L1276A2

• Oil drain outlets

on both sides of pan.

Oil change pump is

optional.

• Side lube oil fill.

Fills and dipstick

available on both

sides of engine.

• 24 volt battery charging

alternator. 12 volt is optional.

• Fuel filter

with drain.

• Large, cast

expansion tank.

Easy coolant

fill. No welds

to break.

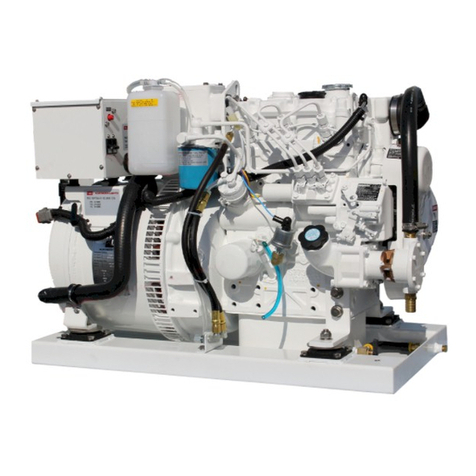

• Sparkling white

IMRON®polyurethane

paint for a tough finish.

L1276A2

Single Side Service.

• Spin-on oil filter

with both full flow and

bypass elements in

one can.

• Crankshaft designed for an

electric clutch PTO.

• Jacket-water cooled, cast

iron exhaust manifold. Two

pass coolant flow for even

temperature control.

• Turbocharger

is jacket water

cooled for

safety.

Optional

wet and

dry exhaust

elbows

available.

• Overhead cam and four valves

per cylinder. Fewer moving

parts, better air flow, and higher

performance.

• 11 gallon oil pan.

• Plate type

engine oil

cooler.

• Closed loop crank

case vent for a clean

engine room.

Reliability, simplicity and durability

from more cubic inches and lower RPM.

High rpm, high performance throw-away

diesels have their place in planing pleasure

craft that rarely get too far from the local yacht

club. But why put one of these engines, even

a derated version, in your commercial boat or

long range cruising yacht? These vessels need

a real, heavy duty diesel that produces high, prop

twisting torque at a rational rpm. They need a

conservatively rated engine with long life features

like the L1276A2.

A commercial heritage

Initially designed for Alaskan fishermen,

Luggers have always been dependable.

Used as prime movers on Northern Lights

marine generator sets, they are well known by

commercial and pleasure craft owners for long

life and smooth, quiet operation. Today,

electronic fuel injected engines

like this L1276A2 are adding US

EPA Tier II compliance to Lugger’s

reputation for reliability, simplicity

and durability.

Ironclad marinization

The L1276A2 has a heavy-duty, overhead cam

tractor block. This high torque design provides

a strong foundation; but a marine engine is only

as good as its marinization. The materials used

must be strong. The design must be clean. Look

at the photo below. Note the lack of hoses, belts,

gaskets and welded cooling components. The

liquid-cooled exhaust manifold is cast iron to

withstand temperature fluctuations and resist

electrolysis. Unlike some engines that only use

bypass water, the 1276 manifold is integrated

into the cooling system mainstream, and two-

pass water flow assures even temperature

control and eliminates hot spots. The piping

is stainless steel or bronze as is the gear

driven raw water pump. The heat exchangers

for the engine and gear have cupro-nickel

elements.

Low rpm horses vs. Paper ponies.

Light-duty, small-displacement diesels are

rated at speeds up to 3000 rpm. This means

high piston speeds, more wear and short life.

The 1276’s power comes from its big 766

cubic inch displacement and long stroke

design. Max rpm is only 2100. Cruise RPM

is 1800 for the continuous rating or 1900 for

medium and high output. Lower rpm also

means less noise and wear, more complete

fuel combustion and longer life.

Wet liners protect your investment.

Lugger cylinder liners are surrounded by

coolant for better heat dissipation. The liners

are replaceable to reduce overhaul costs.

Unlike “linerless” throwaways, a Lugger can

be rebuilt to factory specs in the boat.

Gently turbocharged and aftercooled.

The turbocharger is liquid-cooled for safety.

The aftercooler uses jacket water so the

intake air temp is controlled thermostatically

to avoid over cooling. Over cooling can cause

incomplete combustion and smoke.

Electronic engine control lower fuel costs.

ECU controlled, direct fuel injection, four

valves per cylinder, centered unit injectors and

precise fuel metering all add up to excellent fuel

economy.

Easy to live with.

Low rpm Lugger engines are naturally quiet. No

high rpm whine. Just a steady rhythm. A special

silencer-filter reduces air intake noise. Quiet and

smooth; 1276’s torsional dampener decreases

engine vibration.

Easy to maintain too. Service points are on one

side for easy access. The in-line design gives you

elbow room in the engine space.

Take power from both ends.

The full line of options and accessories lets

you design an engine that is custom built to

match your vessel’s needs. With an optional

front power-take-off your Lugger can power your

vessel’s hydraulic auxiliary systems. It’s more

than an engine, your L1276 is a total marine

power system.

340 /1800 rpm

Continuous

425/2100 rpm

Medium Duty

525/2100 rpm

High Output

HORSEPOWER

• Cupro-nickel

heat exchanger.

• Beltguard protects

the operator.

• Cupro-nicklel gear

oil cooler.