Nordmann Engineering AT4 Quick setup guide

INTEGRATION INSTRUCTIONS FOR NORDMANN AT4

NORDMANN

ENGINEERING

NORDMANN

ENGINEERING

Dampfluftbefeuchter econoVap

Building Management Integration

2559067 EN 1304

@Link

3

Contents

1 Notes for the planning engineer 4

1.1 Overview 4

1.2 Network diagrams 4

1.2.1 BACnet/IP network 5

1.2.2 LonWorks network 5

2 Wiring 6

2.1 Wiring diagram for BACnet/IP 6

2.2 Wiring diagram for LonWorks 7

3 Conguration 8

3.1 ConguringtheNordmannAT4contolunit 8

3.2 Gatewayconguration 9

3.2.1 SettingtheIPaddressandsubnetmask 9

3.2.2 ModifyingtheBACnetNodeID 11

4 Communicationtables 13

4.1 Modbusdataregistertable 13

4.2 Conversiontablesgatewayvariables 15

Ordering form 23

4

1 Notes for the planning engineer

1.1 Overview

The @Link option allows the integration of Nordmann AT4 humidiers into

a BACnet/IP or a LonWorks network. The @Link option features a serial-

interface Gateway which converts the information from the host Modbus

protocol to a specied secondary protocol.

The following protocol options are available and must be specied when

ordering (ordering form see page 23):

Part Number Protocols Part Description

2559069 BACnet/IP BMS AT4 Master set for BACnet /IP

2559070 LonWorks BMS AT4 Master set for LonWorks

2559071 BMS AT4 Slave set for successive units

The following read out and settings functions are available:

Functions AT4

Read out of unit status (operating mode, etc.) X

Read out of service messages X

Read out of analog (%) and sensor (%rh) demand X

Read out of unit type X

Read out actual system request X

Demand signal (%) / sensor signal (%rh) X

Setting the power limitation X

Setting the humidity setpoint (%rh / internal controller) X

Setting the proportional range X

Setting the integral time X

1.2 Network diagrams

It is possible to link up a maximum of 8 units via a single ProtoCessor

Gateway to a building management system. The ProtoCessor Gateway is

connected to the lead unit. All other units (up to a maximum of 8) are daisy-

chained via the NetworkLink terminals.

Since each unit can be separately addressed, it is possible to monitor and

control each unit individually. Different network congurations may be achieved

and are mostly dependant on the type of network present at the site.

5

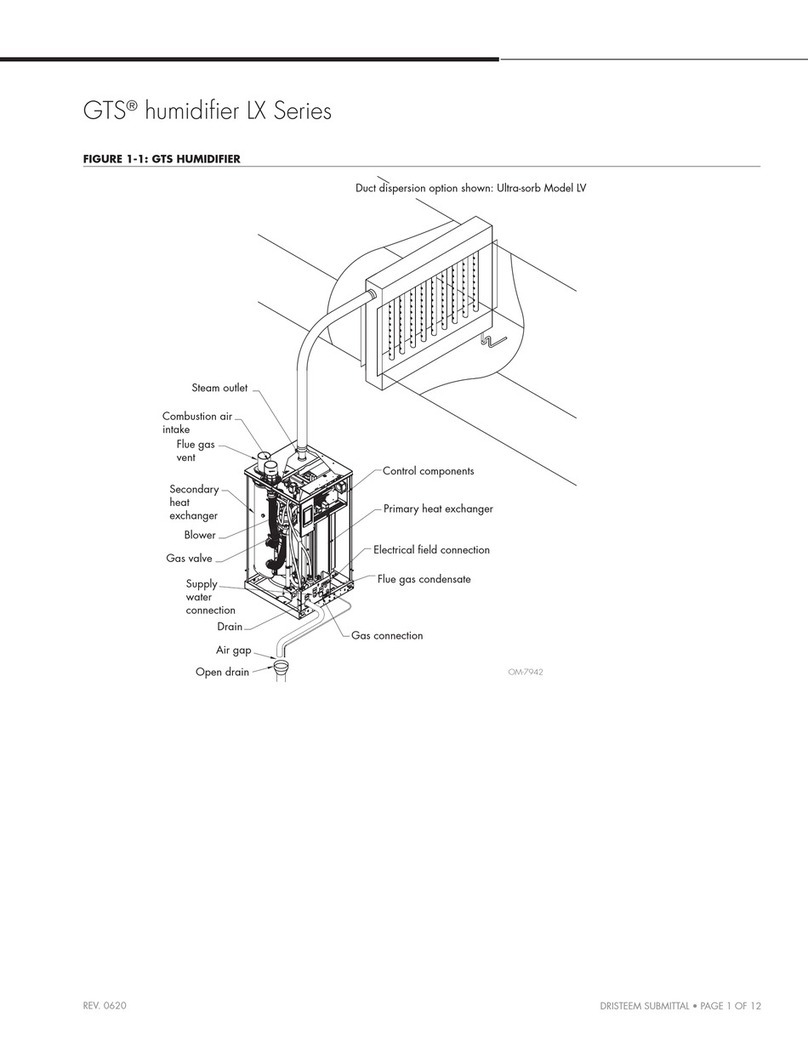

1.2.1 BACnet/IP network

The diagram below shows the connection of a series of Nordmann AT4

units to an Ethernet network. This is only possible for BACnet and is es-

sentially referred to as a BACnet/IP conguration. Please see chapter 2.1

for additional details.

AT4 / 4...8

AT4 / 4...8

Ethernet (BACnet/IP)

Gateway

(connected to leading unit)

LonWorks

Router LonWorks

Device

LonWorks

Device

LonWorks

Device

Network via shielded twisted-pair cable

Gateway

(connected to leading unit)

AT4 / 1

AT4 / 1

AT4 / 2

AT4 / 2

AT4 / 3

AT4 / 3

1.2.2 LonWorks network

This diagram below shows the connection of a series of Nordmann

AT4 units to a LonWorks network via a shielded, twisted-pair

cable. Please see chapter 2.2 for additional details.

6

2 Wiring

The internal wiring and the installation of the Gateway option in the lead-

ing unit as well as the internal wiring of the successive units are made at

the factory. On site only the gateway must be connected to the network

(BACnet/IP or LonWorks) and the successive units must be daisy-chained

via the NetworkLink terminals using two-wire cables (see corresponding

wiring diagrams).

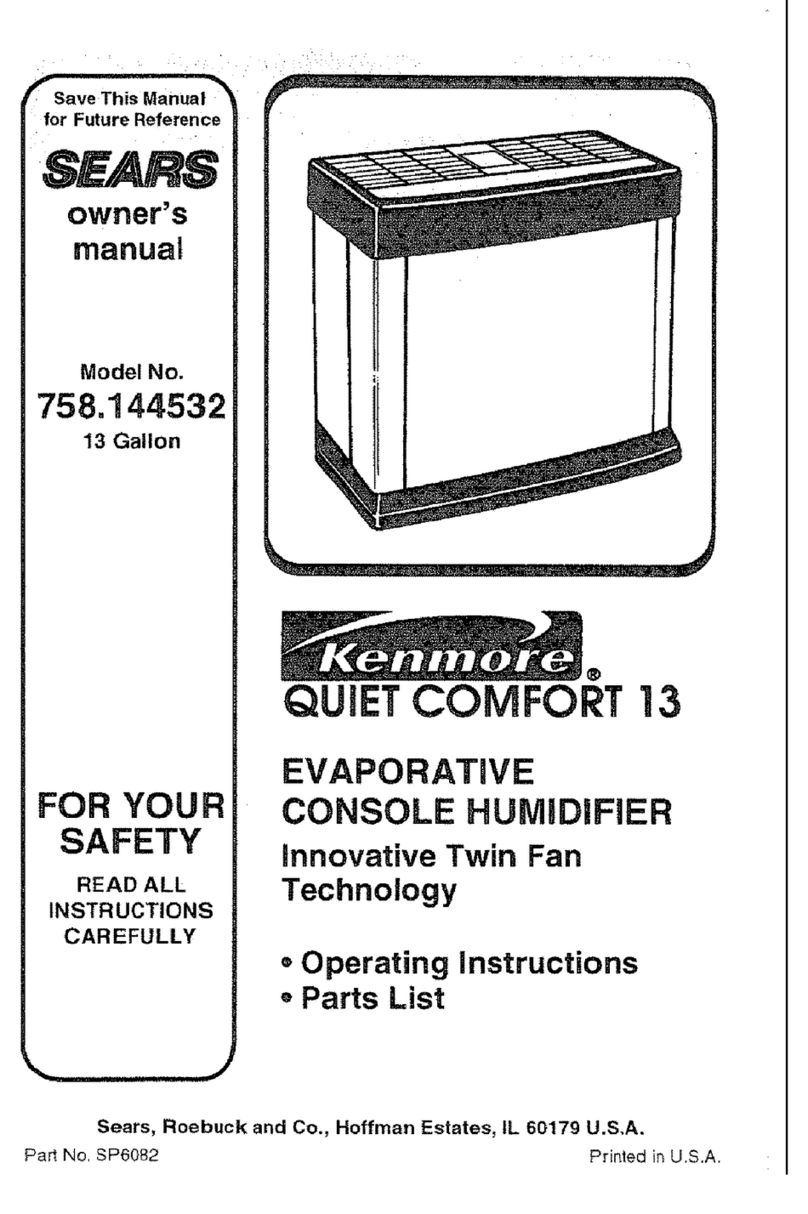

2.1 Wiring diagram for BACnet/IP

+

–

Net +

Net –

L1 N PE

RJ45 RJ45

D0

D1

D0

D1 D0

D1

RJ45

**

****

to network

external

internal

AT4 / Unit 1

(leading unit) RJ45 Bus cable / Ethernet

24 V DC/AC

power supply

NetworkLink

AT4 / Unit 2 AT4 / Unit 3

NetworkLink NetworkLink

The successive units must be connected to the net-

work by daisy-chain via the NetworkLink terminals! max. 50 m

Blue (Pin 5)

Blue (Pin 5)

Blue (Pin 5)

White (Pin 4)

White (Pin 4)

White (Pin 4)

** Termination of the bus system: to ensure the correct function the bus system must be terminated on both ends. For that purpose a jumper must be set on

the connector “JP1-RS 485 Termination” on the control board of the rst and the last Nordmann AT4 unit in the bus system. On all intermediate Nordmann

AT4 units the corresponding jumper must be removed (see above diagram).

7

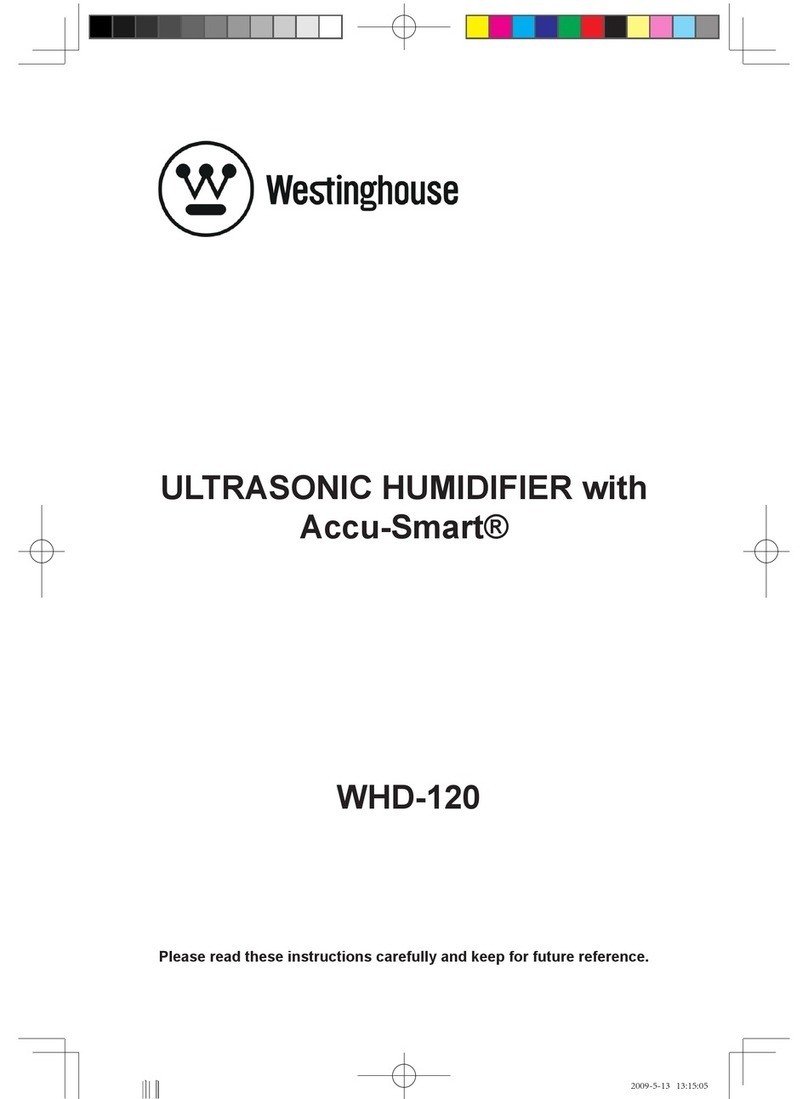

Net +

Net –

–

+

RJ45 RJ45 RJ45

D0

D1

D0

D1 D0

D1

+

–

L1 N PE

**

****

to network (via shielded twisted-pair cable)

external

internal

AT4 / Unit 1

(leading unit)

24 V DC/AC

power supply

NetworkLink

AT4 / Unit 2 AT4 / Unit 3

NetworkLink NetworkLink

The successive units must be connected to the net-

work by daisy-chain via the NetworkLink terminals! max. 50 m

Blue (Pin 5)

Blue (Pin 5)

Blue (Pin 5)

White (Pin 4)

White (Pin 4)

White (Pin 4)

2.2 Wiring diagram for LonWorks

** Termination of the bus system: to ensure the correct function the bus system must be terminated on both ends. For that purpose a jumper must be set on

the connector “JP1-RS 485 Termination” on the control board of the rst and the last Nordmann AT4 unit in the bus system. On all intermediate Nordmann

AT4 units the corresponding jumper must be removed (see above diagram).

8

3 Conguration

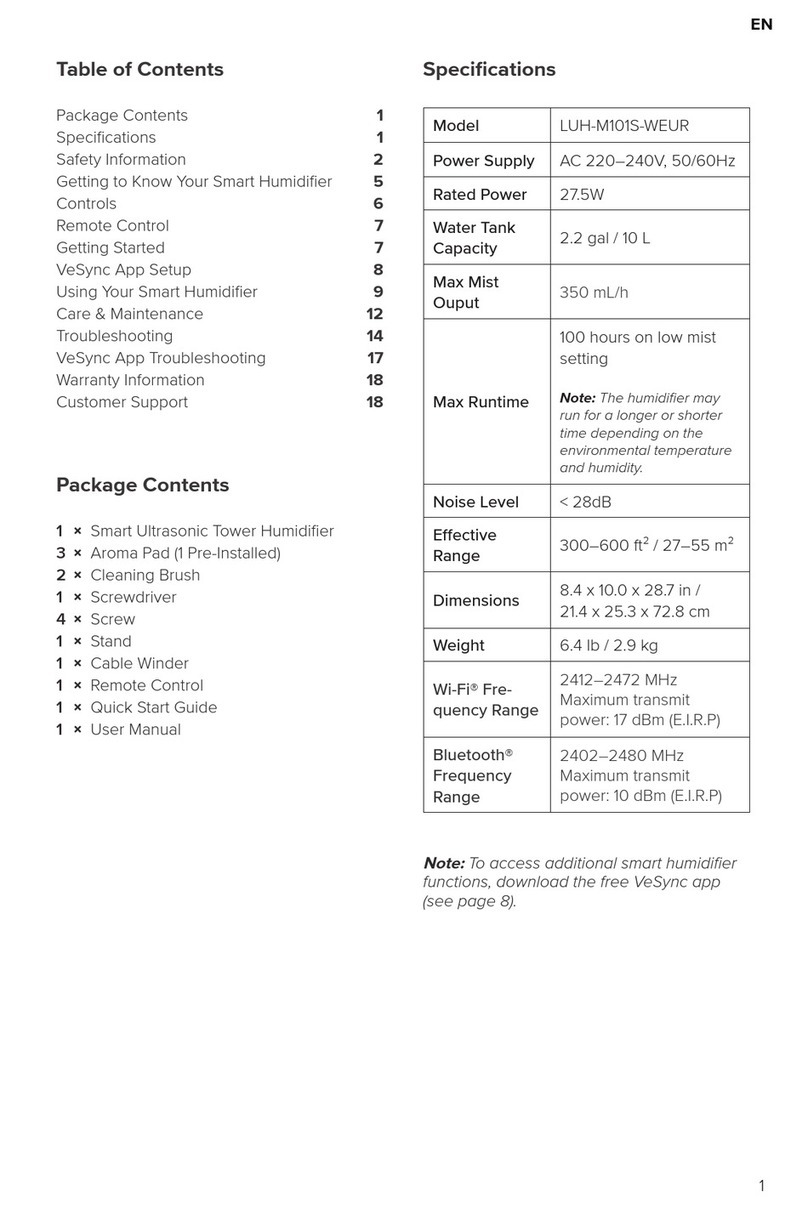

3.1 ConguringtheNordmannAT4contolunit

The settings described below must be congured on each Nordmann AT4 unit (see Nordmann AT4

operating instructions regarding the operation of the control software):

1. Modbus settings

Select the Modbus menu, Path:

Mainmenu>User>Passwordentry:3562>Modbus>Networking

Set Modbus parameters as follows:

Modbus Adr.: desired Modbus address (range: 1...247)

Important: make sure the Modbus address for each unit is unique!

Parity: None1 (no parity, 1 Stop bit)

The following Modbus parameters of the Nordmann AT4 can not be adjusted and are set to the follow-

ing values:

– 9600 baud

– 1 start bit

– 8 data bits

2. Select the signal source

Select the control settings menu, Path:

Mainmenu>User>Passwordentry:3562>Settings>Controls

Select the parameter “SignalSource” and set it to Modbus.

Networking

Parity :None1

Modus Adr. :1

Esc Set

Controls

Timeout :5s

Hum.Control :External

Lim. Control:On

SignalSource:Modbus

Esc Set

User Code

3562

Enter Number

Conrm with Set

Esc Set

Main Menu

Engineering :Set

Diagnostic :Set

User :Set

Esc Set

User

Settings :Set

Modbus :Set

Maintenance :Set

Esc Set

Modbus

Remote :Set

Networking :Set

Esc Set

Menu

AT4 130kg/h 400V3

Standby

2011-02-15 12.00.00

User Code

3562

Enter Number

Conrm with Set

Esc Set

Main Menu

Engineering :Set

Diagnostic :Set

User :Set

Esc Set

User

Settings :Set

Modbus :Set

Maintenance :Set

Esc Set

Settings

Controls :Set

Cylinder :6564

SC-System :Set

Language :English

Power Limit :Set

Esc Set

Menu

AT4 130kg/h 400V3

Standby

2011-02-15 12.00.00

9

3.2 Gatewayconguration

The protocol conguration is made at the factory, prior to nal testing.

The baud rates are adjusted to the following values:

Protocol Baud rate

BACnet/IP 10 / 100 BaseT

LonWorks 78125 bps

3.2.1 SettingtheIPaddressandsubnetmask

For BACnet/IP and LonWorks application, an IP address and the subnet

mask must be assigned to the gateway in order to access it. The IP ad-

dress and subnet mask may be assigned at the factory or can be modied

at any time via the integrated FieldServer GUI (Graphic User Interface) of

the ProtoCessor.

To congure the IP address and the subnet mask via the integrated Field-

Server GUI of the ProtoCessor proceed as follows:

1. Connect the ProtoCessor gateway to a PC using an Ethernet cross-

over cable or directly to the network using a straight cable.

2. The default IPaddress of the ProtoCessor Gateway is set to 10.232.72.172,

Subnet Mask is 255.255.0.0.

Make sure your PCis in the same IP network as the ProtoCessor Gate-

way; otherwise assign a static IP address to your PCon the 10.232.72.0

network.

3. Power up the ProtoCessor Gateway.

4. Open your internet browser and enter the IP address of the gateway

(by default ex factory 10.232.72.172), then conrm the entry with the

Enter key.

10

5. The FieldServer GUI will be started.

6. Select the menu point “Setup > Network Settings” in the “Navigation

Tree”. Enter the appropriate IP-Address and subnetmask. To activate

the new settings, click rst on the button <Update IP settings> and then

on the button <System Restart>. After restart the gateway is congured

to the new IP address and subnetmask.

7. In order to access the ProtoCessor gateway, the IP address of your

laptop must be set to the same network as the ProtoCessor.

11

3.2.2 ModifyingtheBACnetNodeID

1. Enter the (new) IP address of the gateway in your internet browser and

conrm the entry with the Enter key. The FieldServer GUI will be started.

2. Select the menu point “Setup > File Transfer” in the “Navigation Tree”.

Then, click in the “Retrieve” section on the link “cong.csv” and save

the conguration le to the desired loaction on your laptop.

3. Open the conguration le “cong.csv” with a text editor, change in the

section “Server Side Nodes” of the window the Node ID to the appro-

priate value and save the conguration le.

12

4. Select the menu point “Setup > File Transfer” in the “Navigation Tree”.

Click in the “Update” section on the button <Browse...> and select the

conguration le you have modied. Then, click on the button <Submit>

in order to upload conguration le into the ProtoCessor.

As soon as the upload is nished a corresponding message appears

in the upper part of the window. Click on the button <System Restart>

to restart the system with the new settings. After restart the Node IDis

changed to the new value.

13

4.1 Modbusdataregistertable

The following table shows the modbus data registers and their correspond-

ing gateway variables.

Note: the “_x” in the gateway variable name indicates the Modbus address

of the corresponding Nordmann AT4 unit.

Name Description Register Variable name

on Gateway

Read total capacity 0 – 130kg/h 30009

(8)

nvoTotSteamCap_x

Read actual steam capacity 0 – 130kg/h 30010

(9)

nvoSteaActTot_x

Read actual steam capacity A-cylinder 0 – 65kg/h 30011

(10)

nvoSteaActACyl_x

Read humidity or demand 0 – 100% 30012

(11)

nvoRHorDemand_x

Read total demand 0 – 100% 30014

(13)

nvoSteaReqTot_x

Read demand A-cylinder 0 – 100% 30015

(14)

nvoSteaReqACyl_x

Read system operating seconds low Indicates the number of seconds the

humidier has been in operating (0-

65535 sec)

30027

(26)

nvoOperatSec_x

Read system operating seconds high Indicates the number of seconds the

humidier has been in operating (multiply

by 65535 sec)

30028

(27)

Read operating hours/6 A-cylinder h/6 (10 min) 30100

(99)

nvoOpHour6ACyl_x

Read actual steam capacity B-cylinder 0 – 65kg/h 31011

(1010)

nvoSteaActBCyl_x

Read demand B-cylinder 0 – 100% 31015

(1014)

nvoSteaReqBCyl_x

Read operating hours/6 B-cylinder h/6 (10 min) 31100

(1099)

nvoOpHour6BCyl_x

Read controller set point 10 – 95%rH 40005

(4)

nvoSetPointHum_x

Write controller set point nviSetPointHum_x

Read controller proportional band 6 – 65% 40006

(5)

nvoProportBand_x

Write controller proportional band nviProportBand_x

Read controller integral time 0 – 60 minutes 40007

(6)

nvoIntegraTime_x

Write controller integral time nviIntegraTime_x

Read capacity limit 25 – 100% 40013

(12)

nvoCapaciLimit_x

Write capacity limit nviCapaciLimit_x

Read actual humidity value or request 0 – 100% (by Modbus) 40054

(53)

nvoRemRHorDem_x

Write actual humidity value or request nviRemRHorDem_x

4 Communicationtables

14

Name Description Register Variable name

on Gateway

Read info code 1: CF-Card Missing

2: CF-Card Empty

3: CF-Card Invalid

4: CF-Card Incompat

5: Modul-B Missing

6: Main Missing

7: Extended Error

8: Extended Incomp.

9: Illegal HW-Settings

10: Flash R/W Fault

11: Clock R/W Fault

12: Timer Disable

20: Safety Loop Open

21: Cyl.Max&NoCurr

22: Max.Filltime

23: No Current

24: Over Current

25: Excess Current

26: Req.Off Current

27: Foam

28: Cyl. Maintenance

29: Cyl. Maintenance

32: Hum.Sens.Broken

33: Lim.Sens.Broken

34: Modbus Disable

35: Modbus Time Out

36: Standby Drain

37: Forced Drain

30557

(556)

nvoInfoCode_x

Read info priority 0 = Warning

1 = Error

65535 = No Info

30558

(557)

nvoInfoPrio_x

Read service status 0 = no service required

1 = service required

30018

(17)

nvoServStatus_x

Read fault status 0 = no fault

1 = fault

30020

(19)

nvoFaultStatus_x

Read ll valve A-cylinder 0 = off

1 = on

30029

(28)

nvoFillValACyl_x

Read drain pump A-cylinder 0 = off

1 = on

30030

(29)

nvoDrainACyl_x

Read unit status 0 = standby

1 = humidifying

30033

(32)

nvoHumStatus_x

Read safety chain status 0 = open (not ok)

1 = closed (ok)

30301

(300)

nvoExtSChACSta_x

Read ll valve B-cylinder 0 = off

1 = on

31029

(1028)

nvoFillValBCyl_x

Read drain pump B-cylinder 0 = off

1 = on

31030

(1029)

nvoDrainBCyl_x

Registers 3xxxx: read with Modbus function 04

Registers 4xxxx: read with Modbus function 03 and write with Modbus function 06

15

4.2 Conversiontablesgatewayvariables

The following tables show the ProtoCessor gateway varibales and their

BACnet/IP and LonWorks equivalents.

Note: the number at the end of the gateway variables (e.g. “_1”) indicate

the unit number (Modbus number) of the corresponding Nordmann AT4. If

there is only one Nordmann AT4 humidier, all variable names will end in

“_1”. If two units are networked together, the second unit’s variable names

will end in “_2”. For three networked units,… “_3” and so on.

AT4 / Unit 1

ProtoCessor Gateway BACnet LonWorks

Variable Name Type Instance SNVT SNVT # NV Index Element

nvoTotSteamCap_1 AV 1 SNVT_count 8 1 1

nvoSteaActTot_1 AV 2 SNVT_count 8 2 1

nvoSteaActACyl_1 AV 3 SNVT_count 8 3 1

nvoRHorDemand_1 AV 4 SNVT_count 8 4 1

nvoSteaReqTot_1 AV 5 SNVT_count 8 5 1

nvoSteaReqACyl_1 AV 6 SNVT_count 8 6 1

nvoOperatSec_1 AV 7 SNVT_time_hour 124 7 1

nvoOpHour6ACyl_1 AV 8 SNVT_time_hour 124 8 1

nvoSteaActBCyl_1 AV 9 SNVT_count 8 9 1

nvoSteaReqBCyl_1 AV 10 SNVT_count 8 10 1

nvoOpHour6BCyl_1 AV 11 SNVT_time_hour 124 11 1

nvoSetPointHum_1 AV 12 SNVT_count 8 12 1

nviSetPointHum_1 AV 13 SNVT_count 8 13 1

nvoProportBand_1 AV 14 SNVT_count 8 14 1

nviProportBand_1 AV 15 SNVT_count 8 15 1

nvoIntegraTime_1 AV 16 SNVT_count 8 16 1

nviIntegraTime_1 AV 17 SNVT_count 8 17 1

nvoCapaciLimit_1 AV 18 SNVT_count 8 18 1

nviCapaciLimit_1 AV 19 SNVT_count 8 19 1

nvoRemRHorDem_1 AV 20 SNVT_count 8 20 1

nviRemRHorDem_1 AV 21 SNVT_count 8 21 1

nvoInfoCode_1 AV 22 SNVT_count 8 22 1

nvoInfoPrio_1 AV 23 SNVT_count 8 23 1

nvoServStatus_1 BV 1 SNVT_switch 95 51 1

nvoFaultStatus_1 BV 2 SNVT_switch 95 52 1

nvoFillValACyl_1 BV 3 SNVT_switch 95 53 1

nvoDrainACyl_1 BV 4 SNVT_switch 95 54 1

nvoHumStatus_1 BV 5 SNVT_switch 95 55 1

nvoExtSChACSta_1 BV 6 SNVT_switch 95 56 1

nvoFillValBCyl_1 BV 7 SNVT_switch 95 57 1

nvoDrainBCyl_1 BV 8 SNVT_switch 95 58 1

16

AT4 / Unit 2

ProtoCessor Gateway BACnet LonWorks

Variable Name Type Instance SNVT SNVT # NV Index Element

nvoTotSteamCap_2 AV 51 SNVT_count 8 101 1

nvoSteaActTot_2 AV 52 SNVT_count 8 102 1

nvoSteaActACyl_2 AV 53 SNVT_count 8 103 1

nvoRHorDemand_2 AV 54 SNVT_count 8 104 1

nvoSteaReqTot_2 AV 55 SNVT_count 8 105 1

nvoSteaReqACyl_2 AV 56 SNVT_count 8 106 1

nvoOperatSec_2 AV 57 SNVT_time_hour 124 107 1

nvoOpHour6ACyl_2 AV 58 SNVT_time_hour 124 108 1

nvoSteaActBCyl_2 AV 59 SNVT_count 8 109 1

nvoSteaReqBCyl_2 AV 60 SNVT_count 8 110 1

nvoOpHour6BCyl_2 AV 61 SNVT_time_hour 124 111 1

nvoSetPointHum_2 AV 62 SNVT_count 8 112 1

nviSetPointHum_2 AV 63 SNVT_count 8 113 1

nvoProportBand_2 AV 64 SNVT_count 8 114 1

nviProportBand_2 AV 65 SNVT_count 8 115 1

nvoIntegraTime_2 AV 66 SNVT_count 8 116 1

nviIntegraTime_2 AV 67 SNVT_count 8 117 1

nvoCapaciLimit_2 AV 68 SNVT_count 8 118 1

nviCapaciLimit_2 AV 69 SNVT_count 8 119 1

nvoRemRHorDem_2 AV 70 SNVT_count 8 120 1

nviRemRHorDem_2 AV 71 SNVT_count 8 121 1

nvoInfoCode_2 AV 72 SNVT_count 8 122 1

nvoInfoPrio_2 AV 73 SNVT_count 8 123 1

nvoServStatus_2 BV 51 SNVT_switch 95 151 1

nvoFaultStatus_2 BV 52 SNVT_switch 95 152 1

nvoFillValACyl_2 BV 53 SNVT_switch 95 153 1

nvoDrainACyl_2 BV 54 SNVT_switch 95 154 1

nvoHumStatus_2 BV 55 SNVT_switch 95 155 1

nvoExtSChACSta_2 BV 56 SNVT_switch 95 156 1

nvoFillValBCyl_2 BV 57 SNVT_switch 95 157 1

nvoDrainBCyl_2 BV 58 SNVT_switch 95 158 1

17

AT4 / Unit 3

ProtoCessor Gateway BACnet LonWorks

Variable Name Type Instance SNVT SNVT # NV Index Element

nvoTotSteamCap_3 AV 101 SNVT_count 8 201 1

nvoSteaActTot_3 AV 102 SNVT_count 8 202 1

nvoSteaActACyl_3 AV 103 SNVT_count 8 203 1

nvoRHorDemand_3 AV 104 SNVT_count 8 204 1

nvoSteaReqTot_3 AV 105 SNVT_count 8 205 1

nvoSteaReqACyl_3 AV 106 SNVT_count 8 206 1

nvoOperatSec_3 AV 107 SNVT_time_hour 124 207 1

nvoOpHour6ACyl_3 AV 108 SNVT_time_hour 124 208 1

nvoSteaActBCyl_3 AV 109 SNVT_count 8 209 1

nvoSteaReqBCyl_3 AV 110 SNVT_count 8 210 1

nvoOpHour6BCyl_3 AV 111 SNVT_time_hour 124 211 1

nvoSetPointHum_3 AV 112 SNVT_count 8 212 1

nviSetPointHum_3 AV 113 SNVT_count 8 213 1

nvoProportBand_3 AV 114 SNVT_count 8 214 1

nviProportBand_3 AV 115 SNVT_count 8 215 1

nvoIntegraTime_3 AV 116 SNVT_count 8 216 1

nviIntegraTime_3 AV 117 SNVT_count 8 217 1

nvoCapaciLimit_3 AV 118 SNVT_count 8 218 1

nviCapaciLimit_3 AV 119 SNVT_count 8 219 1

nvoRemRHorDem_3 AV 120 SNVT_count 8 220 1

nviRemRHorDem_3 AV 121 SNVT_count 8 221 1

nvoInfoCode_3 AV 122 SNVT_count 8 222 1

nvoInfoPrio_3 AV 123 SNVT_count 8 223 1

nvoServStatus_3 BV 101 SNVT_switch 95 251 1

nvoFaultStatus_3 BV 102 SNVT_switch 95 252 1

nvoFillValACyl_3 BV 103 SNVT_switch 95 253 1

nvoDrainACyl_3 BV 104 SNVT_switch 95 254 1

nvoHumStatus_3 BV 105 SNVT_switch 95 255 1

nvoExtSChACSta_3 BV 106 SNVT_switch 95 256 1

nvoFillValBCyl_3 BV 107 SNVT_switch 95 257 1

nvoDrainBCyl_3 BV 108 SNVT_switch 95 258 1

18

AT4 / Unit 4

ProtoCessor Gateway BACnet LonWorks

Variable Name Type Instance SNVT SNVT # NV Index Element

nvoTotSteamCap_4 AV 151 SNVT_count 8 301 1

nvoSteaActTot_4 AV 152 SNVT_count 8 302 1

nvoSteaActACyl_4 AV 153 SNVT_count 8 303 1

nvoRHorDemand_4 AV 154 SNVT_count 8 304 1

nvoSteaReqTot_4 AV 155 SNVT_count 8 305 1

nvoSteaReqACyl_4 AV 156 SNVT_count 8 306 1

nvoOperatSec_4 AV 157 SNVT_time_hour 124 307 1

nvoOpHour6ACyl_4 AV 158 SNVT_time_hour 124 308 1

nvoSteaActBCyl_4 AV 159 SNVT_count 8 309 1

nvoSteaReqBCyl_4 AV 160 SNVT_count 8 310 1

nvoOpHour6BCyl_4 AV 161 SNVT_time_hour 124 311 1

nvoSetPointHum_4 AV 162 SNVT_count 8 312 1

nviSetPointHum_4 AV 163 SNVT_count 8 313 1

nvoProportBand_4 AV 164 SNVT_count 8 314 1

nviProportBand_4 AV 165 SNVT_count 8 315 1

nvoIntegraTime_4 AV 166 SNVT_count 8 316 1

nviIntegraTime_4 AV 167 SNVT_count 8 317 1

nvoCapaciLimit_4 AV 168 SNVT_count 8 318 1

nviCapaciLimit_4 AV 169 SNVT_count 8 319 1

nvoRemRHorDem_4 AV 170 SNVT_count 8 320 1

nviRemRHorDem_4 AV 171 SNVT_count 8 321 1

nvoInfoCode_4 AV 172 SNVT_count 8 322 1

nvoInfoPrio_4 AV 173 SNVT_count 8 323 1

nvoServStatus_4 BV 151 SNVT_switch 95 351 1

nvoFaultStatus_4 BV 152 SNVT_switch 95 352 1

nvoFillValACyl_4 BV 153 SNVT_switch 95 353 1

nvoDrainACyl_4 BV 154 SNVT_switch 95 354 1

nvoHumStatus_4 BV 155 SNVT_switch 95 355 1

nvoExtSChACSta_4 BV 156 SNVT_switch 95 356 1

nvoFillValBCyl_4 BV 157 SNVT_switch 95 357 1

nvoDrainBCyl_4 BV 158 SNVT_switch 95 358 1

19

AT4 / Unit 5

ProtoCessor Gateway BACnet LonWorks

Variable Name Type Instance SNVT SNVT # NV Index Element

nvoTotSteamCap_5 AV 201 SNVT_count 8 401 1

nvoSteaActTot_5 AV 202 SNVT_count 8 402 1

nvoSteaActACyl_5 AV 203 SNVT_count 8 403 1

nvoRHorDemand_5 AV 204 SNVT_count 8 404 1

nvoSteaReqTot_5 AV 205 SNVT_count 8 405 1

nvoSteaReqACyl_5 AV 206 SNVT_count 8 406 1

nvoOperatSec_5 AV 207 SNVT_time_hour 124 407 1

nvoOpHour6ACyl_5 AV 208 SNVT_time_hour 124 408 1

nvoSteaActBCyl_5 AV 209 SNVT_count 8 409 1

nvoSteaReqBCyl_5 AV 210 SNVT_count 8 410 1

nvoOpHour6BCyl_5 AV 211 SNVT_time_hour 124 411 1

nvoSetPointHum_5 AV 212 SNVT_count 8 412 1

nviSetPointHum_5 AV 213 SNVT_count 8 413 1

nvoProportBand_5 AV 214 SNVT_count 8 414 1

nviProportBand_5 AV 215 SNVT_count 8 415 1

nvoIntegraTime_5 AV 216 SNVT_count 8 416 1

nviIntegraTime_5 AV 217 SNVT_count 8 417 1

nvoCapaciLimit_5 AV 218 SNVT_count 8 418 1

nviCapaciLimit_5 AV 219 SNVT_count 8 419 1

nvoRemRHorDem_5 AV 220 SNVT_count 8 420 1

nviRemRHorDem_5 AV 221 SNVT_count 8 421 1

nvoInfoCode_5 AV 222 SNVT_count 8 422 1

nvoInfoPrio_5 AV 223 SNVT_count 8 423 1

nvoServStatus_5 BV 201 SNVT_switch 95 451 1

nvoFaultStatus_5 BV 202 SNVT_switch 95 452 1

nvoFillValACyl_5 BV 203 SNVT_switch 95 453 1

nvoDrainACyl_5 BV 204 SNVT_switch 95 454 1

nvoHumStatus_5 BV 205 SNVT_switch 95 455 1

nvoExtSChACSta_5 BV 206 SNVT_switch 95 456 1

nvoFillValBCyl_5 BV 207 SNVT_switch 95 457 1

nvoDrainBCyl_5 BV 208 SNVT_switch 95 458 1

20

AT4 / Unit 6

ProtoCessor Gateway BACnet LonWorks

Variable Name Type Instance SNVT SNVT # NV Index Element

nvoTotSteamCap_6 AV 251 SNVT_count 8 501 1

nvoSteaActTot_6 AV 252 SNVT_count 8 502 1

nvoSteaActACyl_6 AV 253 SNVT_count 8 503 1

nvoRHorDemand_6 AV 254 SNVT_count 8 504 1

nvoSteaReqTot_6 AV 255 SNVT_count 8 505 1

nvoSteaReqACyl_6 AV 256 SNVT_count 8 506 1

nvoOperatSec_6 AV 257 SNVT_time_hour 124 507 1

nvoOpHour6ACyl_6 AV 258 SNVT_time_hour 124 508 1

nvoSteaActBCyl_6 AV 259 SNVT_count 8 509 1

nvoSteaReqBCyl_6 AV 260 SNVT_count 8 510 1

nvoOpHour6BCyl_6 AV 261 SNVT_time_hour 124 511 1

nvoSetPointHum_6 AV 262 SNVT_count 8 512 1

nviSetPointHum_6 AV 263 SNVT_count 8 513 1

nvoProportBand_6 AV 264 SNVT_count 8 514 1

nviProportBand_6 AV 265 SNVT_count 8 515 1

nvoIntegraTime_6 AV 266 SNVT_count 8 516 1

nviIntegraTime_6 AV 267 SNVT_count 8 517 1

nvoCapaciLimit_6 AV 268 SNVT_count 8 518 1

nviCapaciLimit_6 AV 269 SNVT_count 8 519 1

nvoRemRHorDem_6 AV 270 SNVT_count 8 520 1

nviRemRHorDem_6 AV 271 SNVT_count 8 521 1

nvoInfoCode_6 AV 272 SNVT_count 8 522 1

nvoInfoPrio_6 AV 273 SNVT_count 8 523 1

nvoServStatus_6 BV 251 SNVT_switch 95 551 1

nvoFaultStatus_6 BV 252 SNVT_switch 95 552 1

nvoFillValACyl_6 BV 253 SNVT_switch 95 553 1

nvoDrainACyl_6 BV 254 SNVT_switch 95 554 1

nvoHumStatus_6 BV 255 SNVT_switch 95 555 1

nvoExtSChACSta_6 BV 256 SNVT_switch 95 556 1

nvoFillValBCyl_6 BV 257 SNVT_switch 95 557 1

nvoDrainBCyl_6 BV 258 SNVT_switch 95 558 1

Other manuals for AT4

2

Table of contents

Other Nordmann Engineering Humidifier manuals

Nordmann Engineering

Nordmann Engineering Omega Pro User manual

Nordmann Engineering

Nordmann Engineering AT4 User manual

Nordmann Engineering

Nordmann Engineering AT4 User manual

Nordmann Engineering

Nordmann Engineering MinAir User manual

Nordmann Engineering

Nordmann Engineering Omega Pro Series User manual

Nordmann Engineering

Nordmann Engineering Omega Pro User manual

Nordmann Engineering

Nordmann Engineering ES4 How to use