GRAUPNER YAK 11 RENO User manual

Other GRAUPNER Toy manuals

GRAUPNER

GRAUPNER BELLANCA User manual

GRAUPNER

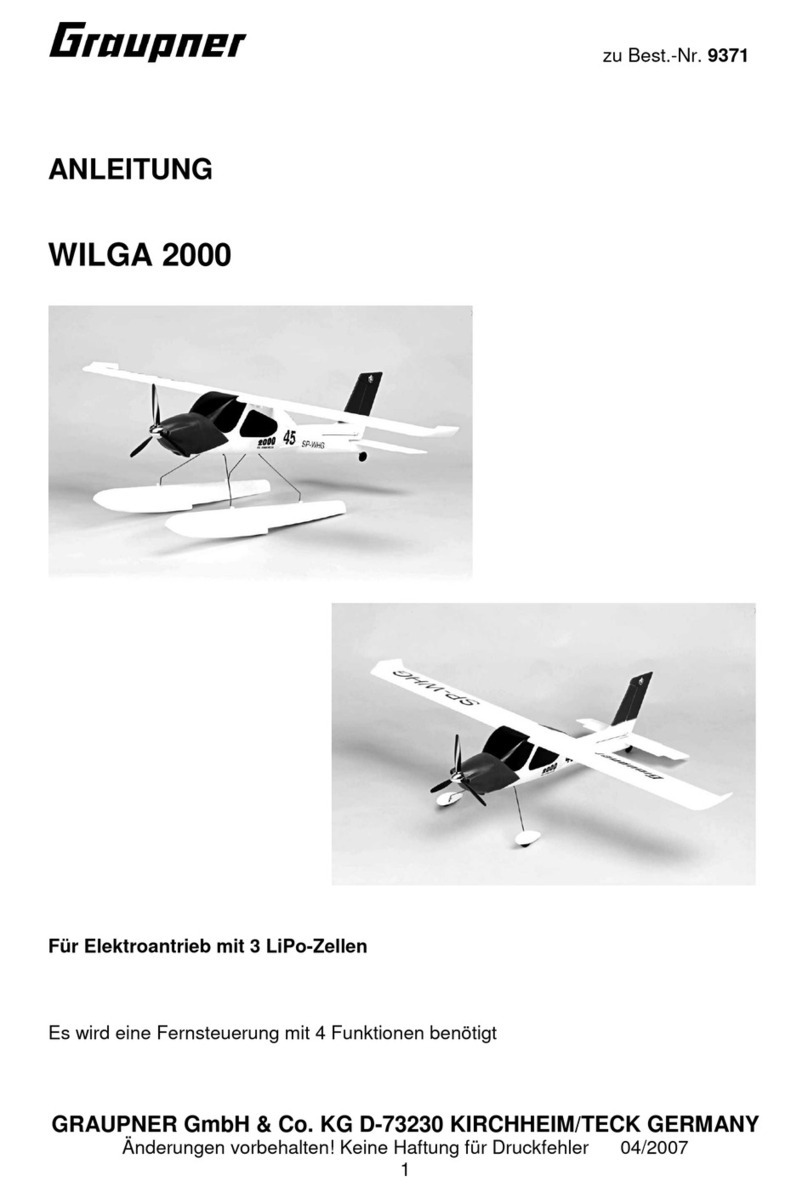

GRAUPNER WILGA 2000 User manual

GRAUPNER

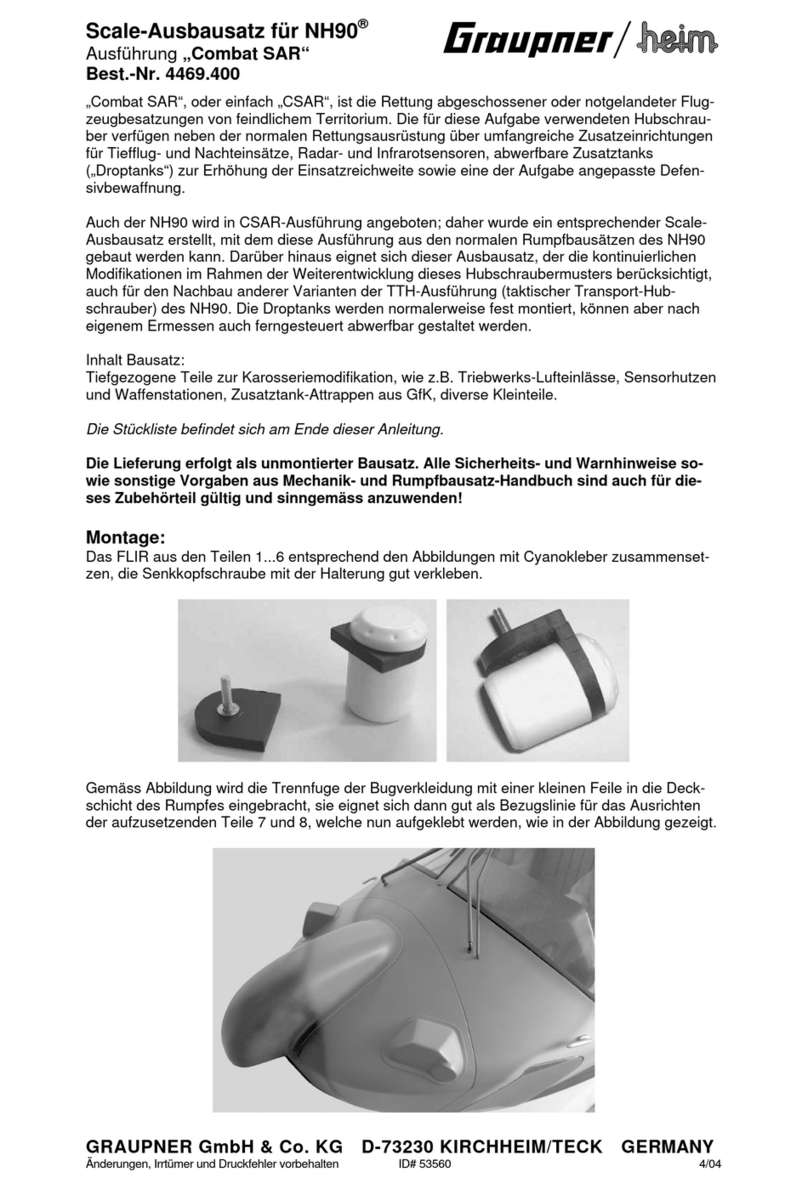

GRAUPNER 4469.400 User manual

GRAUPNER

GRAUPNER MAXIE SPORT 490 Instruction Manual

GRAUPNER

GRAUPNER North American Harvard AT 6 Instruction Manual

GRAUPNER

GRAUPNER TAXI SPORT II Instruction Manual

GRAUPNER

GRAUPNER Micro Magic RTR Quick start guide

GRAUPNER

GRAUPNER DISCUS 2CT Instruction Manual

GRAUPNER

GRAUPNER HYDROPLANE 3D User manual

GRAUPNER

GRAUPNER MICRO MAGIC User manual

GRAUPNER

GRAUPNER PT-109 User manual

GRAUPNER

GRAUPNER EXTRA 300S User manual

GRAUPNER

GRAUPNER 9547 Instruction Manual

GRAUPNER

GRAUPNER CHICO User manual

GRAUPNER

GRAUPNER V-VENTURE User manual

GRAUPNER

GRAUPNER Agusta A119 Koala User manual

GRAUPNER

GRAUPNER ROMMEL User manual

GRAUPNER

GRAUPNER racing Micro Magic HoTT User manual

GRAUPNER

GRAUPNER DIAMANT User manual

GRAUPNER

GRAUPNER SPACEBIRD 2017 User manual