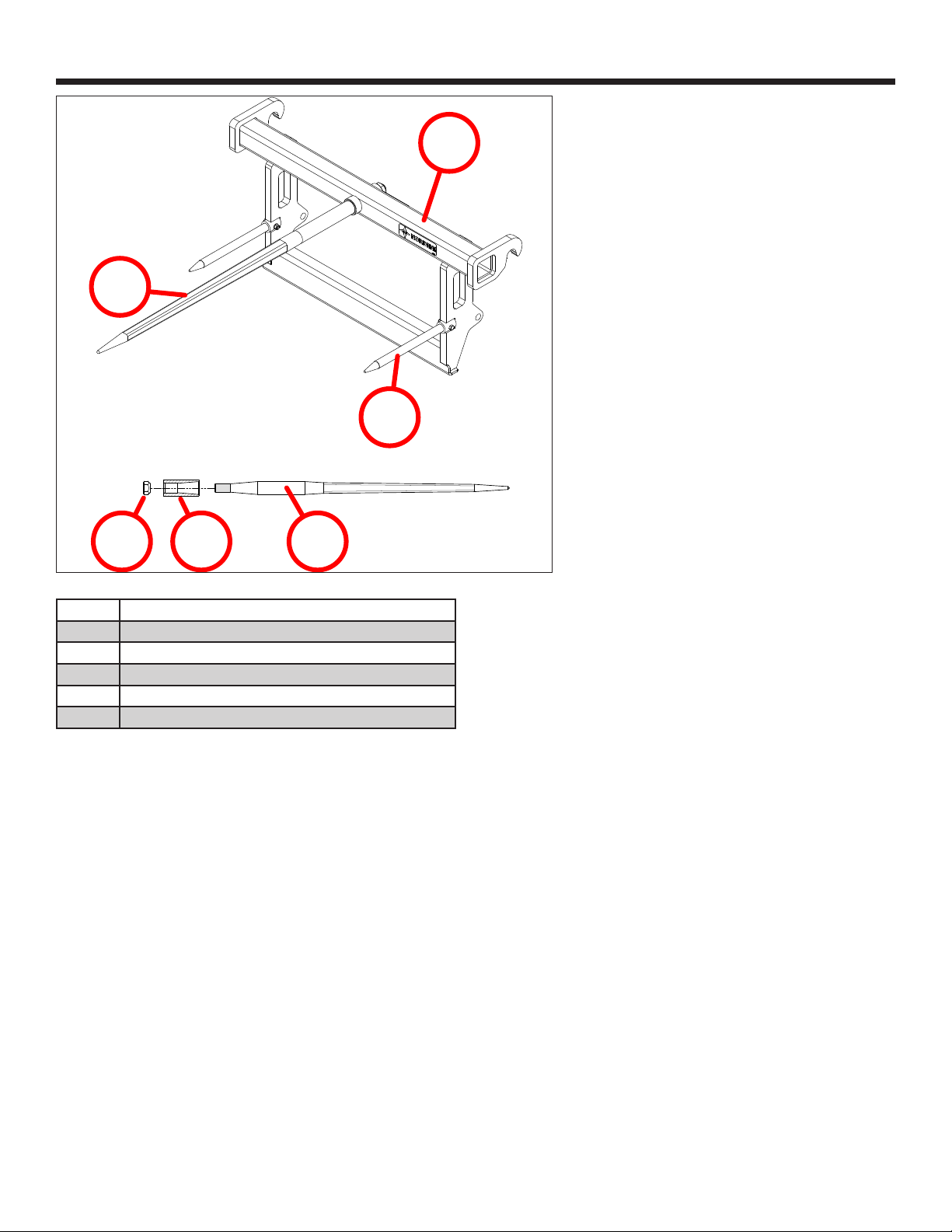

4. Nomenclature

1

2

3

4 5 1

Item Description

1 Spear

2 Anti-Rotation Spike

3Frame(weldment)

4 Spear Nut

5 Spear Sleeve (part of weldment)

Norden Mfg. LLC (877) 296-5851 14 Euro Bale Spear

5. Assembly and Setup

The factory will perform complete assembly of

the bale spears. Upon receipt, the operator must

conduct an initial visual inspection of the attachment.

If applicable, the operator must ensure that all nuts

and bolts are appropriately torqued before using the

attachment.

To orient the spear, the operator should place the

atfaceupwardsandtightenthenutto516ft/lbor

700 N·m. It is critical to ensure that the tapered side

of the nut is facing the socket, as failure to do so

may cause premature failure of the spear. A 41 mm

sockettsthenut–besurecorrecttoolsareused.

Note: Topreventoxidationfromseizingthespear

into the socket, the operator must apply

grease or an anti-seizing compound onto the

primary taper of the replacement spear.

NOTICE

Premature failure of spear may result from

improper tightening of the spear nut.

The operator should periodically make sure the nut

isproperlytightened(516ft/lbor700N·m).Failure

to do so may shorten the life of the spear.

Apply grease or anti-sieze all around full length of taper.

Do not apply grease or anti-sieze on threads or bevel.

Euro Bale Spear 15 Norden Mfg. LLC (877) 296-5851

6. Usage

6.1 User Safety

Referto“2.4GeneralSafety”onpage8for

additional safety information.

6.1.1 Machine Operation Recommendations

WARNING

STOP

Roll Away Hazard

Before leaving the

operator’s seat, make

sure the engine is stopped, the transmission

is placed in park, the key is removed, and the

parking brake is set.

Rollover Hazard

The weight of the machine, plus the bale

spear, if it rolls onto a person, could

cause serious crushing injury or death.

Crush Hazard

The machine must be equipped

with a Roll Over Protective

Structure (ROPS) and a seat belt. A crushing

hazard could occur if the operator is ejected

from the seat while the tractor is in motion.

Fasten the seat belt whenever the tractor is

moving.

Entanglement Hazard

If using a small compact or utility

tractor, keep hands and clothing

clear of any rotating parts. Stay clear of the bale

spear while the machine is moving.

SAFETY

INSTRUCTIONS

The following safety instructions are provided to

help prevent injury or limit bale spear damage.

SI

It is the owner’s responsibility to make

sure any person using a machine with the

attachment, especially if it is loaned or rented,

has been thoroughly trained on its proper and

safe use.

SI

Be certain only physically-able persons will

use the attachment.

SI

Users who have not read and understood

all operating and safety instructions are not

qualified to use the attachment.

SI

If the elderly are assisting with the work,

their physical limitations need to be

recognized and accommodated.

SI

Never allow children to use the attachment.

SI

Be especially observant of the operating

area and terrain – watch for loose fill,

holes, rocks or other hidden hazards. Always

inspect the area prior to operation.

SI

Be careful at the edge of ditches or gullies.

Be careful when working on inclines.

SI

Do not use excessive speed when moving

bales.

SI

Allow for bale spear length when making

turns.

6.1.2 Machine Requirements

WARNING

Machine Operator Manual

Always refer to the machine’s

operator manual to ensure

compatibility and maximum safety.

The machine must be equipped with a front-end

loader with Euro attachment mounting style rated to

lift the bale spear which can weigh up to 122 pounds

plus the weight of the bale.

SAFETY

INSTRUCTIONS

SI

Do not use an oversized machine; the bale

spears are intended to be used on

machines rated up to 120 HP or a 3500 pound

operating capacity.

SI

Using the bale spear with a machine that

exceeds the specified requirements may

cause machine or attachment damage, be a

potential danger to the operator or bystanders,

and will void any warranty.

SI

Always review the “controls” section of the

machine’s Operator Manual to be familiar

with the location, settings, and function of the

controls. Be familiar with all controls before

using this attachment.

Norden Mfg. LLC (877) 296-5851 16 Euro Bale Spear

6.2 Machine Specifications

This section is provided to give the operator general

safety information for the machine. Always follow the

OEM instructions given in the operator’s manual for

the machine.

WARNING

Rollover Hazard

To avoid serious injury or death

from falling, runover, rollover, or

crushing, the machine must have an approved

Roll-Over Protective Structure (ROPS) or ROPS

cab and seat belt.

1. The machine must be equipped with an approved

Roll-Over Protective Structure (ROPS) or ROPS

cab and seat belt.

a. If equipped with a folding ROPS structure,

keep it locked in the UP position.

b. Only operate the machine when seated in the

operator seat.

c. Always fasten seat belt whenever the machine

is moving.

2. If working around dry grass or vegetation, to

reducetheriskofre,donotuseamachinewith

anunder-frameexhaust.

3. Whenever traveling on a public roadway, follow

guidancegivenin“7.Transporting”onpage20.

4. Maintain all manufacturer’s safety shields and

guards

6.3 Attaching to Machine

WARNING

Pinch Point Hazard

Use caution when connecting the

attachment to the machine. Keep

hands and feet from under the attachment and

clear of pinch points between attachment and

machine. Do not allow anyone to stand between

the machine and pallet fork during attachment

process.

1. Ensure there are no potential unintended collisions

between the attachment and the loader before

connectingthemforthersttime.

2. Tilt the tool carrier forward completely to angle the

carrier arms downward toward the attachment.

Position the tool carrier an inch below the

attachment hooks.

3. Drive the machine forwards slowly, centering

the carrier arms between the hooks on the

attachment.

4. When the tool carrier makes contact with the

attachment, raise the loader to engage both hooks

of the attachment on the tool carrier.

5. Roll the tool carrier back toward the machine.

6. If equipped, the hydraulic or electronic powered

locking pins can be engaged. In this case; skip

Steps 7, 8, and 9.

7. If your loader requires manual locking, perform a

full roll back to automatically lock the attachment

onto the tool carrier.

8. If your loader requires a fully manual locking

process:

WARNING

STOP

Roll Away Hazard

Before leaving the

operator’s seat, make

sure the engine is stopped, the transmission

is placed in park, the key is removed, and the

parking brake is set.

a. Raise the back of the attachment slightly off

the ground and angle it back to apply pressure

against the stops.

b. Shut off the machine.

c. Apply the parking brake.

d. Manually lock the attachment to the carrier

assembly.

WARNING

Injury Hazard

To avoid serious injury or death

caused from falling attachment: lock

pins must completely engage attachment eyes.

Crush Hazard

Do not stand under raised

attachment.

9. If equipped, the attachment’s locking lug will

impact/push aside the Click-on system on the

tool carrier, automatically locking the attachment

in position. The lock lever is released and moves

tothe“lockedattachment”position.

Euro Bale Spear 17 Norden Mfg. LLC (877) 296-5851

10. Raise the loader arms until the tool carrier is

clearly visible from the driver’s cab. Inspect

alignment and verify positioning.

11. Pay attention to the tool carrier lock indicators,

whichmaydierdependingonthetypeoftool

carrier installed on the loader. Carefully observe

howyourspecictoolcarrierindicatesalocked

attachment.

12. Before starting work with the loader/attachment,

read“6.4Pre-OperationChecklist”onpage17

to ensure the attachment is correctly locked onto

the loader’s tool carrier:

• Visually check that the locking lever indicates a

locked attachment.

• Visually check that the tool carrier locking pins

are in the locked position.

13. Verify that the attachment is locked in place

on the tool carrier by pressing the front of the

attachment against the ground.

14. Before using the attachment, the operator must

operate it through its full range of motion and

conrmthattheattachmentissecureandsafe.

6.4 Pre-Operation Checklist

Before each use of the attachment, the following

areas should be checked.

Checklist Before Each Use

þTask

Make sure the bale spear is positively attached to the machine.

Referto“6.3AttachingtoMachine”onpage16.

If the machine uses tires, make sure they are inflated properly

and the lug nuts are tight.

Visually inspect the attachment for any loose bolts, worn parts,

or cracked welds. Make necessary repairs before using the

attachment.

Make sure the bale spear is not bent or cracked.

Make sure the operating area is clear, especially of children and

animals.

6.5 Usage

Before using the attachment, the operator must

have a complete understanding of how to operate

the machine including all controls, and how to use

the attachment.

The operator should read and understand the Safety

and Operation Sections of the machine operator’s

manual. It is important to note that these manuals

mustbereadandexplainedtoanyoperatorwho

cannot read. It is crucial to never allow anyone to

operate the machine or use the attachment without

complete operating instructions.

To ensure safety to the operator, bystanders, and

equipment, the operator must become familiar

with the surrounding work area and any obstacles

and hazards contained within before starting any

operation. Special attention should be paid to foreign

debris, rough terrain, steep slopes, bystanders, or

animals in the area.

If the operator is not already familiar with the

process, it is recommended to practice lifting,

lowering, maneuvering, and placing a bale on a

levelsiteuntilthecondenceandskillneededto

safely move bales. It is important to follow the safety

operating procedures that are spelled out in this

Operator’s Manual.

WARNING

Crush Hazard

When handling round bales,

improper use of the machine can

result in serious injury or death to the machine

operator. This could be caused by the bale

rolling backwards into the operator’s station.

Therefore, it is important to handle round bales

safely.

CAUTION

Tip Over Hazard

It is important not to exceed 3,500 lbs.

or the lift capacity of the machine. The

operator should not lift the bale too high,

creating an unstable and unsafe situation. The

operator should also avoid tilting the bale too

far forward, setting up a situation that could

cause the bale to prematurely slide off the

spear(s).

The operator must travel at a safe speed for

ground conditions. Travel slowly over rough

ground or when making turns. Working on or

around slippery or sloped areas could cause the

operator to lose control of the machine.

The operator must not allow bystanders, pets,

or livestock to approach the danger zone of the

working area.

The operator must not leave the machine with

the attachment raised off the ground.

Norden Mfg. LLC (877) 296-5851 18 Euro Bale Spear

6.5.1 Picking Up a Bale

1. Ensure that the weight of the bale does not

exceedthesmallerofthetwoliftcapacities

below:

• The rated lift capacity of the spears (4,046 lbs at

19.68”fromthefrontofthespearsleeve).

• 83% of the rated lift capacity of the machine.

Note: This calculation accounts for the increased

loader stresses caused by the added

extensionoftheattachmentandensures

that the front tires on your tractor are rated

properly for the job. Always fully insert the

spear into the bale before lifting it, as lifting

heavy or frozen bales without fully inserting

the spear can damage the unit and void its

warranty.

NOTICE

Care must be taken to ensure there is enough overhead

clearance and no potential hazards or obstructions that

could interfere with the lifting and placing of the bales.

2. Position the bale spear and push it into the

baleuntilitisrmlyagainsttheframeofthe

attachment. Always center the bale horizontally

on the spear points to optimize stability while

transporting.

3.

Target

Drive the spear into

the bale with the

spear level, centered

horizontally, and the

point of the spear at,

or slightly above, the

vertical center of the

bale, until the spear

is fully inserted and

the bale is against

the bale spear frame.

This will allow the anti-rotation spikes to stabilize

the bale.

Note: Soft center bales will tend to droop after being

lifted by a single spear. Placing the spear

in a lower position in the bale will allow for

more lifting height and lessen the load on the

stabilizer spikes.

NOTICE

Potential Machine Damage

Do not attempt to spear a round bale down from the top

if it is lying on its flat face, as excessive movement of the

machine while operating the loader can seriously damage

the machine and/or its hydraulic cylinders or hoses.

Instead, first tip the bale up on the round side.

SAFETY

INSTRUCTIONS

Transport bales at a height that maintains a

clear line of sight and keep the bale low to the

ground when possible to enhance stability.

4. Advanced operators should spear bales with a

slightly downward motion at a 5° downward angle

of the spear, and lower the boom as the spear

enters the bale to pinch the bale to the ground,

preventing it from sliding away. This method also

makesiteasiertoslidethebaleothespear.

5. After lifting the bale a short distance, tilt the spear

points up 5-10 degrees from horizontal to reduce

thelikelihoodofthebaleaccidentallyslidingo

the spear. Always check to ensure that the bale is

stable before traveling.

Note: Partial engagement of the spear(s) can

damage the spear(s), as it locates the weight

of the bale on the outer end of the spear(s).

Raise and roll back the bale just high enough to

provide ground clearance. If the bale appears

unstable, lower it, remove the spears, and repeat

therststepsuntilthebaleissecure.Tominimize

jerking, stop and start the loader gradually when

lowering or lifting loads.

SAFETY

INSTRUCTIONS

Always ensure the tractor is properly ballasted

before attempting to lift any load with the

attachment. If handling bales with both the

front-end loader and the 3 point hitch on the

tractor, always load the 3 point attachment first

and unload it last.

SI

Make sure that the work area is clear of

children, animals, and other obstacles

before using the attachment. This is particularly

important in areas with higher noise levels or

quiet cabs, as you may not hear people

shouting.

6.5.2 Moving with a Bale

Referto“7.Transporting”onpage22for

additional highway safety information.

CAUTION

Crush / Tip Over Hazard

Never attempt to stop a rolling bale

with the machine.

Euro Bale Spear 19 Norden Mfg. LLC (877) 296-5851

SAFETY

INSTRUCTIONS

SI

Watch for overhead obstructions and side

clearances while moving bales.

SI

Utilize tractors with wide front axles and

move all wheels to their maximum width

position to achieve the highest stability.

SI

Ensure tractors are correctly ballasted

according to the load being transported to

prevent the loss of steering control caused by

improper ballasting.

1. Raise the bale to the minimum height required

for the terrain that must be crossed with the bale.

2. During transport, keep the bale as close to the

ground as possible.

3. When transporting empty, ensure the spear

points are at a safe height and angle that does

not pose a risk of impaling people or livestock.

4. Transport bales fully against the spear frame

and with the spear points raised 5 to 10 degrees

from horizontal. Do not transport bales halfway

or more out on the spear points.

5. Lower the spear points to the ground when

stopped to prevent people or livestock from

being impaled. If the spear cannot rest on the

ground, point it downward for protection.

6. Use gradual acceleration, turning, and braking to

prevent any loss of control.

7. Reduce ground speed when turning and

maintainsucientclearancetoavoidobstacles

such as buildings, trees, and fences.

8. Avoid any obstacles, bumps, or holes in the path

to maintain stability.

9. Transporting bales over ramps, grades, bumpy

ground, soft surfaces, or slippery surfaces can

reduce machine stability and lift capacity and is

extremelydangerous.

10. Always travel straight up and down inclines,

avoid making turns, and keep the spear points

tilted up 5 to 10 degrees from horizontal

regardless of the angle of the incline.

11. When traveling on inclines greater than 10

percent, place the bale on the uphill side of the

machine, when necessary, drivers should drive

up and back down steep inclines.

12. Keep equipment away from electrical power

lines and place orange warning signs under

overhead electrical power lines to indicate the

danger.

13. Frequentlycheckthebaletomakesurethatit

has not become unstable during transport.

6.5.3 Placing the Bale

After the bale has been positioned and stabilized in

the desired location, tilt the spear slightly downward

toenablethebaletoslideothespear.Toprevent

the bale from sliding on the ground, it may be

necessary to apply a small amount of downward

pressure to it.

6.6 Detaching from Machine

CAUTION

Pinch / Crush Hazard

Use caution when disconnecting

the attachment from the machine.

Keep hands and feet from under the attachment

and clear of pinch points. Do not allow anyone

to stand near the machine or attachment when

disconnecting.

1. Movethemachineontoaat,level,solidsurface.

Lower the attachment slightly above the surface

with the hitch angled, front of the attachment

slightly higher than the rear.

2. If your machine is equipped with hydraulically

operated locking pins, retract the coupler lock at

this time. In this case; lower the attachment to

the ground and skip Steps 3, 4, and 5.

3. Shut down the machine and set the parking brake

properly without lowering the attachment.

WARNING

STOP

Unintended

Movement

Before leaving the

operator’s seat, make sure the engine is

stopped, the transmission is placed in park, the

key is removed, and the parking brake is set.

4. Move the locking lever to disengage the locking

pins.

5. Start the engine and lower the attachment to the

ground.

6. Tilt the tool carrier forward to allow the tool carrier

to clear the hooks on the attachment.

7. Make sure the area is clear of bystanders and

animals, then slowly back the machine away from

the attachment, ensuring that the tool carrier does

not interfere with the attachment.

Norden Mfg. LLC (877) 296-5851 20 Euro Bale Spear

7. Transporting

7.1 Highway and Transport Safety

This section is provided to give the operator general

safety information for the machine. Always follow the

OEM instructions given in the operator’s manual for

the machine.

Referto“2.4GeneralSafety”onpage8for

additional safety information.

SAFETY

INSTRUCTIONS

SI

Make sure the machine used is in good

operating condition according to the OEM

user’s manual.

SI

When traveling the attachment on the

highway, make sure the machine has

a clearly visible “Slow Moving Vehicle” placard.

SI

Use approved accessory lighting, flags, or

other necessary warning devices to protect

operators of other vehicles on the highway

during daylight and nighttime transport. Various

safety lights and devices are available from the

OEM of your machine.

SI

Do not allow anyone to ride on the machine

or the bale spear.

SI

Always drive at a safe speed relative to

conditions, and ensure that the speed is

low enough for an emergency stop. Keep speed

to a minimum.

SI

Reduce speed prior to turns to avoid the

risk of overturning.

SI

Always keep the machine in gear to provide

engine braking when going downhill. Do

not coast.

SI

Be a safe and courteous driver. Always

yield to oncoming traffic in all situations,

including narrow bridges, intersections, etc.

Plan your route to avoid heavy traffic.

SI

Travel on roadways in such a way that

faster moving vehicles can pass safely.

SI

Always travel with the attachment in a

position to provide maximum visibility at all

times. Make allowances for increased length

and weight of the bale spear when making turns,

stopping, etc.

7.2 Pre-transport Checklist

1. Before transporting, make sure the maintenance

on the machine is current.

2. If applicable, check the tire pressures on the

machine, and correct if necessary.

3. Make sure the attachment is securely attached

to the machine. Always inspect the bale spear

and frame for damage or abnormal wear before

attaching.

4. Prior to traveling on a public road, have an

observerconrmallrunninglights,brakelights,

turn signals, and hazard lights are working on the

machine.

5. Verify the brakes are operating correctly.

Table of contents

Other Norden Farm Equipment manuals

Popular Farm Equipment manuals by other brands

TATU

TATU LTA 3000 instruction manual

HARVEST

HARVEST H13114XT Operator's manual

IDROFOGLIA

IDROFOGLIA TURBOCAR J1 Operating instructions manual

REIST INDUSTRIES

REIST INDUSTRIES Roto-Rake RR60 Operator and parts manual

Hisarlar

Hisarlar SB1150 User and maintenance manual

Yetter

Yetter Furrow Max 6200-070 owner's manual

ABI Attachments

ABI Attachments ABI RASCAL instructions

AGROdeviate

AGROdeviate Hawkins Corn Reel installation manual

Sulky

Sulky Polyvrac XT 100 VISION Technician's Operating Manual

LEMKEN

LEMKEN Zirkon 10 operating instructions

Degelman

Degelman PRO-CAST 80 Operator's & parts manual

AGCO

AGCO Gleaner S67 Operator's manual