NORTHERN

TELECOM PRACTICES

SECTION

363-2011-300

Issued: 78

11

10

Standard N

DMS-1* DIGITAL MULTIPLEX SYSTEM

SYSTEM OPERATION

I.

2.

3.

4.

CONTENTS

PAGE

GENERAL

.•••••••••••••••••••••••

I

ALARMS

•••.•••••••••••••••••••••

I

Charts

1.

RCT

Alarm Display Operation .... 3

2.

CCT

Alarm Display Operation .

...

4

CONTROLS

•••••••••••••••••••••••

s

Charts

3. Power Supply Reset . • . • . • • • • • • • . s

4. System Controller Restart

.••.••••.

6

s.

Protection Switching, Bypass,

and Loopback . •• . • . • . • . • . • • . • . • 6

6. Traffic Measurement . • . • . • . • • • • . • 10

7.

Priority/Dedicated Selection

.••.••.

II

TEST ACCESS

••••••••••••••••••••

12

Charts

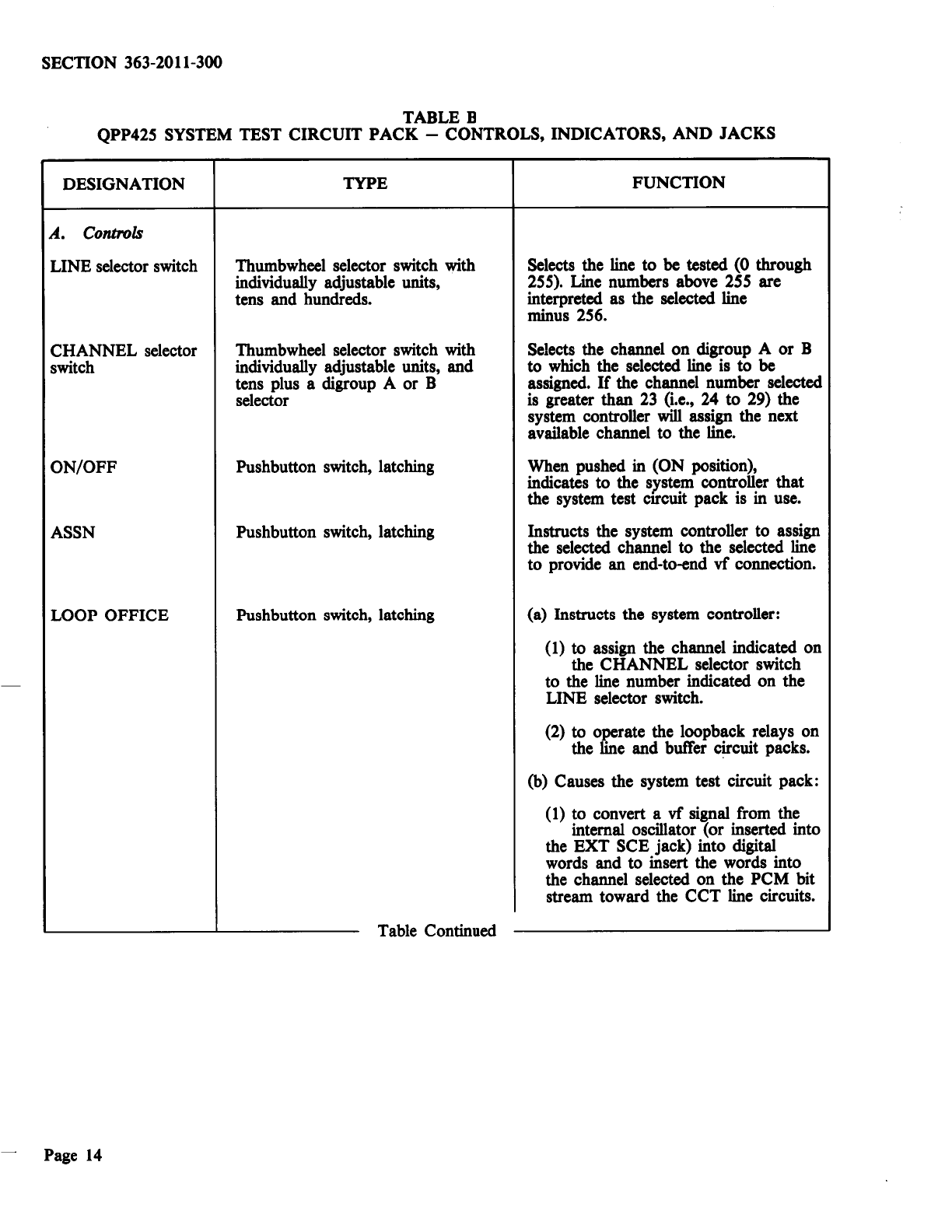

8. QPP425 System Test Circuit Pack

Calibration and Tests . • • • • • • • • . • . 23

9. QPP424 Line Test -Office

Circuit Pack Operation . • . • • • • • • • . 28

10. QPP450 Test Control Circuit

Pack Tests . • • . • . • • • • • . • • • • • • • .

31

11. QPP448 Test Access Circuit

Pack Operation . • • • . • . • • . . • • • • • . 34

S.

ORDER

WIRE

• • • • • • • • • • • • • • • • • • • • 37

Charts

12. Initiating a Call

at

an

RCT

. • . . • • . 37

13. Initiating a Call from a Repeater

Site . • . . . • • . • • • • • • • • • • • • • • • • • . 38

14. Answering a Call

at

the

CCT

.••..

39

6. EMERGENCY

POWER

• • • • • • • • • • • • • 40

Charts

15. Connecting and Removing

an

Emergency Generator

at

an

RCT

40

7.

DIGITAL

LINE

FAULT

LOCATION • • • • • • • • • • • • • • • • • • • • • • •

41

• DMS-1 is a trademark

of

Northern Telecom Limited

I.

GENERAL

1.01 This section outlines procedures required for

the operation

of

the

DMS-1 Digital Multiplex

System. The information contained in this section is

supplementary

to

the descriptive

and

maintenance

practices.

1.02 Reason

for

Reissue:

to

add new

and

revised

information.

1.03 The DMS-1 system normally operates

automatically. The monitor and alarm circuits

within the system detect

and

indicate

any

degradation

in performance

or

any equipment failure. When the

system is functioning correctly and all input signals

are

present, there are

no

visual

or

audible alarms.

When the system detects trouble, office alarms,

remote alarms, and equipment alarms are activated.

1.04 The indicators

on

the faceplates

of

the alarm

circuit packs (Fig. 1

and

2) are used as a

f~rst

step in fault location. The functions

of

these

indicators are described in 363-2011-500.

1.05 Controls

on

the faceplates are used for

adjustments, system testing,

and

fault

location.

2. ALARMS

2.01 Most

RCT

alarms are displayed

on

the

QPP420 ALM

REM

circuit

p_ack

(Fig. 1).

The Remote Concentrator Terminal (RCT) alarms

are

also transmitted

to

the Control Concentrator

Terminal (CCT) and displayed

on

the QPP421

ALARM

OFFICE

circuit pack together with

CCT

alarms. In addition

to

the centralized alarm display,

failure

of

the initial

or

the backup circuit pack, where

optional backup circuit packs are installed, is

indicated by a light

on

the QPP431 SYS

CONT

and

QPP426

RING

GEN.

®Northern Telecom Limited 1977

Printedin

Canada

Page 1

41

Pages