Nordson EFD 7362738 User manual

™

Safety Enclosure for Automated Dispensing

Systems

Operating Manual

Electronic pdf les of Nordson EFD

manuals are also available at

www.nordsonefd.com

Safety Enclosure for Automated Dispensing Systems

2www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

You have selected a reliable, high-quality dispensing system safety enclosure from Nordson EFD, the

world leader in uid dispensing. Nordson EFD automated dispensing systems are designed specically

for industrial dispensing and will provide you with years of trouble-free, productive service.

This manual will help you maximize the usefulness of your automated dispensing system safety

enclosure.

Please spend a few minutes to become familiar with the controls and features. Follow our recommended

testing procedures. Review the helpful information we have included, which is based on more than

50years of industrial dispensing experience.

Most questions you will have are answered in this manual. However, if you need assistance, please do

not hesitate to contact EFD or your authorized EFD distributor. Detailed contact information is provided

on the last page of this document.

The Nordson EFD Pledge

Thank You!

You have just purchased the world’s nest precision dispensing equipment.

I want you to know that all of us at Nordson EFD value your business and will do everything in our power

to make you a satised customer.

If at any time you are not fully satised with our equipment or the support provided by your Nordson

EFD Product Application Specialist, please contact me personally at 800.556.3484 (US), 401.431.7000

I guarantee that we will resolve any problems to your satisfaction.

Thanks again for choosing Nordson EFD.

Srini Subramanian, General Manager

Srini Subramanian

3www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Safety Enclosure for Automated Dispensing Systems

Contents

Contents..........................................................................................................................................................................3

Introduction .....................................................................................................................................................................4

Nordson EFD Product Safety Statement ........................................................................................................................5

Halogenated Hydrocarbon Solvent Hazards ...............................................................................................................6

High Pressure Fluids....................................................................................................................................................6

Qualied Personnel......................................................................................................................................................6

Intended Use ...............................................................................................................................................................7

Regulations and Approvals..........................................................................................................................................7

Personal Safety............................................................................................................................................................7

Fire Safety....................................................................................................................................................................8

Preventive Maintenance ..............................................................................................................................................8

Important Disposable Component Safety Information ................................................................................................9

Action in the Event of a Malfunction............................................................................................................................9

Disposal .......................................................................................................................................................................9

Specications................................................................................................................................................................10

Operating Features........................................................................................................................................................10

Installation .....................................................................................................................................................................11

Unpack the System Components and Install the Feet ..............................................................................................11

(Vision Systems Only) Install the Monitor and Keyboard...........................................................................................11

Install the Robot in the Enclosure..............................................................................................................................12

Connect Cables .........................................................................................................................................................14

Install the Dispensing System and Reinstall the Panels ............................................................................................15

Connect Inputs / Outputs (Optional)..........................................................................................................................16

Initial Startup..............................................................................................................................................................17

Operation.......................................................................................................................................................................19

Starting the System ...................................................................................................................................................19

About the RUN/TEACH Switch..................................................................................................................................19

Running a Program....................................................................................................................................................20

Stopping the System (Emergency Stop)....................................................................................................................20

Resetting the System.................................................................................................................................................20

Service...........................................................................................................................................................................21

Part Numbers ................................................................................................................................................................21

Troubleshooting.............................................................................................................................................................22

Technical Data ...............................................................................................................................................................22

General Block Wiring Diagram (Standard and EU) ....................................................................................................22

Safety Enclosure I/O Terminal Block Pin Assignments..............................................................................................22

Safety Enclosure for Automated Dispensing Systems

4www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Introduction

This manual provides safety, installation, operation, service, and parts information for guarded safety

enclosures for all PROPlus, PRO, EV, E, and R Series automated dispensing systems. The safety

enclosure is shipped fully assembled in a large wooden crate, making installation and setup easy.

For installation in the European Union (EU) and areas with similar regulations, these CE-compliant

enclosures provide full compliance with EU Machinery Directive 2006/42/EC, essential for all production

requirements.

Nordson EFD safety enclosures easily integrate into existing production lines. Each enclosure features an

internal lockable electrical control box and integrated wireways that allow easy cable routing for faster,

safer setup. A safety light curtain at the front opening stops the dispensing cycle anytime an object

passes its sensing eld.

External controls, including START, EMERGENCY STOP, and RUN/TEACH, allow operators to control

the dispensing system from outside of the enclosure. An ergonomic, adjustable monitor bracket and

keyboard tray make it easy to program vision-guided systems at any height.

CE-compliant safety enclosure with an installed automated

dispensing system (EV Series system and standard safety

enclosure shown)

5www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Safety Enclosure for Automated Dispensing Systems

Nordson EFD Product Safety Statement

The safety messages that follow have a CAUTION level hazard.

Failure to comply may result in minor or moderate injury.

CAUTION

READ MANUAL

Read manual for proper use of this equipment. Follow all safety instructions. Task- and equipment-

specic warnings, cautions, and instructions are included in equipment documentation where

appropriate. Make sure these instructions and all other equipment documents are accessible to

persons operating or servicing equipment.

The safety message that follows has a WARNING level hazard.

Failure to comply could result in death or serious injury.

WARNING

ELECTRIC SHOCK

Risk of electric shock. Disconnect power before removing covers and / or disconnect, lock out, and

tag switches before servicing electrical equipment. If you receive even a slight electrical shock, shut

down all equipment immediately. Do not restart the equipment until the problem has been identied

and corrected.

MAXIMUM AIR PRESSURE

Unless otherwise noted in the product manual, the maximum air input pressure is 7.0 bar (100 psi).

Excessive air input pressure may damage the equipment. Air input pressure is intended to be applied

through an external air pressure regulator rated for 0 to 7.0 bar (0 to 100 psi).

RELEASE PRESSURE

Release hydraulic and pneumatic pressure before opening, adjusting, or servicing pressurized

systems or components.

BURNS

Hot surfaces! Avoid contact with the hot metal surfaces of heated components. If contact can not be

avoided, wear heat-protective gloves and clothing when working around heated equipment. Failure

to avoid contact with hot metal surfaces can result in personal injury.

Safety Enclosure for Automated Dispensing Systems

6www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Nordson EFD Product Safety Statement (continued)

Halogenated Hydrocarbon Solvent Hazards

Do not use halogenated hydrocarbon solvents in a pressurized system that contains aluminum components.

Under pressure, these solvents can react with aluminum and explode, causing injury, death, or property damage.

Halogenated hydrocarbon solvents contain one or more of the following elements.

Element Symbol Prefix

Fluorine F “Fluoro-”

Chlorine Cl “Chloro-”

Bromine Br “Bromo-”

Iodine I “Iodo-”

Check the Safety Data Sheet (SDS) or contact your material supplier for more information. If you must use

halogenated hydrocarbon solvents, contact your EFD representative for compatible EFD components.

High Pressure Fluids

High pressure uids, unless they are safely contained, are extremely hazardous. Always release uid pressure before

adjusting or servicing high pressure equipment. A jet of high pressure uid can cut like a knife and cause serious

bodily injury, amputation, or death. Fluids penetrating the skin can also cause toxic poisoning.

Any injury caused by high pressure liquid can be serious. If you are injured or even suspect an injury:

• Go to an emergency room immediately.

• Tell the doctor that you suspect an injection injury.

• Show the doctor the following note.

• Tell the doctor what kind of material you were dispensing.

WARNING

Medical Alert — Airless Spray Wounds: Note to Physician

Injection in the skin is a serious traumatic injury. It is important to treat the injury surgically as soon as possible. Do

not delay treatment to research toxicity. Toxicity is a concern with some exotic coatings injected directly into the

bloodstream.

Qualified Personnel

Equipment owners are responsible for making sure that EFD equipment is installed, operated, and serviced by

qualied personnel. Qualied personnel are those employees or contractors who are trained to safely perform

their assigned tasks. They are familiar with all relevant safety rules and regulations and are physically capable of

performing their assigned tasks.

7www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Safety Enclosure for Automated Dispensing Systems

Nordson EFD Product Safety Statement (continued)

Intended Use

Use of EFD equipment in ways other than those described in the documentation supplied with the equipment may

result in injury to persons or damage to property. Some examples of unintended use of equipment include:

• Using incompatible materials.

• Making unauthorized modications.

• Removing or bypassing safety guards or interlocks.

• Using incompatible or damaged parts.

• Using unapproved auxiliary equipment.

• Operating equipment in excess of maximum ratings.

• Operating equipment in an explosive atmosphere.

Regulations and Approvals

Make sure all equipment is rated and approved for the environment in which it is used. Any approvals obtained for

Nordson EFD equipment will be voided if instructions for installation, operation, and service are not followed. If the

equipment is used in a manner not specied by Nordson EFD, the protection provided by the equipment may be

impaired.

Personal Safety

To prevent injury, follow these instructions:

• Do not operate or service equipment unless you are qualied.

• Do not operate equipment unless safety guards, doors, and covers are intact and automatic interlocks are

operating properly. Do not bypass or disarm any safety devices.

• Keep clear of moving equipment. Before adjusting or servicing moving equipment, shut off the power supply

and wait until the equipment comes to a complete stop. Lock out power and secure the equipment to prevent

unexpected movement.

• Make sure spray areas and other work areas are adequately ventilated.

• When using a syringe barrel, always keep the dispensing end of the tip pointing towards the work and away

from the body or face. Store syringe barrels with the tip pointing down when they are not in use.

• Obtain and read the Safety Data Sheet (SDS) for all materials used. Follow the manufacturer’s instructions for

safe handling and use of materials and use recommended personal protection devices.

• Be aware of less-obvious dangers in the workplace that often cannot be completely eliminated, such as hot

surfaces, sharp edges, energized electrical circuits, and moving parts that cannot be enclosed or otherwise

guarded for practical reasons.

• Know where emergency stop buttons, shutoff valves, and re extinguishers are located.

• Wear hearing protection to protect against hearing loss that can be caused by exposure to vacuum exhaust port

noise over long periods of time.

Safety Enclosure for Automated Dispensing Systems

8www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Nordson EFD Product Safety Statement (continued)

Fire Safety

To prevent a re or explosion, follow these instructions:

• Shut down all equipment immediately if you notice static sparking or arcing. Do not restart the equipment until

the cause has been identied and corrected.

• Do not smoke, weld, grind, or use open ames where ammable materials are being used or stored.

• Do not heat materials to temperatures above those recommended by the manufacturer. Make sure heat

monitoring and limiting devices are working properly.

• Provide adequate ventilation to prevent dangerous concentrations of volatile particles or vapors. Refer to local

codes or the SDS for guidance.

• Do not disconnect live electrical circuits when working with ammable materials. Shut off power at a disconnect

switch rst to prevent sparking.

• Know where emergency stop buttons, shutoff valves, and re extinguishers are located.

Preventive Maintenance

As part of maintaining continuous trouble-free use of this product, Nordson EFD recommends the following simple

preventive maintenance checks:

• Periodically inspect tube-to-tting connections for proper t. Secure as necessary.

• Check tubing for cracks and contamination. Replace tubing as necessary.

• Check all wiring connections for looseness. Tighten as necessary.

• Clean: If a front panel requires cleaning, use a clean, soft, damp rag with a mild detergent cleaner. DO NOT USE

strong solvents (MEK, acetone, THF, etc.) as they will damage the front panel material.

• Maintain: Use only a clean, dry air supply to the unit. The equipment does not require any other regular

maintenance.

• Test: Verify the operation of features and the performance of equipment using the appropriate sections of this

manual. Return faulty or defective units to Nordson EFD for replacement.

• Use only replacement parts that are designed for use with the original equipment. Contact your Nordson EFD

representative for information and advice.

9www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Safety Enclosure for Automated Dispensing Systems

Important Disposable Component Safety Information

All Nordson EFD disposable components, including syringe barrels, cartridges, pistons, tip caps, end caps,

and dispense tips, are precision engineered for one-time use. Attempting to clean and re-use components will

compromise dispensing accuracy and may increase the risk of personal injury.

Always wear appropriate protective equipment and clothing suitable for your dispensing application and adhere to

the following guidelines:

• Do not heat syringe barrels or cartridges to a temperature greater than 38° C (100° F).

• Dispose of components according to local regulations after one-time use.

• Do not clean components with strong solvents (MEK, acetone, THF, etc.).

• Clean cartridge retainer systems and barrel loaders with mild detergents only.

• To prevent uid waste, use Nordson EFD SmoothFlow™ pistons.

Action in the Event of a Malfunction

If a system or any equipment in a system malfunctions, shut off the system immediately and perform the following

steps:

1. Disconnect and lock out system electrical power. If using hydraulic and pneumatic shutoff valves, close and

relieve pressure.

2. For Nordson EFD air-powered dispensers, remove the syringe barrel from the adapter assembly. For Nordson

EFD electro-mechanical dispensers, slowly unscrew the barrel retainer and remove the barrel from the actuator.

3. Identify the reason for the malfunction and correct it before restarting the system.

Disposal

Dispose of equipment and materials used in operation and servicing according to local codes.

Nordson EFD Product Safety Statement (continued)

Safety Enclosure for Automated Dispensing Systems

10 www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Specifications

Item Small Enclosure Large Enclosure

Size 800W× 1920H× 900Dmm

(31.5W× 75.6H× 35.4D")

1000W× 1920H× 1100Dmm

(39.4W× 75.6H× 43.3D")

Construction Extruded aluminum and steel

Weight 215 kg (474.0 lb) 227 kg (500.5 lb)

Input AC (to power supply) 100–240 VAC, ±10%, 50/60Hz, 20 Amp maximum

Output DC (from power supply) 24 VDC, 5 Amp maximum

Ambient operating temperature 10–40° C (50–104° F)

Approvals CE

Operating Features

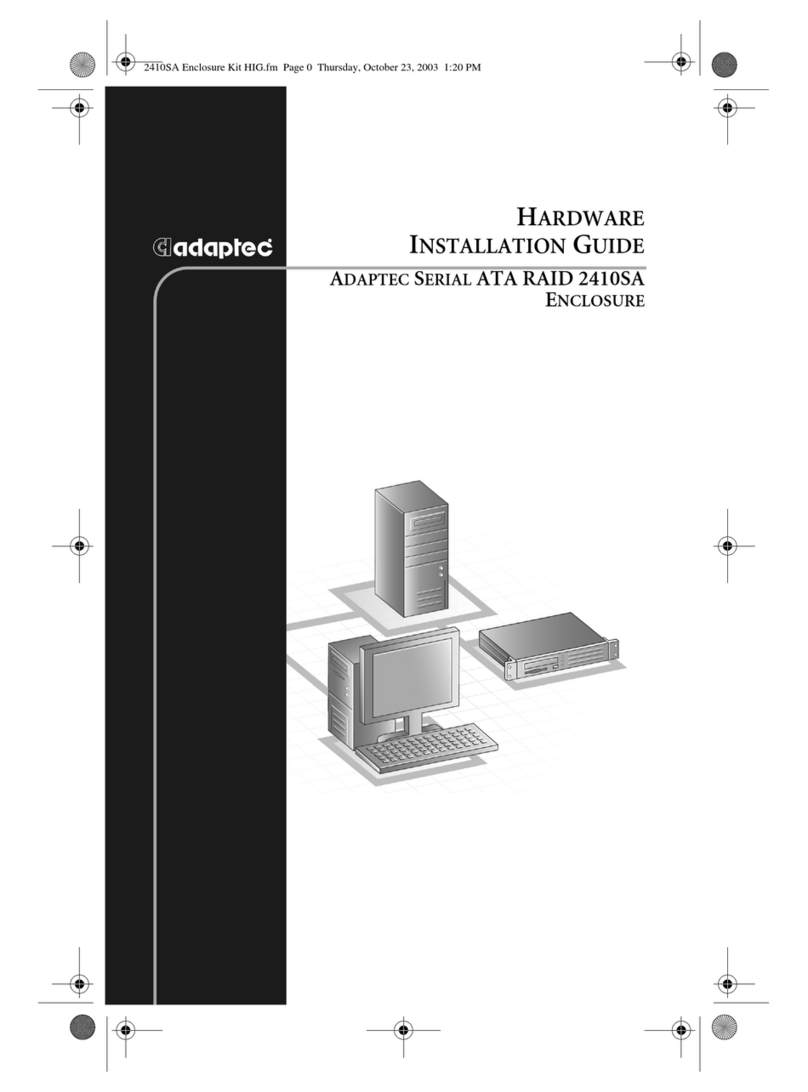

EMERGENCY STOP

and START buttons

(same functionality as

the controls on the

front of the robot)

Mounting base

(for the articulating arm

with monitor stand and

the keyboard tray for

vision-guided systems)

Keys

(for the lockable

electrical box

located on the

back of the

enclosure)

(On the back of the enclosure)

Main disconnect switch

(designed for lockout / tagout)

and lockable electrical box

(includes I/O terminal blocks)

Power strip

(for a valve controller

or other ancillary

component)

Light curtain beams

Light switch

(for the overhead

light inside the

enclosure)

(On the back right

side of the enclosure)

Safety enclosure

power inlet

RUN/TEACH switch

(the switch must be

in the RUN position

to run programs)

Large storage area

(for use as needed)

RESET button

(present only on EU

safety enclosures)

11www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Safety Enclosure for Automated Dispensing Systems

Installation

Use this section in tandem with the Quick Start Guide and the valve system manuals to install all components of the

system.

You will need the following items:

• Pallet jack

• Open-end wrench set

• Adjustable open-end wrench

• 4 mm and 5 mm hex keys

• (Vision systems only) Four M4 x 12 screws to install the monitor

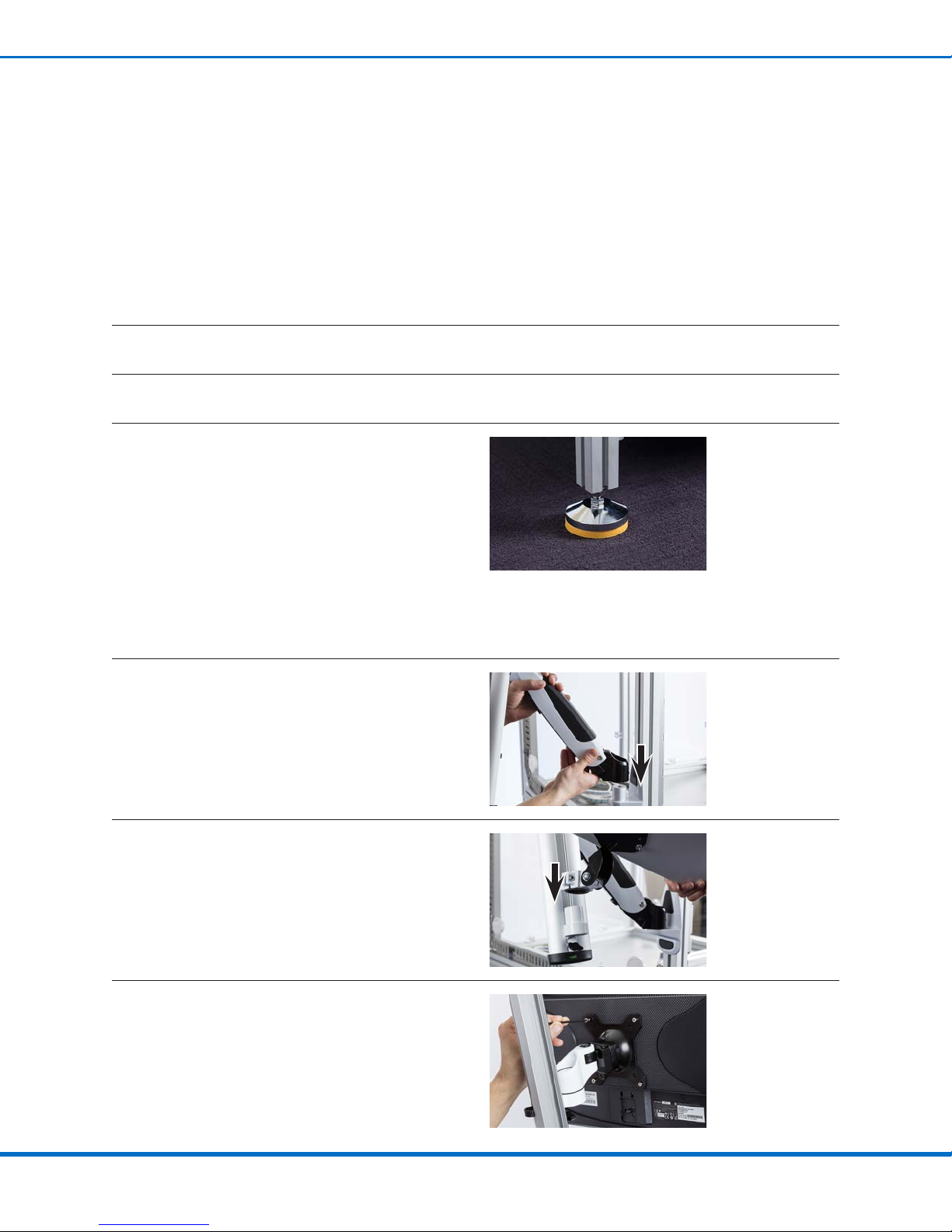

Unpack the System Components and Install the Feet

1. Remove loose items from inside the enclosure (feet, articulating arm, keyboard tray, and loose hardware).

2. Carefully remove the enclosure and stand it upright.

3. Use a pallet jack to lift a corner of the enclosure

and then use an adjustable open-end wrench to

install the feet. Repeat to install the remaining

feet.

(Vision Systems Only) Install the Monitor and Keyboard

1. Install the articulating arm on the mounting base.

2. Install the keyboard tray on the articulating arm.

3. Use four (4) M4 x 12 screws (customer-supplied)

to secure the monitor to the monitor mounting

plate.

Safety Enclosure for Automated Dispensing Systems

12 www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

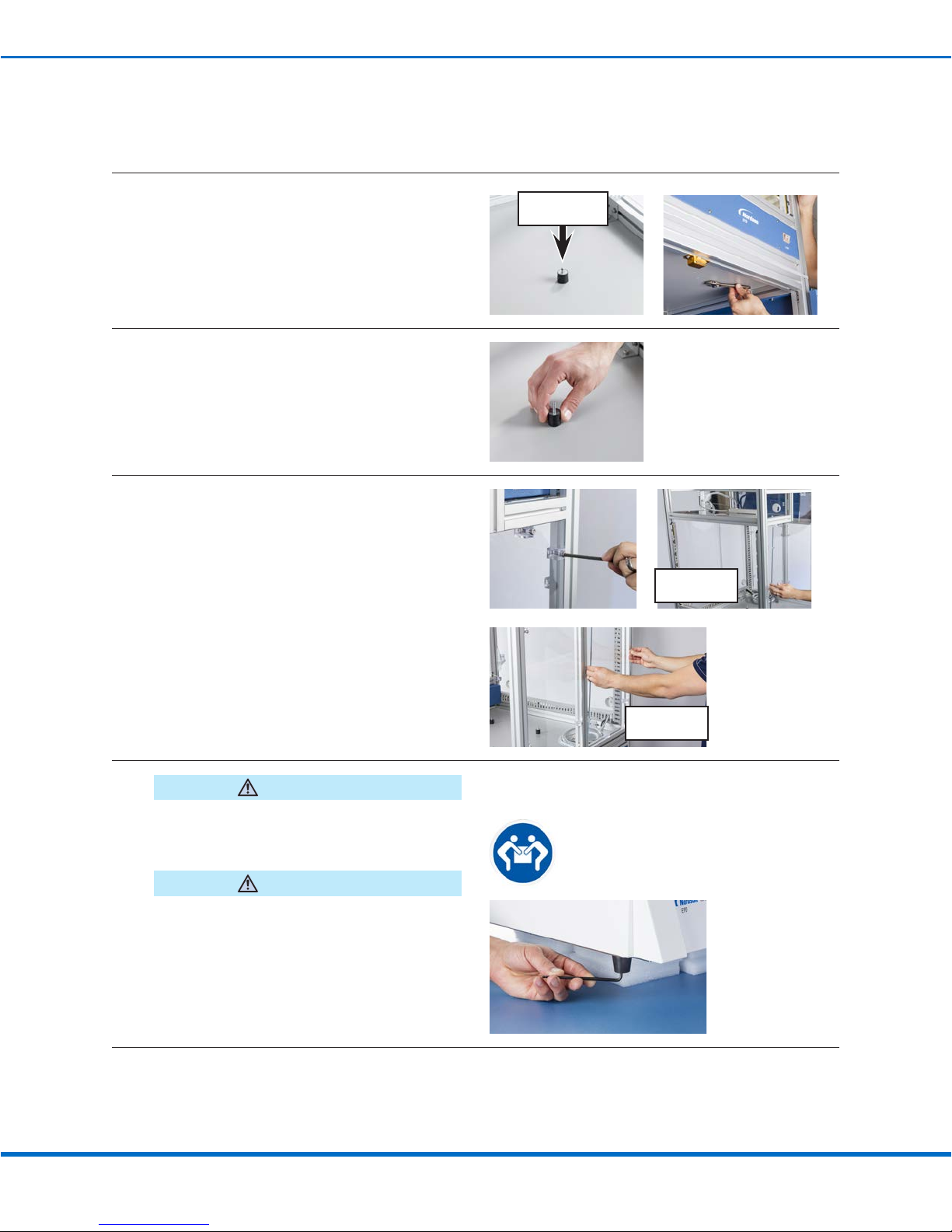

Install the Robot in the Enclosure

1. Open the enclosure doors and use an open-end

wrench to remove the M5 hex nuts that secure

the vibration isolators.

NOTE: The vibration isolators are secured to the

enclosure by a locking nut that is accessible only

by opening the enclosure doors.

Vibration isolator

(top view)

2. Remove the four (4) vibration isolators from the

enclosure.

3. a. Use a 5 mm hex key to remove the right-side

clear panel (9 screws) and the two back clear

panels (6 screws each).

b. Set the panels and screws aside in a safe

location. Right-side

panel removal

Back panel

removal

4.

Moving the robot requires a minimum of two

people. Do not attempt to lift the robot without

assistance.

WARNING

Avoid tilting the robot, and never lay the robot on

its side. Doing so can damage the circuitry.

CAUTION

a. Use foam (or a similar methodology) to

carefully and safely elevate the robot such

that you can access the robot feet.

b. Use a 4 mm hex key to remove the four (4)

existing feet from the robot.

Continued on next page

Installation (continued)

13www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Safety Enclosure for Automated Dispensing Systems

5. By hand, install the vibration isolators (that were

removed from the safety enclosure) on the robot

where the robot feet were previously installed.

Hand tighten.

6.

Moving the robot requires a minimum of two

people. Do not attempt to lift the robot without

assistance.

WARNING

Position the robot inside the safety enclosure,

aligning the feet to the correct holes for your

robot model.

NOTE: The safety enclosure bottom provides

holes for the multiple robot sizes.

7. Open the enclosure doors and use an open-

end wrench to install the M5 nuts removed

previously, thus securing the robot to the

enclosure.

Installation (continued)

Install the Robot in the Enclosure (continued)

Safety Enclosure for Automated Dispensing Systems

14 www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Installation (continued)

Connect Cables

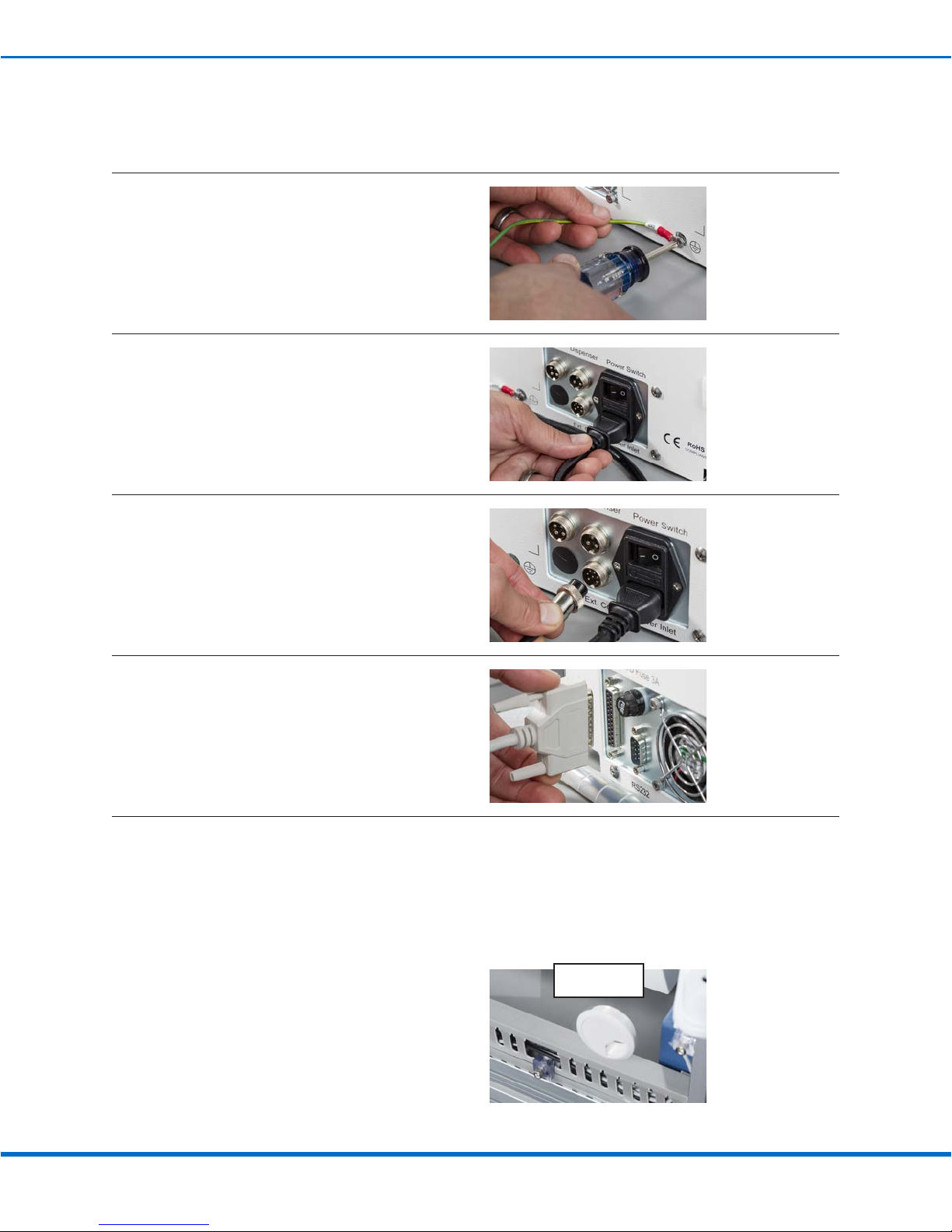

1. Use a Phillips-head screwdriver to connect the

ground wire to the ground connection on the

back of the robot.

2. Connect the power cable to the Power Inlet.

3. Connect the input / output safety plug cable to

the Ext. Control port.

4. Connect the input / output (I/O) cable to the IO

Port.

5. (Vision systems only)

• Connect the monitor power and DispenseMotion™controller cables to the robot.

(Teach Pendant systems only)

• Connect the Teach Pendant to the Teach Pendant port on the front of the robot.

NOTES:

- Cables can be routed through the grommet

holes provided on all sides of the safety

enclosure.

- Refer to the Quick Start Guide for the

correct cable connections for your system.

Grommet for

cable routing

15www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Safety Enclosure for Automated Dispensing Systems

Install the Dispensing System and Reinstall the Panels

1. Install the dispensing system. Refer to the

dispensing component manuals for complete

installation instructions.

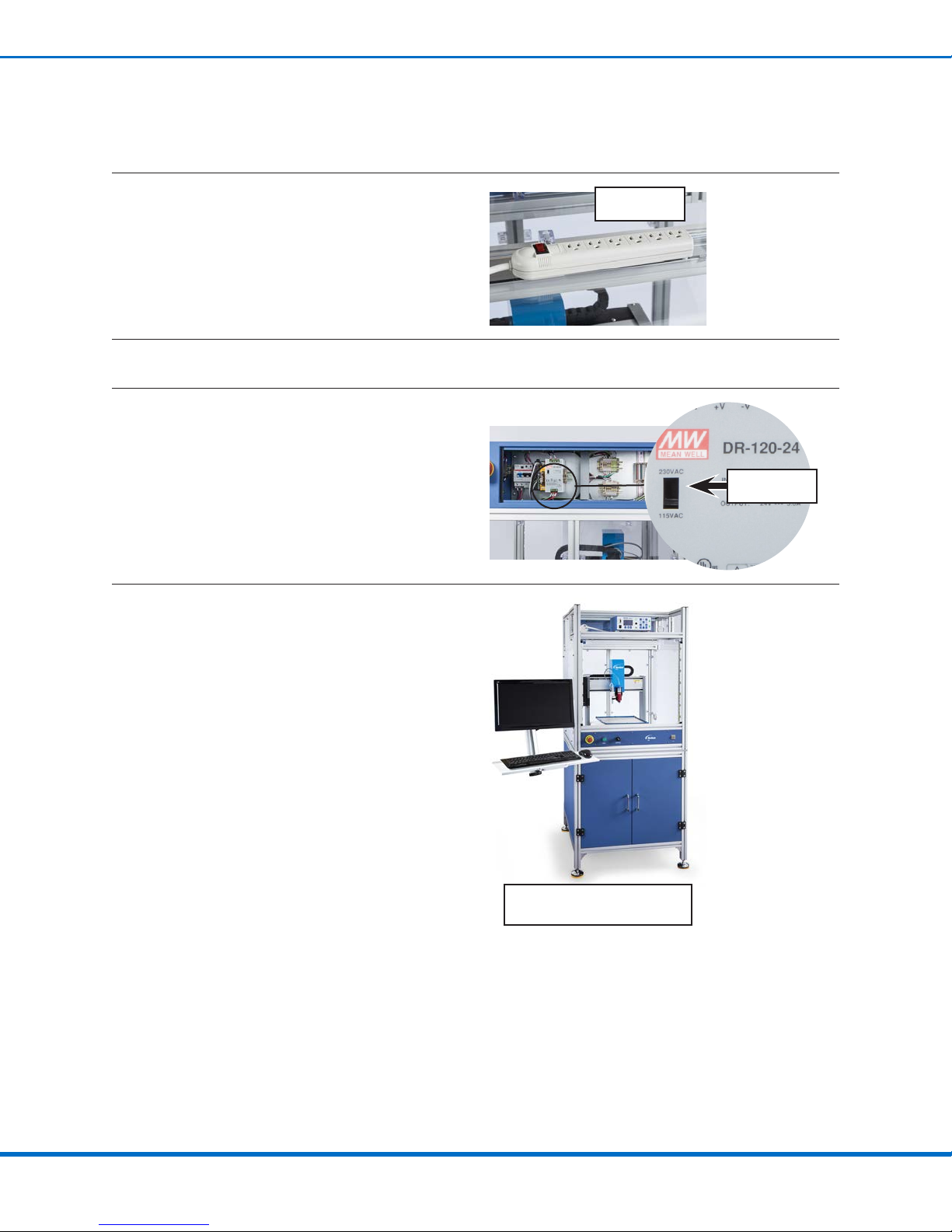

NOTE: A power strip is provided on the front

top of the enclosure. This location is ideal for a

dispense valve controller.

Power strip on

top of enclosure

2. Reinstall the back clear panels and the right-side clear panel using the screws removed previously.

3. a. Open the electrical box on the back of the

safety enclosure.

b. Set the 24V voltage supply switch to the

correct setting for your installation.

AC supply

voltage switch

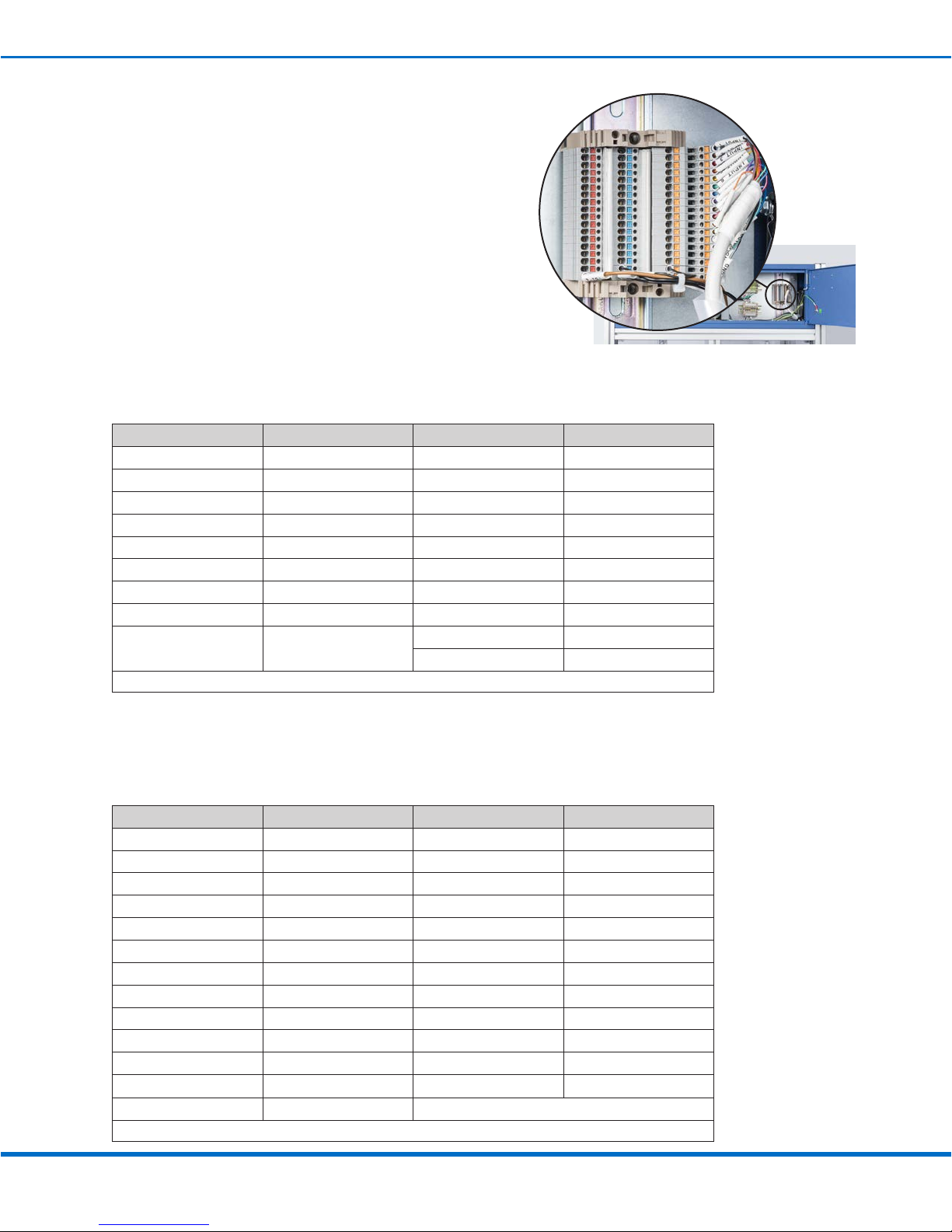

The automated dispensing system is now fully

installed in the safety enclosure.

Continue to the next procedures to connect

inputs / outputs and to power on the complete

system for the rst time.

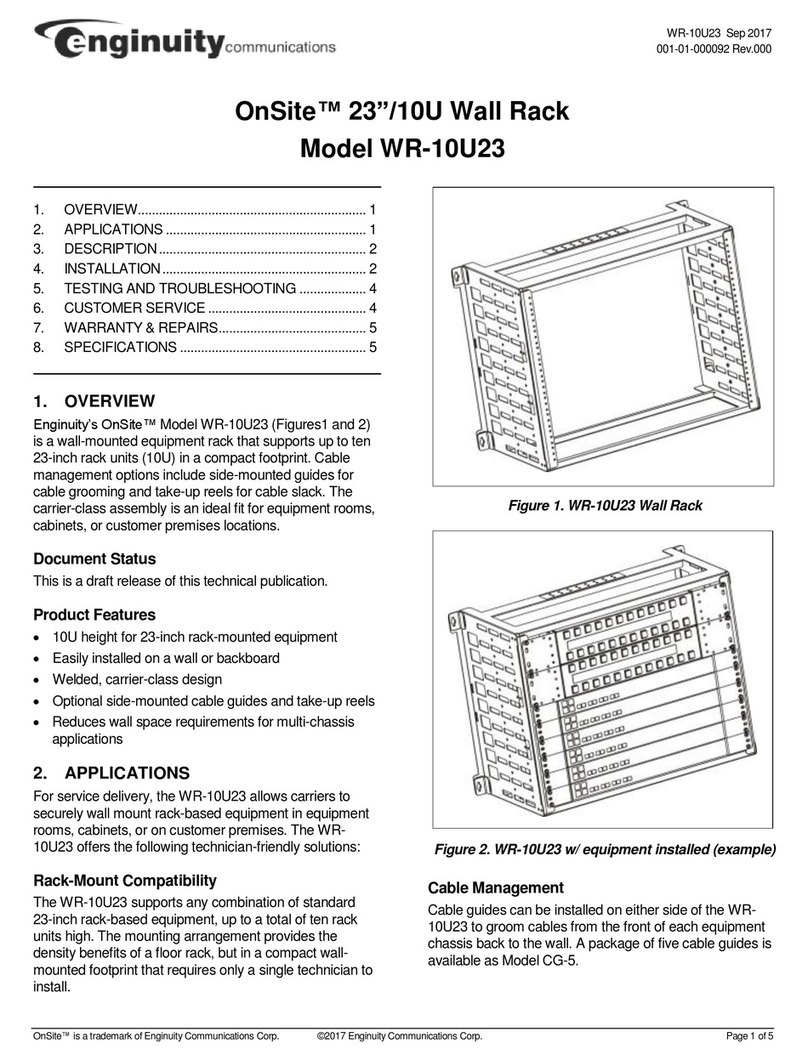

Example of a fully installed system

(EV Series system shown)

Installation (continued)

Safety Enclosure for Automated Dispensing Systems

16 www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

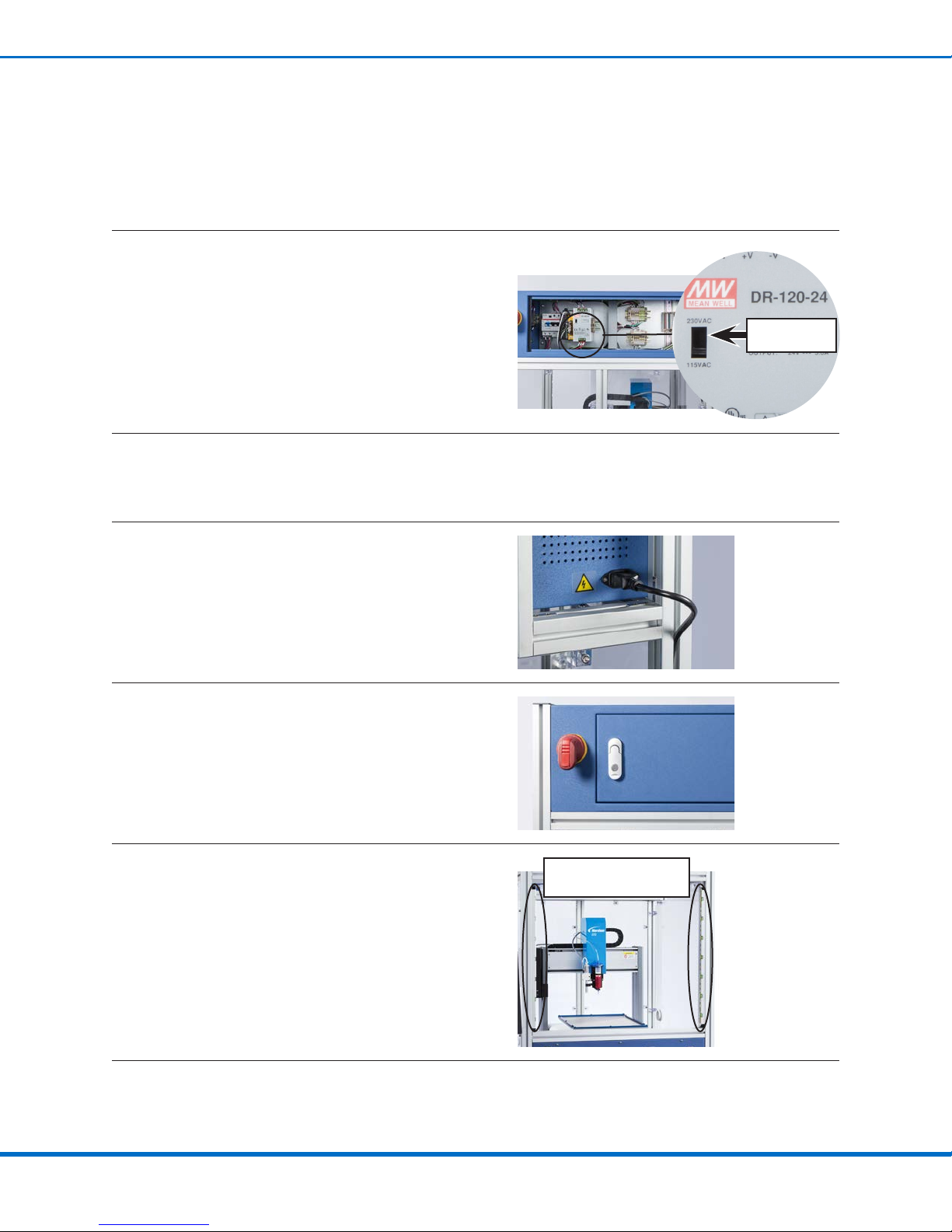

Safety Enclosure I/O Terminal Block Pin Assignments

Block Number* Assignment Block Number* Assignment

Block 1 Input 1 Block 9 Output 1

Block 2 Input 2 Block 10 Output 2

Block 3 Input 3 Block 11 Output 3

Block 4 Input 4 Block 12 Output 4

Block 5 Input 5 Block 13 Output 5

Block 6 Input 6 Block 14 Output 6

Block 7 Input 7 Block 15 Output 7

Block 8 Input 8 Block 16 Output 8

Block 17 GND

Block 18 GND

*Each terminal block has a dedicated +24V terminal and ground rails for connecting external equipment.

The safety enclosure terminal block pin assignments extend to the 25-position I/O Port connector on the back of the

robot. Refer to the table below for robot I/O Port pin assignments.

Robot I/O Port Pin Assignments

Pin Assignment Pin Assignment

Pin 1 Input 1 Pin 14 Output 1

Pin 2 Input 2 Pin 15 Output 2

Pin 3 Input 3 Pin 16 Output 3

Pin 4 Input 4 Pin 17 Output 4

Pin 5 Input 5 Pin 18 Output 5

Pin 6 Input 6 Pin 19 Output 6

Pin 7 Input 7 Pin 20 Output 7

Pin 8 Input 8 Pin 21 Output 8

Pin 9 N/C* Pin 22 N/C*

Pin 10 N/C* Pin 23 N/C*

Pin 11 Ground* Pin 24 +24 VDC*

Pin 12 Ground Pin 25 +24 VDC*

Pin 13 Ground

*These signals are not connected to the safety enclosure I/O terminal block.

Installation (continued)

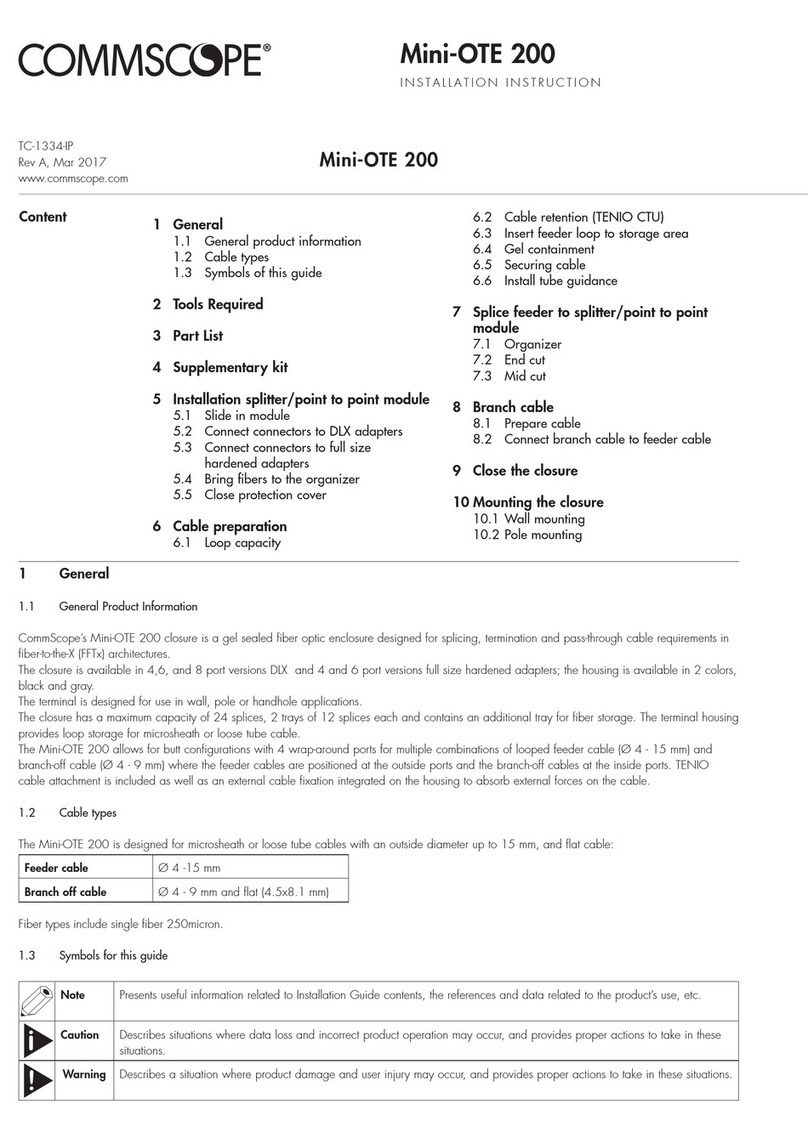

Location of the I/O terminal block inside the

electrical box

Connect Inputs / Outputs (Optional)

The electrical box on the back of the safety enclosure includes

an I/O terminal block. The terminal wires are labeled, and each

terminal provides a signal, power, and ground connection. This

terminal block mimics the functionality of the IO Port on the back

of the robot.

Make the I/O connections as needed for your operation.

NOTES:

• Outputs from the robot I/O Port are rated at 125 mA.

• Courtesy +24VDC output is rated at 5.0 Amp.

17www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Safety Enclosure for Automated Dispensing Systems

Initial Startup

NOTE: This startup procedure applies only to the rst power-on of the enclosure after installation. For routine

operation, refer to “Operation” on page 19.

1. Verify that the 24V voltage supply switch inside the

electrical box is set to the correct voltage.

AC supply

voltage switch

2. Ensure that:

• All system cables are properly connected as applicable for your installation.

• The dispensing system installation is complete.

3. Connect the 5 m safety enclosure power cable to the

power inlet on the right side of the enclosure and to

the power source.

4. Turn the main disconnect switch located on the back

of the safety enclosure to the ON position.

When the system is powered on, the light curtain and

all I/O connections are automatically active.

If the light curtain is interrupted by any passing object

(such as a hand reaching into the enclosure), the

system enters an emergency stop condition.

Location of the light curtain

beams and sensors

Continued on next page

Installation (continued)

Safety Enclosure for Automated Dispensing Systems

18 www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Installation (continued)

Initial Startup (continued)

5. Open the DispenseMotion software and set “Out 8” to “Running.” Refer to the “I/O Pin Function Setup”

appendix in the robot operating manual for instructions.

NOTE: The system includes a relay switching pin that is connected to output 8 on the I/O terminal block.

When the output 8 signal exceeds 24V (goes “high”), the system breaks the circuit between EMG IN and

EMG OUT. When output 8 is high and the light curtain is broken, the Emergency Stop signal locks and

the robot enters a “hard lock” state. When Output 8 is low and the light curtain is broken, the Emergency

Stop signal is not triggered, meaning the robot is in a “soft lock” state. For the system to use this soft lock

feature correctly, output 8 (“Out 8”) in the DispenseMotion software must be set to Running.

DispenseMotion software screens used to set up Inputs / Outputs (refer to the robot operating manual for the complete

procedure)

19www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Safety Enclosure for Automated Dispensing Systems

Operation

Once the robot is properly installed in the enclosure, follow these procedures for

routine operation to ensure personnel safety.

Starting the System

1. Turn the main disconnect switch located on the back of the safety enclosure

to the ON position.

2. Refer to the robot operating manual for additional robot-specic power-on

steps (such as switching on the DispenseMotion controller).

NOTE: When the system is powered on, the light curtain and all I/O

connections are automatically active. If the light curtain is interrupted by

any passing object (such as a hand reaching into the enclosure), the system

enters an emergency stop condition. An emergency stop may also be

triggered by a customer-specic I/O connection.

3. Press the EMERGENCY STOP button to test it. If an emergency shutdown

occurs, the system is operating properly.

4. Verify that the light curtain is functioning properly by moving a

test object into the light curtain eld. If an emergency shutdown

occurs, the system is operating properly.

NOTE: Nordson EFD strongly recommends performing the

following additional checks of the light curtain operation:

• Ensure that the safety enclosure is in a location that is free of

light interference, such as from uorescent lamps.

• Check the sheaths of the wiring connected to the light curtain

controller (inside the electrical box) for damage and replace

any damaged wiring. Refer to “Service” on page 21 for the

location of the light curtain controller.

About the RUN/TEACH Switch

The safety enclosure provides a RUN/TEACH switch that affects

system operation. The default position of the RUN/TEACH switch is

the RUN position, which allows normal operation. Placing the switch

in the TEACH position deactivates the light curtain, allowing the

operator to run the robot at a reduced speed (without dispensing) or

to service the robot. When the RUN/TEACH switch is in the TEACH

position, the system will not run a dispense cycle.

When the RUN/TEACH switch is in the RUN position:

• The light curtain is active — any object that passes the light curtain causes an

emergency shutdown condition.

• Pressing the green START button starts a dispense cycle.

When the RUN/TEACH switch is in the TEACH position:

• The light curtain is deactivated, allowing the operator to reach inside the

enclosure without triggering an emergency shutdown.

• The robot cannot execute a dispense program.

Main disconnect switch

Controls on the front of the

safety enclosure (standard

enclosure shown)

Safety Enclosure for Automated Dispensing Systems

20 www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Operation (continued)

Controls on the front of a

standard safety enclosure

Controls on the front of an

EU safety enclosure

Running a Program

NOTE: These steps are for a typical operation and may vary depending on the

application.

1. Open the program to be run. Refer to the robot manual as

needed for instructions on opening a program.

2. Turn the RUN/TEACH switch to the TEACH position.

3. Place a workpiece on the robot work surface.

4. Turn the RUN/TEACH switch to the RUN position.

5. Use the green START button on the front of the safety enclosure

to run programs as follows:

• Press the START button to start a dispense cycle.

• While a dispense program is running, press the START button

a second time to pause the dispense cycle.

• Press a the START button a third time to resume a paused

dispense cycle.

Stopping the System (Emergency Stop)

An emergency stop condition occurs when the user presses the

EMERGENCY STOP button on the front of the safety enclosure or

when the light curtain eld is broken.

When an emergency condition occurs:

• The dispense cycle stops and cannot be restarted from the

stopped location

• The system requires a reset. Refer to “Resetting the System”

below.

Resetting the System

When an emergency stop condition occurs, follow these steps to

restart the system.

1. If applicable, correct the condition that caused the emergency

stop.

2. If the EMERGENCY STOP button is pressed in, turn it

clockwise to reset it.

3. (EU safety enclosures only) Press the blue RESET button to

re-enable power to the robot motors.

4. Press the START button to reset the position of the robot.

5. Resume normal operation.

This manual suits for next models

3

Table of contents