Nordmann Engineering ES4 How to use

SHORT FORM INSTRUCTIONS

Steam air humidier

Nordmann ES4

2559454-A EN 1806

Thank you for choosing Nordmann

Installation date (MM/DD/YYYY):

Commissioning date (MM/DD/YYYY):

Site:

Model:

Serial number:

Proprietary Notice

This document and the information disclosed herein are proprietary data of Nordmann Engineering AG. Neither

this document, nor the information contained herein shall be reproduced, used, or disclosed to others without the

written authorisation of Nordmann Engineering AG, except to the extent required for installation or maintenance

of recipient's equipment.

Liability Notice

Nordmann Engineering AG does not accept any liability due to incorrect installation or operation of the equipment

or due to the use of parts/components/equipment that are not authorised by Nordmann Engineering AG.

Copyright Notice

© Nordmann Engineering AG, All rights reserved.

Technical modications reserved.

3

Contents

1 Introduction 4

2 Product Overview 5

2.1 Models overview 5

2.2 Identicationoftheunit 6

2.3 Steamhumidierconstruction 7

2.4 Humidicationsystemoverview 8

3 Installation overviews 10

4 Wiring diagram/Current data 12

4.1 WiringdiagramNordmannES4 12

4.2 Currentdata 13

5 Productspecications 14

5.1 Technicaldata 14

5.2 Unitdimensions 15

4

1 Introduction

The present short form instructions are a summary of the most important

information from the installation and operating instructions of the Nord-

mann ES4.

The present short form instructions do not replace the installation and

operating instructions of the Nordmann ES4. In either case the installation

and operating instructions of the Nordmann ES4 must be read before car-

rying out any work on the Nordmann ES4 and the information and safety

instructions in it must be followed and upheld.

5

2 Product Overview

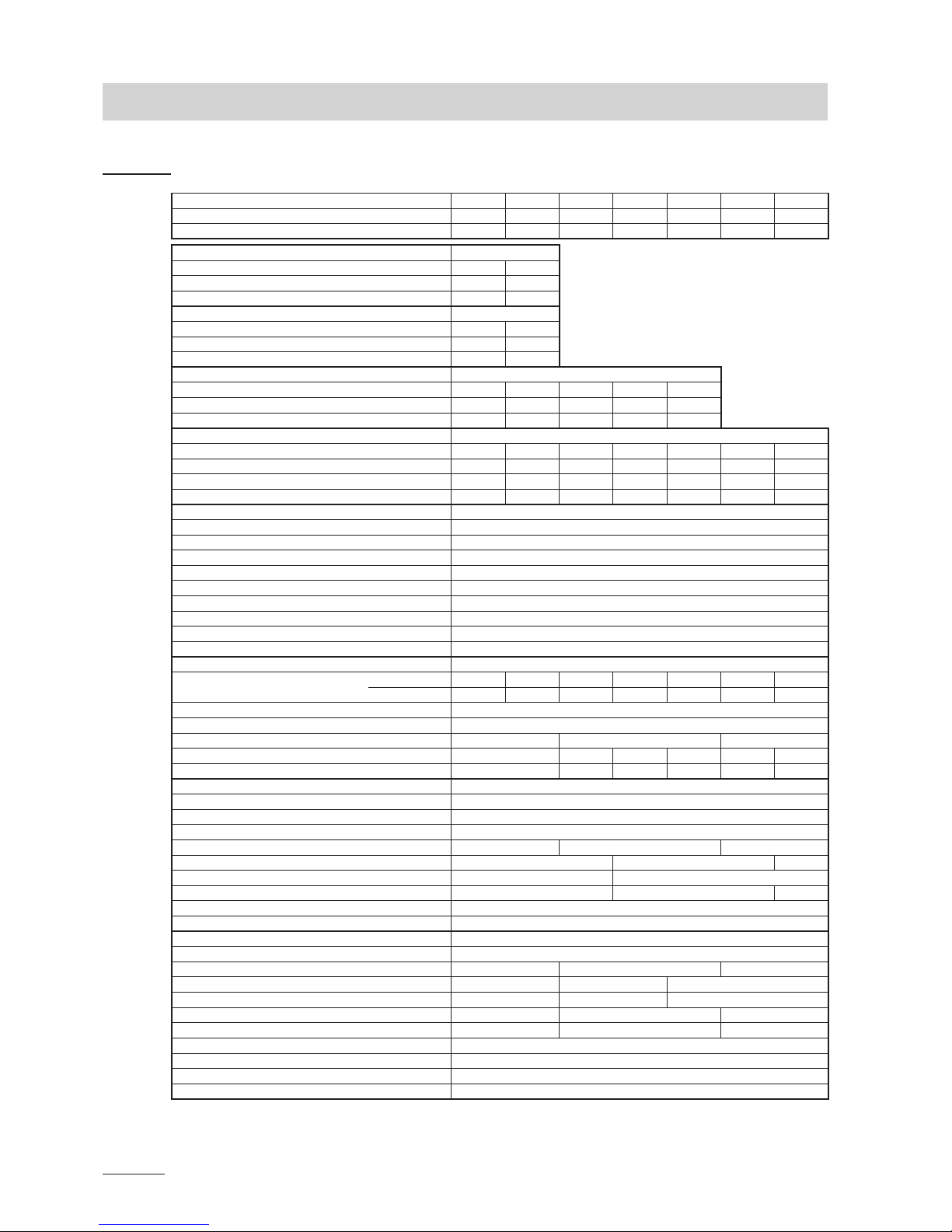

2.1 Models overview

Steam air humidiers Nordmann ES4 are available with different heating

voltages and steam capacities ranging from 5 kg/h up to a max. of

65 kg/h.

Heating voltage ** Max. steam capacity

in kg/h

Model

Nordmann ES4

Unit size

Unit small Unit large

400V3

(400 V/3~/50...60 Hz)

5 534 1

8 834 1

15 1534 1

23 2364 1

32 3264 1

45 4564 1

65 6564 1

400V2

(400 V/2~/50...60 Hz)

5 524 1

8 824 1

230V3

(230 V/3~/50...60 Hz)

5 532 1

8 832 1

15 1532 1

23 2362 1

32 3262 1

230V1

(230 V/1~/50...60 Hz)

5 522 1

8 822 1

** Other heating voltages on request

Key model designation

Example:

Nordmann ES4 4564 400V3

Product designation:

Unit model:

Heating voltage:

400V/3~/50...60Hz: 400V3

400V/2~/50...60Hz: 400V2

230V/3~/50...60Hz: 230V3

230V/1~/50...60Hz: 230V1

6

2.2 Identicationoftheunit

The identication of the unit is found on the type plate:

Nordmann Engineering AG, Talstrasse 35-37, 8808 Pfäfkon SZ, Switzerland

Type: ES4 4564 Ser.Nr.: XXXXXXX 02.10

Heating voltage: 400V / 3~ / 50...60Hz Power: 33.8 kW

Steam capacity: 45.0 kg/h Ctrl. Voltage: 230V / 1~ / 50...60Hz

Water pressure: 1...10 bar

Engineered in Switzerland, Made in Germany

Type designation Serial number (7 digits) Month/Year

Heating voltage

Maximum steam capacity per unit

Admissible water supply pressure

Power consumption

Control voltage

Field with certication symbols

7

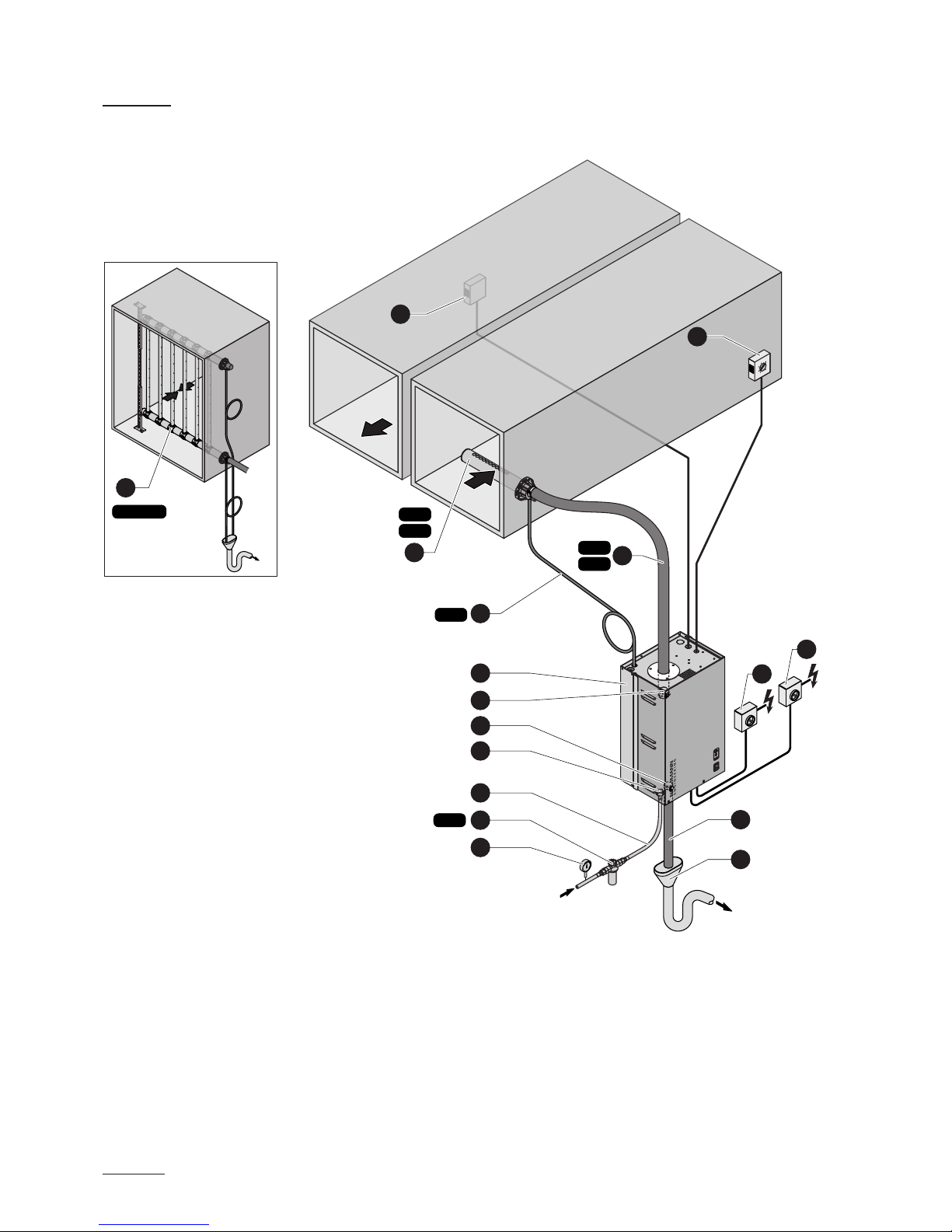

2.3 Steamhumidierconstruction

1 Housing (small, large)

2 Cable openings, top side

3 SC pump (option)

4 Main contactor

5 Power board

6 Terminals heating voltage (option)

7 Remote operating and fault

indication board (option)

8 Control board with ES4 Card

9 Power supply unit 24 V (option)

10 Drain/info key

11 Operation status indicators

12 Unit switch

13 Water cup

14 Filling hose

15 Water supply hose

16 Overow hose

17 Drain valve

18 Inlet valve

19 Water supply connector

20 Drain connector

21 Cable openings, bottom side

22 Type plate

23 Steam cylinder

24 Level sensor

25 Electrode plug

26 Steam outlet

gure shows small unit

3

2

1

4

5

6

7

9

12

11

10

8

19

20

21

23

24

25

26

22

13

15

18

17

14

16

8

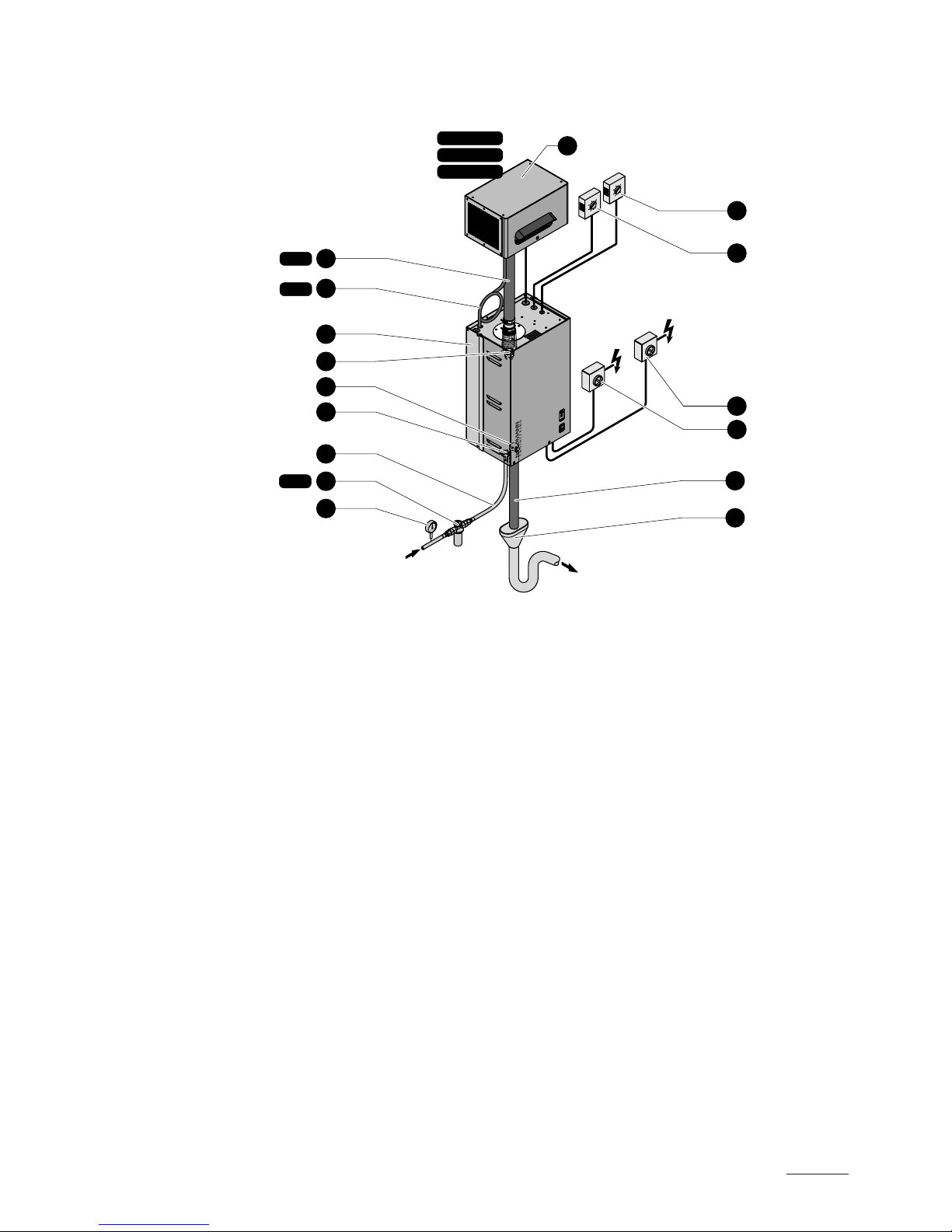

2.4 Humidicationsystemoverview

System overview duct humidication

1 Steam humidier

2 Steam connector

3 Water drain connector

4 Water supply connector

5 Water connection hose G 3/4"- G 3/8"

(included in the delivery)

6 Filter valve (accessory “Z261”)

7 Manometer (installation recommended)

8 Funnel with siphon (building side)

9 Water drain hose (included in the delivery)

10 Service switch control voltage supply (building side)

11 Service switch heating voltage supply (building side)

12 Steam hose (accessory “DS..”)

13 Condensate hose (accessory “KS10”)

14 Steam distribution pipe (accessory “DV41-

..”/“DV71-..”)

15 Steam distribution system (accessory “MultiPipe”)

16 Humidity controller 0-10V or Humidistat

17 Safety humidistat

125...1250 µS/cm

1...10 bar

1...40 °C

16

15

ONOFF

1

2

3

4

5

6

7

DS35

DS22

Z261

ONOFF

12

13

17

KS10

11

10

14

DV41

DV71

MultiPipe

8

9

9

System overview room humidication

125...1250 µS/cm

1...10 bar

1...40 °C

1 Steam humidier

2 Steam connector

3 Water drain connector

4 Water supply connector

5 Water connection hose G 3/4"- G 3/8"

(included in the delivery)

6 Filter valve (accessory “Z261”)

7 Manometer (installation recommended)

8 Funnel with siphon (building side)

9 Water drain hose (included in the delivery)

10 Service switch control voltage supply (building side)

11 Service switch heating voltage supply (building side)

12 Steam hose (accessory “DS..”)

13 Condensate hose (accessory “KS10”)

14 Ventilation unit (accessory “FAN4 N...”)

15 Humidity controller 0-10V or Humidistat

16 Safety humidistat

ONOFF

ONOFF

10

11

15

16

1

3

4

5

6

7

Z261

DS80

KS10 13

12

FAN4 N S W

FAN4 N M W

FAN4 N L W

2

8

9

14

10

Control voltage

Heating voltage

On/Off-ControlContinuous control 0-10V

External safety chain

3 Installation overviews

Installation overview duct humidication

X3

L1 NSC1SC2

B3

max.

ES4

ekt.

CONT.SIGN

V+ IN GND

X1

+ –

0-10V

A1

CONT.SIGN

V+ IN GND

X1

On/Off

A2

On/Off Mode

JP1

On/Off Mode

JP1

ES4

ext.

ES4

ext.

Q3

230V/1

~/

50...60Hz

L1 N

F3

X3

L1 NSC1SC2

ES4

ext.

L1

Q2

K1

X0

F2

L1 L2 L3

L1 L2 L3

L1 L2 L3

400 V/3~/50..60 Hz

230 V/3~/50..60 Hz

Q2

F2

L1 N PE

PE

PE

230 V/1~/50..60 Hz

Q2

F2

L1 L2

400 V/2~/50..60 Hz

PE

ES4

ext.

≥ 40 mm

min. 50 cm

ONOFF

DS35

DS22

Z261

ONOFF

125...1250 µS/cm

1...10 bar

1...40 °C

ø14/7 mm

G 3/4"

G 1/2"

G 3/8"

Q2

Q3

B3

DV41

DV71

Pmin

1500 Pa

-800 Pa

Pmax

Rmin. 300 mm

Ømin.

200 mm

min. 300 mm

min. 300 mm

min. 20 %

–

KS10

min. 5 %–

min. 20 %

+

A1 / A2

ø 30 mm

11

Installation overview room humidication

Control voltage

Heating voltage

On/Off-ControlContinuous control 0-10V

External safety chain

X3

L1 NSC1SC2

B3

max.

ES4

ext.

CONT.SIGN

V+ IN GND

X1

+ –

0-10V

A1

CONT.SIGN

V+ IN GND

X1

On/Off

A2

On/Off Mode

JP1

On/Off Mode

JP1

ES4

ext.

ES4

ext.

L1

Q2

K1

X0

F2

L1 L2 L3

L1 L2 L3

L1 L2 L3

400 V/3~/50..60 Hz

230 V/3~/50..60 Hz

Q2

F2

L1 N PE

PE

PE

230 V/1~/50..60 Hz

Q2

F2

L1 L2

400 V/2~/50..60 Hz

PE

ES4

ext.

X3

L1 NSC1SC2

ES4

ext.

Q3

L1 N

F3

FAN4 N...

L1 N

ONOFF

ONOFF

FAN4 N S W

FAN4 N M W

FAN4 N L W

Q2

Q3

Z261

125...1250 µS/cm

1...10 bar

1...40 °C

ø14/7 mm

≥ 40 mm

G 3/4"

G 1/2"

G 3/8"

min. 50 cm

Ømin.

100 mm

A1 / A2

B3

ø 30 mm

DS80

KS10

12

4.1 Wiring diagram Nordmann ES4

A1 Continuous controller (active 0-10V)

A2 On/Off controller (passive 24VDC), set jumper on JP1

A3 On/Off control (active 230VAC)

B1 Ventilation interlock

B2 Airow monitor

B3 Safety humidistat

F1 Internal fuse power board (6.3 A, slow acting)

F2 External fuse heating voltage supply

F3 External fuse control voltage supply

F4 External fuse 230V On/Off control

H1 Remote operating and fault indication (option “RFI”)

J Short circuited, if no external monitoring devices are connected

JP1 Jumper On/Off mode

K External safety chain (230V/5A)

K1 Main contactor (for connecting the heating voltage supply to the unit)

M Fan unit FAN4.../Turbo...

Q2 External service switch heating voltage supply

Q3 External service switch control voltage supply

S1 Rotary switch "Cylinder type”

S2 Potentiometer “Drain factor”

S3 Potentiometer “Power limitation”

S4 DIP switch “General unit settings”

X0 Connection terminal heating voltage (option THV)

X1 Connection terminal control signal

X2 Connection terminal On/Off control active

X3 Connection terminal control voltage

Control board Power board

ES4 Card

red yellow green

F1

(6.3 AT)

CONT.SIGN

V+ IN GND

X2 X3

VD

MAIN SUPPLY

L1 NSC1SC2

LEV.SENSOR

Driver board

CPU board

J1

X1

CURRENT SENSOR

CPU BOARD

1 2

On/Off

JP1 must be plugged

B3

K

B2

B1

J

Q3

230 V/1~/50..60 Hz

L1 N

F3

On/Off Mode

JP1

+ –

0-10V

A1

H1

A2

A3

F4

230V

L1’

1 2 3 4 5 6 7 8 9 10

Error Service Steam Unit On

Cylinder

Drain Factor

Power Limit

Manual Drain

Low Conduct.

Standby Drain

Force Drain

Cylinder A/D

GFCI-Mode

Offset

Settings

0

DriverRFI

ON

1 2 3 4 5 6

J8

J1

V+ IN GND

X5

X7

X8

X4

1 2 3 4

SWITCH

1 2 3 4

INLET

1 2

CONTACTORDRAIN

∆p

max.

M

L1 N

PE

S1

S2

S3

S4

L1

Q2

K1

X0

F2

L1 L2 L3

L1 L2 L3

L1 L2 L3

400 V/3~/50..60 Hz

230 V/3~/50..60 Hz

Q2

F2

L1 N PE

PE

PE

230 V/1~/50..60 Hz

Q2

F2

L1 L2

400 V/2~/50..60 Hz

PE

ES4

ext.

4 Wiring diagram/Current data

13

4.2 Current data

Heating voltage Max. steam

capacity

[kg/h]

Nordmann

ES4 ..

Nominal power

[kW]

Nominal

current

[A]

Main fuses F2

[A]

400V3

(400 V/3~/50...60 Hz)

5 534 3.8 5.4 3x 10

8 834 6.0 8.7 3x 16

15 1534 11.3 16.2 3x 20

23 2364 17.3 24.9 3x 35

32 3264 24.0 34.6 3x 50

45 4564 33.8 48.7 3x 63

65 6564 48.8 70.4 3x 100

400V2

(400 V/2~/50...60 Hz)

5 524 3.8 9.4 2x 16

8 824 6.0 15.1 2x 20

230V3

(230 V/3~/50...60 Hz)

5 532 3.8 9.4 3x 16

8 832 6.0 15.1 3x 20

15 1532 11.3 28.2 3x 35

23 2362 17.3 43.3 3x 63

32 3262 24.0 60.2 3x 80

230V1

(230V/1~/50...60Hz)

5 522 3.8 16.3 25

8 822 6.0 26.1 35

14

5 Productspecications

5.1 Technicaldata

Steam capacity in kg/h 5 8 15 23 32 45 65

Capacity range in kg/h 1...5 1.6...8 3...15 4,6...23 6,4...32 9...45 13...65

Nominal power in kW 3,8 6,0 11,3 17,3 24,0 33,8 48,8

Heating voltage 230V/1~/50..60Hz *

Unit model 522 822

Nominal current in A 16,3 26,1

Steam cylinder type ** 522A 822A

Heating voltage 400V/2~/50..60Hz *

Unit model 524 824

Nominal current in A 9,4 15,0

Steam cylinder type ** 524A 824A

Heating voltage 230V/3~/50..60Hz *

Unit model 532 832 1532 2362 3262

Nominal current in A 9,4 15,1 28,2 43,3 60,2

Steam cylinder type ** 532A 832A 1532A 2362A 3262A

Heating voltage 400V/3~/50..60Hz *

Unit model 534 834 1534 2364 3264 4564 6564

Nominal current in A 5,4 8,7 16,2 24,9 34,6 48,7 70,4

Steam cylinder type ** 534A 834A 1534A 2364A 3264A 4564A 6564A

Steam cylinder type *** 534A-L 834A-L 1534A-L 2364A-L 3264A-L 4564A-L ---

Control voltage 1 x 230V / 50-60 Hz

Operating conditions

Admissible water pressure 1...10 bar

Water quality Untreated drinking water with a conductivity of 125...1250 µS/cm

Admissible water temperature 1...40 °C

Admissible ambient temperature 1...40 °C

Admissible ambient humidity max. 75% rh (non condensing)

Admissible duct air pressure -0.8 kPa...1.5 kPa; overpressure kit (option) up to 10.0 kPa

Type of protection IP 20

Conformity CE, VDE, GOST

Dimensions/Weights

Housing (WxHxD) in mm 377x612x279 1 1 1

492x670x351 1 1 1 1

Water supply connector G 3/4" (outside thread)

Water drain connector ø 30 mm

Steam connector 1 x ø 22 mm 1 x ø 35 mm 2 x ø 35 mm

Net weight in kg 19 19 28 28 28 28

Operating weight in kg 24 30 65 65 65 65

Options

Cable gland 1xCG

Overpressure set 1xOPS

Remote operating and fault indication 1xRFI

Steam hose connector with condensate trap 1xCT22 1xCT35 2xCT35

Internal control voltage supply 1xS-CVI 1xM-CVI 1xL-CVI

Transformer (400 V/230 V) 1xM-Trafo 1xL-Trafo

Terminals heating voltage 1xS-THV 1xM-THV 1xL-THV

SC pump 1xSC

24 VDC power supply 1x24VDC

Accessories

Filter valve Z261

Steam distribution pipe 1x DV41-... 1x DV71-... 2x DV71-...

Steam distribution system MultiPipe ––– 1xSystem 1 1xSystem 2

Fan unit 1xFAN4 N S W 1xFAN4 N M W 1xFAN4 N L W

Steam hose / meter 1xDS22 1xDS35 2xDS35

EcoTherm insulation hose 1xECT22 1xECT60 2xECT60

Condensate hose / meter KS10

Duct humidistat 1xHBC

Room humidistat 1xHSC

All-waether protective housing Layout according to the separate data sheet

* Other heating voltages on request

** Steam cylinder for water conductivity from 125 to 1250 µS/cm (standard version)

*** Steam cylinder for low water conductivity from 80 to 125 µS/cm

15

5.2 Unit dimensions

Nordmann ES4 5/8/15 (dimensions in mm)

187

127

176

65

ø30

377

61269

279

144

130

61

120 120

189

490

16

Nordmann ES4 23/32/45/65 (Dimensions in mm)

ø30

492

670

69

351 246

180 180

50

547

223

163

118

229

180

182

Nordmann Engineering AG

Lindenhofstrasse 28, 4052 Basel, Switzerland

Phone +41 61 404 46 50, Fax +41 61 404 46 79

www.nordmann-engineering.com,

CH94/0002.01

Table of contents

Other Nordmann Engineering Humidifier manuals

Nordmann Engineering

Nordmann Engineering Omega Pro User manual

Nordmann Engineering

Nordmann Engineering MinAir User manual

Nordmann Engineering

Nordmann Engineering AT4 Quick setup guide

Nordmann Engineering

Nordmann Engineering AT4 User manual

Nordmann Engineering

Nordmann Engineering Omega Pro Series User manual

Nordmann Engineering

Nordmann Engineering Omega Pro User manual

Nordmann Engineering

Nordmann Engineering AT4 User manual