1. PART I – INSTALLATION

We will present the essential data, technical characteristics and our advice for the

correct installation, use and maintenance of the appliances described. Let us remind

you that the appliances are professional use and that all procedures of installing,

connecting to the distribution network and positioning of the appliance in operation

should be carried out by properly qualified personnel and that all safety measures

applicable in the country of installation should be observed.

The manufacturer cannot be held responsible for any possible damage to

property, human beings or animals that might be caused by misuse of the

appliance or by using the appliance for purposes other than those

recommended for or not foreseen in this manual.

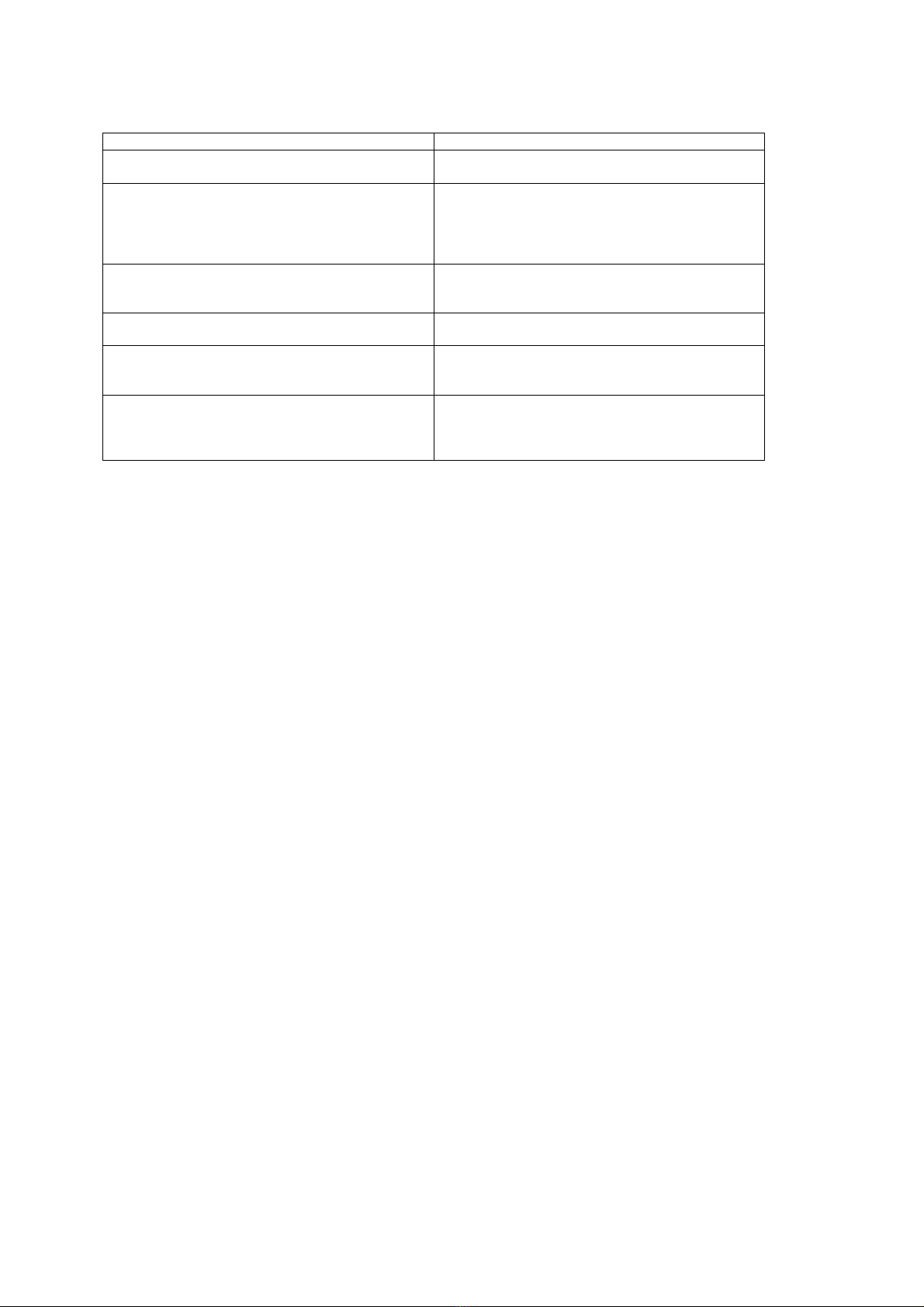

FIGURE 1: Technical Characteristics

Consumption Calories

Model Dimensions

(cm) Oven

Dimensions Type Frame Burner kW G30

Kg/h G20

m³/h G25

m³/h Mj

GASE21 32,5X36,5X16 - A INOX CAST IRON 6 0,43 0,49 0,62 21,6

GASE22 62,5X36,5X16 - A INOX CAST IRON 10,5 0,83 1,11 1,29 37,8

GASE23 93X36,5X16 - A INOX CAST IRON 16,5 1,32 1,60 1,92 59,4

GASE24 62,5X70X16 - A INOX CAST IRON 21 1,62 2,20 2,52 75,6

GASE26 93X70X16 - A INOX CAST IRON 31,5 2,34 3,24 3,82 113,4

GASE2 40.5 X 70 X 43 - A INOX CAST IRON 10.5 0.83 1.11 1.29 37.8

GASE2A 82 X 40.5 X 43 - A INOX CAST IRON 7.5 0.59 0.79 0.92 27

GASE2B 82 X 40.5 X 43 - A INOX CAST IRON 9 0.71 0.95 1.11 32.4

EGAS4 82 X 70 X 43 - A INOX CAST IRON 18 1.42 1.90 2.22 64.8

EGAS6 119 X 70 X 43 - A INOX CAST IRON 27 2.13 2.86 3.32 97.2

FGASE4 82 X 70 X 95 55x52x25 A INOX CAST IRON

& INOX 24.5 1.93 2.59 3.02 88.2

FGASE6 119 X 70 X 95 55x52x25 A INOX CAST IRON

& INOX 33.5 2.64 3.54 4.12 120.6

Unit Big Medium Small Oven

Normal Thermal energy provided KW 6 4.5 3 5

Reduced thermal energy provided KW 2 1 1 1.70

G 30 Main air regulation at 28… 30 mbar Mm APERTA APERTA APERTA APERTA

G 20 Main air regulation at 20 mbar Mm 11 APERTA 8.0 9

G 30 Main air regulation at 50 mbar Mm 16 APERTA 8 11

G 25 Main air regulation at 25 mbar Mm 11 APERTA 8 9

G 25 Main air regulation at 20 mbar Mm 11 APERTA 8 9

G 30 Main burner nozzle at 28… 30 mbar Mm 1.25 1.20 0.85 1.30

G 20 Main burner nozzle at 20 mbar Mm 1.90 1.60 1.30 2.00

G 30 Main burner nozzle at 50 mbar Mm 1.10 0.95 0.75 1.15

G 25 Main burner nozzle at 25 mbar Mm 2.00 1.65 1.40 2.10

G 25 Main burner nozzle at 20 mbar Mm 2.10 1.70 1.45 2.20

G 30 Pilot burner nozzle (28… 30 mbar and

50 mbar) No 20 20 20 20

G 20 Pilot burner nozzle at 20 mbar No Registered Registered Registered Registered

G 25 Pilot burner nozzle at 20 mbar & 25

mbar No Registered Registered Registered Registered

G 30 by-pass valve (28… 30 mbar and 50

mbar) Mm 55 40 40 --

G 20 by-pass valve at 20 mbar Mm Registered Registered Registered Registered

G 25 by-pass valve at 20 mbar & 25 mbar Mm Registered Registered Registered Registered