NORIS VD61 User manual

Instruction Manual

VD61

NAN-KD-0031-EN_V01.01 | 05/05/2021

| Issue NORIS Automation GmbH

2/ 23 Instruction Manual VD61

Issue

Information on issue

Document ID NAN-KD-0031-EN

Issue V01.01

Date April 2021

NORIS Automation GmbH Table of contents

Instruction Manual VD61 iii

Table of contents

1General information 4

2General information on this instruction manual 6

2.1 Scope of validity 6

2.2 Subject of the instruction manual 6

2.3 Use of safety and warning notes 6

2.4 Scope of delivery 7

2.5 Accessories and spare parts 7

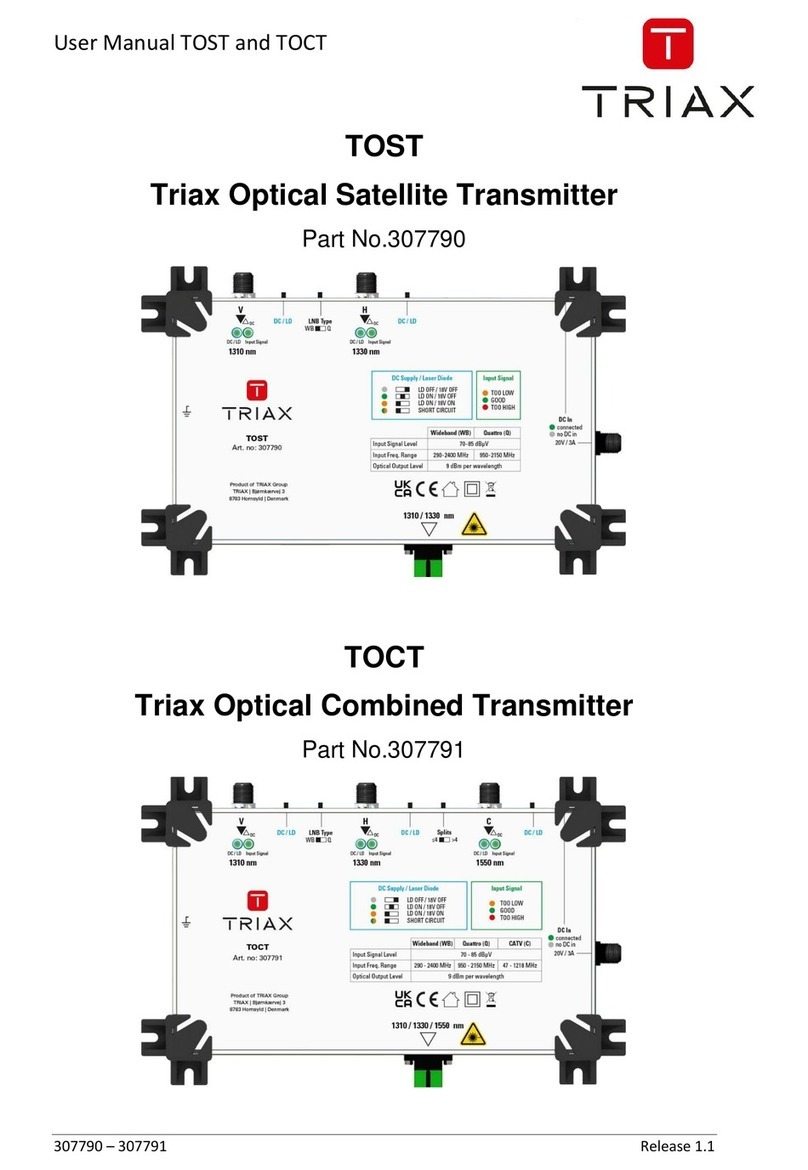

3Product description 8

3.1 Safety notes 8

3.2 Scope of application 9

3.3 Measuring principle 9

3.4 Type code 9

4Technical data 10

5Installation and commissioning 13

5.1 Tools and equipment 13

5.2 Dimensions 14

5.3 Installation 16

5.4 Electrical connection 18

6Maintenance 20

7De-installation and disposal 21

8Troubleshooting 22

9Service 23

1| General information NORIS Automation GmbH

4/ 23 Instruction Manual VD61

General information

Use for intended purpose

▪ Theproductmayonlybeusedfortheapplicationsspecifiedinthis

document and in the technical documentation. Transportation with due

care and attention, correct storage and installation as well as careful

use and maintenance during operation of the product must be ensured

to guarantee trouble-free and safe operation.

▪ Theproductmustbeusedatalltimesinagreementwiththetechnical

specifications. In particular, compliance with the ambient conditions

recommended in the technical documentation must be ensured.

Installation, assembly, repair and maintenance work

▪ Observetherelevantnationalregulationsandobservetheapplicable

standards and directives for special applications.

▪ Installation,assembly,repairandmaintenanceworkmustbecarried

out exactly according to the installation and maintenance instructions

applicable to the individual products in order to guarantee their func-

tional reliability and avoid installation errors and damage.

▪ Installation,assembly,repairandmaintenanceworkmustonlybeper-

formed by qualified and authorised technical personnel in accordance

with the relevant documentation, especially the safety and warning in-

formation contained therein.

▪ Makesurethatnoexcessparts(screws,tools,etc)areleftbehindin

or on products after performing installation, assembly, repair or main-

tenance work. Non-compliance with this requirement may cause mal-

functions and/or damage to the products or the system.

▪ Makesureafunctiontestiscarriedoutoncompletionofinstallation,

assembly, repair and maintenance work to ensure trouble-free opera-

tion of the products.

Suitable tools and equipment

Onlysuitabletoolsandequipment,especiallymaterialsprovidedbyNO-

RIS, are to be used for installation, assembly, repair and maintenance

work. Damaged products or components are to be replaced only by genu-

ineNORIScomponentsorparts.NORISshallacceptnoliabilitywhatsoev-

er for any damage incurred as the result of using unauthorised spare parts.

This will invalidate the warranty. Keep the operating instructions in a place

that is accessible to all users at any time.

Modification of products

NORISshallacceptnoliabilitywhatsoeverifunauthorisedmodifications

have been made to the products. This will also invalidate the warranty.

Therefore, consult our technical staff before undertaking any modifications.

1

NORIS Automation GmbH General information | 1

Instruction Manual VD61 5/ 23

Shipping, appropriate storage and packaging

Products that are sent in for repair must be appropriately packaged to pre-

ventdamage(fromimpacts,moisture,staticcharge,etc).Makesurethat

products and all spare parts are stored correctly. Refer to the correspond-

ing technical information for further information.

Disclaimer

We review the contents of our technical documentation at regular intervals

to ensure it agrees with our products. Nevertheless, variations cannot be

completelyruledout.NORISthereforecannotguaranteecompleteagree-

ment of the documentation contents with the hardware and software.

Changes and corrections will be included in subsequent issues of the tech-

nical documentation.

2| General information on this instruction manual NORIS Automation GmbH

6/ 23 Instruction Manual VD61

General information on this instruction

manual

Scope of validity

This instruction manual applies to the sensors listed below:

Sensor type Product revision

VD61 A

Important information on the use of this instruction manual

and supplementary information

In addition to the information in this instruction manual, refer also to the in-

formation in the customer drawing for installation, commissioning and oper-

ation.

Subject of the instruction manual

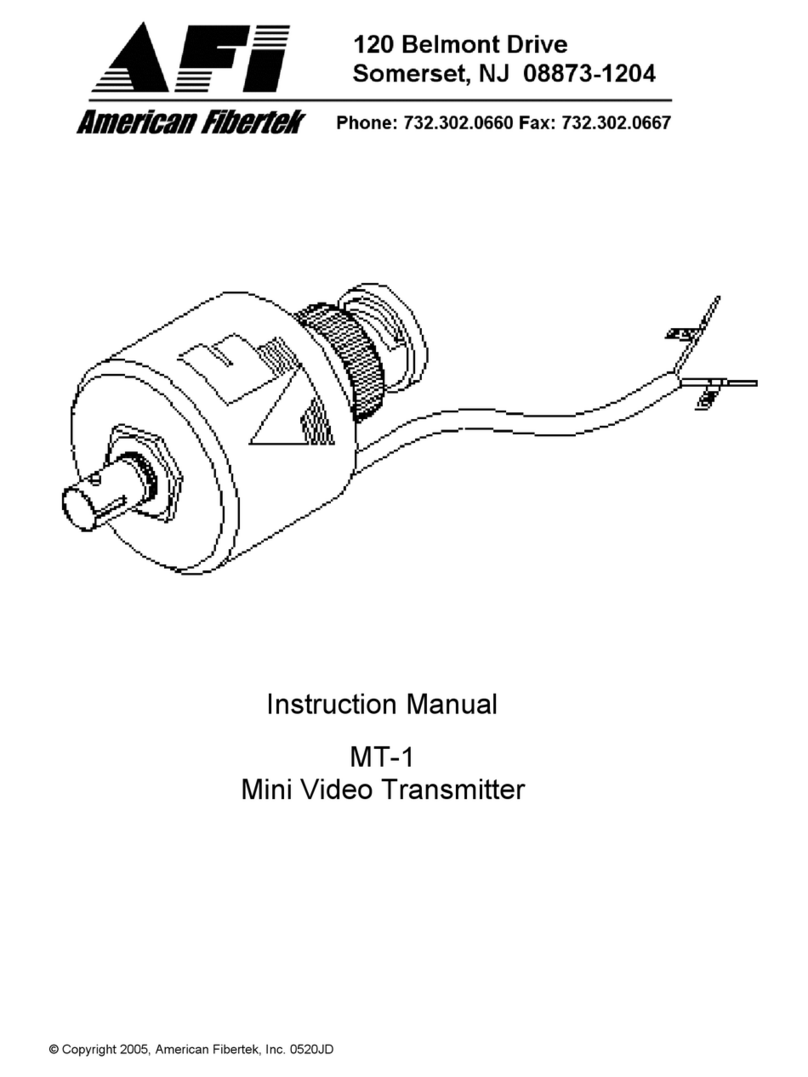

The subject of this instruction manual is the installation, commissioning,

operation and maintenance of pressure transmitter series VD61. Further-

more, this instruction manual also contains important troubleshooting infor-

mation.

Use of safety and warning notes

Warning about the type and source of immediate danger that

leads to death or serious injuries when disregarding the given

precautions.

Warning about the type and source of danger that may possibly

lead to death or serious injuries when disregarding the given

precautions.

Warning about the type and source of danger that may lead to

minor injuries when disregarding the given precautions.

Warning about the type and source of danger that may lead to

material damages when disregarding the given precautions.

2

2.1

2.2

2.3

DANGER

WARNING

CAUTION

NOTICE

NORIS Automation GmbH General information on this instruction manual | 2

Instruction Manual VD61 7/ 23

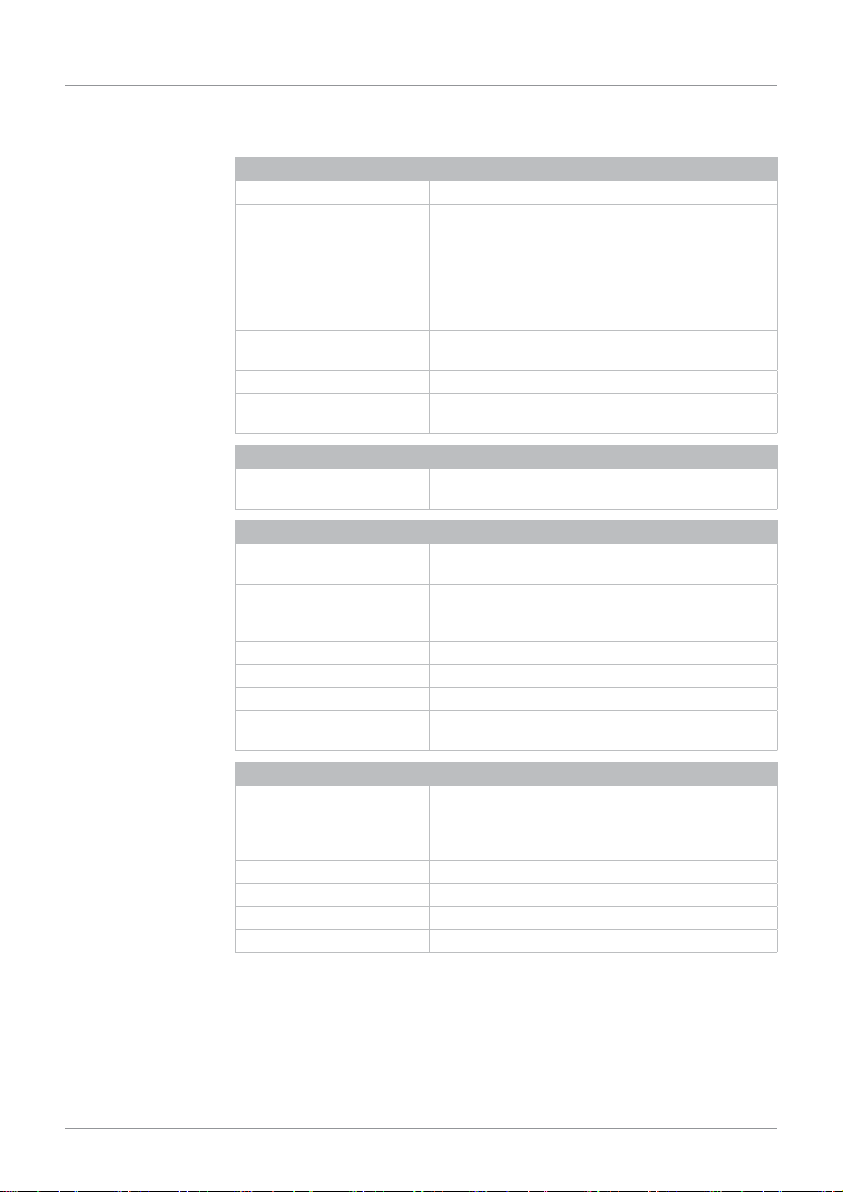

Scope of delivery

Pressure transmitters type series VD61 are delivered without accessories.

Accessories have to be ordered separately.

Accessories and spare parts

Available accessories

Adapter with G½ male

thread

Attenuator with G½ male thread

Pos. Description Drawing no. Order no.

01 Adapter with G½ male thread 59.201 522004

02 Attenuator K6 for heavy oil 59.201 522001

03 Attenuator K7 for light oil 59.201 522002

04 Attenuator K8 for air/water 59.201 522003

Available spare parts

There are no additional spare parts available for pressure transmitters type

series VD61.

2.4

2.5

3| Product description NORIS Automation GmbH

8/ 23 Instruction Manual VD61

Product description

Safety notes

Select the appropriate pressure transmitter with regard to scale

range, performance, medium-contacting parts and specific

measurement conditions prior to installing and starting the in-

strument

Otherwisethetransmittercandbedamaged.

Observe the relevant national regulations and observe the ap-

plicable standards and directives for special applications (e.g.

with dangerous media such as acetylene, flammable gases or

liquids and toxic gases or liquids and with refrigeration plants

or compressors).

If you do not observe the appropriate regulations, serious injuries

and/or damage can occur!

Open pressure connections only after the system is without

pressure!

Please make sure that the pressure transmitter is only used

within the overload threshold limit all the time!

Observe the ambient and working conditions outlined in „Tech-

nical data”.

Observe the technical data for the use of the pressure transmit-

ter in connection with aggressive / corrosive media and for the

avoidance of mechanical hazards. Open circuit before removing

connector / cover.

Ensure that the pressure transmitter is only operated in accord-

ance with the provisions i.e. as described in the following in-

structions.

Do not interfere with or change the pressure transmitter in any

other way than described in these operating instructions.

Remove the pressure transmitter from service and mark it to

prevent it from being used again accidentally, if it becomes

damaged or unsafe for operation.

Otherwiseseriousinjuriesmayoccurandthetransmittercanbe

damaged.

Take precautions with regard to remaining media in removed

pressure transmitter.

Remaining media in the pressure port may be hazardous or toxic!

3

3.1

NOTICE

CAUTION

CAUTION

CAUTION

NORIS Automation GmbH Product description | 3

Instruction Manual VD61 9/ 23

Scope of application

Series VD61 pressure transmitters are mainly used in: Shipbuilding indus-

try, transport technology, machinery and equipment. They measure the

pressure of liquid or gaseous media.

Caution: An unsuitable pressure medium can damage or even

destroy the pressure sensor!

Therefore, please check whether the pressure medium is suitable

for the medium-contacting parts of the pressure sensor before in-

stallation and use. For further information please read the technical

data.

Measuring principle

The pressure prevailing within the application is transformed into a stand-

ardised electrical signal through the deflection of the diaphragm, which

acts on the sensor element with the power supply fed to the transmitter.

This electric signal changes in proportion to the pressure and can be eval-

uated correspondingly.

Type code

Type code structure

VD 6 1 -15 Example: VD61-15

Construction type 6

Signal output

Measuring range

Type code VD61-…

Construction

type

6Construction type 6

Signal output 14 … 20 mA

Measuring

range

-_ _ _ See table "'Measuring range' [}11]"

VD 6 1 -300 Example: VD61-300

3.2

NOTICE

3.3

3.4

4| Technical data NORIS Automation GmbH

10 / 23 Instruction Manual VD61

Technical data

Electrical connection

Supply voltage 8 ... 30 VDC

Current limitation Power supply by energy-limited electrical circuit

in accordance with 9.3 of UL/EN/IEC 61010-1

or LPS in accordance with UL/EN/IEC 60950-1

or Class 2 in accordance with UL1310/UL1585

(NECorCEC)(thepowersupplymustalsobe

suitable for operation at an altitude above 2000

m,ifusedintheseheights)

Reverse voltage protec-

tion

X1+ against X1-

Electrical connection Connecting terminal for max. 1.5 mm²

Pressure connection G¼femalethread(adapterforG½malethread

available,seeaccessories)

Signal acquisition

Standard measuring

range

See measuring range table

Electrical output

Outputsignalandmaxi-

mum permissible load

4...20mA,2-wire,RA≤(UB-8V)/0.02A

Accuracy ≤±1%oftherange(includingnon-linearity,

hysteresis, zero point and final value deviation

(IEC6198-2))

Non-linearity ≤±0.5%ofrange

Non-repeatability ≤0.1%ofrange

Long-term drift ≤±0.1%ofrange(underreferenceconditions)

Transient response Transient recovery time < 4 ms;

turn on-time < 15 ms

Environmental influences

Operatingtemperature Permissible measured medium temperature:

-30 ... +100 °C

Permissible ambient temperature:

-30 ... +100 °C

Storage temperature -30 ... +100 °C

Vibration resistance IEC60068-2-6:10g(resonance)

Shock resistance IEC60068-2-27:500g(mechanical)

Protection class IP64 according to EN 60529

4

NORIS Automation GmbH Technical data | 4

Instruction Manual VD61 11 / 23

Mechanical properties

Material Parts in contact with measured medium: < 10

bar CrNi steel 303 and CrNi steel 316L; > 10

barCrNisteel316Land13-8PH(AISI),hous-

ing:Aluminium,powder-coated(checkthe

pressure medium for suitability for medi-

um-contactingparts)

Weight Approx. 560 g

Other

Approvals DNV

CE Conformity Pressure Equipment Directive 97/23/EC; EMC

Directive 2004/108/EC EN 61326 Emission

(Group1,ClassB)andinterferenceimmunity

(industrialenvironment)

Measuring range VD61

Code Measuring range Overload

1 0 ... 1 bar 2 bar

1,6 0 ... 1.6 bar 3.2 bar

2,5 0 ... 2.5 bar 5 bar

3 0 ... 3 bar 6 bar

4 0 ... 4 bar 8 bar

5 0 ... 5 bar 10 bar

6 0 ... 6 bar 12 bar

10 0 ... 10 bar 20 bar

15 0 ... 15 bar 30 bar

16 0 ... 16 bar 32 bar

20 0 ... 20 bar 40 bar

25 0 ... 25 bar 50 bar

30 0 ... 30 bar 60 bar

40 0 ... 40 bar 80 bar

50 0 ... 50 bar 100 bar

60 0 ... 60 bar 120 bar

100 0 ... 100 bar 200 bar

120 0 ... 120 bar 240 bar

150 0 ... 150 bar 300 bar

160 0 ... 160 bar 320 bar

180 0 ... 180 bar 360 bar

250 0 ... 250 bar 500 bar

300 0 ... 300 bar 600 bar

400 0 ... 400 bar 800 bar

600 0 ... 600 bar 1200 bar

150P 0 ... 150 psi 300 psi

1M1 -1 ... 1 bar 4 bar

4| Technical data NORIS Automation GmbH

12 / 23 Instruction Manual VD61

Measuring range VD61

1,6M1 -1 ... 1.6 bar 5.2 bar

2,5M1 -1 ... 2.5 bar 7 bar

3M1 -1 ... 3 bar 8 bar

4M1 -1 ... 4 bar 10 bar

Preferred types

Features marked with a symbol at the end of the line are preferred fea-

tures. If you select a preferred feature for each placeholder, the device is

specified as preferred type. Preferred types are available quickly from

stock.Othertypeswillbedeliveredaccordingtoscheduledappointments.

NORIS Automation GmbH Installation and commissioning | 5

Instruction Manual VD61 13 / 23

Installation and commissioning

Tools and equipment

Have the following tools and equipment ready for commissioning:

▪ Open-endedspanner(spannerwidth27)

▪ Screwdriver

Make sure that the tools and equipment are in perfect working

order.

Otherwisethepressuretransmittercanbedamaged.

5

5.1

NOTICE

5| Installation and commissioning NORIS Automation GmbH

14 / 23 Instruction Manual VD61

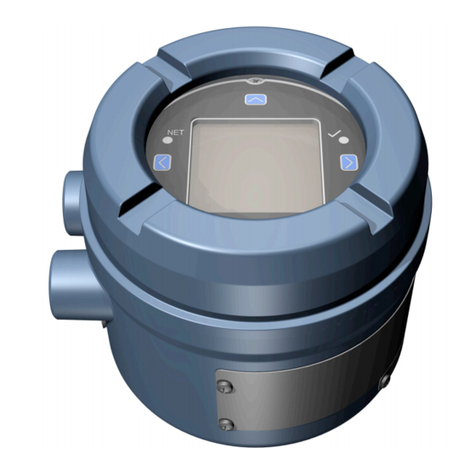

Dimensions

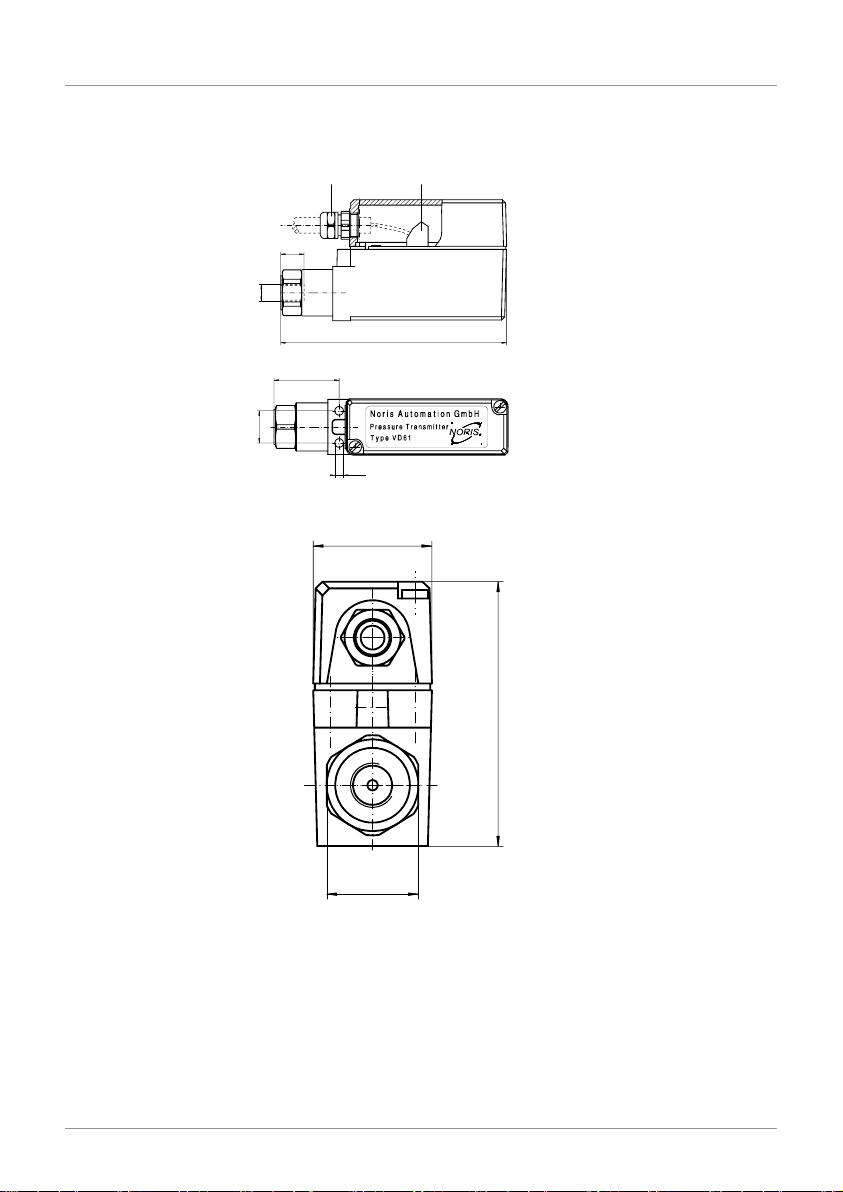

AB

C

D

E

Side view

A)CableglandM16(cableØ5…10

mm)

B)Terminalforcableupto1.5mm2

C)15mm

D)G1/4femalethread

E)146mm

B

A

C

Top view

A)40.5mm

B)20mm

C)Ø5.3mm

A

B

C

Front view

A)35mm

B)78mm

C)WAF27

5.2

NORIS Automation GmbH Installation and commissioning | 5

Instruction Manual VD61 15 / 23

E

A

B

C

D

F

E

A

B

C

D

F

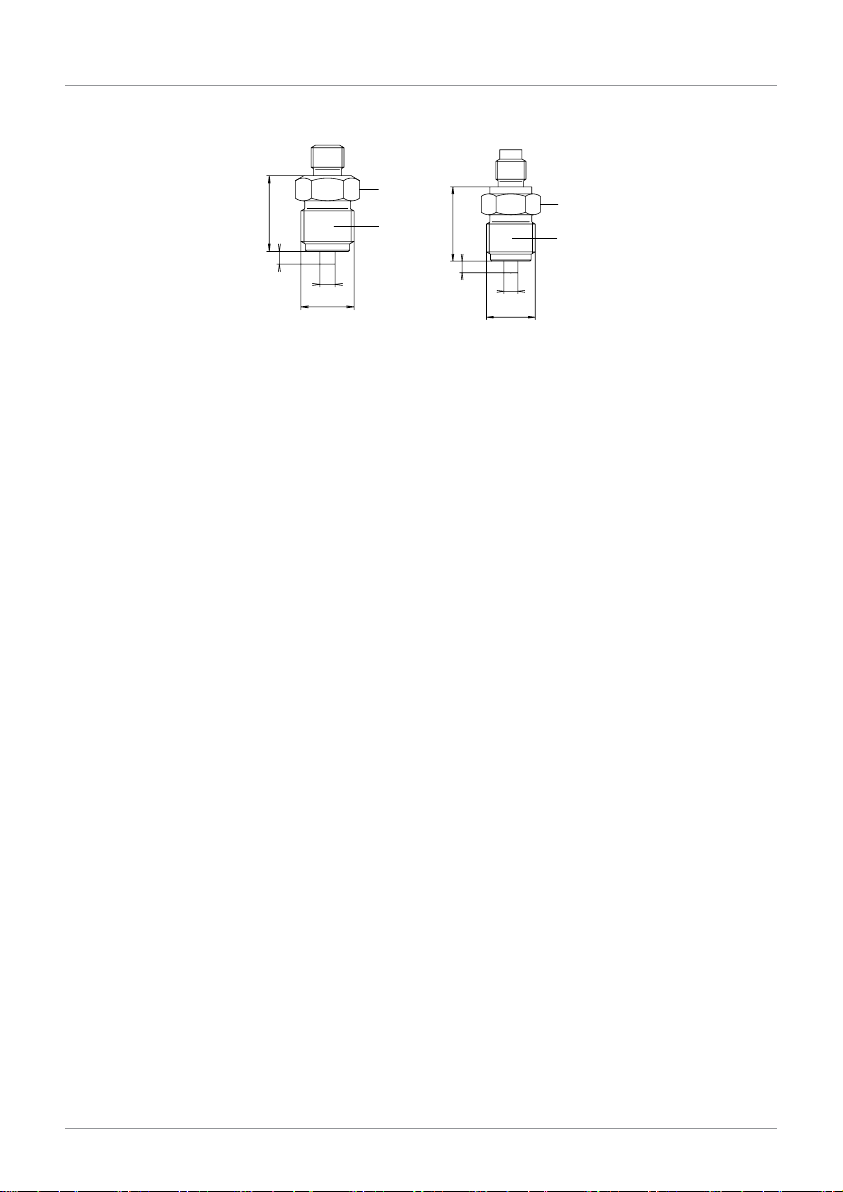

Adapter with G½ male

thread

A)32mm

B)5mm

C)Ø6mm

D)G1/2

E)WAF22

F)Material1.4435

Attenuator with G½ male thread

A)32mm

B)5mm

C)Ø6mm

D)G1/2

E)WAF22

F)Material1.4435

5| Installation and commissioning NORIS Automation GmbH

16 / 23 Instruction Manual VD61

Installation

Install the transmitter in your application in compliance with the following

notes:

▪ Duringmounting,makesurethatthesealingandsealingfacesare

clean and undamaged.

▪ Whenscrewingin,donotcrossthethreads.Thismaydamagethe

transmitter.

Follow the instructions to install the pressure transmitter

A. Screw the pressure transmitter on the mounting surface. Therefore,

twoboreholesarelocatedinthetransmitterhousing(seenextfig.,

Pos.F).Therefore,useappropriatescrews(typeM5,e.g.M5x45).

Type of screw and screw length depend on the mounting surface.

Ensure that the pressure transmitter is bolted down tightly on

the surface.

Otherwisethepressuretransmitterandthepipeconnectioncanbe

damaged.

1: VD61 opened with markings

Follow the instructions to install the pressure connection

5.3

NOTICE

NORIS Automation GmbH Installation and commissioning | 5

Instruction Manual VD61 17 / 23

2: VD61-10 pressure connection

A. Connect the pressure connection appropriately to the pressure

transmitter.

➩Use an open-ended spanner to counter the screw connection.

Therefore,usethenutofthepressuretransmitter(seeprevi-

ousfig)andnotthetransmitterhousing.

➩When screwing, do not cross the threads.

➩If you use an attenuator or an adapter, screw it between the

pressure transmitter and the pressure connection. Pay atten-

tion that you also use the nut of the pressure transmitter for

countering. The screw connection must be seal and fixed

properly.

Avoid improper installation!

Otherwisethepressuretransmittercanbedamaged.

NOTICE

5| Installation and commissioning NORIS Automation GmbH

18 / 23 Instruction Manual VD61

Electrical connection

Note the following instructions for electrical transmitter connection:

▪ Thepressuretransmittermustbegroundedviatheprocessconnec-

tion.

▪ Thepowersupplyforthepressuretransmittermustbemadeviaan

energy-limited electrical circuit in accordance with section 9.3 of UL/

EN/IEC 61010-1, or an LPS per UL/EN/IEC 60950-1, or class 2 in ac-

cordancewithUL1310/UL1585(NECorCEC).Thevoltagesupply

must be suitable for operation above 2,000 m should the pressure

transmitter be used at this altitude.

▪ Makesurethatnomoistureentersthecableend.

X1+

X1-

VD61 Connection diagram

Follow the instructions to connect the cable to the pressure transmit-

ter

A. Loosenthetwoscrews(seenextfig.,Pos.A).

B. Opencarefullythecovering(seenextfig.,Pos.B)

C. Loosenthecablegland(seenextfig.,Pos.C)andinsertthecable

through the cable gland.

➩Therefore, use a cable with a diameter of 5 ... 10 mm and a cross

section of max. 1.5 mm2.

D. Connectthewiringaccordingtoconnectiondiagram(seeprevious

fig.)totheconnectionterminalofthepressuretransmitter.Notethe

terminal markings X1+ and X1- on the connection circuit board. The

use of wire end ferrules is recommended.

E. Close the covering.

➩Ensure the correct position of the sealing: The flat side must be

layedonthetransmitterhousing(seenextfig.,Pos.E).

5.4

NORIS Automation GmbH Installation and commissioning | 5

Instruction Manual VD61 19 / 23

If the sealing is not installed correctly, moisture can enter the

transmitter housing!

This may lead to incorrect measurement, signal loss or may even

damage the transmitter.

F. Screw the covering onto the housing by using both screws.

G. Fix the cable gland and check whether the cable is tightly fixed.

3: VD61 opened with markings

NOTICE

6| Maintenance NORIS Automation GmbH

20 / 23 Instruction Manual VD61

Maintenance

This transmiter is maintenance-free. Repairs must only be carried out by

the manufacturer. However, note the following instructions for cleaning, if

the transmitter is damaged and you have to remove it or before you send it

back to the manufacturer.

▪ Beforecleaning,correctlydisconnectthepressuretransmitterfromthe

supply voltage and the pressure supply.

▪ Cleantheinstrumentwithamoistcloth.CAUTION! Do not touch the

measuring material, if used with media that may harm people.

Otherwise serious injuries can be the result.

▪ Washorcleanthedismountedinstrumentbeforereturningit,inorder

to protect persons and the environment from exposure to residual me-

dia. CAUTION! Residual media in dismounted devices could harm

people and environment.

▪ Takesufficientprecautionarymeasures.

▪ NOTICE! Do not use any pointed or hard objects for cleaning, as

they may damage the diaphragm of the process connection.

6

Maintenance

Cleaning

Table of contents