OM-NI 2/20

18

YEARLY

• Condenser Coils

Back ush condenser coils annually, or more frequently

depending on water quality. Periodically chemical clean-

ers are needed to remove marine growth or scale. Consult

the condenser coil cleaning section for instructions on

chemically cleaning the coils. We recommend that certi-

ed technicians perform this service.

Condenser Coil & Raw Water System Cleaning

Prior to cleaning the condenser coil or raw water piping

take baseline readings such as refrigerant pressures,

amperages and the temperature of each condenser coil

wrap.

Turn o the unit and raw water pump. Close the thru-hull

valve.

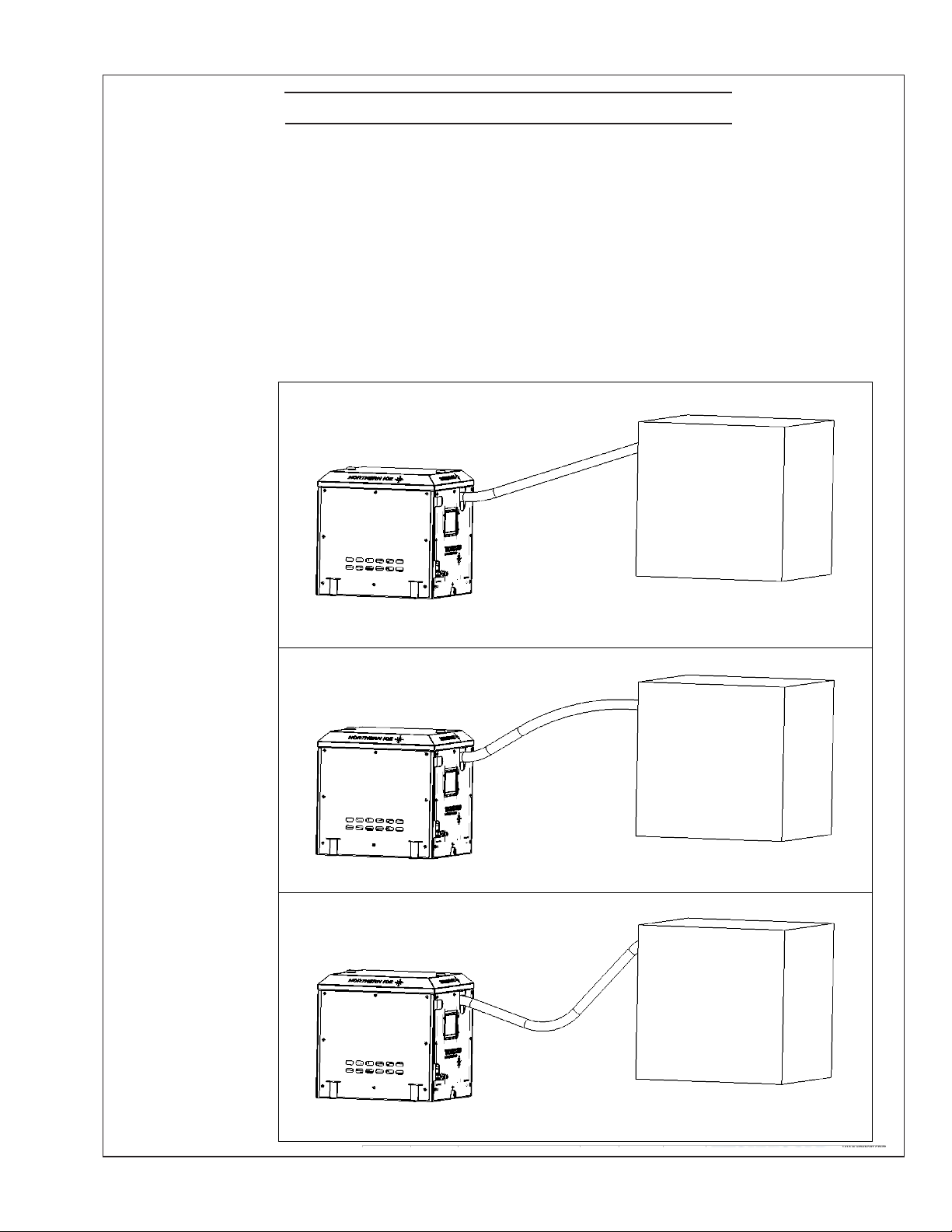

The entire raw water system can be ushed at the same

time. However, the most eective way to clean the system

is to isolate each section (condenser, manifold, piping)

and clean individually.

Before using chemicals to clean the system it should be

back-ushed with fresh water into a container. The pres-

sure generated from the dockside water connection or the

onboard fresh water pump is usually greater than what is

generated by the system's raw water pump. This pressure

can usually ush out a signicant amount of debris and

contaminants from inside the system.

After the back-ushing; the system should be checked

again to see if there was a change in the baseline read-

ings. If within the normal range then no further cleaning

is needed.

Back-ushing with fresh water should be part of your

maintenance schedule. The frequency is dependent on

the usage of the system and water conditions in the areas

where the boat operates. It may only require it once a year

or every 3 months. In harsh conditions it may be required

more frequently.

If the back-ushing has minimal impact on the system

cleanliness then chemical cleaning is needed.

There are numerous chemicals available for cleaning raw

water systems onboard vessels. Some are environmentally

friendly and some are more aggressive. Any chemical or

mix used for the cleaning of the system must be captured

and disposed of in accordance with Federal, State and/or

Local Regulations.

Maintenance

Follow all directions and warnings provided by the manu-

facturer of the chemical. Safety equipment and clothing

must be used to protect personnel and prevent damage to

the surrounding area or equipment.

Chemical cleaners are available at local Marine Whole-

salers, Online or at Commercial Supply Houses. When

selecting a cleaner make sure it is compatible with the

materials in the raw water circuit. Some cleaners are made

to clean a specic contamination such as Algae or Crusta-

ceans and Calcication, some clean a broad spectrum of

contaminants.

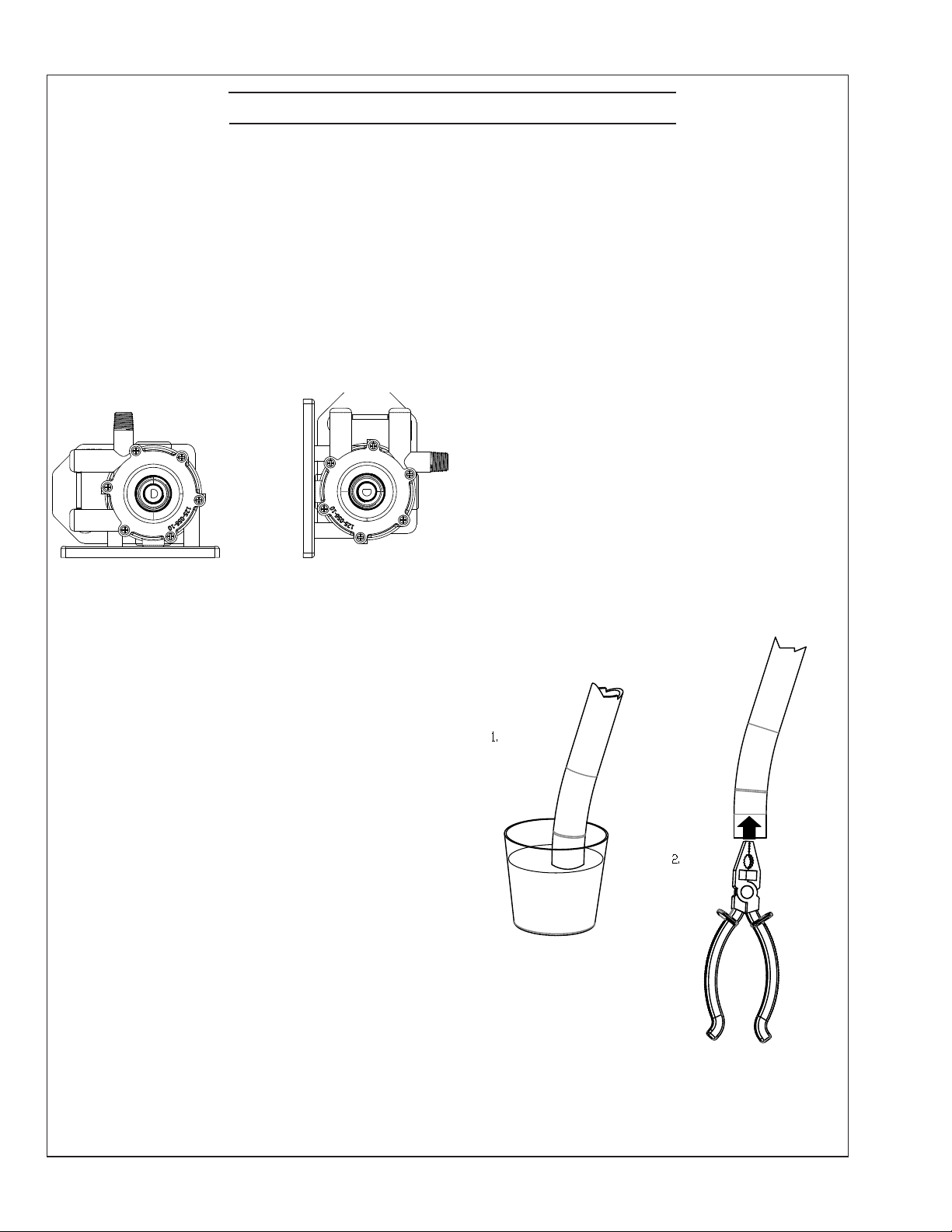

Some chemical manufacturers have a cleaning kit avail-

able for purchase. It usually includes a chemical container

with hose connections, hose, chemical pump, lter, and

other miscellaneous items. You could also make up your

own kit. A Technicold TE500 pump is a good quality,

chemical resistant, submersible pump that can be used

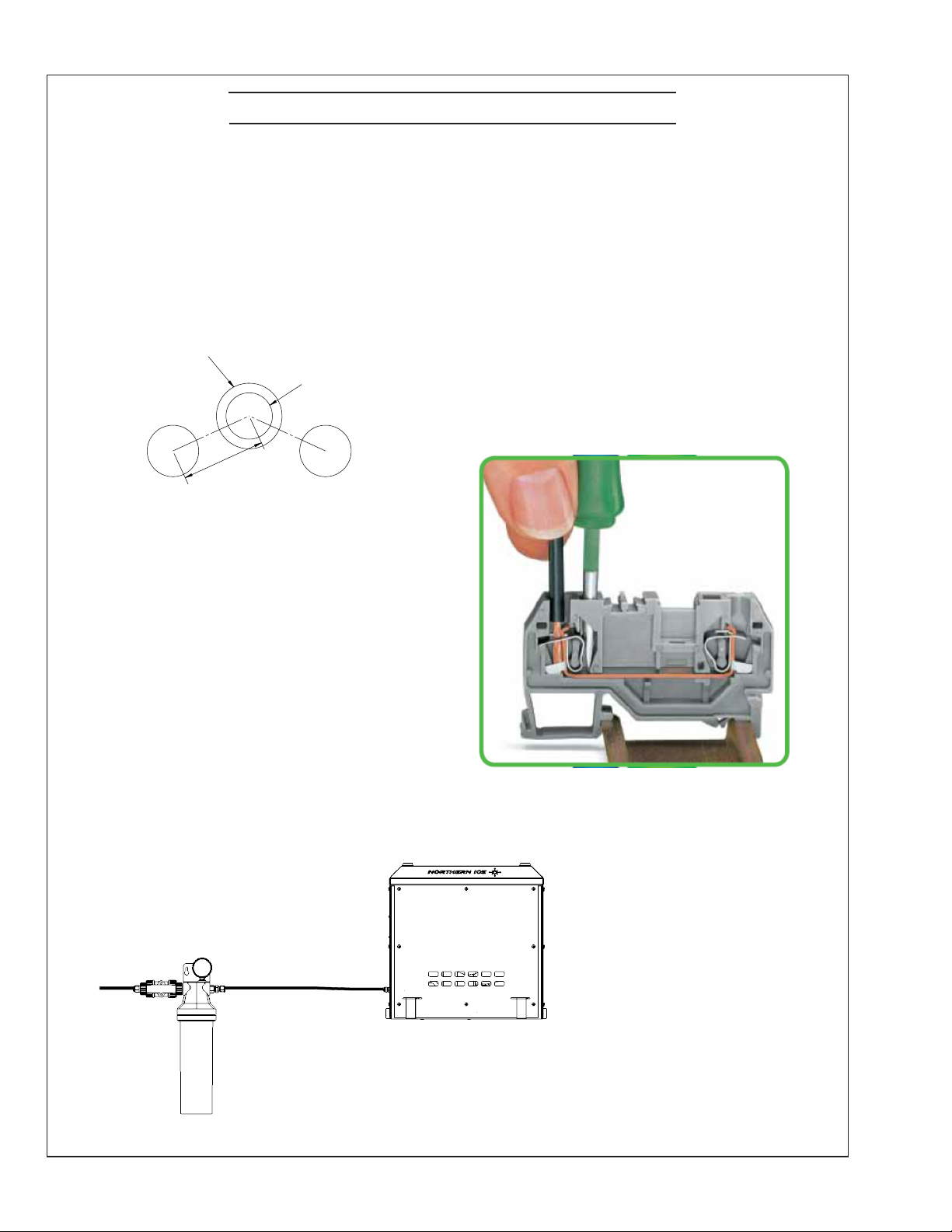

for this purpose. When using any pump for cleaning, a

strainer/lter/screen must be installed on the inlet of the

pump to prevent debris from damaging the impeller.

The container should be of sucient volume for the

chemical/water mix required. The chemical pump can be

placed outside of the container. A bulkhead tting would

be installed in the side of the container and a hose con-

nected from it to a strainer, then to the inlet of the pump.

Connect a hose from the discharge of the pump to the

inlet of the coil/manifold/piping to be cleaned. Another

hose goes from the outlet of the coil/manifold/piping back

into the bucket. If using a submersible pump a bulkhead

tting is not needed. The pump can be placed directly in

the container with a strainer/lter/screen attached to the

inlet. Check the ltration on the inlet of the pump regu-

larly and clean as needed.

Make sure that any materials used (container, hoses, t-

tings, pump, etc.) to ush the system are compatible with

the chemical used.

Use caution when mixing the chemical and water that you

do not splash it on yourself or the surrounding area.

Once you have set up your cleaning kit it should be oper-

ated with fresh water to check for leaks prior to adding the

chemical mix. Protect the area where you are working to

prevent damage from splashing or spilled chemical.