Endress+Hauser HART iTEMP TMT182B User manual

Other Endress+Hauser Transmitter manuals

Endress+Hauser

Endress+Hauser CM14 User manual

Endress+Hauser

Endress+Hauser Flowmeter Proline 300 Technical specifications

Endress+Hauser

Endress+Hauser Flowmeter Proline 300 Technical specifications

Endress+Hauser

Endress+Hauser cerabar S User manual

Endress+Hauser

Endress+Hauser iTEMP PCP TMT 121 User manual

Endress+Hauser

Endress+Hauser HART Proline 400 Technical specifications

Endress+Hauser

Endress+Hauser tmt142 Technical specifications

Endress+Hauser

Endress+Hauser iTEMP TMT162 Installation instructions

Endress+Hauser

Endress+Hauser iTEMP TMT162 User manual

Endress+Hauser

Endress+Hauser iTEMP TMT162 Technical specifications

Endress+Hauser

Endress+Hauser iTEMP TMT82 User manual

Endress+Hauser

Endress+Hauser AT1000 AT1 User manual

Endress+Hauser

Endress+Hauser iTEMP TMT86 Technical specifications

Endress+Hauser

Endress+Hauser Liquiline CM442R User manual

Endress+Hauser

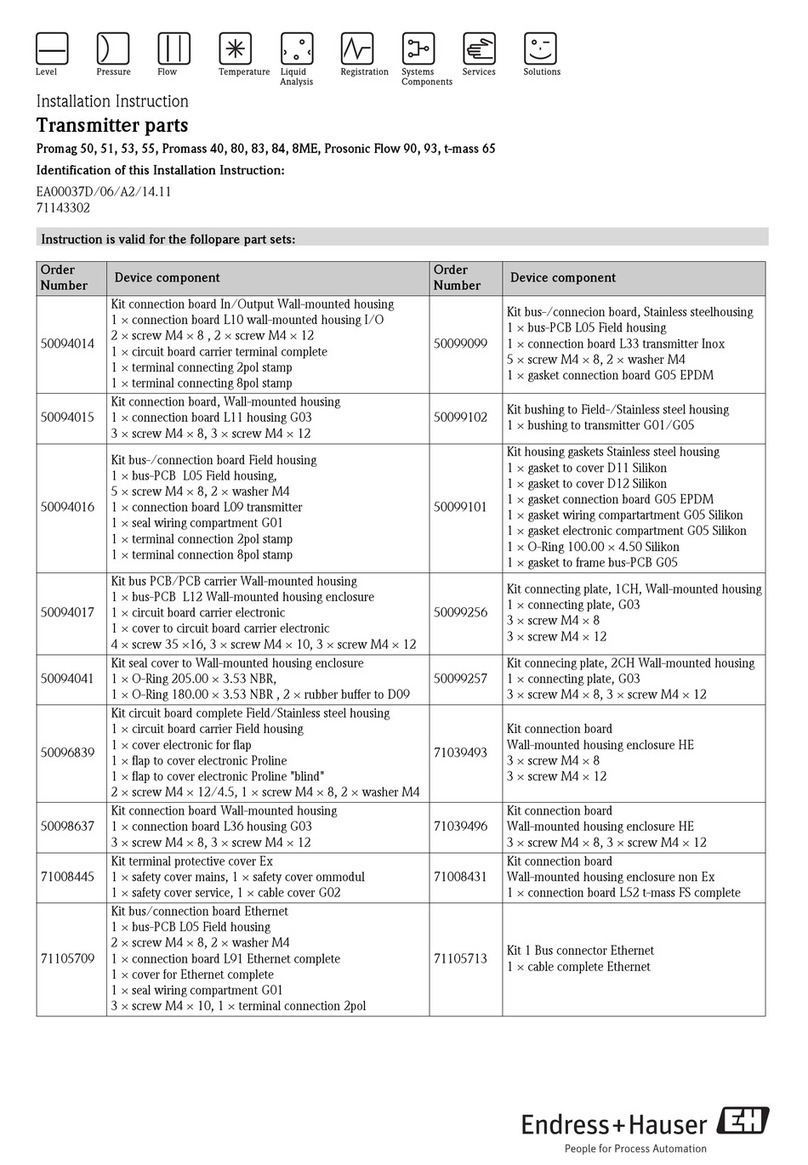

Endress+Hauser Proline Promag 50 User manual

Endress+Hauser

Endress+Hauser Deltabar M PMD55 User manual

Endress+Hauser

Endress+Hauser RMA42 User manual

Endress+Hauser

Endress+Hauser Liquiline M CM42 Instructions for use

Endress+Hauser

Endress+Hauser PROFIBUS DP Proline 100 Technical specifications

Endress+Hauser

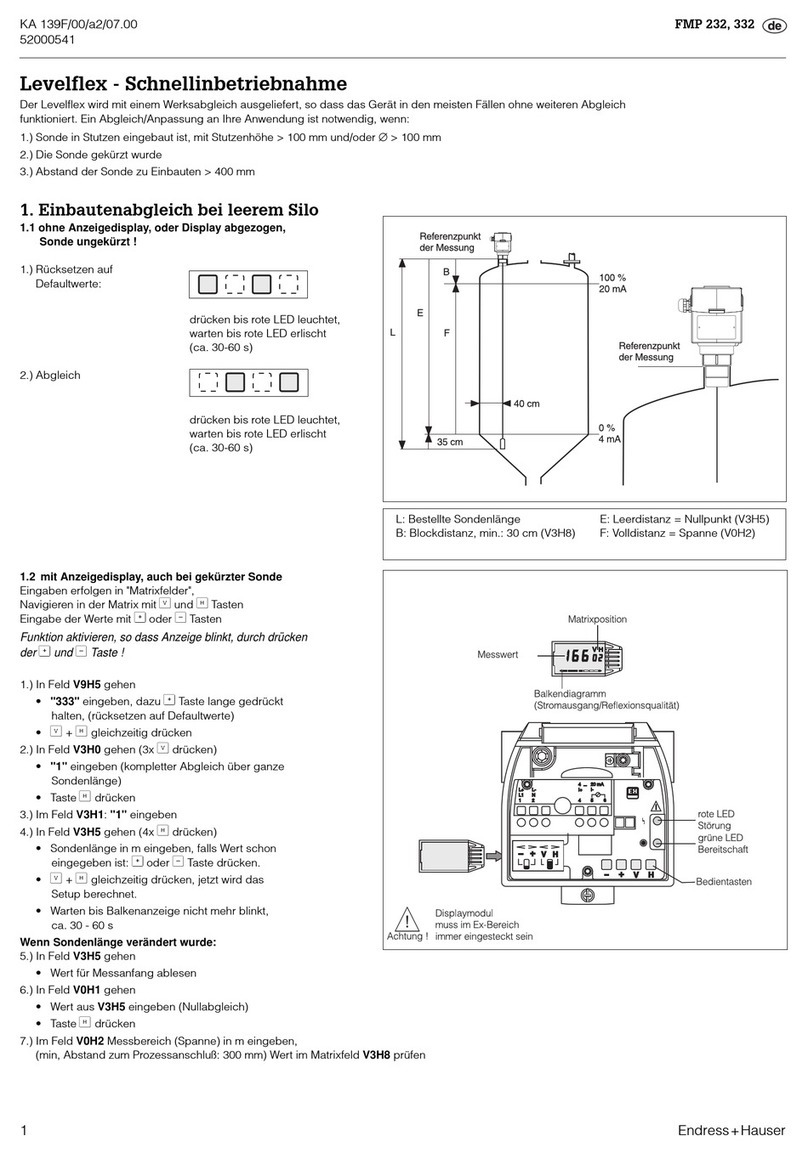

Endress+Hauser Levelflex FMP 232 Specification sheet

Popular Transmitter manuals by other brands

Dejero

Dejero EnGo 3x manual

Rosemount

Rosemount 4600 Reference manual

Speaka Professional

Speaka Professional 2342740 operating instructions

trubomat

trubomat GAB 1000 instruction manual

Teledyne Analytical Instruments

Teledyne Analytical Instruments LXT-380 instructions

Rondish

Rondish UT-11 quick start guide