10

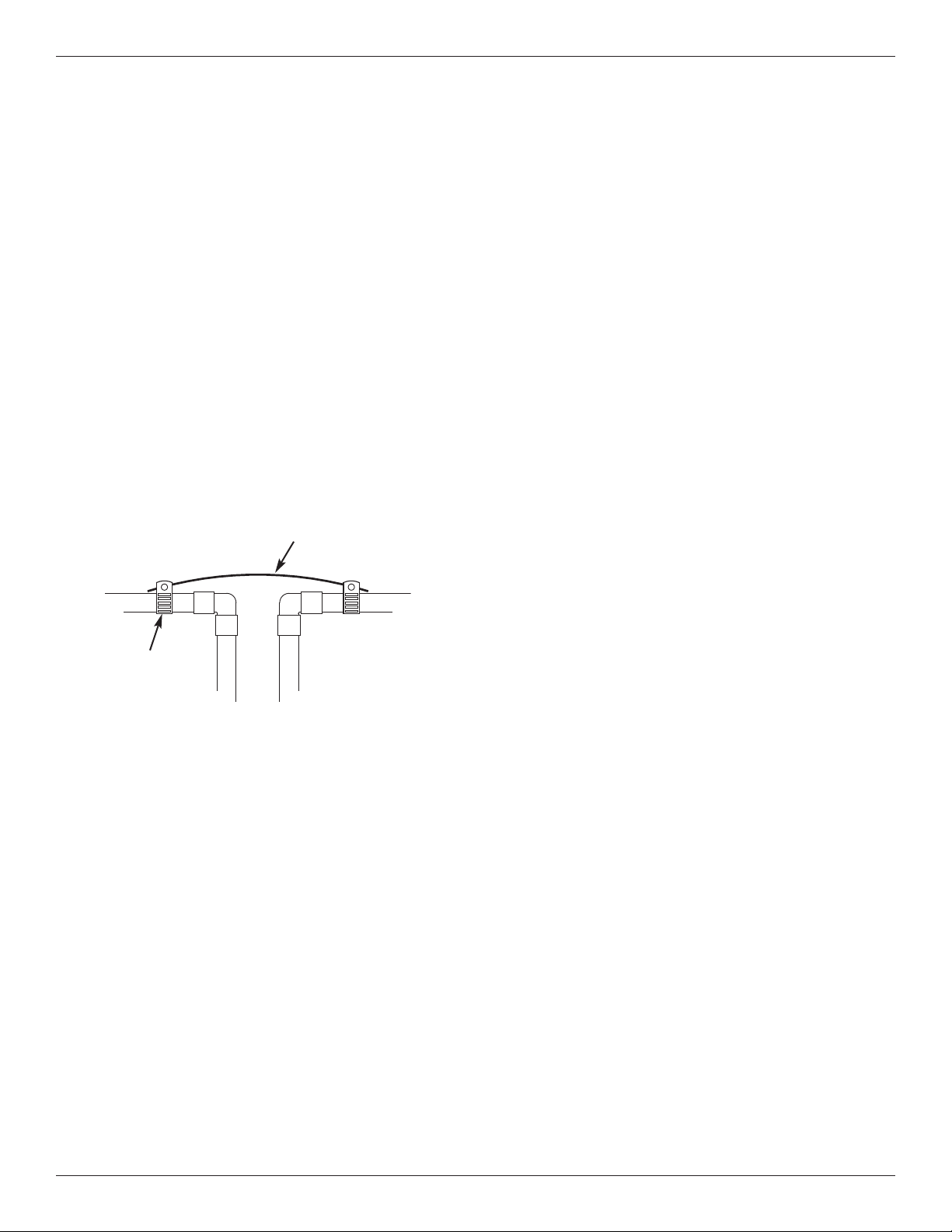

COLD WATER PIPE GROUNDING

CAUTION: The house cold water pipe (metal only)

is often used as a ground for the house

electrical system, The 3-valve bypass

type of installation, shown in Figure 8,

will maintain ground continuity. If you

use a plastic bypass valve at the unit,

continuity is broken. To restore the

ground, do the following:

1. Install a #4 copper wire across the removed section

of main water pipe, securely clamping it at both

ends (See Figure 14) - parts not included.

NOTE: Check local plumbing and electrical codes

for proper installation of the ground wire.

The installation must conform to them. In

Massachusetts, plumbing codes of

Massachusetts shall be conformed to.

Consult with your licensed plumber.

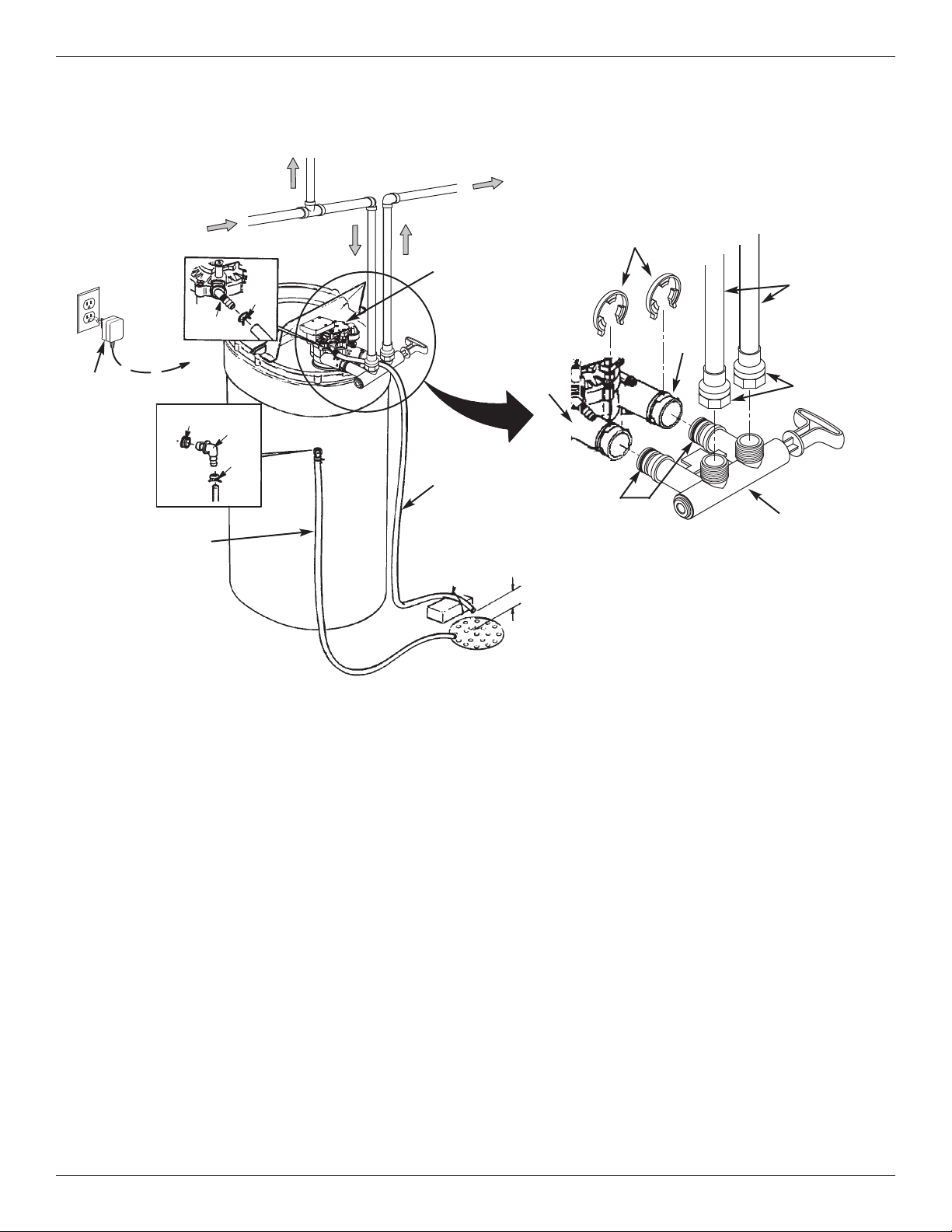

Installation Instructions

INSTALL VALVE DRAIN HOSE

NOTE: See valve drain options on pages 6 & 7.

1. Measure, cut to needed length and connect the 3/8”

drain line (provided) to the water softener valve

drain fitting. Use a hose clamp to hold the hose in

place.

IMPORTANT: If codes require a rigid drain line see

“Valve Drain requirements" section.

2. Run the drain hose (or a rigid line) to the floor drain.

Secure drain hose. This will prevent “whipping'' dur-

ing regenerations. Be sure to provide a 1-1/2”

minimum air gap to prevent possible sewer

water backup. See “Air Gap Requirements" sec-

tion.

NOTE: In addition to a floor drain, you can use a laun-

dry tub or standpipe as a drain point for this

hose. Avoid long drain hose runs, or elevating

the hose more than 8 feet above the floor.

FIG. 14

Ground

Wire

lamp (2)

1. Measure, cut to needed length and connect the 3/8”

drain line (provided) to the salt storage tank overflow

elbow and secure in place with a hose clamp.

2. Route the hose to the floor drain, or other suitable

drain point no higher than the drain fitting on the salt

storage tank (This is a gravity drain). If the tank

overfills with water, the excess water flows to the

drain point. ut the drain line to the desired length

and route it neatly out of the way.

IMPORTANT: For proper operation of the water soften-

er, do not connect the water softener

valve drain tubing to the salt storage

tank overflow hose.

ADD WATER AND SALT TO THE SALT

STOR AGE TAN

1. Using a container, add about three gallons of clean

water into the salt storage tank.

2. Add salt to the storage tank. Use nugget, pellet or

coarse solar salts with less than 1% impurities.

PLUG IN THE POWER SUPPLY

During installation, the water softener wiring may be

moved or jostled from place. Be sure all leadwire con-

nectors are secure on the back of the electronic board

and be sure all wiring is away from the valve gear and

motor area, which rotates during regenerations.

1. Plug the water softener’s power supply into an elec-

trical outlet that is not controlled by a switch and is

approved by local codes.

NOTE: The water heater is filled with hard water and,

as hot water is used, it will refill with condi-

tioned water. In a few days, the hot water will

be fully conditioned. To have fully conditioned

hot water immediately, wait until the initial

recharge is over. Then, drain the water heater

(following instructions for water heater) until

water runs cold.

PROGRAM THE CONTROLLER

1. Install the softener’s top cover and salt lid.

2. omplete the Programming Steps on Pages 13 & 14.

INSTALL SALT STORAGE TAN OVERFLOW

HOSE