Enginuity OnSite WR-10U23 User manual

WR-10U23 Sep2017

001-01-000092 Rev.000

OnSite™is a trademark ofEnginuityCommunications Corp. ©2017 EnginuityCommunications Corp. Page1 of5

OnSite™23”/10U Wall Rack

Model WR-10U23

1. OVERVIEW.................................................................1

2. APPLICATIONS......................................................... 1

3. DESCRIPTION........................................................... 2

4. INSTALLATION.......................................................... 2

5. TESTING AND TROUBLESHOOTING ................... 4

6. CUSTOMER SERVICE............................................. 4

7. WARRANTY & REPAIRS.......................................... 5

8. SPECIFICATIONS..................................................... 5

1. OVERVIEW

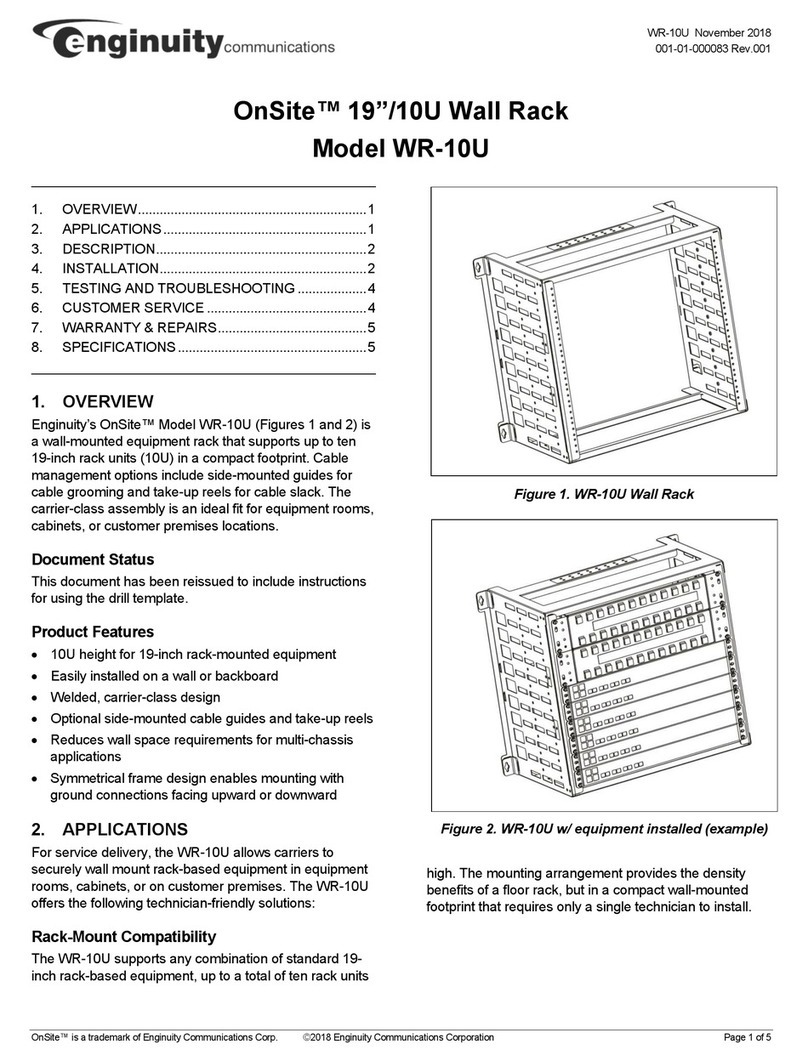

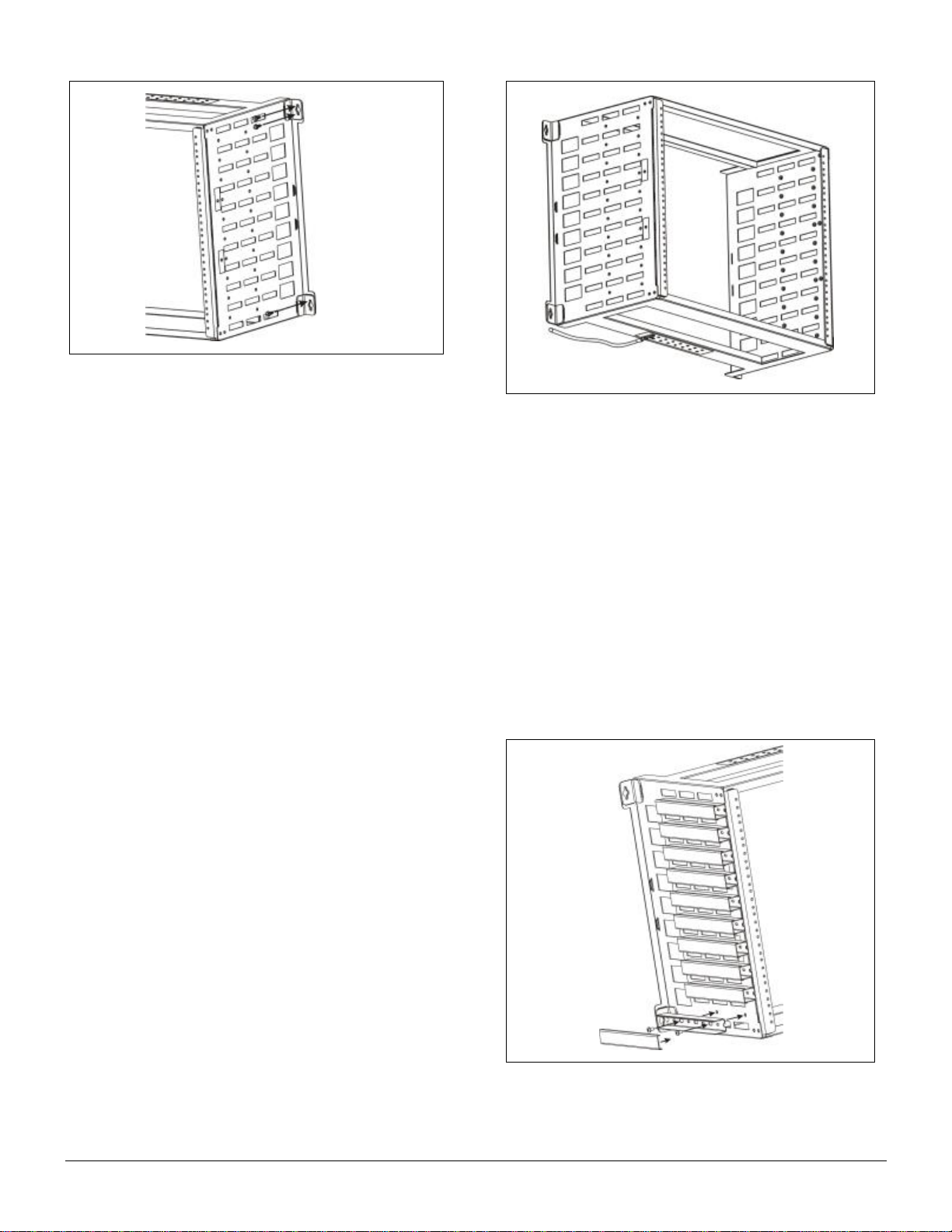

Enginuity’s OnSite™ ModelWR-10U23 (Figures1 and 2)

is a wall-mountedequipment rack that supports up toten

23-inch rack units (10U) in a compact footprint. Cable

management options include side-mounted guides for

cable grooming and take-up reelsfor cable slack. The

carrier-class assembly is an ideal fit for equipment rooms,

cabinets, or customer premises locations.

Document Status

This is a draft release of this technical publication.

Product Features

•10U height for 23-inch rack-mounted equipment

•Easily installed on a wall or backboard

•Welded, carrier-class design

•Optional side-mounted cable guides and take-up reels

•Reduces wall space requirements for multi-chassis

applications

2. APPLICATIONS

For service delivery, the WR-10U23 allows carriers to

securely wall mount rack-based equipment in equipment

rooms, cabinets, or on customer premises. The WR-

10U23 offers the following technician-friendly solutions:

Rack-Mount Compatibility

The WR-10U23 supports any combination of standard

23-inchrack-based equipment, up to a total of ten rack

units high. The mounting arrangement providesthe

densitybenefitsof a floor rack, but in a compact wall-

mounted footprint that requires only a single technician to

install.

Cable Management

Cable guides can be installed on either side of the WR-

10U23 to groom cablesfrom the front of each equipment

chassis back to the wall. A package of five cable guides is

available as Model CG-5.

Figure 1. WR-10U23 Wall Rack

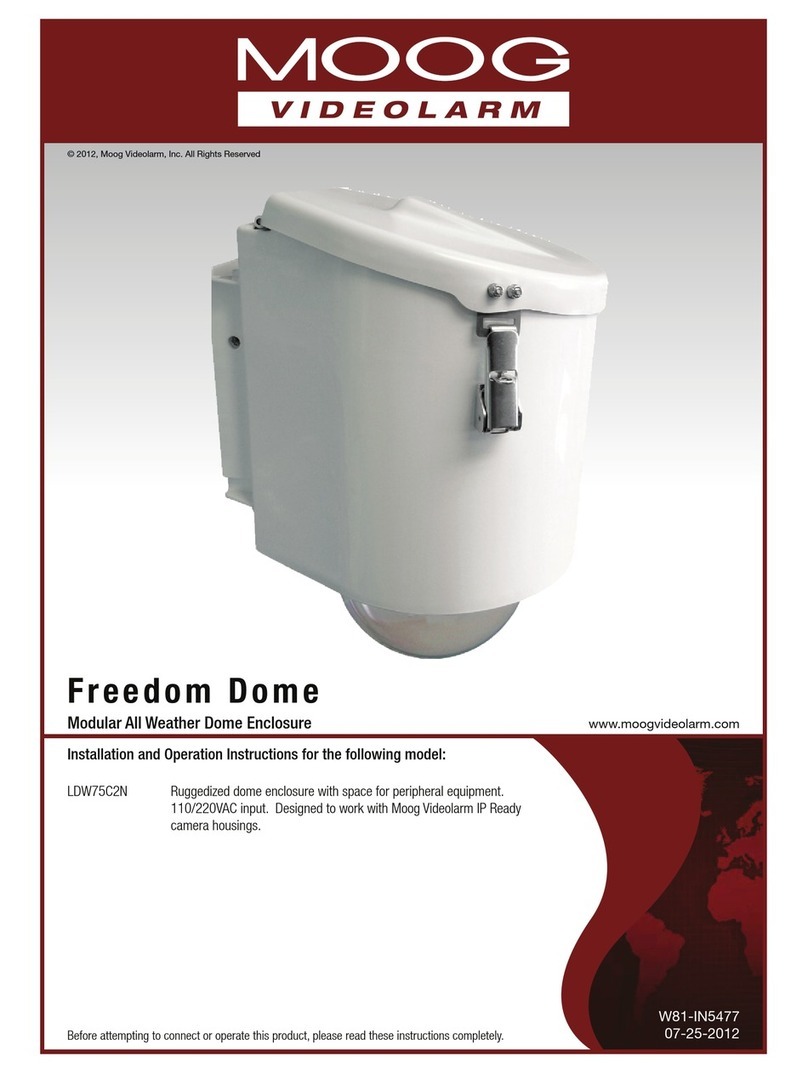

Figure 2. WR-10U23 w/ equipment installed (example)

001-01-000092 Rev. 000 Page2 of5

A side plate with cable take-up reels, Model SPL-4H, can

be added to store excess cable length being fed to

installed equipment. The SPL-4H mounts to either side of

the WR-10U23 and includes two adjustable, split reels.

3. DESCRIPTION

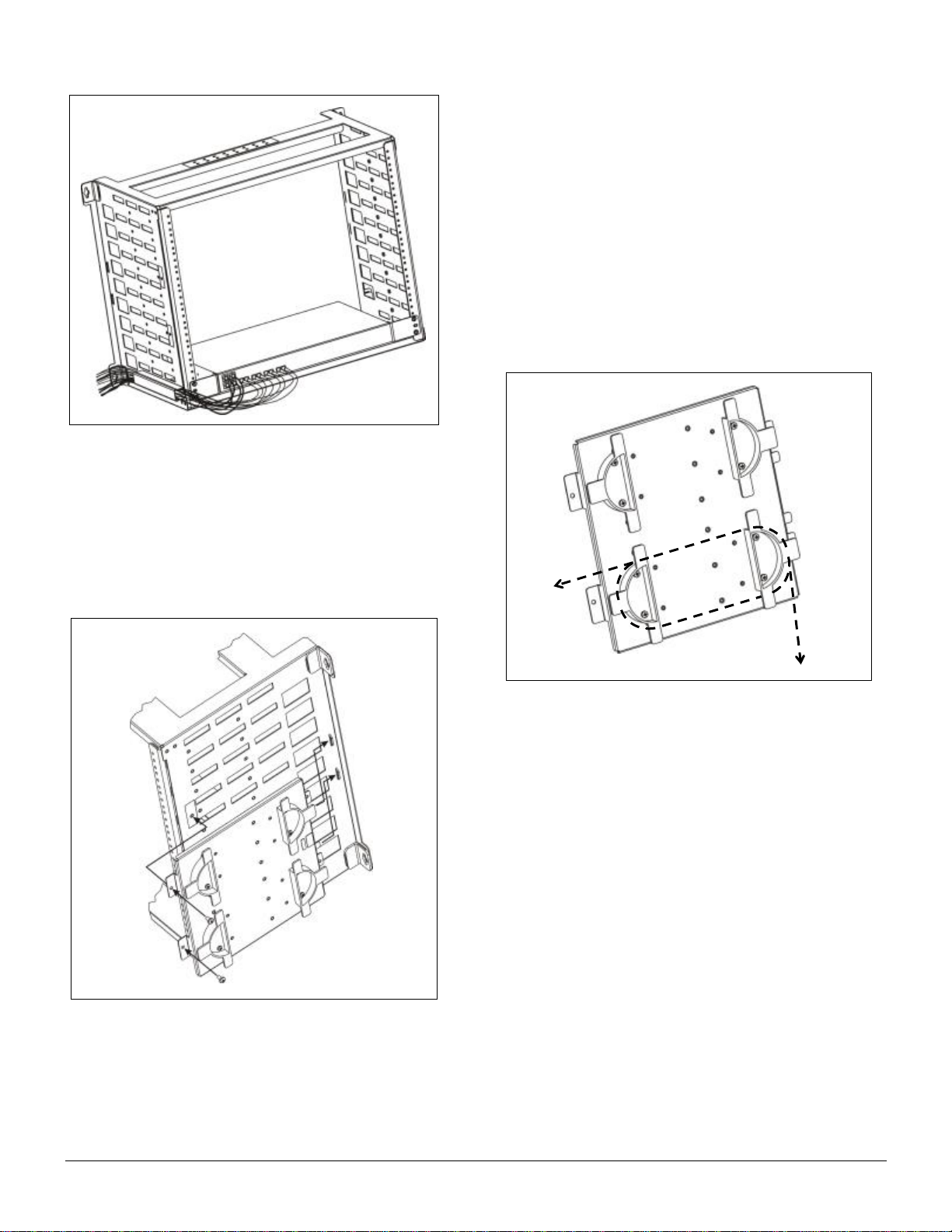

The WR-10U23 (Figure 3) features welded steel, carrier-

class construction. The front of the frame provides two

vertical railswith standard threaded hole spacing for up to

ten rack units. Eight pairs of threaded grounding holes

and pre-installed screws are provided on the rear

crossbar for attachment of ground lugs. One pair of holes

supports grounding of the WR-10U23 itself and the other

seven pairs of holes support ground connections from

installed equipment. The unpainted grounding area

provides metal-to-metal contact with ground lug surfaces.

Cable Guides

Optional cable guides with removable covers (Figure 4)

can be attached to either side of the WR-10U23 frame.

Upto ten cable guides can be installed per side.

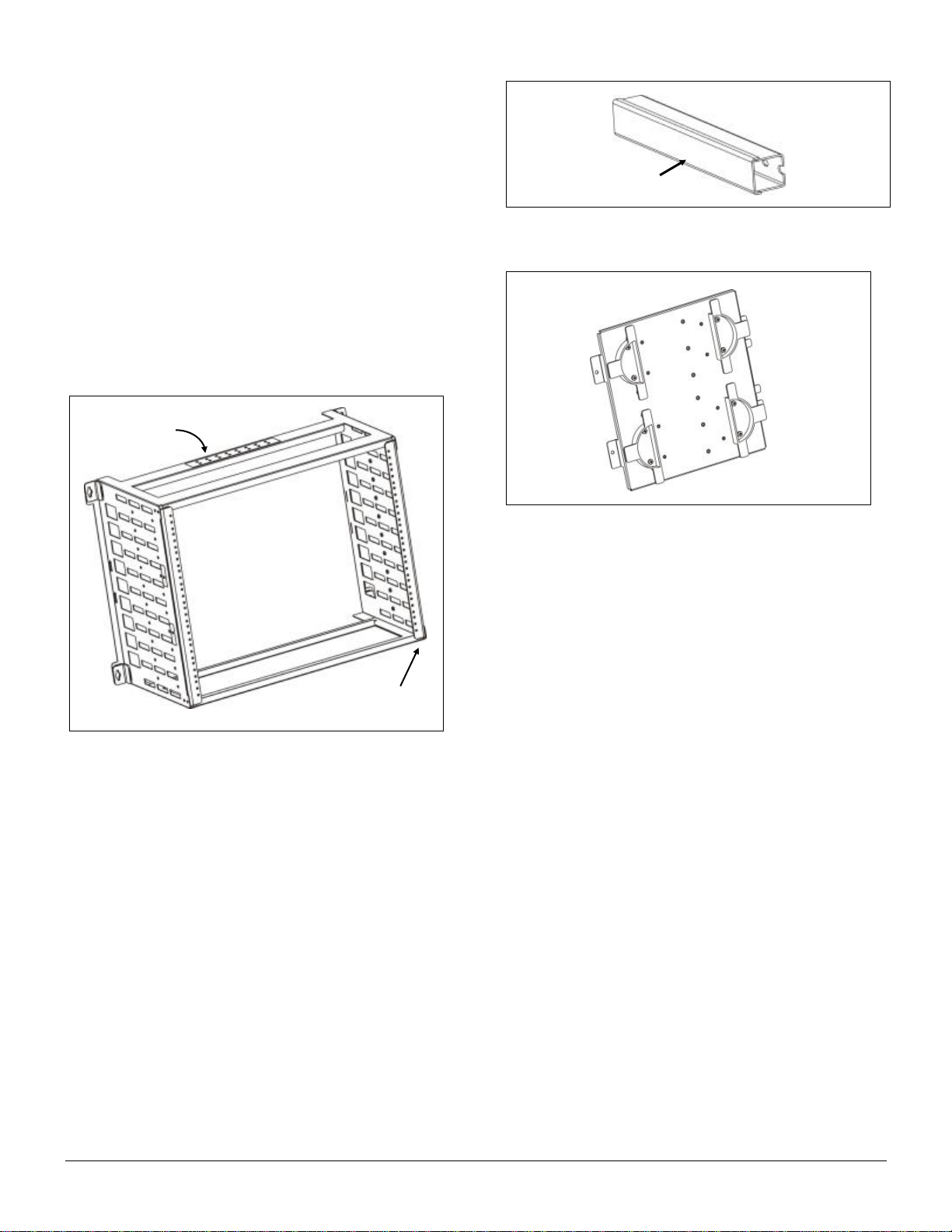

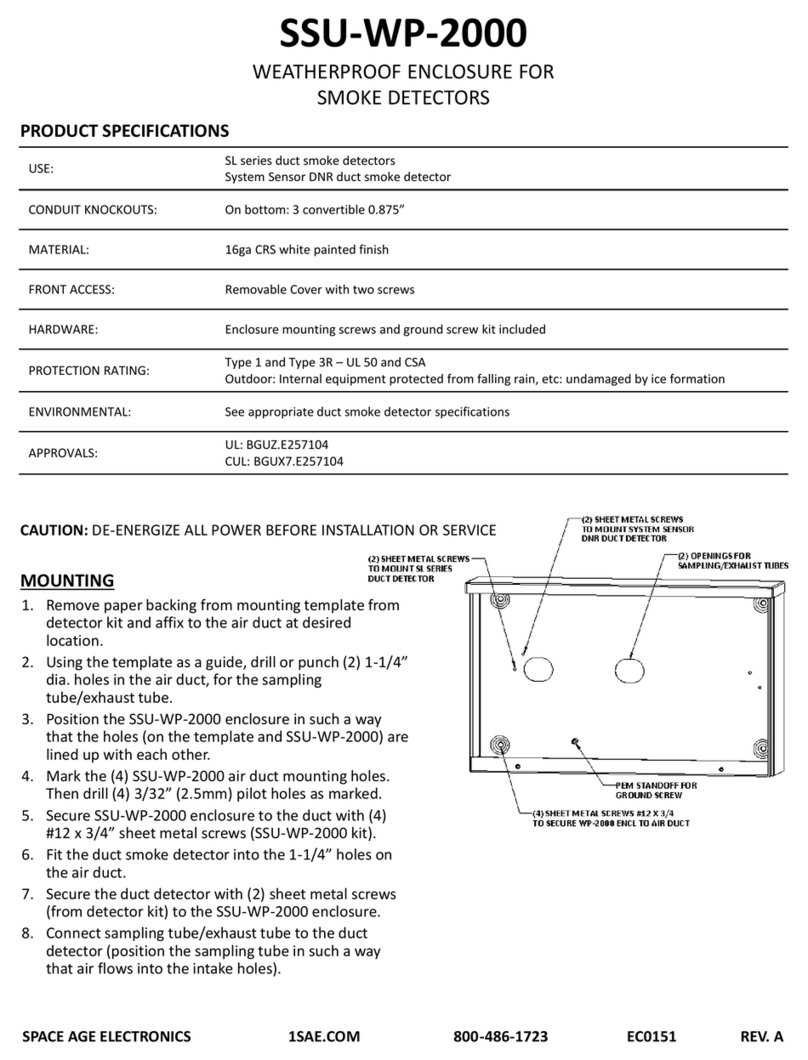

Side Plate with Take-up Reels

Anoptional side plate, Model SPL-4H (Figure 5), provides

two adjustablecable take-up reels. The reels are sized to

maintain proper bend radius infiber applications. The

metal platecan be attached to either side of the WR-

10U23 frame using the included hardware.

4. INSTALLATION

The WR-10U23 shipping cartoncontainsthe following:

•Pre-assembled mounting frame

•Six (6) #12 x 1” slotted hex screws, self-tapping

•Product documentation

Installation stepsare described indetailbelow.

A. Mounting frame

Selectan appropriate location on awall or backboard

to installthe mounting frame. Choose amounting

surface and hardware that can support the combined

weight of the mounting assembly and equipment that

isto be installed. Mounting to a 3/4” thick backboard

with #12 x 1” screws isrecommended. Maximum

weight holding capacity of the WR-10U23 is 200 lbs.

Determine the desired orientation of the ground lugs.

The symmetrical design of the WR-10U23 frame

allows it to be installed with the grounding holesfacing

upward or downward.

Hold the emptymounting framefirmlyagainst the wall

or backboard in a level position and mark screw

locations for each of the four mounting brackets

located at the rear corners of the frame. The frame will

be fastened with two screws in each of the upper

brackets and one screw in each of the lower brackets,

as shown in Figure 6.

Figure 3. WR-10U23 Features

Figure 4. Cable guide

Figure 5. Model SPL-4H Side Plate

Slide on/off cover

Threaded

grounding holes

Standard threaded hole

spacingfor up to10 rack units

001-01-000092 Rev. 000 Page3 of5

Remove the mounting frame from the wall and drill

pilot holes for each of the marked screw locations.

Before attempting to fasten the mounting frame to the

wall, insert a screw into the toppilot hole oneither the

left or right side. Partially thread the screw into the

hole, leaving the screw head approximately 1/4” from

the surface.

Hold themounting frame against the wall while resting

the cutout of the bracket on the installed screw.Align

the other five mounting holes and install a screw in

each hole. Tighten all six (6) screws securely.

B. Frame grounding

Locate the eight (8) pairs of pre-installed grounding

screws with lock washers on the crossbar of the

frame. The grounding screws are 10-32 x 3/8” on 5/8”

centers.

Install a dualground lug (customer provided) with

holes on 5/8” centers beneath the included screws

and washers onone pair of grounding holes. Tighten

the screws to fasten the lug to the mounting frame.

The example in Figure 7 illustrates the frame

positioned with grounding screws facing downward.

Connect a ground wire of appropriate gauge tothe

ground lug, and attachthe other end of thewire to a

bonded ground point, per local proceduresfor network

equipment.

C. Equipment Installation

Install rack equipment with 23” hole spacing by

carefully sliding the chassis through the front of the

WR-10U23 and aligning chassis mounting ears with

the threaded holes in the rails of the WR-10U23

frame. Insert and tighten #12-24 machine screws

(customer provided) oneach side of thechassis. An

example of a fully populated wall rack is shown in

Figure 2.

Attach ground lugs associatedwitheach equipment

chassis to the threaded ground holes onthe WR-

10U23 crossbar as needed.

D. Optional Cable Guide Installation

To install a cable guide to the side of the mounting,

first remove the sliding cover from the cable guide.

Insert two of the #10-32 x 3/8” screws (included in

CG-5 package)through the cableguide and into the

threaded holes onthe side of the WR-10U23 frame

(Figure 8).

Groom cabling from the front of the chassis to the wall

through the cable guide on the side of the WR-10U23,

as shown inFigure 9, and replace the sliding cover.

Figure 6. Mounting screw locations

Figure 7. Frame grounding example

Figure 8. Cable guide installation

001-01-000092 Rev. 000 Page4 of5

E. Optional Side Plate Installation

Threaded holes on both sides of the WR-10U23 frame

allow anoptional side plate (Model SPL-4H) or additional

cableguides to be installed to expand cable

management. The SPL-4H provides two split and

adjustable take-up reels, as illustrated inFigure 5.

To install and use the SPL-4H side plate, refer to Figure

10 andthe steps below.

Slide the two narrower tabs at the edge of theSPL-4H

into the openings on the side of the WR-10U23,

toward the rear of themounting.

Align the wide tabs at the front edge of the SPL-4H

with the threaded holes on the side of the WR-10U23

frame. Use the two (2) included #10-32 x3/8” screws

to securely fasten the side plate to the frame.

Carefullywrap cables around the take-up reels to

reduce slack as needed. Example routing is shown in

Figure 11. Alternate mounting holesare included on

the side plate for repositioning the half-reels, if desired.

5. TESTING AND TROUBLESHOOTING

Equipment installed in the WR-10U23 should betested

according the manufacturer’s instructions.

6. CUSTOMER SERVICE

Customer Sales and General Support

Monday through Friday, 8:00 a.m.–5:00 p.m. CST

Toll Free: 800-980-ECOM (3266), Local: 630-444-0778

24/7 SalesSupport: sales@enginuitycom.com

24/7 Technical Support:

Toll Free: 800-841-1005

E-mail: support@enginuitycom.com

Enginuity Communications

3545 Stern Avenue

St. Charles, IL 60174

Figure 9. Cable guide application

Figure 10. SPL-4H installation

Figure 11. Cable take-up reel routing

001-01-000092 Rev. 000 Page5 of5

7. WARRANTY & REPAIRS

Warranty

Enginuity warrants this product for one (1) year from date

of purchase. Any attempt to repair or modify the

equipment by anyone other than an authorized Enginuity

representative will void thewarranty.

This limited warranty does not cover any losses or

damages resulting from shipment to or from the

customer, or from improper installation, abuse,

modifications, or unauthorized repair by other than

Enginuity personnel.

Repair and Return

Enginuityequipment will be repaired or replaced without

cost during the warranty period if the product is defective

for any reasonother than abuse, improper use, or

improper installation. Before returning defective

equipment, first request a Return Material Authorization

(RMA) numberfrom Enginuity. Once anRMA number is

obtained, return the unit, freight prepaid, along with a brief

description of the problem, to:

Enginuity Communications

3545 Stern Avenue

St. Charles, Illinois 60174

ATTN: Repair & ReturnDept.

Replacements will be shipped in the fastest manner

consistent with the urgency of the situation. Repair or

replacement of faulty equipment beyond thewarranty

period is availablefor a nominal charge.

8. SPECIFICATIONS

Mounting Frame

Part Number

WR-10U23

Description

OnSite™ 23”/10U wall rack

Height

19.25 inches

Width

26.7 inches

Depth

12.6 inches

Weight

14.8 pounds

Capacity

10 rack units, total installed equipment weight not to exceed 200 lbs.

Operating Temperature

0 to 50C

Standards Compliance

Meets applicable Telcordia NEBS requirements, including Zone 4 seismic.

Optional Side Plate

Part Number

SPL-4H

Description

Side plate for wall rack with (2) adjustable take-up reels

Height

10.5 inches

Width

11.3 inches

Depth

1.3 inches

Weight

2.5 pounds

Additional Cable Guides

Part Number

CG-5

Description

Pack of (5) cable guides for wall rack

Height

1.0 inches (each)

Width

1.3 inches (each)

Depth

7.8 inches (each)

Weight

2.0 ounces (each)

Table of contents

Other Enginuity Enclosure manuals

Popular Enclosure manuals by other brands

SPACE AGE ELECTRONICS

SPACE AGE ELECTRONICS SSU-WP-2000 manual

TOOQ

TOOQ TQE-2510B user manual

HGST

HGST Ultrastar Serv60+8 installation guide

DeLOCK

DeLOCK 42633 user manual

Dormakaba

Dormakaba Crane 4000LE Installation, Setup and Troubleshooting Manual

Extron electronics

Extron electronics PowerCage 1600 user guide

StorageWorks

StorageWorks EK-SMRAB-IG installation guide

Compaq

Compaq 4354R - StorageWorks Enclosure Storage Addendum

Icy Box

Icy Box IB-WF200HD manual

Akitio

Akitio Taurus Mini Super-S3 LCM Setup guide

Cooler Master

Cooler Master ATCS 840 installation guide

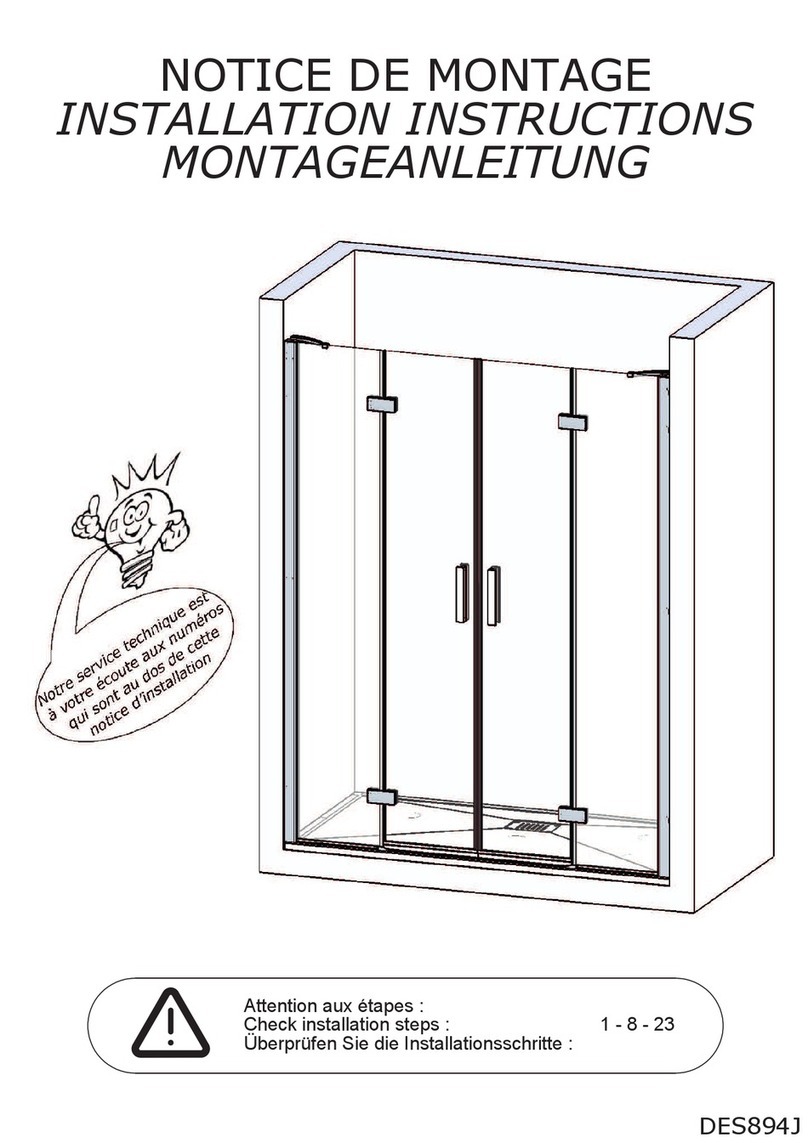

Kinedo

Kinedo Kinespace 2P installation instructions