Nordson EFD ProcessMate 6500 User manual

™

ProcessMate 6500 Temperature Control Unit

Operating Manual

Electronic pdf files of Nordson EFD

manuals are also available at

www.nordsonefd.com

ProcessMate 6500 Temperature Control Unit

2www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Welcome to the ProcessMate™Temperature Control Unit, the most efficient process environmental

control system on the market.

This manual will help you maximize the usefulness of your new ProcessMate.

Please spend a few minutes to become familiar with the controls and features. Follow our recommended

testing procedures. Review the helpful information we have included, which is based on more than

50years of industrial dispensing experience.

Most questions you will have are answered in this manual. However, if you need assistance, please do

not hesitate to contact EFD or your authorized EFD distributor. Detailed contact information is provided

on the last page of this document.

The Nordson EFD Pledge

Thank You!

You have just purchased the world’s finest precision dispensing equipment.

I want you to know that all of us at Nordson EFD value your business and will do everything in our power

to make you a satisfied customer.

If at any time you are not fully satisfied with our equipment or the support provided by your Nordson

EFD Product Application Specialist, please contact me personally at 800.556.3484 (US), 401.431.7000

I guarantee that we will resolve any problems to your satisfaction.

Thanks again for choosing Nordson EFD.

Tara Tareso, General Manager

Tara

3www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 6500 Temperature Control Unit

Contents

Contents..........................................................................................................................................................................3

Nordson EFD Product Safety Statement ........................................................................................................................4

Halogenated Hydrocarbon Solvent Hazards ...............................................................................................................5

High Pressure Fluids....................................................................................................................................................5

Qualified Personnel......................................................................................................................................................5

Intended Use ...............................................................................................................................................................6

Regulations and Approvals..........................................................................................................................................6

Personal Safety............................................................................................................................................................6

Fire Safety....................................................................................................................................................................7

Preventive Maintenance ..............................................................................................................................................7

Important Disposable Component Safety Information ................................................................................................8

Action in the Event of a Malfunction............................................................................................................................8

Disposal .......................................................................................................................................................................8

Specifications..................................................................................................................................................................9

Parts List .......................................................................................................................................................................11

Installation .....................................................................................................................................................................12

Unpack the Unit.........................................................................................................................................................12

Connect Power ..........................................................................................................................................................12

Connect Air Input.......................................................................................................................................................12

Connect Thermocouple .............................................................................................................................................13

Attach Process Feed Lines........................................................................................................................................13

Connect Exhaust Mufflers .........................................................................................................................................13

Configuration.................................................................................................................................................................14

Features & Controls: Front & Rear Panels.....................................................................................................................15

Front Panel Digital Display ............................................................................................................................................16

Digital Display ............................................................................................................................................................16

Change from Centigrade to Fahrenheit .....................................................................................................................16

Air Settings ................................................................................................................................................................16

Care and Preventative Maintenance .............................................................................................................................17

Frequently Asked Questions .........................................................................................................................................18

Troubleshooting ............................................................................................................................................................19

ProcessMate 6500 Temperature Control Unit

4www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Nordson EFD Product Safety Statement

The safety messages that follow have a CAUTION level hazard.

Failure to comply may result in minor or moderate injury.

CAUTION

READ MANUAL

Read manual for proper use of this equipment. Follow all safety instructions. Task- and equipment-

specific warnings, cautions, and instructions are included in equipment documentation where

appropriate. Make sure these instructions and all other equipment documents are accessible to

persons operating or servicing equipment.

The safety message that follows has a WARNING level hazard.

Failure to comply could result in death or serious injury.

WARNING

ELECTRIC SHOCK

Risk of electric shock. Disconnect power before removing covers and / or disconnect, lock out, and

tag switches before servicing electrical equipment. If you receive even a slight electrical shock, shut

down all equipment immediately. Do not restart the equipment until the problem has been identified

and corrected.

MAXIMUM AIR PRESSURE

Unless otherwise noted in the product manual, the maximum air input pressure is 7.0bar (100psi).

Excessive air input pressure may damage the equipment. Air input pressure is intended to be

applied through an external air pressure regulator rated for 0 to 7.0bar (0 to 100psi).

RELEASE PRESSURE

Release hydraulic and pneumatic pressure before opening, adjusting, or servicing pressurized

systems or components.

BURNS

Hot surfaces! Avoid contact with the hot metal surfaces of heated components. If contact can not be

avoided, wear heat-protective gloves and clothing when working around heated equipment. Failure

to avoid contact with hot metal surfaces can result in personal injury.

5www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 6500 Temperature Control Unit

Nordson EFD Product Safety Statement (continued)

Halogenated Hydrocarbon Solvent Hazards

Do not use halogenated hydrocarbon solvents in a pressurized system that contains aluminum components.

Under pressure, these solvents can react with aluminum and explode, causing injury, death, or property damage.

Halogenated hydrocarbon solvents contain one or more of the following elements.

Element Symbol Prefix

Fluorine F “Fluoro-”

Chlorine Cl “Chloro-”

Bromine Br “Bromo-”

Iodine I “Iodo-”

Check the Safety Data Sheet (SDS) or contact your material supplier for more information. If you must use

halogenated hydrocarbon solvents, contact your EFD representative for compatible EFD components.

High Pressure Fluids

High pressure fluids, unless they are safely contained, are extremely hazardous. Always release fluid pressure before

adjusting or servicing high pressure equipment. A jet of high pressure fluid can cut like a knife and cause serious

bodily injury, amputation, or death. Fluids penetrating the skin can also cause toxic poisoning.

Any injury caused by high pressure liquid can be serious. If you are injured or even suspect an injury:

• Go to an emergency room immediately.

• Tell the doctor that you suspect an injection injury.

• Show the doctor the following note.

• Tell the doctor what kind of material you were dispensing.

WARNING

Medical Alert — Airless Spray Wounds: Note to Physician

Injection in the skin is a serious traumatic injury. It is important to treat the injury surgically as soon as possible. Do

not delay treatment to research toxicity. Toxicity is a concern with some exotic coatings injected directly into the

bloodstream.

Qualified Personnel

Equipment owners are responsible for making sure that EFD equipment is installed, operated, and serviced by

qualified personnel. Qualified personnel are those employees or contractors who are trained to safely perform

their assigned tasks. They are familiar with all relevant safety rules and regulations and are physically capable of

performing their assigned tasks.

ProcessMate 6500 Temperature Control Unit

6www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Nordson EFD Product Safety Statement (continued)

Intended Use

Use of EFD equipment in ways other than those described in the documentation supplied with the equipment may

result in injury to persons or damage to property. Some examples of unintended use of equipment include:

• Using incompatible materials.

• Making unauthorized modifications.

• Removing or bypassing safety guards or interlocks.

• Using incompatible or damaged parts.

• Using unapproved auxiliary equipment.

• Operating equipment in excess of maximum ratings.

• Operating equipment in an explosive atmosphere.

Regulations and Approvals

Make sure all equipment is rated and approved for the environment in which it is used. Any approvals obtained for

Nordson EFD equipment will be voided if instructions for installation, operation, and service are not followed. If the

equipment is used in a manner not specified by Nordson EFD, the protection provided by the equipment may be

impaired.

Personal Safety

To prevent injury, follow these instructions:

• Do not operate or service equipment unless you are qualified.

• Do not operate equipment unless safety guards, doors, and covers are intact and automatic interlocks are

operating properly. Do not bypass or disarm any safety devices.

• Keep clear of moving equipment. Before adjusting or servicing moving equipment, shut off the power supply

and wait until the equipment comes to a complete stop. Lock out power and secure the equipment to prevent

unexpected movement.

• Make sure spray areas and other work areas are adequately ventilated.

• When using a syringe barrel, always keep the dispensing end of the tip pointing towards the work and away

from the body or face. Store syringe barrels with the tip pointing down when they are not in use.

• Obtain and read the Safety Data Sheet (SDS) for all materials used. Follow the manufacturer’s instructions for

safe handling and use of materials and use recommended personal protection devices.

• Be aware of less-obvious dangers in the workplace that often cannot be completely eliminated, such as hot

surfaces, sharp edges, energized electrical circuits, and moving parts that cannot be enclosed or otherwise

guarded for practical reasons.

• Know where emergency stop buttons, shutoff valves, and fire extinguishers are located.

• Wear hearing protection to protect against hearing loss that can be caused by exposure to vacuum exhaust

port noise over long periods of time.

7www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 6500 Temperature Control Unit

Nordson EFD Product Safety Statement (continued)

Fire Safety

To prevent a fire or explosion, follow these instructions:

• Shut down all equipment immediately if you notice static sparking or arcing. Do not restart the equipment until

the cause has been identified and corrected.

• Do not smoke, weld, grind, or use open flames where flammable materials are being used or stored.

• Do not heat materials to temperatures above those recommended by the manufacturer. Make sure heat

monitoring and limiting devices are working properly.

• Provide adequate ventilation to prevent dangerous concentrations of volatile particles or vapors. Refer to local

codes or the SDS for guidance.

• Do not disconnect live electrical circuits when working with flammable materials. Shut off power at a disconnect

switch first to prevent sparking.

• Know where emergency stop buttons, shutoff valves, and fire extinguishers are located.

Preventive Maintenance

As part of maintaining continuous trouble-free use of this product, Nordson EFD recommends the following simple

preventive maintenance checks:

• Periodically inspect tube-to-fitting connections for proper fit. Secure as necessary.

• Check tubing for cracks and contamination. Replace tubing as necessary.

• Check all wiring connections for looseness. Tighten as necessary.

• Clean: If a front panel requires cleaning, use a clean, soft, damp rag with a mild detergent cleaner. DO NOT

USE strong solvents (MEK, acetone, THF, etc.) as they will damage the front panel material.

• Maintain: Use only a clean, dry air supply to the unit. The equipment does not require any other regular

maintenance.

• Test: Verify the operation of features and the performance of equipment using the appropriate sections of this

manual. Return faulty or defective units to Nordson EFD for replacement.

• Use only replacement parts that are designed for use with the original equipment. Contact your Nordson EFD

representative for information and advice.

ProcessMate 6500 Temperature Control Unit

8www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Important Disposable Component Safety Information

All Nordson EFD disposable components, including syringe barrels, cartridges, pistons, tip caps, end caps,

and dispense tips, are precision engineered for one-time use. Attempting to clean and re-use components will

compromise dispensing accuracy and may increase the risk of personal injury.

Always wear appropriate protective equipment and clothing suitable for your dispensing application and adhere to

the following guidelines:

• Do not heat syringe barrels or cartridges to a temperature greater than 38° C (100° F).

• Dispose of components according to local regulations after one-time use.

• Do not clean components with strong solvents (MEK, acetone, THF, etc.).

• Clean cartridge retainer systems and barrel loaders with mild detergents only.

• To prevent fluid waste, use Nordson EFD SmoothFlow™pistons.

Action in the Event of a Malfunction

If a system or any equipment in a system malfunctions, shut off the system immediately and perform the following

steps:

1. Disconnect and lock out system electrical power. If using hydraulic and pneumatic shutoff valves, close and

relieve pressure.

2. For Nordson EFD air-powered dispensers, remove the syringe barrel from the adapter assembly. For Nordson

EFD electro-mechanical dispensers, slowly unscrew the barrel retainer and remove the barrel from the actuator.

3. Identify the reason for the malfunction and correct it before restarting the system.

Disposal

Dispose of equipment and materials used in operation and servicing according to local codes.

Nordson EFD Product Safety Statement (continued)

9www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 6500 Temperature Control Unit

Specifications

NOTE: Specifications and technical details are subject to change without prior notification.

Item Specification

Cabinet size 18.9Wx 7.1HX 15.9Dcm (7.5Wx 2.8Hx 6.3D")

Weight 1.0 kg (2.2 lb)

Input AC (to power supply) 100–240 VAC (±10%) ~50/60Hz, 0.6 A

Output DC (from power supply) 24 VDC, 1.04 A maximum

Power requirements 24 VDC, 1.04 A maximum

Standard air input *2.8–7.5bar (40–110psi)

*WARNING: DO NOT exceed 7.5bar (110psi) or damage to the unit may

occur.

Air usage Up to 85 L/min (3 CFM). See page 16 for details.

Temperature control** ±0.1º C from 10–40º C (50–104° F)

Ambient operating conditions** Temperature: -10–55º C (14–131º F)

Humidity: 85% RH at 30ºC non-condensing

Height above sea level: 2000 m maximum (6562 ft)

Approvals CE, China RoHS

**Under normal operating temperatures, the ProcessMate 6500 can maintain dispense process chamber setpoint within ±0.1º C,

from 10–40º C (50–104° F). Normal operating conditions are considered to be an ambient air feed between 15–27º C (60–80º F).

The ProcessMate 6500 will operate quite effectively outside of these temperatures, but it will affect the maximum and minimum

temperatures the unit can generate.

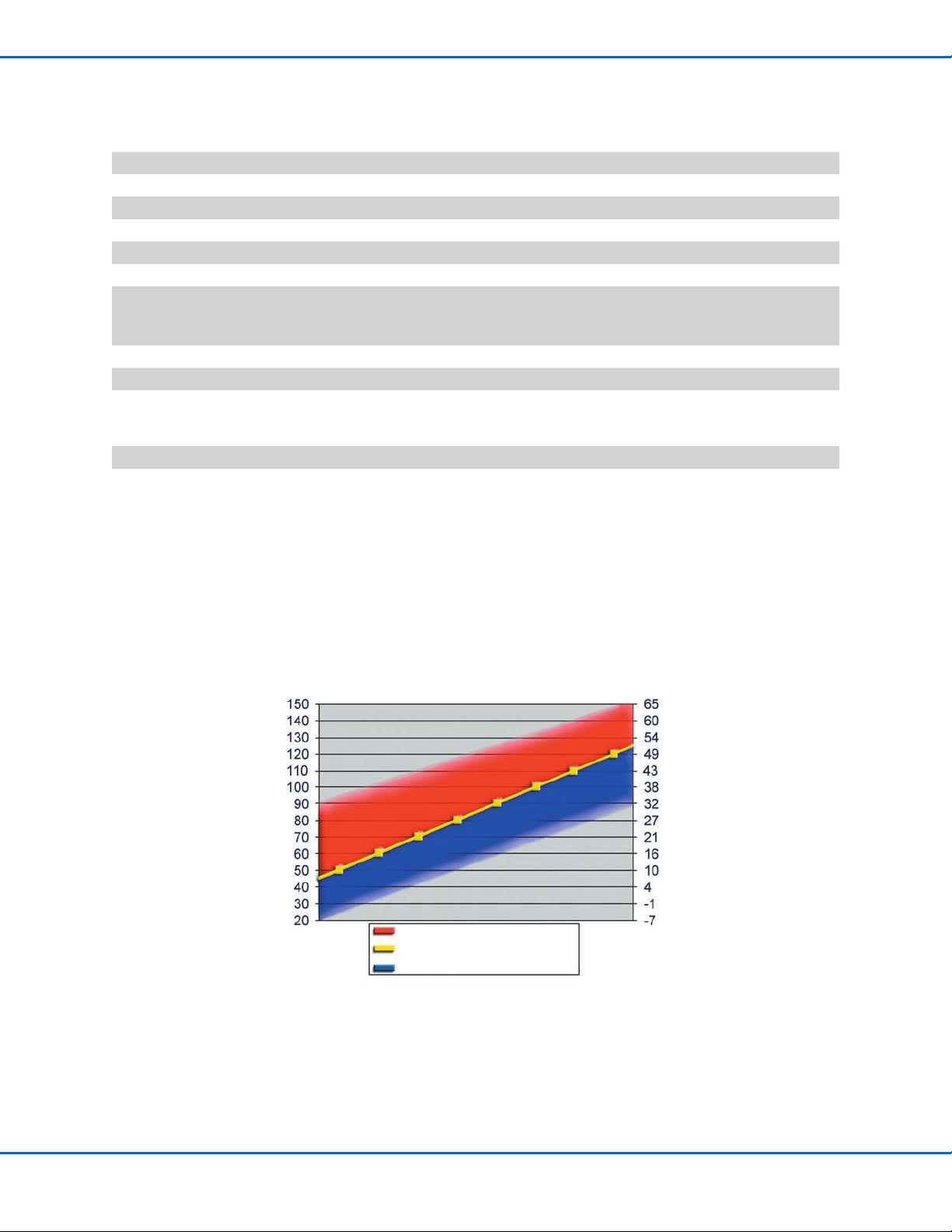

Maximum / Minimum Temperatures

Based on Ambient Conditions*

Heating Capabilities of ProcessMate

Ambient Conditions*

Cooling Capabilities of ProcessMate

*Ambient conditions include the ProcessMate unit, hoses,

process chamber, and compressed air temperature.

Temp (°C)Temp (°F)

ProcessMate 6500 Temperature Control Unit

10 www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

RoHS标准相关声明标准相关声明 (China RoHS Hazardous Material Declaration)

产品名称

Part Name

有害物质及元素

Toxic or Hazardous Substances and Elements

铅

Lead

(Pb)

汞

Mercury

(Hg)

镉

Cadmium

(Cd)

六价铬

Hexavalent

Chromium

(Cr6)

多溴联苯

Polybrominated

Biphenyls

(PBB)

多溴联苯醚

Polybrominated

Diphenyl Ethers

(PBDE)

外部接口

External Electrical

Connectors

X00000

O: 表示该产品所含有的危险成分或有害物质含量依照EIP-A, EIP-B, EIP-C

的标准低于SJ/T11363-2006 限定要求。

Indicates that this toxic or hazardous substance contained in all the homogeneous materials for this part, according to EIP-A, EIP-B, EIP-C is below the

limit requirement in SJ/T11363-2006.

X: 表示该产品所含有的危险成分或有害物质含量依照EIP-A, EIP-B, EIP-C

的标准高于SJ/T11363-2006 限定要求.

Indicates that this toxic or hazardous substance contained in all the homogeneous materials for this part, according to EIP-A, EIP-B, EIP-C is above the

limit requirement in SJ/T11363-2006.

Specifications (continued)

11www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 6500 Temperature Control Unit

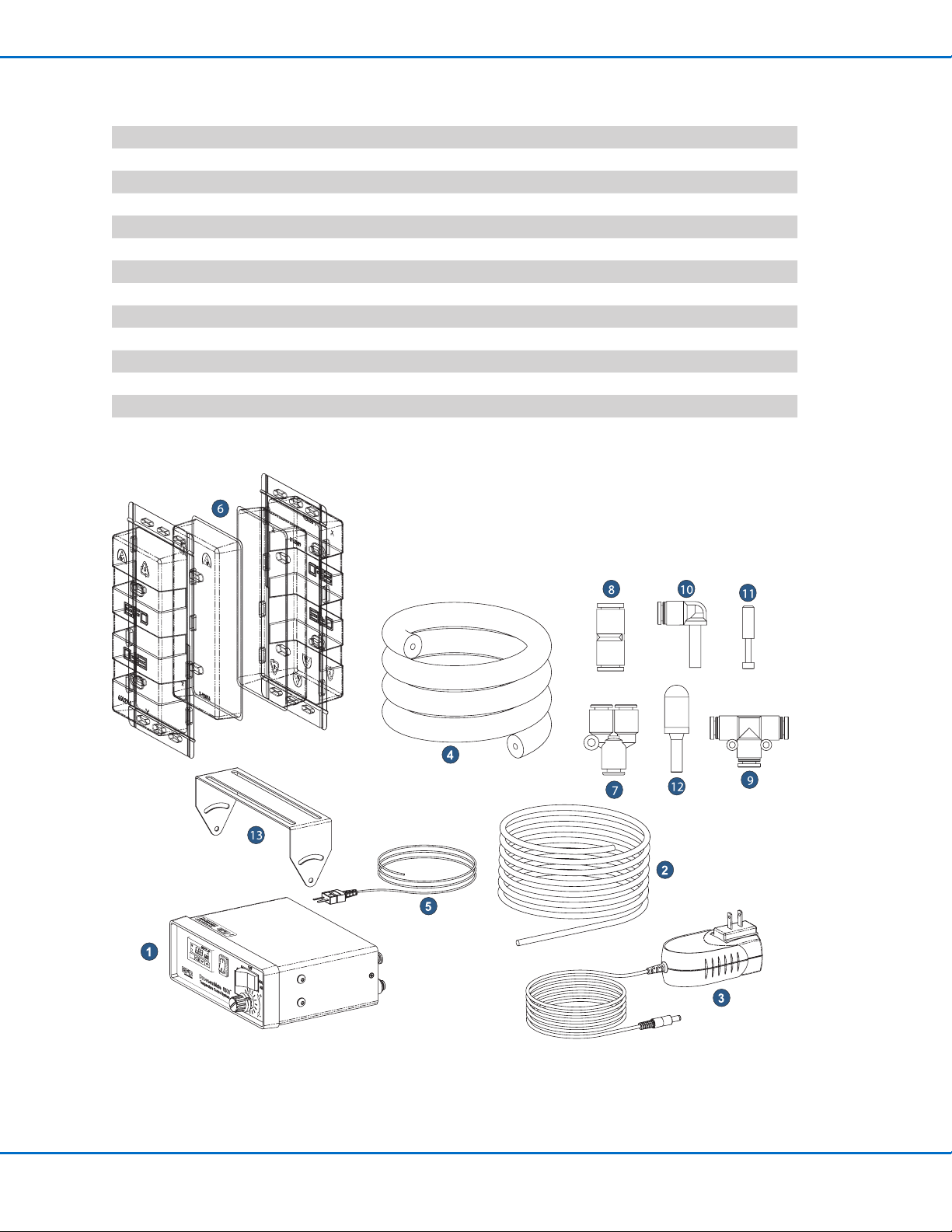

Parts List

Item Part # Description Quantity

1 7020340 ProcessMate 6500 temperature control unit (1)

2 7002004 Tubing, 6 mm OD, urethane, blue 14.5 ft (4.50 m)

3 7015199 25W universal power supply (1)

4 7020364 Insulation, 1/4" ID X 3/8" wall 6 ft (1,87 m)

5 — Thermocouple, K type (1)

6 — Temperature control chamber (1)

7 — Fitting, union, Y, 6 mm, push-in (1)

8 — Fitting, union, strt, 6 mm push-in (1)

9 7020375 Fitting, union, tee, 6 mm push-in (1)

10 7020377 Fitting, stem elbow, 6 mm push-in (2)

11 — Plug, 6 mm push-in (2)

12 — Muffler, 6 mm push-in (3)

13 7020800 Pivot bracket (1)

ProcessMate 6500 Temperature Control Unit

12 www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Unpack the Unit

Use the checklist enclosed with the ProcessMate to identify all

items. If there is any discrepancy, please call us immediately.

1

Installation

2Connect Power

a. Connect the power plug to the power pack. The unit

is shipped with a USA-compatible plug and three

international plugs. Attach the correct plug to match

local power outlets.

b. Connect the power cord into the back of the

ProcessMate.

c. Connect the power cord into your local power source.

3Connect Air Input

NOTE: Clean, dry, filtered factory air is required to meet the

warranty. If your air supply is not filtered, order the EFD five-

micron filter / regulator (part #7016547).

a. Push one end of the air input hose into the input fitting

on the back of the ProcessMate.

b. Connect the other end of the hose to your plant air

supply.

DO NOT exceed 7.5bar (110psi) or damage to the unit may

occur.

CAUTION

c. Set the plant air supply within 5.5–6.9bar (80–100psi).

13www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 6500 Temperature Control Unit

Installation (continued)

4Connect Thermocouple

a. Plug the K-type thermocouple lead into the back panel

of the ProcessMate.

b. Connect the other end of the lead to the process

hardware.

*Option: Route the thermocouple lead with either air line

tube inside the insulation. See directions below.

NOTE: Longer thermocouple leads can be used when

required. These are available from a variety of sources in

many lengths. Only K-Type thermocouple leads should

be used with the ProcessMate. Using a different type will

result in incorrect temperatures.

5Attach Process Feed Lines

a. Slide the insulation over the cold process feed line.

b. Slide the insulation over the hot process feed line.

*Option: Route the thermocouple lead with either the hot

or cold process feed line.

c. Insert the cold process feed line into the cold process

fitting.

d. Insert the hot process feed line into the hot process

fitting.

6Connect Exhaust Mufflers

• Insert a muffler into each exhaust port for both cold and

hot feed exhausts.

NOTE: Tubing can be purchased as an accessory to route

for remote exhaust in lieu of mufflers.

ProcessMate 6500 Temperature Control Unit

14 www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

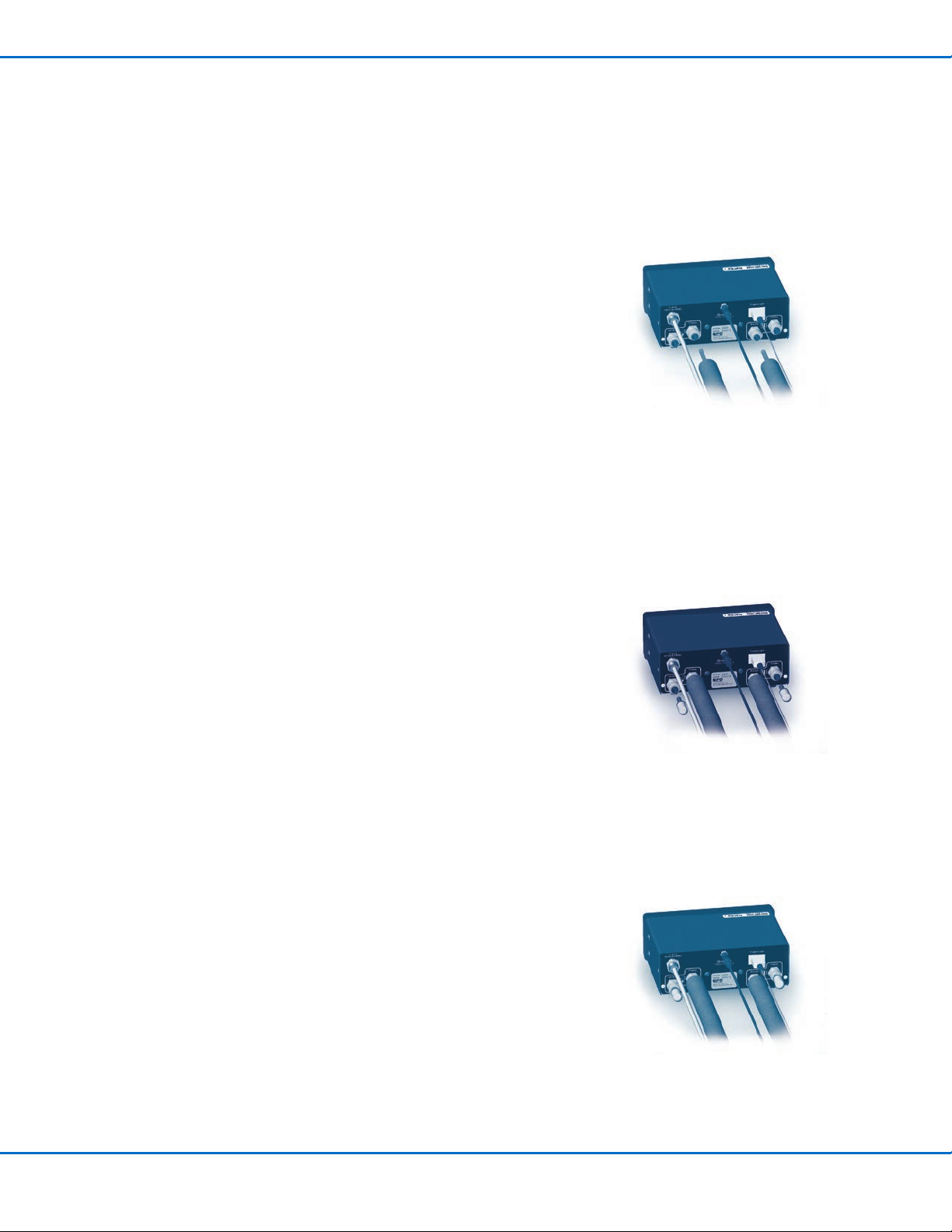

Configuration

The ProcessMate can be plumbed in a variety of configurations depending on your specific needs. All of the

hardware required for each of these setups is included with your unit.

Configuration A

Applications requiring both heating and chilling

capabilities. (Facilities or machines which

experience temperature fluctuations above and

below the required process temperature require

both hot and cold.)

Configuration B

Applications requiring both heating and chilling

in a compact space. Hot and cold airstreams

may be joined together with the supplied “Y”

fitting. (The unit will cycle more often as the

common tube retains some of the thermal

energy.)

Configuration C

A process that only requires cold air flow.

(Ambient conditions are well above desired

temperature within the chamber.)

Configuration D

A process that only requires hot air flow.

(Ambient conditions are well below desired

temperature within the chamber.)

15www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 6500 Temperature Control Unit

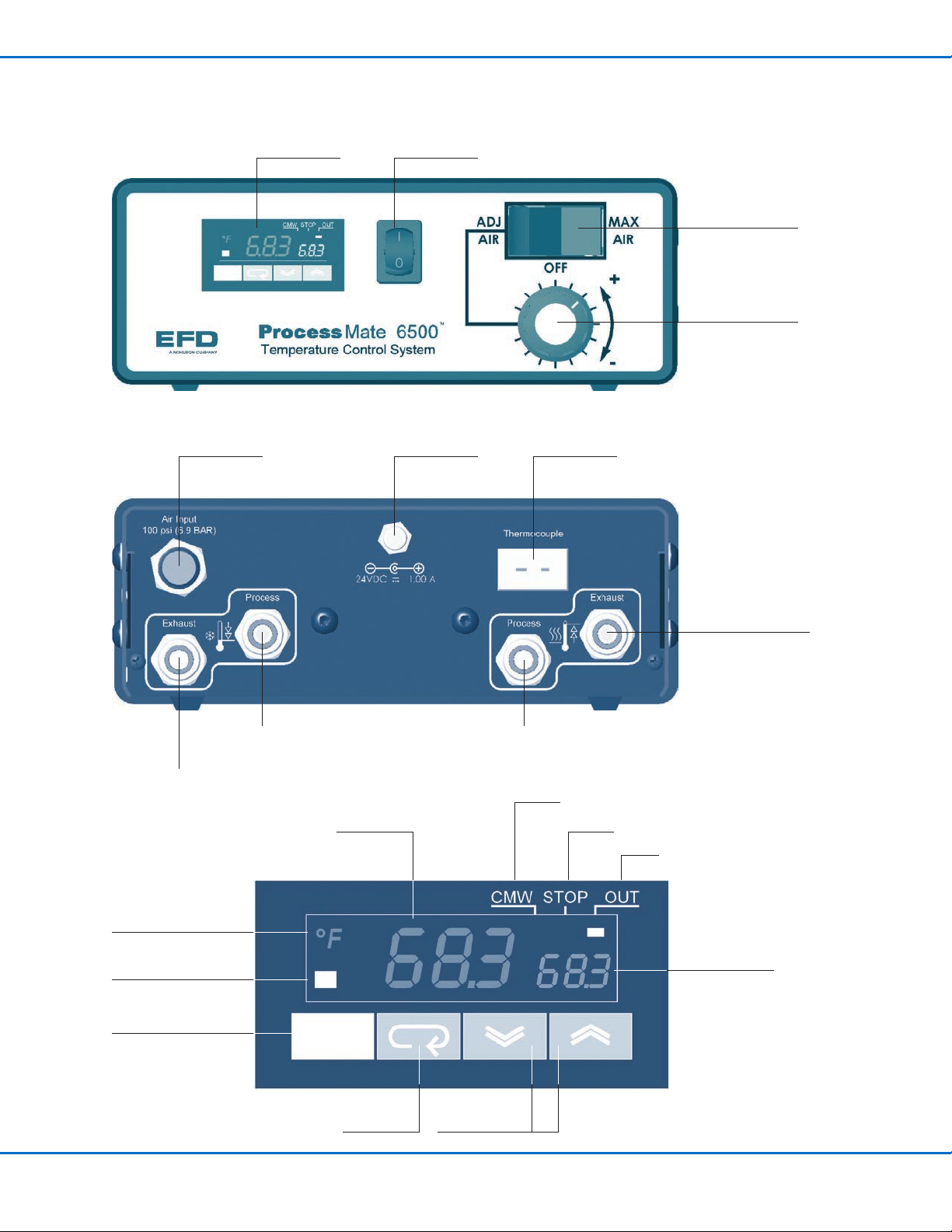

Features & Controls: Front & Rear Panels

Digital display Power switch

Air input Power cord Thermocouple

Air switch

Flow control knob

To exhaust feed line

Cold process feed line Hot process feed line

To exhaust feed line

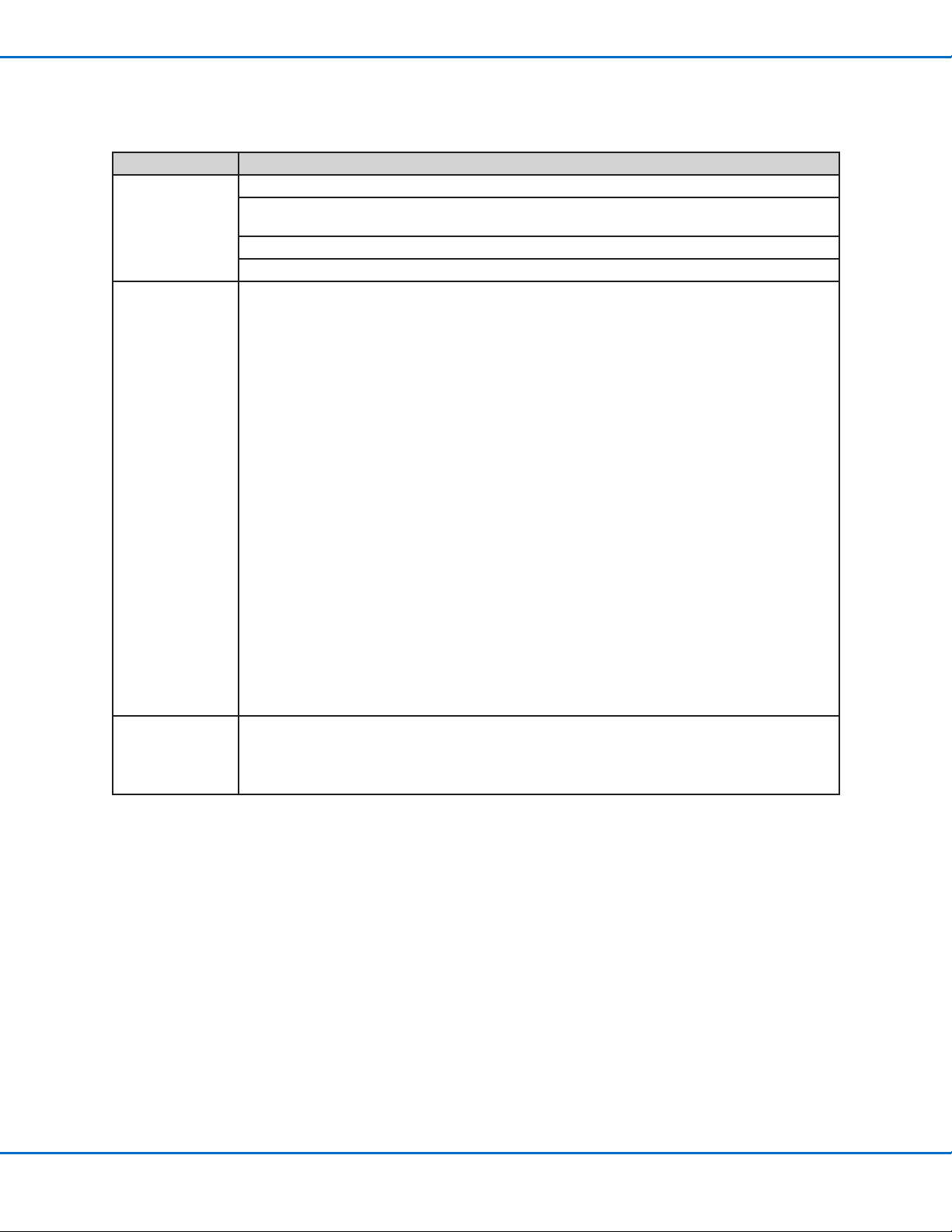

No.2 display

OUT

STOP

CMW

No. 1 display

Temperature unit

Alarm output indicator

Level key

Mode key Up / Down keys

ProcessMate 6500 Temperature Control Unit

16 www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Front Panel Digital Display

Digital Display

Level key Use to access advanced features of the controller. (Refer to manufacturer’s documentation

supplied with unit.)

Mode key Use to access advanced features of the controller. (Refer to manufacturer’s documentation

supplied with unit.)

No. 1 display Actual temperature as measured by the thermocouple

No. 2 display Process temperature setpoint

Up / down keys Use to change the temperature setpoint value displayed on the No. 2 display

AAlarm indicator light—lights up whenever the unit is adding cold air to the process

CMW* Communications writing enable / disable indicator lights

STOP* Control stop indicator

OUT* Control output 1 & 2 indicators

*Advanced features NOT used by ProcessMate

Change from Centigrade to Fahrenheit

• Hold down the Level Key for 3 seconds. [Cn-t] will appear.

• Press the Mode Key. [d-u] will appear.

• Press the Up arrow key to change from C to F or vice-versa.

• Return to the Temperature Display by holding the Level Key for 3 seconds.

Air Settings

OFF Stops all air from flowing through the unit

MAX Air Maximum air flow through the unit (approximately 3CFM

or 85 LPM). This also produces the maximum degree of

heating or chilling. Once near to the desired temperature,

the “ADJ Air” setting should be used.

ADJ Air The ADJ (Adjustable) Air setting is used to precisely

control the air flow. The knob is labeled with +/- markings

and allows more or less air to reach the process. Set the

knob to the minimum amount required to maintain the

desired temperature.

17www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 6500 Temperature Control Unit

Care and Preventative Maintenance

The ProcessMate and accessories will last a long time if they are maintained properly and handled with care.

• The ProcessMate should be kept clean and dry.

• Make sure the unit is unplugged when conducting maintenance on the unit.

• Clean the unit with a damp sponge or cloth. Use warm water and mild soap solution, if required. DO NOT allow

drips or excess water inside the unit. DO NOT spray or pressure wash unit.

• The ProcessMate does not have any user serviceable parts inside. Removing the protective housing will void

the product warranty.

• External parts should be monitored for wear. Inspect the tube insulation regularly for signs of aging and

cracking. Inspect air fittings for signs of leakage.

• Contact EFD for replacement parts.

ProcessMate 6500 Temperature Control Unit

18 www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Frequently Asked Questions

Can I Modify the Clamshell Process Chambers?

YES.

• The clamshell process chambers (sold separately) are simple and easy to modify.

• The plastic can be cut to customize the box to fit individual process requirements.

• The boxes are disposable. If the box becomes soiled or damaged, replacements are readily available from EFD.

Can I Make My Own Process Chamber?

YES.

For those who wish to make their own process chamber, follow the guidelines below:

• The chamber should cover the entire material path (syringe, valve, fittings, etc, leaving only the needle or exit

point exposed).

• The chamber should have a minimum of “dead air” space. The less space inside the chamber, the easier it is to

maintain temperatures within.

• The chamber should allow the heated / chilled air to circulate freely around the process hardware within.

• The chamber must have a vent that allows air to exit the chamber. Plan ahead to determine where the heated /

chilled air can freely enter, circulate, and then exit the chamber.

• The chamber should either be made of transparent materials, or be provided with a window to allow monitoring

of material levels.

• In order to maintain temperatures well above or below ambient conditions, the chamber should be made

from or contain an insulated material or have double-walled construction. This will help to maintain desired

temperatures.

19www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 6500 Temperature Control Unit

Troubleshooting

If you encounter a problem that you cannot readily solve, call Nordson EFD.

Problem Possible cause and correction

No power Be sure that there is power available at the wall receptacle.

Unplug the unit. Make sure AC/DC power supply’s main plug adapter is firmly seated and

locked on the supply body.

Make sure that the power lead is firmly inserted and seated at the rear of the unit.

If the unit still does not have power, call EFD for assistance.

Unit will not

maintain pre-set

temperature

1. Make sure the thermocouple is solidly plugged into the rear of the unit and that the lead

is affixed to the process hardware.

2. Check the incoming air pressure and flow. For maximum efficiency, the unit must be

supplied with 6.9 bar (100psi) of clean, dry air.

3. If the pressure is fluctuating or dropping, the unit efficiency will be reduced. Insufficient

air flow will cause degradation to the minimum and maximum temperatures the unit can

provide.

4. Check the air pressure to ensure that it is not varying. If needed, use the filter / regulator

(EFD part #7016547).

5. A slow drop or rise from the desired temperature (usually over the course of several

hours) can be caused by moisture inside the air supply that is causing freezing inside the

unit. This will reduce the air flow and degrade the minimum and maximum temperatures

the unit can provide.

To properly diagnose whether this is occurring, shut off the unit for several minutes to allow

the potential blockage to thaw. Turn the unit back on. If the temperature resumes the required

setpoint, it is a sure sign that moisture is present.

If your process is not dependent on the unit running continuously, shut down the unit in

between runs to prevent moisture buildup in the unit.

The preferred method is to install line dryers: refrigerant type, in-line desiccant, or membrane

dryers. The desiccant and membrane type dryers have been shown to produce substantial

dew point reductions, and are the preferred method to reduce moisture in the unit. These are

available from EFD.

Condensation

forms on the

tubing

Condensation may form on the process supply tubing if temperature setpoints are well below

ambient room temperature and relative humidity is high.

Tube insulation supplied with the unit will prevent condensation from forming and will also

increase overall efficiency.

NORDSON EFD ONE YEAR LIMITED WARRANTY

This NordsonEFD product is warranted for one year from the date of purchase to be free

from defects in material and workmanship (but not against damage caused by misuse,

abrasion, corrosion, negligence, accident, faulty installation, or by dispensing material

incompatible with equipment) when the equipment is installed and operated in accordance

with factory recommendations and instructions.

NordsonEFD will repair or replace free of charge any defective part upon authorized return

of the part prepaid to our factory during the warranty period. The only exceptions are those

parts which normally wear and must be replaced routinely, such as, but not limited to, valve

diaphragms, seals, valve heads, needles, and nozzles.

In no event shall any liability or obligation of NordsonEFD arising from this warranty exceed

the purchase price of the equipment.

Before operation, the user shall determine the suitability of this product for its intended use,

and the user assumes all risk and liability whatsoever in connection therewith. NordsonEFD

makes no warranty of merchantability or fitness for a particular purpose. In no event shall

NordsonEFD be liable for incidental or consequential damages.

This warranty is valid only when oil-free, clean, dry, filtered air is used, where applicable.

For Nordson EFD sales and service in over

40 countries, contact Nordson EFD or go to

www.nordsonefd.com.

Global

800-556-3484; +1-401-431-7000

Europe

00800 7001 7001

Asia

The Wave Design is a trademark of Nordson Corporation.

©2021 Nordson Corporation 7365331 v012721

Table of contents

Popular Temperature Controllers manuals by other brands

Sterlco

Sterlco 6017 Series Operation and installation manual

meitav-tec

meitav-tec ERT100-LCD-IR operating manual

Ever Cool

Ever Cool TC140 Operating & maintenance instruction manual

Bryant

Bryant SYSTXBBECW01-A installation instructions

Extech Instruments

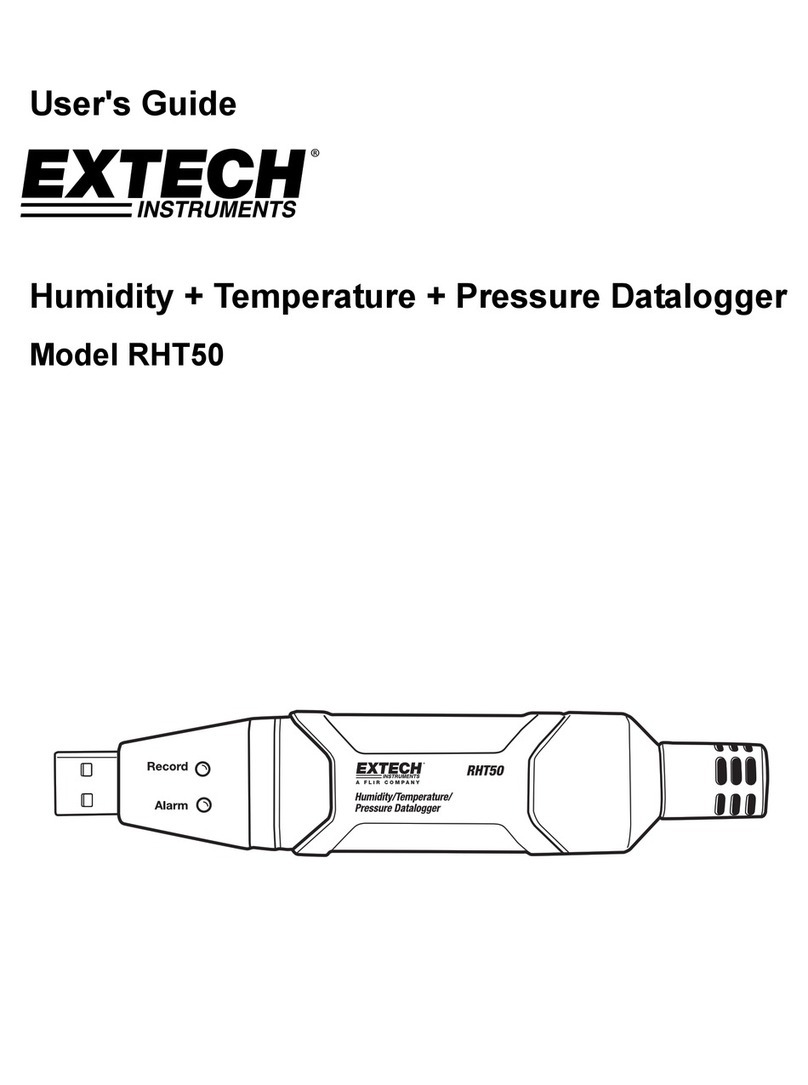

Extech Instruments RHT50 user guide

Autonics

Autonics TC3YT-B4R3 Simple operation manual