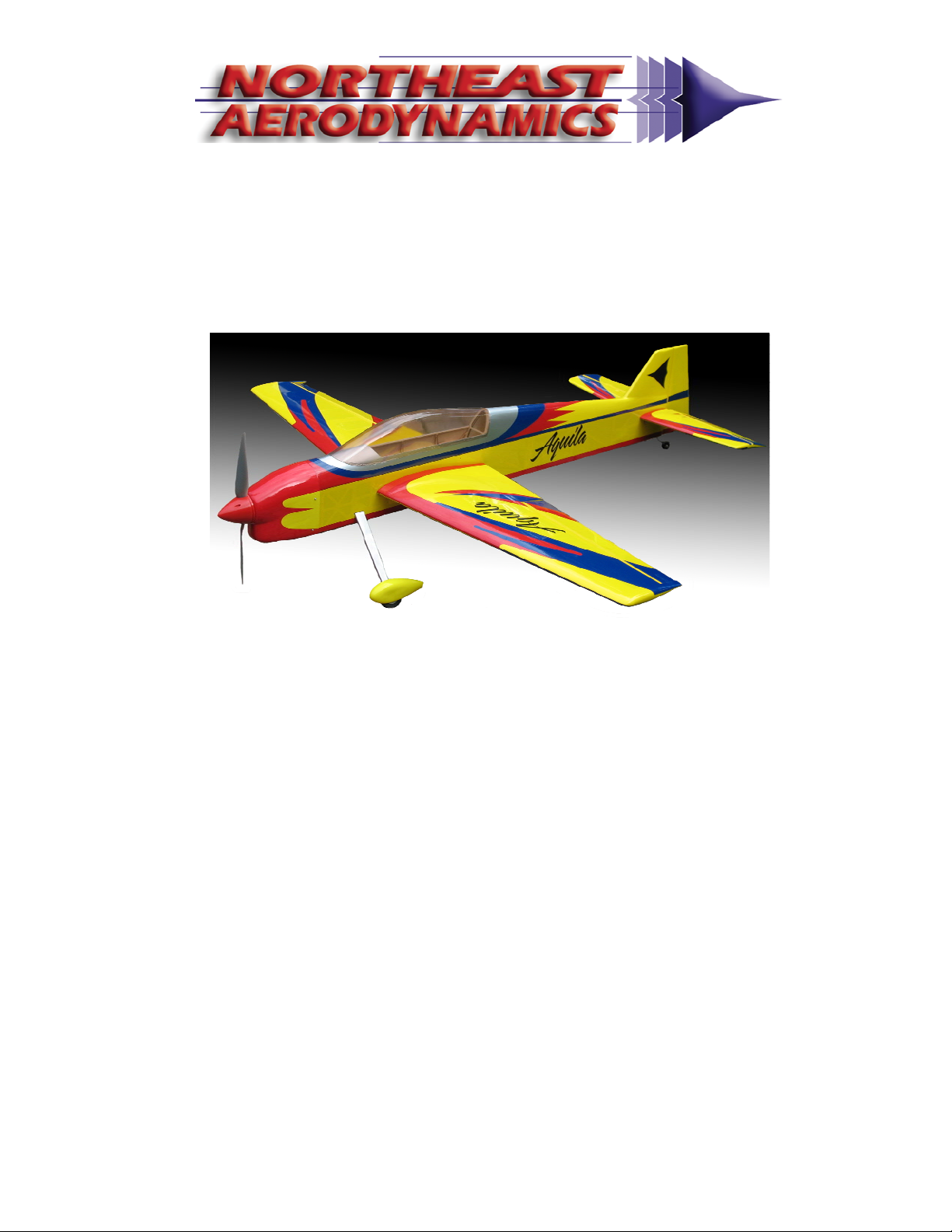

Northeast Aerodynamics 2M Aquila F3A User manual

Copyright © 2008, Northeast Aerodynamics, Inc. v1.1

2MAquilaF3A

AssemblyManual

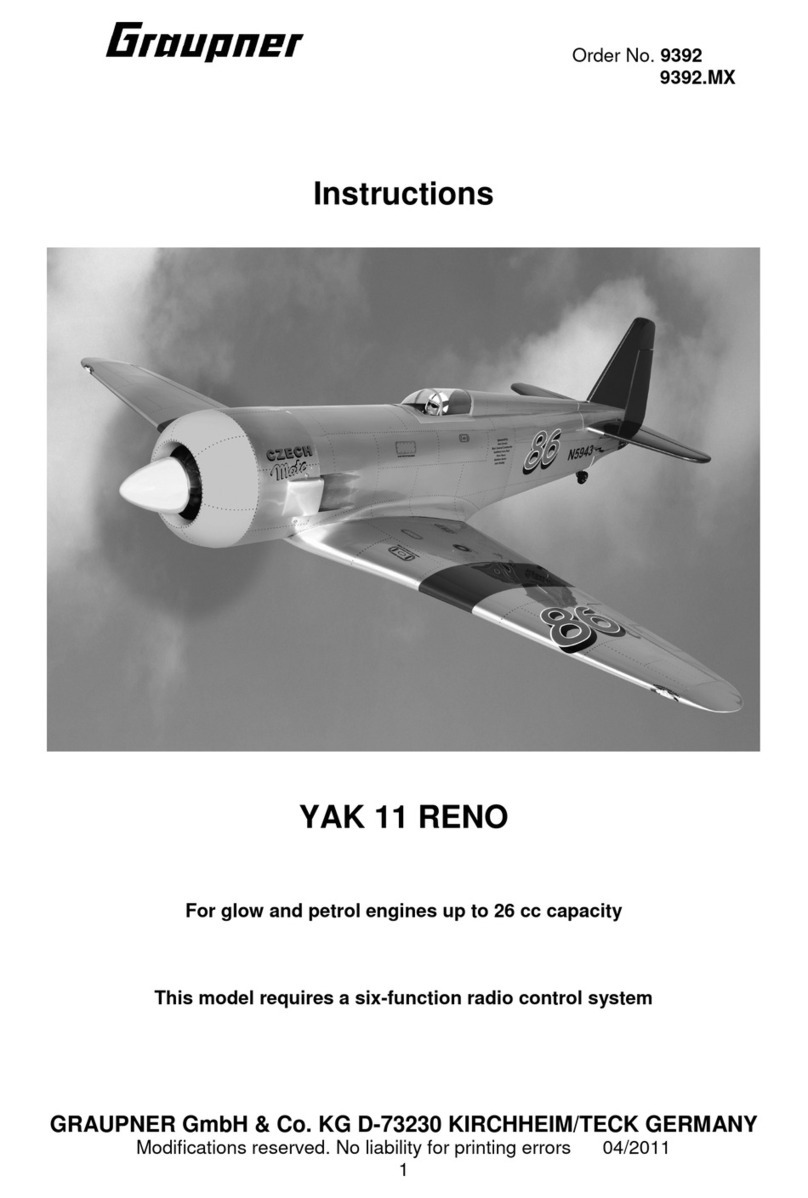

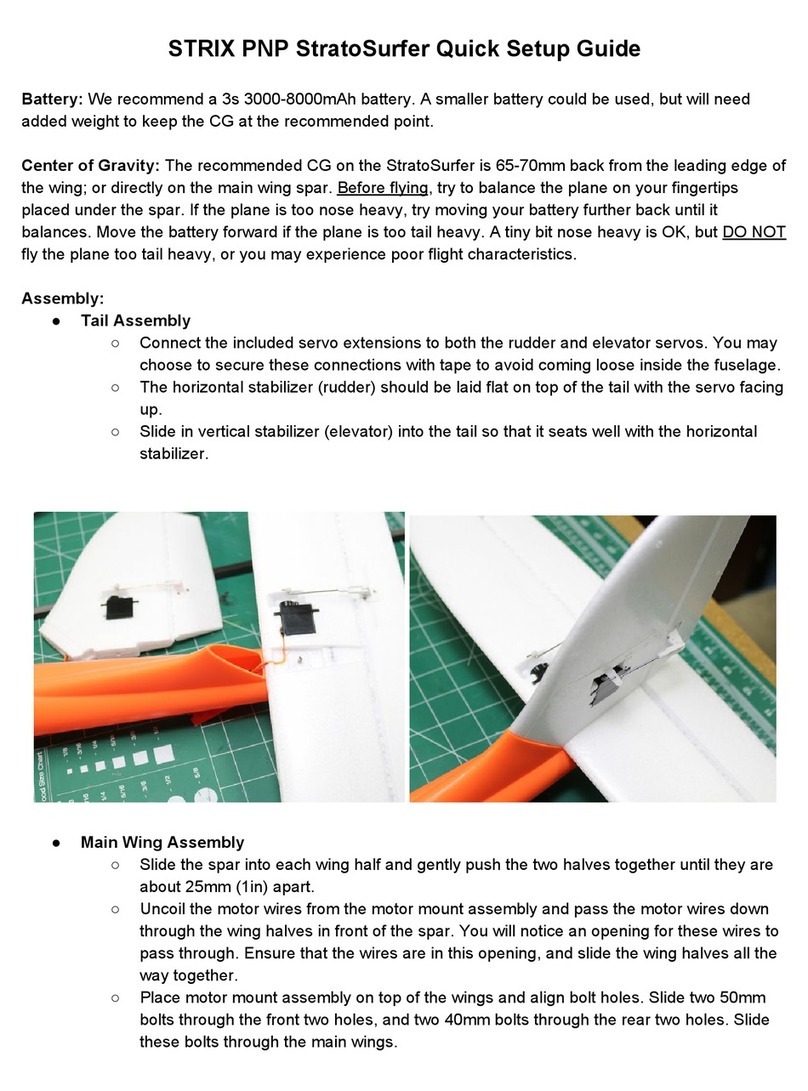

Fig1:Completed2MAquilaF3A

(YellowColorSchemeShown)

SPECIFICATIONS

EngineRequirement1.20to1.40cu.In.2C

AXI5330/FAI(orequivalent)

WingSpan70in.

WingArea900sq.in

FuselageLength77in.

WeightRange9.3lbs

WingLoadingrange21.9oz/sq.ft.@9.3lbs

CubicWingLoading8.8

RadioFunctionThrottle,Elevator,Rudder,Aileron

NumberofServos5

- 2 -

Introduction

TheAquilaF3APatternairplanewasbornoutoftheneedforhighqualityARF

airplanescapableofcompletingtheMaster'spatternwitheaseyetbeableto

beflownbynoviceF3ApilotseffectivelyintheSportsmanclass.Bylookingat

theindustrywedecidedtobuildthisairplanearoundtwodifferentpower

plants.

ThefirstpowerplantistheOS1.20AXenginewiththestockmuffler.This

engineismorethancapableofflyingthisairplanethroughthesequences

withoutthecomplexityofapiped‐enginearrangement.Thissimplifiesthe

designandmaintenancesothattheentrylevelF3Apilotcaneasilytransition

fromhisSportairplanetoanF3Acapableairplane.

WantaPipe?ApipetunnelishiddenbeneaththeMonokoteonthebellyof

theAquila.Soifastandardmufflerarrangementisnottoyourliking,oryou

justwantmorepower,youcaneasilyaddyourpipetothisairplane!

ThesecondpowerplantistheAXI5330/FAIelectricmotor.Couplethismotor

witha10SpackofLiPobatteriesandyou'llhaveanelectricF3Aairplane

capableofcompletingtheMaster'spatternschedulewithpowertospare!

TheAquilahasreceivedthebenefitof2yearsdevelopmentanddesignand

wasdesignedfromthegrounduptobeathoroughbredF3Aperformerand

notasportairplanethatlookslikeapatternship.

Ourwhitecolor‐schemewasselectedafterlengthydebatesandisdesignedfor

easeofvisibilityduringallaspectsofflightfromtake‐off,maneuvers,to

landing.WehaverecentlyaddedaYellowcolor‐schemetoourAquilaF3A

ARFs.WecoverourAquilaARFsonlyinhighqualityMonokotefilm.

- 3 -

Builtusingthelatestdesignandmanufacturetechnologies,thekitfeaturesall

built‐upconstructionforeaseofmaintenanceandrepair,shouldyouneedto.

Thedesignwasalsogivenenoughgroundclearancetosupportan18"

propeller.Theairplanealsofeaturesafloatingfirewallarrangementthatlets

youexactlypositionyourmotor(electricorglow)tothecowlandspinner

plate.Oncepositioned,thefloatingfirewallisfixedinplace.

Wantsomethingdifferent?Sendusasketchwithyourowncolorscheme.If

yourschemehasbroadappeal,we'llconsideritforinclusioninourcolor

schemeofferingsandyou'llgetthecreditforthecolorschemedesign.

Thehardwarepackageisfairlycomplete;howeverthehardwareismetric‐size.

You'llneedtoaddyourradiogear,engine,etc.Controlhornsareprovided,as

arethewheels,andothercomponentsincludingafueltank.Asalways,itis

yourresponsibilitytoensurethehardwareyouuseinyourairplaneis

satisfactoryfortheconditionsyouintendtoflyin.Pleasefeelfreeto

substitutehardwareandinstallationpracticesasyourexperiencedictates.

TheconstructionoftheAquilaF3Aismostlybalsa,lite‐ply,andsomefiberglass

(cowl,wheelpants,etc).Thisenablesustobuildtheseaircraftverylightand

verystrong.The2‐piecewingissupportedbyanannealedaluminum25mm

diameterwingtubeandsocket.Thehorizontalstabilizersarealsosupported

byatubeandareremovableforeasytransportation.

- 4 -

Tools,Supplies,andAccessories

TOOLSNEEDEDTOBUILDTHE2MAQUILAF3A

Phillipsandpan‐headscrewdrivers(various

sizes)

CanopyGlue

ElectricorhanddrillandvariousdrillbitsHingeGlue

Needle‐nosedpliersLow‐tackMaskingtape

#11knifeThread‐lockingcompound

SmallMetricsocketsThinandMediumThickCA

8‐32Tap

ACCESSORIESNEEDEDTOCOMPLETETHISKIT

(1)Receiverandon‐boardradiogearper

yourspecifications

(1)12”fuelline

(1)engine(1)muffler

(5)StandardSizedHigh‐PrecisionServos

(DigitalServosarepreferred)

(?)22‐AWGservowiretosupportyour

servoinstallation

6‐32all‐threadrodforruddercontrolhorn4‐40orHeavyDutyPull‐Pullsystemfor

Rudder

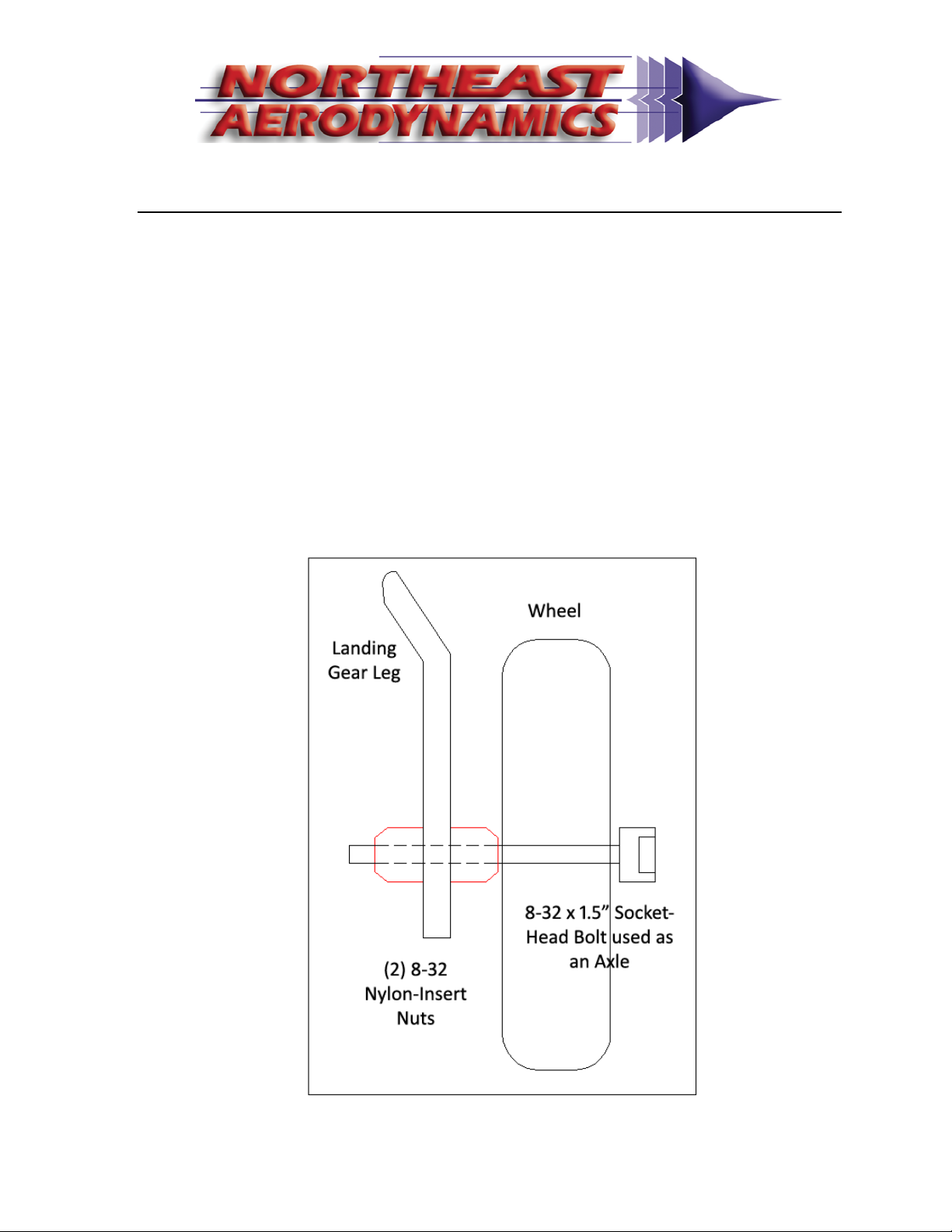

(2)8‐32x1.5”socket‐headboltsforaxles(4)8‐32nyloninsertnuts

Pre‐ConstructionAids

Pleaseinspectthekituponarrivalandfamiliarizeyourselfwithallpartsinthe

kitandtheinstructionspriortobeginningconstruction.

Note:Alloftheboltsandnutsshippedwiththiskitaremetricthreadandsize.

Manyofthemountingpackagesofmountinghardwarearegenericforusein

multipleairplanes–notalloftheseitemswillbeusedbytheAquila.

- 5 -

BillofMaterials

o1FuelTankBagincludingafueltank,stopperandhardware.Fueltankismarkedas380mlin

volumebutisactually450mlinvolume.

o2nylonzip‐ties,inawhiteplasticbag,tomountthefueltankintothefuselage.

oTailWheelBagincludingmountinghardware.

o1MainWheelBagincluding2wheelsandmountinghardware.Werecommendreplacingthe

hardwareincludedinthisbagwith(2)8‐32x1.5socketheadboltsand(4)nylon‐insertnuts.

o1EngineMountincludingmountinghardware.Althoughthisenginemountandhardwarecan

beusedwiththekit,werecommendtheHyde‘C’mountfortheOS1.20AXengine.

o1SetAluminumLandingGearwithmountinghardware.NotethereisaLeftandaRightgearleg

andtheboltsare4mmthickand20mmor16mmlongalongwithappropriatelysizedwashers.

o13‐1/8”RedSpinnerwithmountinghardware.Werecommenda3”FAI‐styleTrue‐Turn

spinner.

o22CAHinges

o1PackageofCockpitMountinghardware(with2nylonboltsinsidetoholdthecockpitinplace

throughthefuselagesides).

o1Pull‐PullRudderCableset.Werecommendreplacingthiswitha4‐40heavydutypull‐pullset.

o1Packageofcontrolhorns.Thispackagealsoincludesasetforuseontherudder;however,

theywillnotfittheAquila’srudder.Werecommendusing6‐32all‐threadrodforcontrolhorns.

o1Packageof(2)wheelpants.

o1Packagefloatingfirewalllasercutwood.Assemblyrequired.

o1Wingtube‐‐25mmO.D.x26”length,with0.05”wallthickness

o1Stabtube–12.5mmO.D.

o1PackageElevatorpushrodassembly

o1Fuselagewithcowl,cockpitandcanopy

o2Stabilizer/elevatorhalves(leftandright)

o2Winghalveswithailerons(leftandright)

o1Rudder

o1bagofbolts,screws,plywood:

o(4)SocketheadM4x16mmformountingthelandinggeartothefuselage

o(4)SocketheadM3x20mmformountingthehorizontalstabilizerstothefuse

o(2)8‐32x2”NylonSlottedheadboltsforretainingthecockpittothefuselage

o(4)self‐taping#2x9/16”screwsformountingthecowltothefuselage

o3.5mmplywoodelevatorbearingdoubler

- 6 -

Attachingthecontrolhorns

1. Acompletesetofcontrolhornsareprovidedforyouinthekit.These

controlhorns,withtheexceptionoftherudderpair,canbeusedwith

yourAquilakit.However,werecommendthatyoureplacethe

providedhardwareanduse6‐32all‐threadrodtocreateyourcontrol

horns.

Apicturebelowwillguideyouinaddingthe6‐32controlhornsproperlyto

yourAquilaairplane:

- 7 -

AttachingtheControlSurfaces

1Selectacontrolsurfacetobeginwith,liketherightaileron.

2Removetheaileronfromthewing.

3Examinethepre‐cuthingeslots.Adjusttheseasneededtoensurethe

slotsarecenteredonboththewingandtheaileron.

4Lookingatthehinge,imagingthehingelineonthehinge.Pushapin

throughthecenterofthehingecenteredonthehingeline.Repeatfor

allofthehingesontheaileron.

5Insertthehingesintothecontrolsurfaceuntilthepincontactsthe

aileron.Thepinwillstopthehingefromgoingintotheaileronmore

thanhalf‐way.Dothisforalloftheaileronhinges.

6Aligntheailerontothewingandgentlyinsertallofthehingesintothe

wingwhilekeepingthehingehalf‐wayintheaileron.

7Oncetheaileronisproperlyseated,use3‐4ofdropsofthinCAfrom

thetopofeachhinge.

8FlipthewingoverandaddacoupleofdropsofthinCAtothebottom

ofthehingeandallowtheCAtocurecompletely.

9Removethepinsandflextheaileronuntilitmovesfreely.Checkfor

properandfreemovementofthecontrolsurface.Adjustasneeded.

10 RepeatSteps1through8foralloftheremainingcontrolsurfacestobe

hinged.

11 Setasideandallowtheseassembliestodrycompletely.

12 Itisagoodideatosealthehingelinewithsomeextracovering

materialorpackingtape(notprovided)fromtheundersideofthe

hingeline.

- 8 -

InstallingtheRudderServo

1. Installyourrudderservointotheprovidedmountinsidethefuselage

underthecockpit.

2. Locatethepull‐pullwireexitholespre‐cutintothefuselagesidesand

openupthecoveringhereasneededtorunyourpull‐pullcables

cleanlybetweenyourruddercontrolarmsandtheservocontrolarms.

3. Installthepull‐pullwirepertheinstructionsthatcamewiththepull‐

pullwirekityouselectedusingtheguidesbuiltintothefuselagesides.

Use4‐40gaugehardware.

4. Tensionthepull‐pullwirestoyourpreferences.

MountingtheHorizontalStabilizers

1. AttachyourselectedElevatorControlhornstotheelevatorhalves.

2. Usingthestabtubeprovidedattacheachstabilizerhalfwiththescrew

andwasherprovidedintothe3mm“T”‐nutsburiedinthefuselage.

Useadropofmedium‐holdthread‐lockingcompound(youdowantto

beabletoremovetheseboltssomeday)tosecurethestabboltsin

place.

3. Sincethesizeofthestabtubesleevevariesslightly,yourstabtubemay

havealightlyloosefitoraslightlytightfitforthefuselagesectionof

thesleeve.Werecommendthatyousandthetubeslightlyinthe

centersectiontoallowatighttubetofiteasierandthatyoubuildup

thecenterofthestabtubeifithasaslightlyloosefit.

- 9 -

MountingtheElevatorServo&Linkage

1. Youcanusetheservomountprovidedinthefuselagetomountyour

elevatorservo.Howeverthiswillintroduceaslightdifferential

betweenup‐elevatoranddown‐elevatorbecauseofthegeometry

differencebetweentheelevatorcontrolarmmovinginahorizontal

planeandtheelevatorsmovinginaverticalplane.

2. Abettersolutionistobuildanelevatorservomountingplatethat

allowstheelevatorservotobemountedonitssidethereforeallowing

theelevatorcontrolarmtobeinthesameplaneastheelevators.

3. Whicheversolutionyouselect,aligntheservosothattheservoarmis

exactlycenteredinthefuselage.

4. Thepush‐pullcontrolrodsystemusedintheAquilaisusedinagreat

manypatternplaneinstallationsandshouldbefamiliartomany

modelers.Feelfreetosubstituteyourowninstructionshereifyoufeel

theyarebettersuitedtoyourneeds.

5. LookingatthelongCFrodyouwillnoticethatthemanufacturer

anticipatedyourneedsandpre‐drilledholesinbothendsforthewire

pushrodstoattach.Unfortunatelytheholesthatarepre‐drilledforyou

arenotinthecorrectplace.PleaseusethickCAtoclosethepre‐drilled

holes.

6. Turnthefuselageupsidedownandlooktothetailoftheairplane.

Thereyouwillfindaremovablehatch.Pleaseremovethishatchfor

now.Thishatchallowsyoutoseewheretheelevatorpush‐rodswill

exitthefuselageandallowsyoutoseeawoodenbearing(platewitha

holeinit)thatwillsupporttheCFelevatorpushrod.

- 10 -

7. Usethedrawingbelowtoguideyourinstallationthroughthenextfew

steps:

8. Tapeorpinyourelevatorhalvesatafulldown‐elevatordeflection.

9. TapetheelevatorcontrolrodstotheCFtubeasshownintheright‐

handsideoftheabovefigure.

10. InserttheCFelevatorpushrodintothewoodbearinginsidetheaftend

ofthefuselageandadjustthepositionofthetwowirepushrodsuntil

themeetupproperlywiththeelevatorcontrolhorns.Ensurethatthe

CFpushrodisinsertedthroughthebearingbyatleasta1/4"orslightly

more.

11. CarefullyremovetheCFpushrodwiththetwowirepushrodsstill

attached.MarktheCFrodattheendwherethetwowirepushrods

wereattachedandthenremoveallofthetape.

12. Puta1/4”‘L’‐bendintothenon‐threadedendofeachpushrod.Then

measure1/4"aftofthemarksyoumadeinstep11.Drilla1/16”hole

intotheCFrodatthemarkthatyoujustmade.Placethewire

pushrodsalongtheCFpushrodandthe‘L’‐bendsintotheholesyou

madeearlier.UsethickCAtogluethewirepushrodstotheCF

pushrod.UsekickertosettheCA.

13. OncetheCAhasset,usestrongnylonthread,orKevlarthread,towrap

thejointcompletely,andthenapplythinCAtothethread.Heatshrink

tubingprovidedcanbeusedovertheCAjointstofurtherstrengthen

thewiretoCFjoint.

- 11 -

14. ReinstalltheCFpushrodwiththetwowirepushrodassemblyintothe

fuselageandintothebearingintheaftofthefuselage.Connectthe

wirepushrodendstotheelevatorcontrolhornsandsettheelevators

toneutral.Temporarilytapetheelevatorhalvesinthisposition.

15. Locatethelaser‐cut1/16”plywoodelevatorpushrodbearingdoubler.

ThepiecegetsaddedtotheendoftheCFpushrodfrombehindthe

bulkheadwiththebearinginit.Thebearingthatisinthebulkheadhas

aloosefit.This1/16”plywoodbearinghasaslightlysnugfitandwill

keeptheCFrodfrommovingaround.Trialfitthisbearingacoupleof

timesbeforeattemptingtoglueitinplace.Onceyouaresatisfiedthat

youcancorrectlyinstallthispart,addacoupleofdropsofthickCAto

thefrontfaceofthe1/16”plywoodpartandslipitontothebackofthe

CFrodandpressitintoplaceonthebackofthebulkhead.Youneed

enoughgluetoholdthepartinplacebuttoomuchgluemightglue

yourCFelevatorpushrodtothebearing.

16. Releasethetape,orpins,holdingtheelevatorandmanuallymovethe

elevatorsthroughthefullrangeofmotionneeded(bothupanddown)

andensurenothingisbindingandthatyouhavefreemovement.

Adjustthesetupasneeded.

17. Withyourelevatorservoinstalled,connectthewirepushrodtothe

elevatorservocontrolarm.

18. Settheelevatorhalvestoneutralandtape,orpin,theminthis

position.Alsosettheelevatorservoatneutral.

19. Youshouldseethatthewirepushrodconnectedtotheelevatorcontrol

armoverlapstheCFpushrod.UsethickCAandkickertogluethewire

pushrodtotheCFpushrod.

20. OncetheCAhasset,usestrongnylonthread,orKevlarthread,towrap

thejointcompletely,andthenapplythinCAtothethread.Heatshrink

tubingprovidedcanbeusedovertheCAjointstofurtherstrengthen

thewiretoCFjoint.

21. Justaftofthecockpitinsidethefuselageusescrapwoodtobuilda

supportfortheelevatorCFpushrod.

22. Remembertofreeyourelevatorhalvesandtestforfullmotion.

23. Adjustasneeded.

- 12 -

MountingtheWings

1. Installyouraileronservosintothewings,oneservoperwing.Usea

goodqualityhighprecisionservo(digitalservosprovidethebest

performance)andheavydutyextensionleadsfromtheservosthrough

theservotunneltothewing’sroot.

2. Usingasharphobbyknife,carefullyopenthecoveringonthefuselage

sidefortheservotunnel,andthewing‐retentionboltholelocatedjust

behindthewingtube.

3. Securingthewingtothefuselageforflight.Threealternativesare

presentedhere:

a. Thewingrootribhashada“T”nutembeddedintothewingso

thatyoucansecurethewingtothefuselagefrominsidethe

fuselageusingthegraynylonboltsandwasherssupplied.

b. Analternativemethodistolocatethehardpointatthewingtube

endontheundersideofthewing.Thishardpointcanbedrilled

andtappedsothatyoucansecurethewingstotheoutsideedge

ofthetube.Ifyouusethismethod,addapieceofhardwood

insidethewingtubeendfirstandallowittobedrilledandtapped

whenyouaddyourhold‐downscrewstothewing.

c. Usingascrewordowel,taptheembedded“T”nutinthewing

rootbackintothewingandremovethe“T”nutfromthewing.

Glueina1/4‐20nylonboltsothattheboltshaftextendsintothe

fuselageandsecurethebolttothewingwithepoxy.Nowenlarge

theholesinthefuselagesidetoallowtheboltshafttoenter.Use

awingnuttosecurely“pull”thewingtothefuselageby

tighteningthewingnuttothefuselageside.

- 13 -

MountingtheCockpitandCanopy

1. Thecockpitissecuredbytwodowelsinthefrontthatslipinto

correspondingholesinF1andbytwoscrewsintheback.

2. Placethecockpitontothefuselage.

3. Carefullylocatethetwoscrewsholesfortheretainingboltsonthe

fuselagesideandopenthecoveringthereusingthe“T”pinmethod

describedearlier.

4. Tapthefingerunderthecockpitforan8‐32thread.Addacoupleof

dropsofthinCAintothefreshlycutthreadsandthenwaitfortheCAto

curecompletely.Really,waitforittocompletelycure.Thentapthe

holeagainwiththe8‐32tap.Usethe8‐32x2”nylonboltsprovidedto

retainthecockpittothefuselage.Yes,youcancuttheboltlength

down.

5. Removethecockpitandlinethefuselagecockpitopeningandturtle‐

deckopeningwithwaxpaperandre‐installthecockpitandscrewitinto

place.Thewaxpaperwillpreventyoufromgluingyourcanopy/cockpit

tothefuselage.

6. Trimthecanopytofit.

7. Usingcanopyglue,gluethecanopytothecockpit/fuselageandholdin

placewithmasking/painter’stapeuntilthegluehascompletelycured

(24‐hours).Youcanalsouseaclearflexibletape(notprovided)to

securethecanopyinplaceinadditiontothecanopyglue.

- 14 -

AttachingtheLandingGear

1. Locatethelandinggearslotsinthesideofthefuselageandcarefully

openthecoveringwitha#11knife.

2. Locatethe(4)4mmx16mmsocketheadbolts

3. Locatethelandinggearboltholesinsidethefuselage.

4. Slidethelandinggearinthroughtheslotsinthefuselagesidesuntilthe

holesinthelandinggearalignwiththeholesinthelandinggearmount

insidethefuselage.

5. Inserteachlandinggearboltthroughasuppliedwasher.

6. Addadropofmediumholdthread‐lockingcompoundtotheendofthe

landinggearboltsandinserttheboltsthroughthelandinggearand

intothethreaded“T”nutsinsidethefuselage.Adjusttheholesinthe

landinggearifneeded.

7. Carefullytightenthelandinggearboltsuntilthelandinggearissnug.

- 15 -

MountingtheWheelsandWheel‐Pants

1. Wehavefoundthatthesuppliedhardwareshouldbelookedatbutnot

usedformountingyourwheelsorwheelpantstotheAquila.We

recommendthatyouuse(2)8‐32x1.5”socketheadboltsand(4)8‐32

nyloninsertnutstomountyourwheelstothealuminumlandinggear

asdescribedbelow.

2. Inserttheboltthroughthecenterofyourwheel.Attachanyloninsert

nuttotheboltbackwards.Thiskeepstheflatsideofthenutawayfrom

thewheel.Tightenthisnutuntilyouareclosetothewheelandthe

wheelstillrotatesfreely.

3. Slidetheaboveassemblythroughtheholeinthelandinggearand

secureitwithanothernyloninsertnut(correctlyorientated).Tighten

thisnutuntiltheassemblyistightlyheldtothealuminumlandinggear.

- 16 -

4. Trialfityourwheelpantstothelandinggearwiththewheelalready

installed.Notethereisaleftwheelpantandarightwheelpant.You

willneedtocutaverticalslotintothewheelpantandplywoodinsertto

allowthewheeltoslipovertheaxle.Noteyouwillalsoneedtomake

theopeninginthewheelpantforthewheelslargertousethesupplied

wheels.Adjustasneededuntilthewheelpantslipsoneasilyandinto

thecorrectposition.

5. Settheplaneonitswheelsandadjusttheangleofthewheelpantsso

thatthewheelpanthasclearanceinthistake‐off/landingposture.

6. Usealong1/16”drillbitanddrillpilotholesintothewheelpantsusing

thepre‐drilledholesinthelandinggearasaguide.Useself‐taping

screwstolockthewheelpantsinplace.

7. Mountthetailwheelwiththeprovidedhardware.

- 17 -

MountingCowl

1. Trialfitthecowlinplace.Notewherethemountingtabsextend

forwardofF1.

2. Carefullytapethecowlinplaceusingbluelow‐tackpainter’smasking

tapeandmarkwheretodrillpilotholesforthemountingscrews

3. Carefullydrill4pilotholes,onepertab,usinga1/16”drillbit.Then

removethecowl.

4. Enlargetheholesinthecowlslightly.Thiswillallowthescrewstopass

freelyinandoutofthecowl.

5. Enlargetheholesintheplywoodmountingtabstoallowa½”pieceof

yellowinnernyrod(notsupplied)tofitintotheholessnugly.Gluethe

yellownyrodintotheholeswithepoxyandensurethenyrodisflushto

theoutsideofthemountingtab(thisisthesidethatwillcomein

contactwiththecowl.

6. Beforemountingthecowl,useascrewandscrewitintoeachnyrod

endtoestablishthreadsontheinsideofthenyrod.

- 18 -

7. Reinstallthecowlandcarefullyseatthescrewsintothecenterofthe

nyrodandtakecarenottoallowthescrewstocutnewholesinthe

plywoodtabs.

8. Removethecowl.

- 19 -

MountingYourEngine

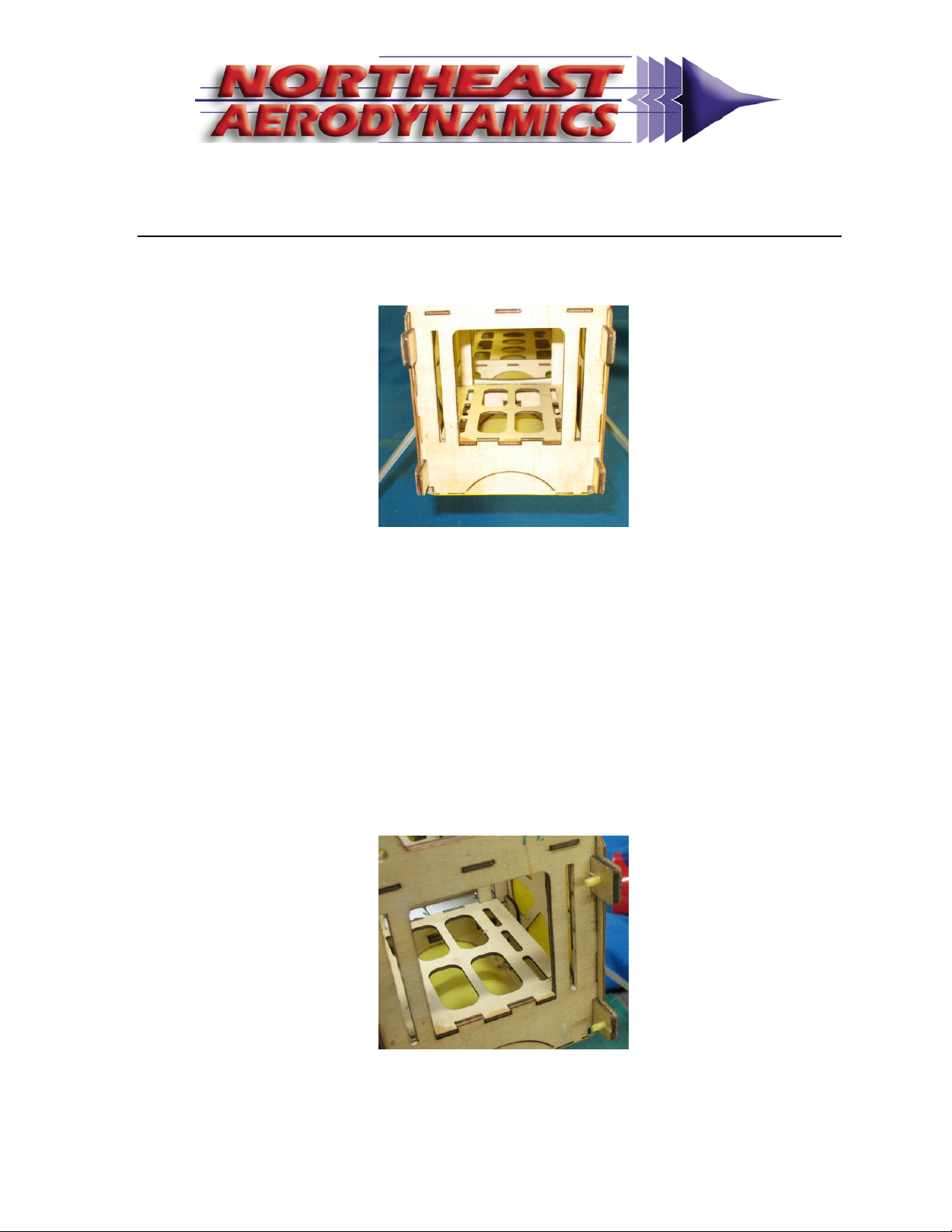

1. Identifythepiecesofthefloatingfirewallassembly.

2. Usingabuildersquare,orothersquarecorner,assembleandalign

partsA,B,andC.NotetoobtaintheproperRight‐Thrustbothsides

mustbesquareasshown.

3. Gluethepiecestogetherusingepoxyandclampinplaceuntiltheepoxy

hascuredcompletely.Thenbracewiththetrianglestockprovided.

- 20 -

4. Youmightneedtoadjusttheopeningsinthefuselagetoallowthe

floatingfirewalltopassfreelythroughthepre‐cutslots.

5. Slidethefloatingfirewallintotheslotsandinstallyourenginemount.

Table of contents