2

Even with a carburetor

modification, the engine horse

power will decrease about 3.5%

for each 1,000 foot (300 meter)

increase in altitude. The effect

of the altitude on the

horsepower will be greater if no

carburetor modification is made.

NOTE: When the carburetor

has been modified for high

altitude operation, the air-fuel

mixture will be too lean for low

altitude use. Operation at

altitudes below 5,000 feet

(1,500 meters) with a modified

carburetor may cause the

engine to overheat and result in

serious engine damage. For

use at low altitudes, have a

qualified mechanic return the

carburetor to its original factory

specifications.

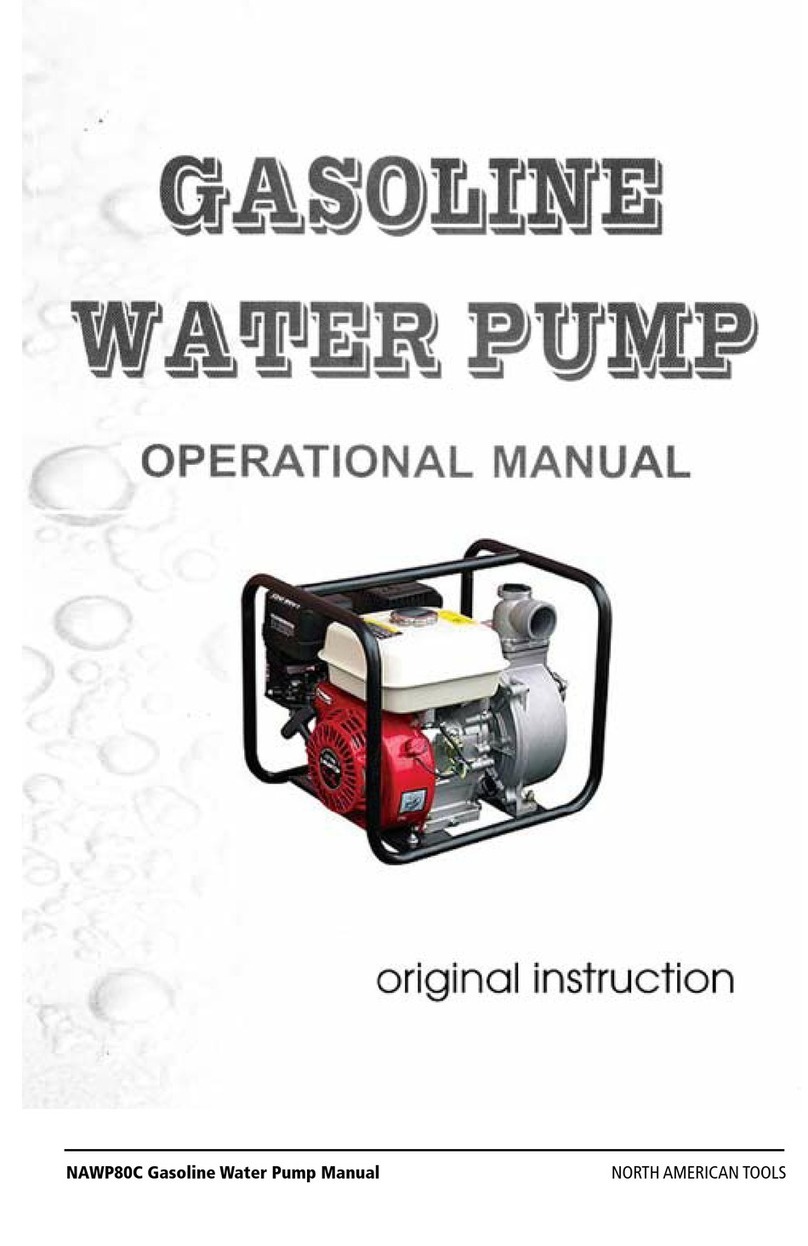

SAFETY INSTRUCTIONS

1) This pump is designed to

only pump water that is not

intended to be consumed by

humans. Using the pump for

other uses can result in injury to

the operator or damage to the

pump and other property.

Pumping flammable liquids (ex:

gasoline or fuel oils) can result

in a fire or explosion that can

cause serious injury. Pumping

sea water, beverages, acids,

chemical solutions or any other

liquid that promotes corrosion

can damage the pump.

2) Know how to stop the pump

quickly and understand how to

operate all of the controls.

Never permit anyone to operate

the pump without proper

instructions.

3) Do not allow children to

operate the pump. Keep children

and pets away from the

operation area.

4) Do not wear loose clothing or

jewelry. Pull back long hair. Keep

your hair, clothing and gloves

away from moving parts.

5) Do not operate the pump in

explosive atmospheres such as

in the presence of flammable

liquids, gases or dust. The

engine creates sparks which may

ignite the dust or fumes.

6) Gasoline is extremely

flammable and gasoline vapors

can explode. Refuel the pump

outdoors and in a well ventilated

area. If any fuel is spilled, ensure

the area is dry before starting the

pump.

7) The muffler becomes very hot

during operation and remains hot

for a while after the engine stops.

Be careful not to touch the

muffler while it is hot. Allow the

engine to cool before storing the

pump indoors.

8) To prevent fire hazards and

provide adequate ventilation,

keep the pump at least three feet

away from walls and other

equipment during operation. Do

not place flammable objects

close to the pump.

9) Exhaust gas contains

poisonous carbon monoxide.

Avoid the inhalation of exhaust

gas. Never run the pump in a

closed garage or confined area.

10) Do not overload the pump.

Use the correct pump for your

application. It will perform the job

better and safer at the rate for

which it was designed.

BEFORE OPERATION

1) Check the condition of the

pump and for signs of damage.

Look for leaks of oil or gas. Check

that all nuts, bolts, screws,

connectors and clamps are tight.

Remove any excessive dirt or

debris, especially around the

engine muffler and recoil starter.

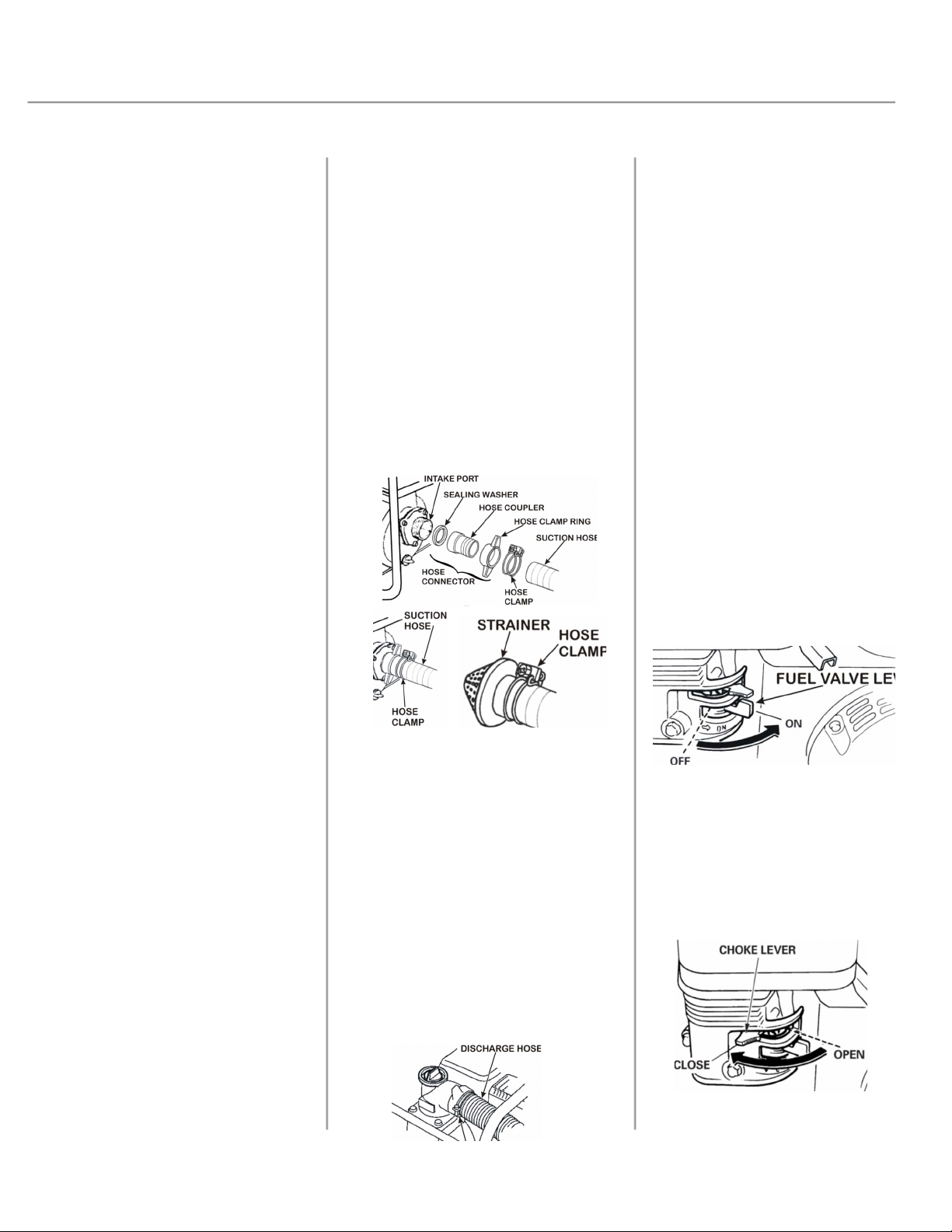

2) Check the suction and

discharge hoses. Ensure the

hoses are in proper condition and

free of cracks and damage.

Check the sealing washer in the

suction hose is in working order.

Ensure the hose connectors and

clamps are securely installed.

Ensure the strainer is in good

condition and is installed on the

suction hose.

3) Check the engine oil level.

Running the engine with low oil

can cause damage. An oil sensor

will automatically stop the engine

before the oil level falls below a

safe limit. To avoid an

unexpected shutdown, always

check the level before startup.

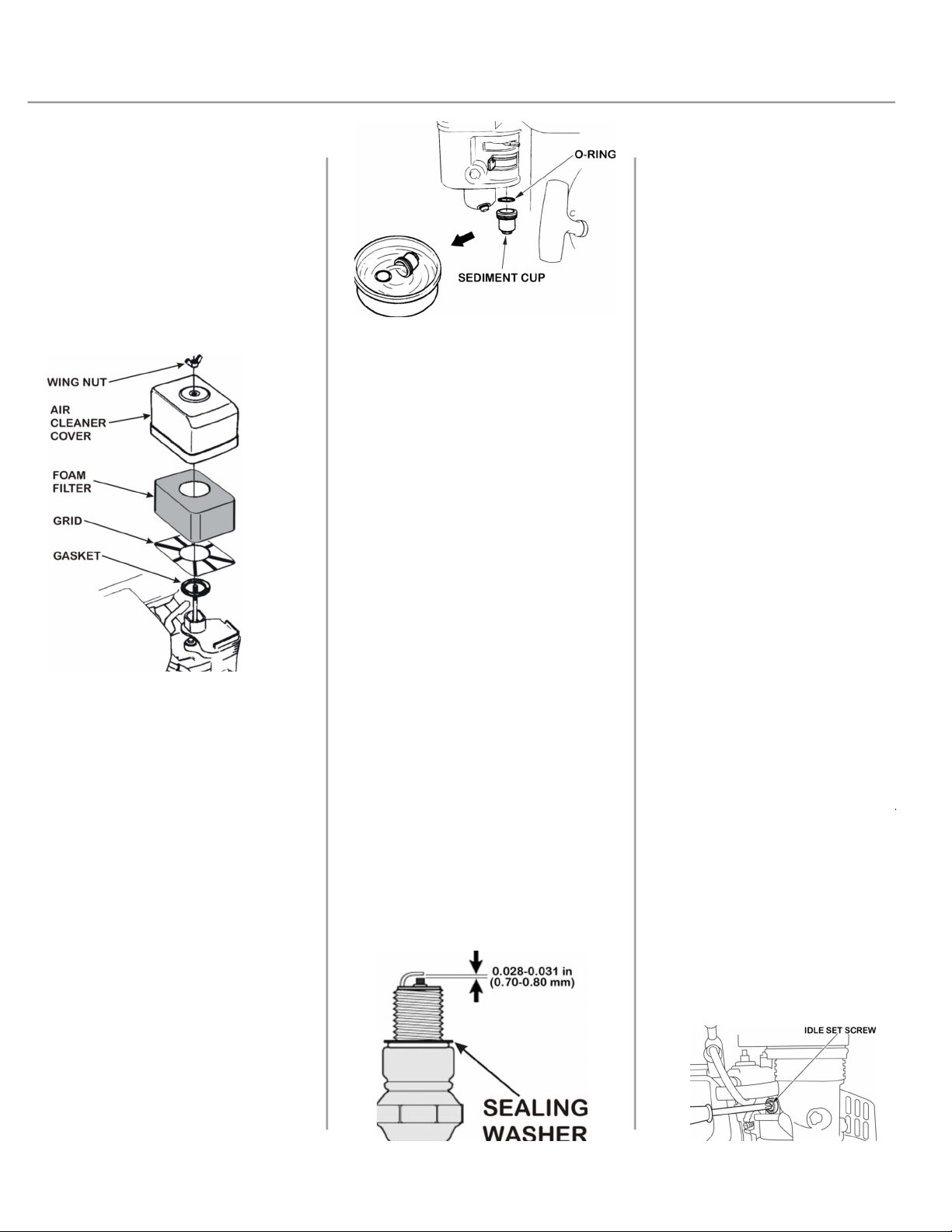

4) Check the air filter. A dirty filter

will restrict the air flow to the

feedback@natitools.com