Hisarlar SB1150 Operating instructions

SILAGE BALER MACHINE

USER AND MAINTENANCE MANUAL

HSR_SB1150_00TR

HİSARLAR SB1150

SILAGE BALER MACHINE

USER AND MAINTENANCE MANUAL

0 TABLE OF CONTENTS

Preface................................................................................................................. 10

1.1 Technical Changes..................................................................................... 10

1.2 Part Delivery Process.............................................................................. 11

GENERAL INFORMATION............................................................................................. 11

1.3 Safety Rules................................................................................................. 12

1.3.1 Safety Rules Applied by Users........................................................................................ 12

1.3.2 Operating of the Machine for Non-Design Purposes................................. 12

1.3.3 Equipped and Trained Operator................................................................................ 12

1.3.4 Safety Accessories............................................................................................................. 12

1.3.5 Fire Probability....................................................................................................................... 13

1.3.6 Selection of the Area Machine to be Used......................................................... 13

1.3.7 Regular Maintenance and Cleaning of the Machine..................................... 13

1.3.8 Use of Original Spare Parts and Accessories.................................................. 13

1.3.9 User Manual..............................................................................................................................13

1.3.10 Usage Rights.......................................................................................................................... 13

SAFETY INFORMATION................................................................................................ 13

1.4 Symbols........................................................................................................ 14

1.5 Design Purpose of the Machine............................................................. 16

1.6 Warranty Liability...................................................................................... 17

WARRANTY INFORMATION........................................................................................

17

1.7 Out of Warranty Conditions................................................................... 18

1.8 Warranty Expiring Conditions............................................................... 19

1.9 Warranty Procedure................................................................................ 19

1.10 Machine Delivery Form.......................................................................... 20

TECHNICAL INFORMATION..................................................................................................... 22

2.1 Model Information.................................................................................... 22

2.2 Dimensions................................................................................................ 23

2.3 Machine Direction................................................................................... 24

2.4 Storage Conditions................................................................................. 25

2.5 Machine Identification Label.................................................................. 25

2.6 Safety Labels.............................................................................................. 26

TABLE OF CONTENTS..................................................................................................

30

3.1 Working Principle of the Machine......................................................... 31

MACHINE INFORMATION............................................................................................

31

3.2 Loading Tank............................................................................................... 32

Closing Side Covers....................................................................................................................... 32

Adjusting Balance Legs............................................................................................................... 33

Conveyor Belt and Tension Unit............................................................................................ 33

3.3 Transmitter Unit....................................................................................... 34

3.4 Netting Unit................................................................................................ 34

Switch Group...................................................................................................................................... 35

Lighting Lamp.................................................................................................................... 35

Magnetic Brake................................................................................................................ 35

Manual Operating Switch (Green)....................................................................... 35

Manual Stop Switch (Red)........................................................................................ 35

Emergency STOP Switch.......................................................................................... 35

3.5 Bale Room................................................................................................... 37

3.6 Stretching Unit......................................................................................... 37

3.7 Control Panel............................................................................................. 38

Main Switch....................................................................................................................... 38

Emergency STOP Switch......................................................................................... 38

Manual Stop Switch (Red)....................................................................................... 38

Screen Connection Port........................................................................................... 38

Automatic-Manual Mode Transition Switch(Amber)............................ 38

Manual Operating Switch (Green)...................................................................... 38

Panel Key.............................................................................................................................. 38

3.8 Balance Legs............................................................................................... 39

3.9 Weight Arrow and Its Hook................................................................... 39

0 TABLE OF CONTENTS

3.10 Hydraulic Control Valves...................................................................... 40

3.11 Operator Screen...................................................................................... 41

3.11 Operator Screen...................................................................................... 42

3.11.1 Main Screen......................................................................................................................... 43

3.11.2 Main Screen........................................................................................................................ 44

3.11.3 Manual Operating Screen......................................................................................... 45

3.11.4 Setting Screen.................................................................................................................. 51

3.11.5 Tracking Screen............................................................................................................... 53

3.11.6 Alarm Screen.................................................................................................................... 53

3.11.7 Alarm List............................................................................................................................. 54

4.1 Operating of New Machines................................................................... 57

4.2 Pulling the Machine off to the Highway.............................................. 58

4.3 Towing the Machine................................................................................. 59

4.3.1 Dismantling Bunker Channel....................................................................................... 59

4.3.2 Closing Bunker Side Covers........................................................................................ 60

4.3.3 Pulling the Bunker to the Towing Position........................................................ 60

4.3.4 Weight Arrow and Its Hook......................................................................................... 61

4.3.5 Closing Balance Legs....................................................................................................... 62

4.3.6 Disconnection of Main Power Connection....................................................... 62

4.3.7 Pulling the Hydraulic Valves to the Towing Position.................................. 63

4.3.8 Connecting the Tractor Signalling Cable........................................................... 64

4.3.9 Signalization Control........................................................................................................ 65

4.3.10 Last Controls Before Towing................................................................................... 66

4.3.11 Getting the Machine Ready to Re-Work.......................................................... 66

4.4. Operating the Machine.......................................................................... 67

4.4.1 Consumables......................................................................................................................... 67

Net Technical Specifications.................................................................................. 67

Stretch Film Specifications..................................................................................... 67

Hydraulic Oil Technical Specifications.............................................................. 67

Automatic Lubrication................................................................................................. 67

4.4.2 Placing the Net..................................................................................................................... 68

Net Feeding Mile.............................................................................................................. 69

Passing the Net through the Cylinders........................................................... 70

4.4.3 Putting the Stretch Film............................................................................................... 71

4.4.4 Operating in Auto Mode................................................................................................ 72

MAINTENANCE INFORMATION.................................................................................

75

5.1 Operator Adjustment, Control and Maintenance........................... 75

5.1.1 Electrical System Check................................................................................................. 76

Cable Check........................................................................................................................ 76

Sensors Check................................................................................................................. 76

Control Panel Check..................................................................................................... 76

Operator Screen Check.............................................................................................. 76

5.1.2 Tire Check..................................................................................................................................77

Tire Rotation....................................................................................................................... 77

Tire Pressures................................................................................................................... 77

5.1.3 Chain Check............................................................................................................................. 78

Bale Room Chains........................................................................................................... 78

Transportation Conveyor Chain.................................................................. 78

Loader Conveyor Chain....................................................................................... 79

5.1.4 Hydraulic Oil Tank................................................................................................................ 80

Oil Level Check................................................................................................................... 80

Hydraulic Hose Check.................................................................................................. 80

5.1.5 Belt Adjustments................................................................................................................ 81

Packing Belt Tension.................................................................................................... 81

Bale Room Belt Adjustments.................................................................................. 82

Bale Room Tension Spring Adjustments........................................................ 83

5.1.6 Automatic Lubrication..................................................................................................... 83

0 TABLE OF CONTENTS

Automatic Lubricating Screen............................................................................... 84

Technical Specifications............................................................................................. 85

Addition of Oil.................................................................................................................... 85

5.1.7 Manual Lubrication............................................................................................................ 86

5.2 Periodical Maintenance Table............................................................... 88

5.2.1 First Maintenance............................................................................................................. 88

5.2.2 Daily Maintenance............................................................................................................ 88

5.2.3 Two Days Maintenance................................................................................................. 89

5.2.4 Seasonal/Annual Maintenance................................................................................. 90

5.3 Authorized Services................................................................................. 90

1 GENERAL INFORMATION

TABLE OF CONTENTS.................................................................................................. 10

Preface................................................................................................................. 11

1.1 Technical Changes.................................................................................. 11

GENERAL INFORMATION............................................................................................

11

1.2 Part Delivery Process............................................................................. 12

1.3 Safety Rules................................................................................................ 13

1.3.1 Safety Rules Applied by Users.................................................................................... 13

1.3.2 Operating of the Machine for Non-Design Purpose................................... 13

1.3.3 Equipped and Trained Operator................................................................................ 13

1.3.4 Safety Accessories............................................................................................................ 13

SAFETY INFORMATION...............................................................................................

13

1.3.5 Fire Probability..................................................................................................................... 14

1.3.6 Selection of the Area for Use of Machine.......................................................... 14

1.3.7 Regular Maintenance and Cleaning of the Machine.................................... 14

1.3.8 Use of Original Spare Parts and Accessories................................................. 14

1.3.9 User Manual............................................................................................................................ 14

1.3.10 Usage Rights........................................................................................................................ 14

1.4 Symbols........................................................................................................ 15

1.5 Design Purpose of Machine.................................................................... 17

WARRANTY INFORMATION........................................................................................

18

1.6 Warranty Liability...................................................................................... 18

1.7 Out of Warranty Conditions................................................................... 19

1.8 Warranty Expiring Conditions............................................................... 20

1.9 Warranty Procedure................................................................................. 20

1.10 Machine Delivery Form.......................................................................... 21

10

Preface

1.1 Teknik Değişiklikler

HİSARLAR CUSTOMER SERVICES

Hisar District 1047th Str. No:2 26550 Tepebaşı

Eskişehir / TÜRKİYE

Tel: +90 222 411 24 30

Faks: +90 222 411 22 47

444 77 57

GENERAL INFORMATION

This user manual is designed to help you use your machine safely and efficiently. The manual

must be read carefully before the machine is first used.

This manual contains information about the machine's efficiency, first intervention in case

of a possible failure and authorized services. For this reason, it should be kept in a place

that is easily accessible during use of the machine.

If the machine is to be sold, the user manual must be delivered to the new owner of the

machine in order to benefit from this information.

Information, warnings and rules given in the manual are assembled assuming that the user

has sufficient professional experience and education. In addition to the information contai-

ned in it, it is essential to comply with the the local and national professional chambers’

regulations on general occupational health and safety issues.

This manual has been prepared for use in all models of HİSARLAR silage baler machines.

For this reason, there may be differences between the information given in the context and

your machine.

In addition to the subjects contained in the content, you can contact the HİSARLAR

Customer Service or authorized services of HİSARLAR for detailed information.

All information and technical data contained in this manual are

applicable at the time of printing. HİSARLAR works with the principle

of continuous growth and development; and it reserves the right to

change product specifications without notice any time.

For correct and safe use of the machine, changing parts of the

document should be added to the manual.

Silage Baler Packing Machine User Manual

11

HSR_SB1150_00TR

GENEL BİLGİLER

WARNING

»Part Delivery

Mechanical shocks and Vibrations

Moisture

Static Electricity

factors may cause damage to electronic parts.

1.2 Parça Gönderim İşlemi

INFORMATION

»Packing of the Parts

The use of protective and safe materials in the packaging of parts

prevents the parts from being damaged during transportation.

HİSARLAR CUSTOMER SERVICES

Hisar District 1047th Str. No:2 26550 Tepebaşı

Eskişehir / TÜRKİYE

Tel: +90 222 411 24 30

Faks: +90 222 411 22 47

444 77 57

Some parts may continue to function if damaged; this damage may not

be noticed during repair. However, parts may stop working properly

shortly after they are returned.

Electronic parts must be packed in anti-static sheaths and placed in

cartons after the necessary protective support has been added. Conta-

ct of electronic parts with static electricity storing polystyrene, foamed

plastic or plastic film should be avoided.

For detailed information on transporting or packing of parts,

you can call HİSARLAR Customer Service.

If any part of the machine is sent to the factory for repair or

fixation, you must use the address below.

12

1.3.Safety Rules

1.3.1.Safety Rules Applied by Users

1.3.3.Equipped and Trained Operator

1.3.2.Operating of the Machine for Non-Design Purposes

1.3.4.Safety Accessories

SAFETY INFORMATION

HİSARLAR machines are designed in a way that will not harm the

operator or third parties during use, and taking into account

international safety guidelines.

However, even the safest machines can cause dangerous situations

when necessary precautions are not taken and applied incorrectly.

Warning signs should be inspected at regular intervals and should

be renewed if damaged.

In addition to user training; signs including easy to understand

service, maintenance and safety instructions must be kept in the

working area. Understanding the general safety rules in the machi-

ne's operating environment is under your responsibility as a user.

The user manual should always be kept close to the machine and in

an easily accessible location. Do not place any objects such as

clothes, covers, tool boxes, etc. on the machine.

Do not touch the damaged insulation material or wet cabling. If you

notice such a situation, notify HİSARLAR authorized service.

Use of the machine under the heading "Non-Design Purpose of the

Machine" may result in life-threatening situations or material

damage which can not be fixed.

Use of the machine outside the raw materials and operating values

specified in the sales contract; life-threatening situations, or materi-

al damage that can not be fixed.

Unconscious use can cause the machine to shorten its life and

reduce its efficiency.

The information, warnings and guidelines in the user manual are

designed assuming that the user has enoughprofessional

experience and education. So make sure that those who use the

machine have enough knowledge and equipment.

Never let anyone who is younger than 18 years old and / or not

received enough technical training enter the working area of the

machine.

Depending on which materials are baled, the machine may generate

loud noise and dust during operation.

For dangerous situations that can occur in the work area, make

sure that all employees who are near the machine or who are in

charge of maintenance and repair of the machine use;

• Ear Protectors

• Safety goggles

• Protective cap

• Protective gloves

• Appropriate work clothes for the job description.

Warning signs should be

inspected at regular intervals

and should be renewed if

damaged.

Use your device within the

operating values determined

by the technical team.

Unconscious use can cause

the machine to shorten its

life and reduce its efficiency.

Silage Baler Packing Machine User Manual

13

HSR_SB1150_00TR

1.3.5.Fire Probability

1.3.6.Selection of the Area Machine to be Used

1.3.7 Makinenin Düzenli Bakım ve Temizliği

1.3.8.Use of Original Spare Parts and Accessories

1.3.9 Kullanım Kılavuzu

1.3.10 Kullanım Hakları

Please keep the equipment in accordance with the fire regulations in

your area, in the work area and in easily accessible places. Inform

users of fire fighting and prevention issues or provide them with the

necessary training.

Make sure that the floor where you will place the machine is flat,

horizontal and stationary. Operating the machine on uneven

grounds may cause vibration of some parts and loosening of some

connections.

Ensure that inspection, maintenance and repair work performed on

the machine are recorded in the form of written text. Keeping a

report book with operating values will provide ease of use when the

device is under the control of a different user or when it is transfer-

red to someone else.

Regular cleaning on the machine, however, ensures that the machi-

ne operates well and safely. Clean the machine and its immediate

surroundings regularly.

Unless otherwise stated, machine maintenance and cleaning work is

done when the machine is completely still and can not be operated

by someone else.

This manual is prepared to help you for safe and efficient use of your

machine. Before using the machine for the first time, it must be read

carefully.

Because it contains information about the first intervention in the

event of possible malfunctions and authorized services, it must be in

place where it can be easily reached during use.

In case the machine is sold or pass into other hands; the user

manual must be delivered to the new owner of the machine in order

him to use this information.

© 2017 HİSARLAR A.Ş. All Rights Reserved.

All rights reserved.

Any part of this guide can not be copied, transmitted or published

electronically, mechanically or by

photocopy or by any other ways without the prior written consent

of HİSARLAR MACHINE Industry and Trade Inc.

To ensure that machine warranty and user safety are not put at

risk; only use genuine HİSARLAR spare parts and accessories. In

case of any malfunction, you can contact authorized services of

HİSARLAR.

For possible problems, service and spare parts information, you can

contact the HİSARLAR Customer Service or its authorized services.

Check the pressure values

of the fire tubes at specific

time intervals.

Check the report book held

for the device at specific

time intervals.

Check the report book held

for the device at specific

time intervals.

14

1.4 Semboller

DANGER

»Danger Text

Used to describe situations that may cause serious damage and

loss of lives if not followed

WARNING

»Warning Text

It is used to describe situations where damage may occur if attention

is not paid.

OPTION

»Optional Feature

This symbol is used for features not found in all machines (model

differences, models specific to a particular country, optional

equipment).

INFORMATION

»Informational Text

Used to tell important additional information related to the subject.

»Environmental Safety Text

Used to describe situations that may cause harm to the environment

in case of failure to comply with the stated rules.

ENVIRONMENTAL SAFETY

MECHANICAL MAINTENANCE AND REPAIR

»Mechanical Maintenance and Repair

It is used to describe that the described maintenance and repair

work must be carried out by a mechanical technician.

SAFETY INFORMATION

The use of warning signs in

the manual in accordance

with warnings, signs and

texts increases the work

safety.

Silage Baler Packing Machine User Manual

15

HSR_SB1150_00TR

ELECTRICAL MAINTENANCE AND REPAIR

»Electrical Maintenance and Repair

It is used to describe that the described maintenance and repair

work must be carried out by an electrician

OPERATOR

»Do It Yourself

It is used to describe that the described maintenance, repair and

control work must be performed by the operator.

AUTHORIZED SERVICE

»Call the Service

It is used to describe that the HİSARLAR authorized service should

be called for the described maintenance, repair and control work.

CHECK WITH TOOLKIT

»Do with Toolkit

Used to describe that the described maintenance and control tasks

must be performed using standard toolkits.

ROTATING PART

»Rotating Part

Used to describe when moving and rotating parts can cause operator

damage.

HOT SURFACE

»Hot Surface

Some parts may heat up when your machine is operating. It is used to

describe the risk of burning in case of contact with these parts.

1.4.Symbols

SAFETY INFORMATION

16

1.4.Symbols

YÜKSEK SES

»Loud Noise

Used to describe situations when it is necessary to use ear protectors

for the noise generated during operation.

PROTECTIVE GOGGLES

»Wear Protective Goggles

Used to describe situations protective goggles should be used

against the broken or flying pieces coming from the material being

operated during the work.

PROTECTIVE GLOVES

»Wear protective gloves

Used to describe situations where protective gloves should be used

against accidents that may occur during operation.

1.5.Design Purpose of the Machine

SAFETY INFORMATION

The Silage Baler Wrapper Machine is designed to compress all kinds of minced soft organic

material in the best possible way, bring it to a bale form, and wrap it with stretch film and

pack in a way that it does not get air.

For the use of different materials, you need to obtain information from the HİSARLAR

Customer Service and confirm the accuracy of the material. Use of the machine for

non-design purposes may result in serious propert damage and / or serious injuries that

may result in death.

Silage Baler Packing Machine User Manual

17

HSR_SB1150_00TR

1.6.Warranty Liability

WARNING

»Warning Text

The Silage Baler Packing Machine, you purchased is warranted for

the conditions stated in this document on condition that the

principles specified in the user manual are followed.

Failures arising from machine use against the terms described in the

machine manual are not covered by the warranty.

All of the terms and conditions set forth in this document are

binding on other persons who take over the Machine as if they

were the first owner of the Machine. The person who takes over

the machine shall be deemed to have accepted this term.

SAFETY INFORMATION

In this section, the warranty conditions to be applied in HİSARLAR product machines

purchased, used or utilized for commercial and professional purposes except for the

consumers specified in the Law no. 6502.

1. Warranty period starts from the machine's delivery date and lasts for two years or when

40,000 bales are finished (whichever comes first).

2. Including all parts of the machine, whole machine is within the guarantee of our firm.

3. In the warranty period of the machine, repair will be carried out without any charge for

the cost of the workmanship, the part price changed or any other name in case of malfunc-

tion due to material and workmanship or assembly errors.

4. Failures arising from machine use against the terms described in the machine manual

are not covered by the warranty.

5. Warranty period starts when the customer signs the "Machine Delivery Form" indica-

ting stating that the Machine is complete, free of defects and that all of its functions are

working upon delivery of the customer and ends on conditions specified in Article 1.

6. Warranty is not covered by any loss or damage (including loss of profits, loss of workfor-

ce, loss due to not realizing or retardation of the expected business savings etc. and losses

under any other name) that the customer is directly or consequently suffered or affected

adversely.

18

1.7 Garanti Dışı Durumlar

WARRANTY INFORMATION

1. Any consumable material (filters, oils, liquids, light bulbs and all other consumab-

le materials similar thereto).

2. Additional maintenance and lubrication and periodic operations required from

the user.

3. Wear and tear due to normal usage (wear, tear and aging of all belts, light bulbs

and lighting, signaling equipment, tire parts and all similar equipment and parts).

4. Any maintenance and repair work resulted from accidents or misuse (including

not using the machine in accordance with the rules and / or User Manual, bad

road conditions, bad field conditions, negligence, accidents, external factors, and

failures arising from repair and / or modifications and / or alterations, additions

made by the purchaser which affect machine’s reliability and performance and

features specified in User Manual , defects that may occur due to insufficiency of

machine’s oil and other fluids and/or due to being different from those recommen-

ded, failure to use consumables recommended for the machine, etc.)

5. Using the machine in different ways and for different purposes other than the

purpose of the machine specified under the heading of "Machine Design Purpose"

6. Failures that arise as a result of the use of parts instead of the original and

equivalent spare parts in the maintenance and repair of the machine are not

covered by the warranty. If the machine owner does not perform periodical

maintenance and repair of the machine during the warranty period and as a result

the work is done it erroneously, the party performing the work and the customer

are responsible.

7. HİSARLAR is not liable for any defective material, warranty application, and / or

damage to other machine components of spare parts used, and material and legal

consequences due to the damage of these parts to the other components of the

machines resulting from the use of spare parts instead of original or equivalent

spare parts obtained from HİSARLAR.

8. In the cases listed above, the buyer can not demand the cancellation of the sales

agreement or the removal of the damage in any way.

Silage Baler Packing Machine User Manual

19

HSR_SB1150_00TR

1.8.Expiration of Warranty

1.9.Warranty Procedure

WARNING

»Garanti İşlemleri

The fact that the service personnel starts the warranty period on

machines that are under warranty period does not mean that the

repair work of the machine will be done under warranty.

As a result of the inspection made by the service staff, the decision

of whether or not the declared fault is covered by warranty is made

by the After-Sales Services department of HİSARLAR.

WARRANTY INFORMATION

1. Use of machine contrary to the instructions in the user manual,

2. Repair, modification or dismantling of the machine at service stations not

authorized by HİSARLAR.

3. Exceeding the load-capacity limit specified on the machine identification label.

4. Not performing periodic maintenance of the machine within the specified time

intervals.

5. Damage and / or alteration on descriptive numbers, letters, plates, labels, such

as the machine serial number indicated on the machine identification label.

6. The use of spare parts other than original and / or equivalent spare parts in the

machine other than supplied by HİSARLAR or damage to the other vehicle compo-

nents as a result of the use of such spare parts.

7. Operating machine for non-design purposes.

8. Not using the consumables recommended by the producer of the machine.

If your machine is experiencing a fault while the warranty is in progress, stop

the machine so that the fault does not grow any further. Communicate with the

authorized service of the HİSARLAR that provide service in your area and report

the fault.

The service staff will review your machine on site and fill out the "Warranty

Service Form" and will issue a copy of the form to you and start the warrantypro-

cedures.

20

1.10.Machine Delivery Form

WARRANTY INFORMATION

The Machine Delivery Form is a form signed by the customer in 3 copies after the

delivery of the machine to the customer. One of the form copies is delivered to the

customer. The second copy remains in the relevant seller. The third is kept at the

after-sales service department of HİSARLAR. The date on which the customer

signed the form is the date when the warranty period commenced.

SERVICE FORM

………..…..…. /……….…..…. /20………..….

Customer Name:

Product Name:

Product Range:

Serial Number:

Address:

Phone:

E-mail:

Sales Dealer:

Invoice Date:

Service Demand Date:

Service Date:

Service Type:

Malfunction

Maintenance

Commissioning

Service Technician:

Starting (Km): Finish (Km):

Starting (H): Finish (H):

CUSTOMER COMPLAINT /WORK COMPLAINT

OPERATIONS CARRIED OUT PART NO/PART

NAME

Number of pieces/

Unit anty

E/H

PRICE

PARTS TOTAL:

ROAD COST:

……………….……..km X

……………....……..TL/km

WORKMANSHIP

PRICE

…………….……..hour X

……………..……..TL/hour

OTHER COSTS:

GENERAL TOTAL

DETECTIONS/FINDINGS

Report written by / Signature Customer or

Official/

Signature

Approved by

/Signature

Company Official/

Detection

Warr

Signature

*I APPROVE the service operations to be done by you related to the machine The operations to be performed and the

spare parts to be used and other payments to be made outside the scope of the guarantee are to be PAID by me/us.

Silage Baler Packing Machine User Manual

Table of contents

Popular Farm Equipment manuals by other brands

New Holland

New Holland CX8080 Service manual

TERMET

TERMET MATADOR SUPER SECURIT 3000 instruction manual

Orion

Orion FDR1000300 Assembly manual

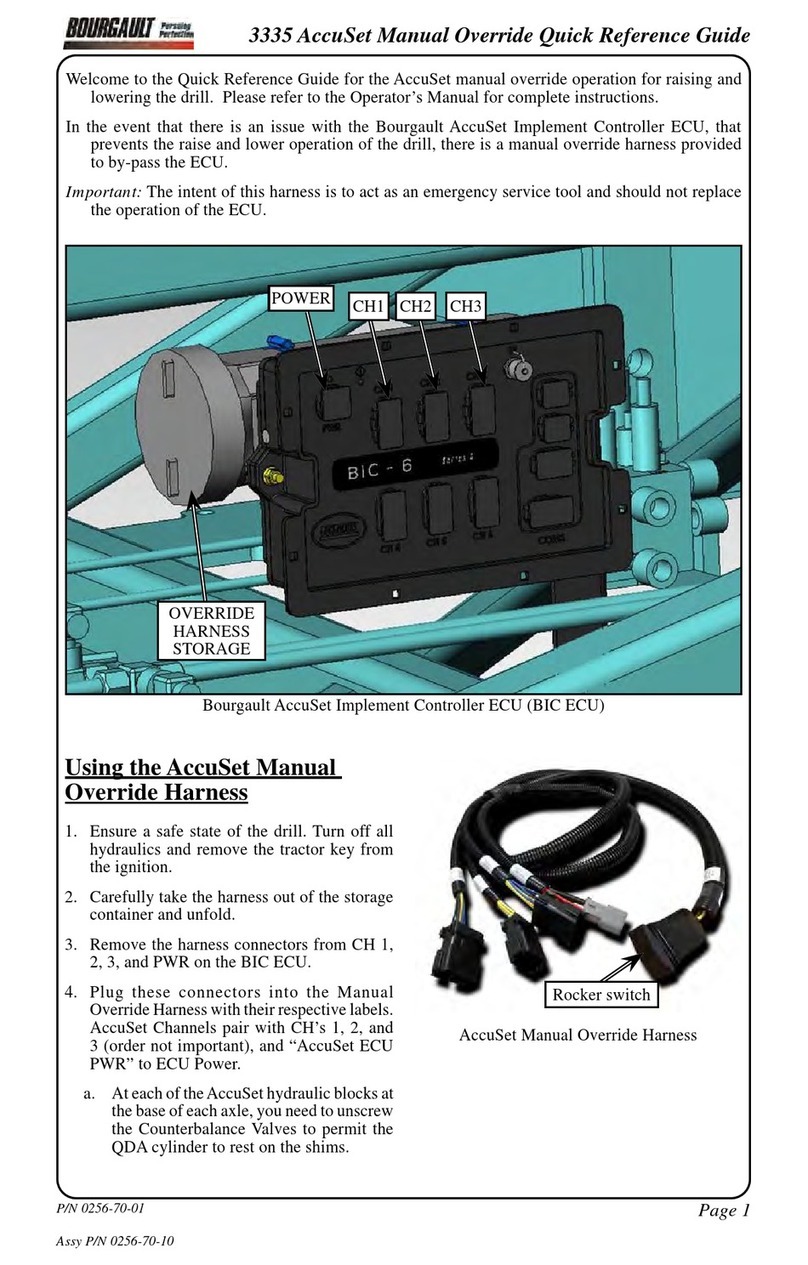

Bourgault

Bourgault AccuSet Quick reference guide

Hanskamp

Hanskamp FeedStation 42000 Installation and operating instruction

Jay-Lor

Jay-Lor 4000 TWIN AUGER Series Operator's manual

Pottinger

Pottinger NOVACAT 262 Operator's manual

HOMEBIOGAS

HOMEBIOGAS Farmer's system installation guide

HE-VA

HE-VA Sub-Tiller Series Operating Instructions, Declaration of Conformity, Spare Parts List

Raven

Raven VSN Operation manual

HANMEY

HANMEY Power Harrow instruction manual

Volac

Volac EWE2 operating instructions