Northland 18AF-SB Manual

Installation

Operation

and

Maintenance

Instructions

Built-In

Refrigerator/Freezer

NORTHLAND BUILT-IN REFRIGERATOR/FREEZER

TABLE OF CONTENTS

Section Page

UNPACKING THE UNIT 1

PRE-INSTALLATION 2

INSTALLATION 3

CORNER INSTALLATION AND INSTALLING TWO UNITS SIDE BY SIDE 4

LEVELING THE UNIT 5

INSTALLING THE CABINET 6

INSTALLING THE MODULE 7

INSTALLING THE ICE MAKER 8

ALTITUDE ADJUSTMENT FOR TEMPERATURE CONTROL 9

INSTALLING THE GRILLE ASSEMBLY 10

HINGE AND GASKET ADJUSTMENT AND FACE MOUNTED DOOR HANDLES 11

INSTALLING THE SIDE PANELS AND KICK PLATE 12

CUSTOM DOOR PANELS AND SPECIFICATIONS 13

CUSTOM GRILLE PANELS AND SPECIFICATIONS 14

TRIMLESS DOOR PANELS AND SPECIFICATIONS 15

TRIMLESS GRILLE PANELS AND SPECIFICATIONS 16

GLASS PANEL READY WOOD FRAME DOOR SPECIFICATIONS 17

INSTALLING A DOOR FRAME TO THE GLASS DOOR 18

INSTALLATION CHECKS/COMMON ERRORS 19

TROUBLESHOOTING 20

USE AND CARE GUIDE 21

WARRANTY 24

Before you begin - Read these instructions completely and carefully.

IMPORTANT - Save these instructions for local inspector’s use.

IMPORTANT - OBSERVE ALL GOVERNING CODES AND ORDINANCES.

Note to Installer - Be sure to leave these instructions with the consumer.

Note to Consumer - Keep these instructions for future reference.

UNPACKING THE UNIT

1

Remove Packaging

Your refrigerator/freezer has been packed for shipment

with all parts that could be damaged by movement

securely fastened. Before using, be sure all packing

materials and tape have been removed.

Important

Keep your carton packaging until your refrigerator/

freezer has been thoroughly inspected and found to be

in good condition. If there is damage, the packaging

will be needed as proof of damage in transit.

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving our plant. Responsibility for

its safe delivery was assumed by the retailer upon ac-

ceptance of the shipment. Claims for loss or damage

sustained in transit must be made on the retailer as

follows:

Exterior and Concealed Damage•

Any damage must be reported immediately to your

retailer.

DO NOT RETURN DAMAGED MERCHANDISE TO

THE MANUFACTURER - FILE THE CLAIM WITH

THE RETAILER.

Safety

Protect your kitchen floor. Remove all packing materi-

als from cabinet and if there was no freight damage

then destroy cartoning, plastic bags and any exterior

wrapping material. Children should never use these

items for play. Remove all staples from your carton.

Staples can cause severe cuts and destroy finishes if

they come in contact with other appliances or furniture.

Carefully read and follow the child safety precautions

in the pamphlet enclosed with your new refrigerator.

It is published by the Association of Home Appliance

Manufacturers.

Tools to Have Available for Installation

Phillips Screwdriver•

Flat Blade Screwdriver•

5/16 inch & 1/4 inch Hexhead Nutdriver•

Level•

Drill and Drill Bit (#6 - .204)•

7/16 inch & 1/2 inch Open End Wrench•

Pliers•

Adjustable Wrench•

1/4 inch Open End Wrench•

Tape Measure•

PRE-INSTALLATION

2

Floor under product MUST be at or above the same level as the surrounding FINISHED floor, for ease of installa-

tion and removal.

Electrical: Provide 115 Volt, 60 Cycle, Single Phase, 15 Amp, AC Receptacle. It is recommended that a separate

circuit, serving only this appliance, be provided. *Two (2) units side-by-side require separate circuits, except the

60SS and 72SS (see Instruction Sheet 34361-000). Electrical opening should be placed 78 1/2 inches minimum

from the floor.

Plumbing: Ice maker water supply line (1/4 inch OD copper tubing) to come up the rear of cut-out opening ap-

proximately 78 inches off the floor depending on height adjustment. Tubing should then pass around the right side

of the module and around the front to the solenoid valve (see Installation Instructions provided with the unit).

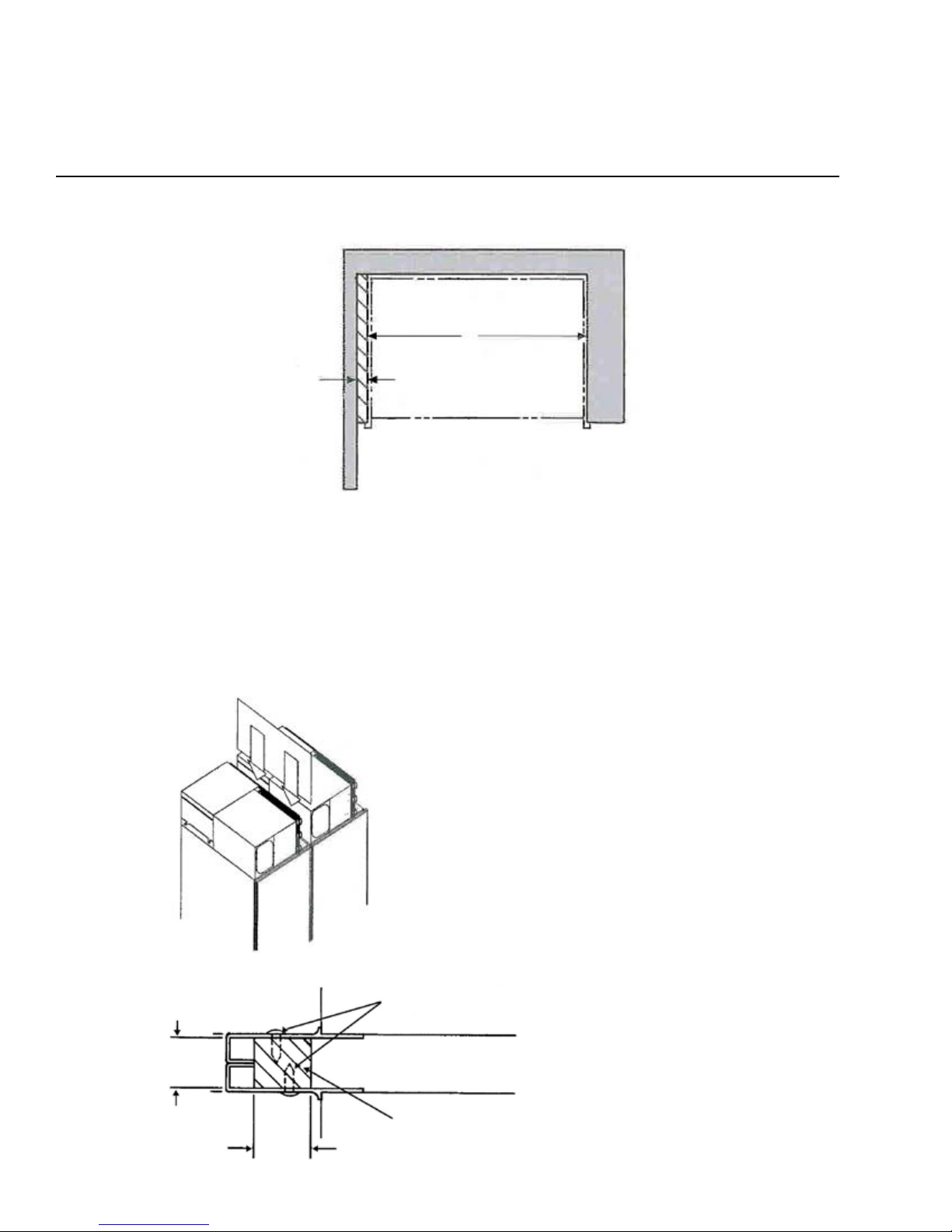

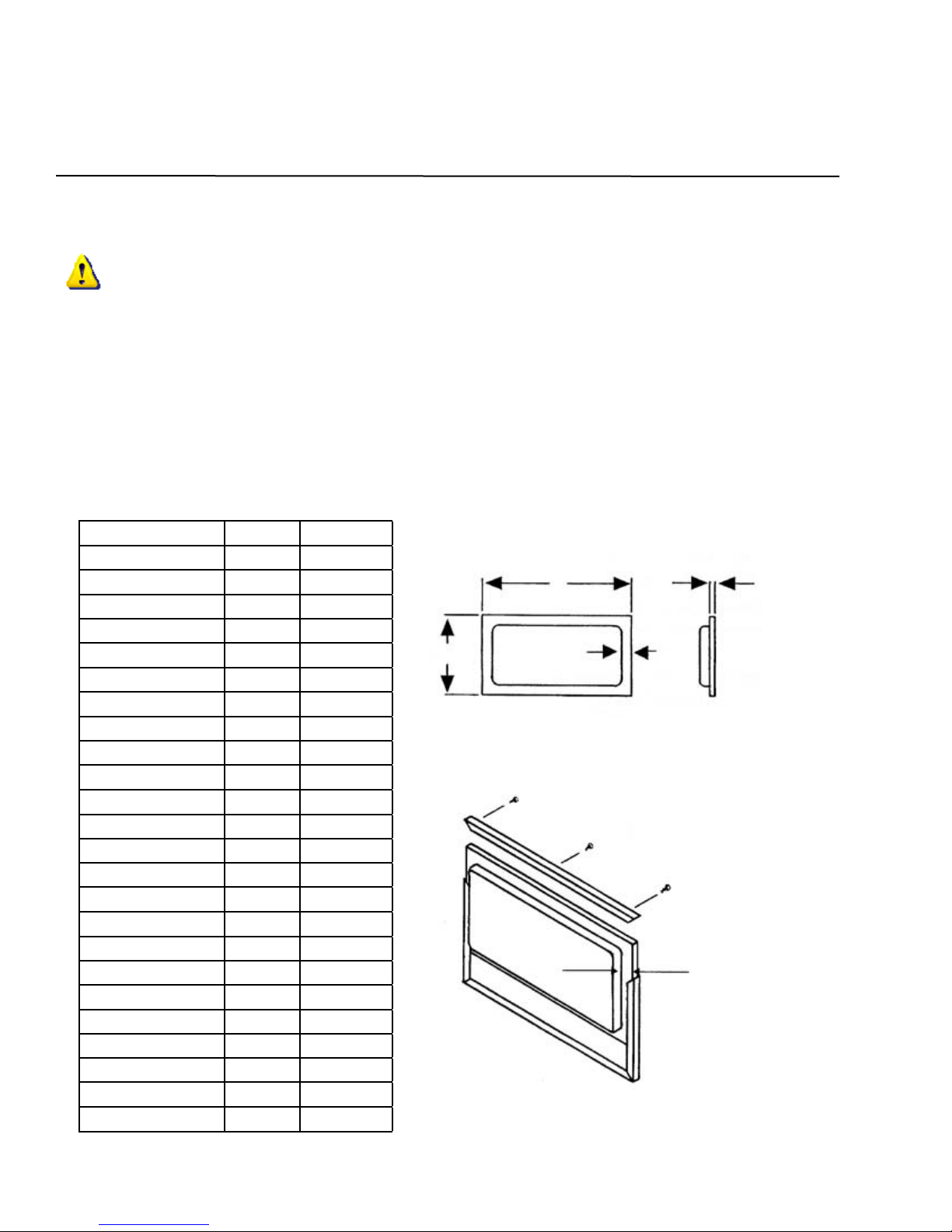

Cut-Out Detail for 1 Unit

Cut-Out Width = “A”

*Cut-Out Detail for 2 Units

Placed Side by Side

Cut-Out Width = “A” + “A” + 1/2”

Model

Cut-Out

Width

(inches)

18AR 17 1/2

18AF 17 1/2

18TF 17 1/2

18WC 17 1/2

24AR 23 1/2

24AF 23 1/2

24TF 23 1/2

24WC 23 1/2

24BC 23 1/2

242Z 23 1/2

30AR 29 1/2

30AF 29 1/2

30TF 29 1/2

36AR 35 1/2

36AF 35 1/2

36TF 35 1/2

36SS 35 1/2

363D 35 1/2

42SS 41 1/2

48SS 47 1/2

54SS 53 1/2

60SS 59 1/2

66SS 65 1/2

72SS 71 1/2

NOTE: Allow for three (3) inch high removable filler panel for easy removal of power module.

Receptacle must be placed in

this location for 18” models.

22”

22”

Ice Maker

Tubing

20”

Min. (typ)

*See note below.

A A

A

83 3/4”

to

84 1/2”

24”

24”

78”

approx.

78 1/2”

Min.

(typ) 1/2”

83 3/4”

to

84 1/2”

Electrical Connection

The module comes with a 3-prong power suppply

cord. It must be plugged into a mating 115 volt, 60

Hz, 15 amp separately fused, 3-prong grounded

outlet serving only this product, and wired in accor-

dance with National and Local Electrical Codes and

ordinances. A time delay fuse or circuit breaker is

recommended. DO NOT USE AN EXTENSION CORD

OR ADAPTER PLUG.

DO NOT REMOVE THE GROUND PRONG FROM

THE POWER SUPPLY CORD UNDER ANY CIRCUM-

STANCES!

If voltage varies by 10 percent or more, performance

of your refrigerator/freezer may be affected. Operat-

ing the refrigerator/freezer with insufficient voltage can

damage the compressor. Such damage is not covered

under your warranty. If you suspect your voltage is

high or low, consult your power company for testing.

Do NOT pinch, knot, or bend the power cord in any

manner.

NEVER unplug the refrigerator/freezer by pulling on

the power cord. Always grip the plug firmly and pull

straight out from the receptacle. To avoid electrical

shock, unplug the refrigerator/freezer before cleaning

and before replacing a light bulb.

NOTE: Turning the control to “OFF” turns off the

compressor, but does not disconnect power to the light

bulb or other electrical components. The unit MUST

be unplugged or turned off at the circuit breaker.

INSTALLATION

3

Select Location

Locate the refrigerator/freezer in the coolest part of the

room, out of direct sunlight and away from heating

ducts or registers.

Do not place the refrigerator/freezer next to heat-

producing appliances such as a range, oven or dish-

washer. If this is not possible, a section of cabinetry

or an added layer of insulation between the two (2)

appliances will help the refrigerator/freezer operate

more efficiently.

IMPORTANT

When installing the water line for the ice maker, be

sure to install a SHUT-OFF VALVE at a convenient loca-

tion between the refrigerator and the supply line.

Required water pressure range is 20 to 120 psi.

Also required is an in-line WATER FILTER between the

refrigerator and the supply line to prevent sediment

from blocking water flow through the water solenoid

valve.

NOTE: Self-piercing water valves and plastic tubing

are NOT approved for water supply to ice maker.

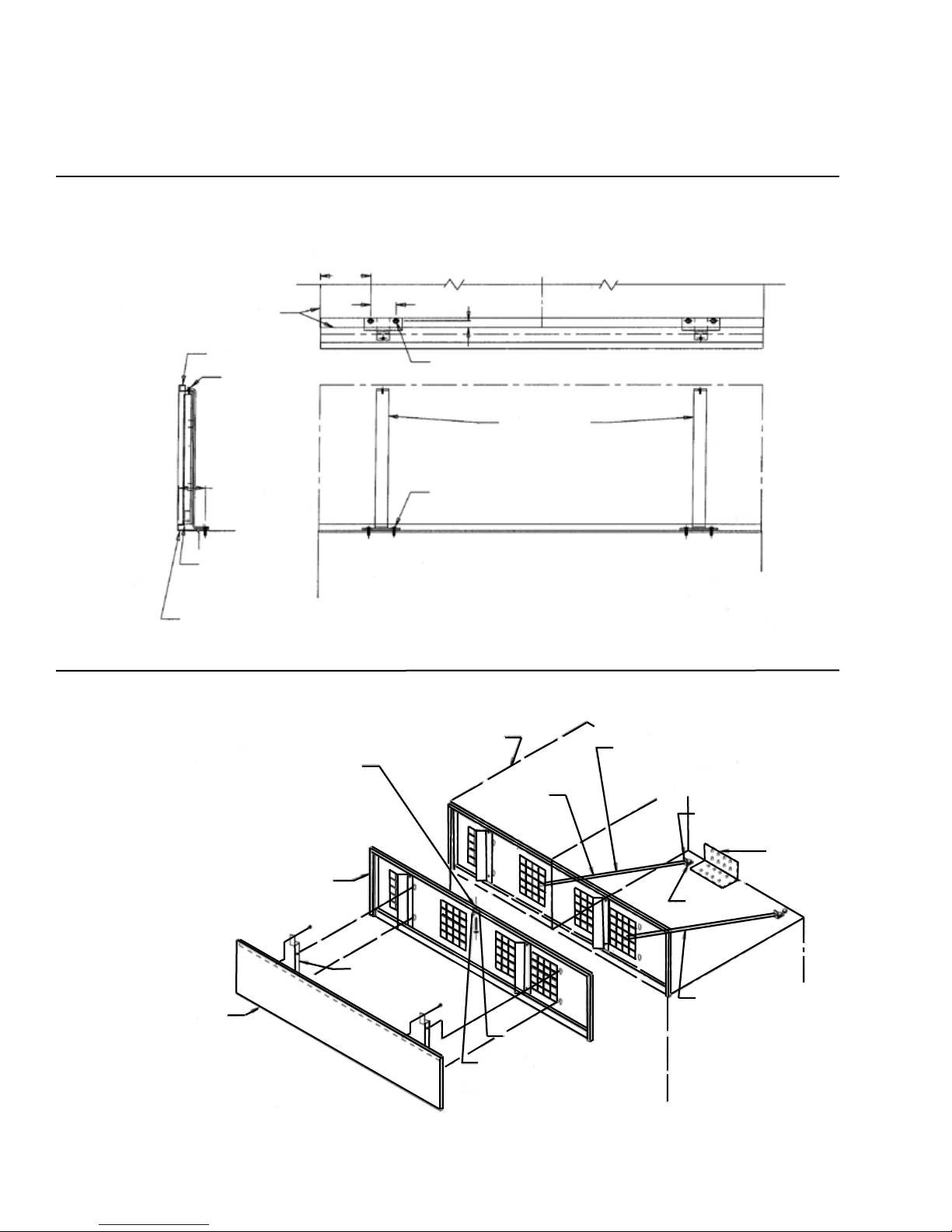

Installing Two Units Side-By-Side

When two (2) units are installed together, a 23 1/2

inch x 12 inch (minimum) divider panel needs to be

installed between the two (2) modules (refer to Illustra-

tion) with self-tapping screws. The divider panel can

be made of any material available, (i.e. 1/32 inch

aluminum, 1/8 - 1/4 inch wood paneling), or you can

order Kit # 34747-000 from the Northland Service

Department. Locate the divider panel approximately

one (1) inch down from the top of the cabinet and

flush with the back of the cabinet. Drill three (3) pilot

holes approximately 1/2 inch up from the bottom of

divider panel, through panel, and into cabinet. Secure

the panel to the cabinet with three (3) screws using

pilot holes previously drilled.

CORNER INSTALLATION AND INSTALLING TWO UNITS SIDE-BY-SIDE

4

Enclosure must permit refrigerator to be removed

for service.

PANEL READY UNITS: For corner installations, a

minimum one (1) inch filler must be used as shown

above.

ANY UNIT WITH FACE MOUNTED HANDLE: Filler

must be three (3) inches minimum.

A

Cabinet Outline

1” or

3” Min.

Filler

Install wood shim to one of the•

cabinets before installing cut-

out cavity (not provided).

After properly installing both•

cabinets, drill trim and install

pan head screws (provided).

Drill three (3) holes each side

equal distance apart in vertical

section of aluminum frame and

install screws as shown.

Wood Shim

7/8” x 1” x 68”

7/8”

1”

NOTE: Unit MUST be installed level in all planes, on a floor that is strong enough to support a fully loaded

refrigerator/freezer.

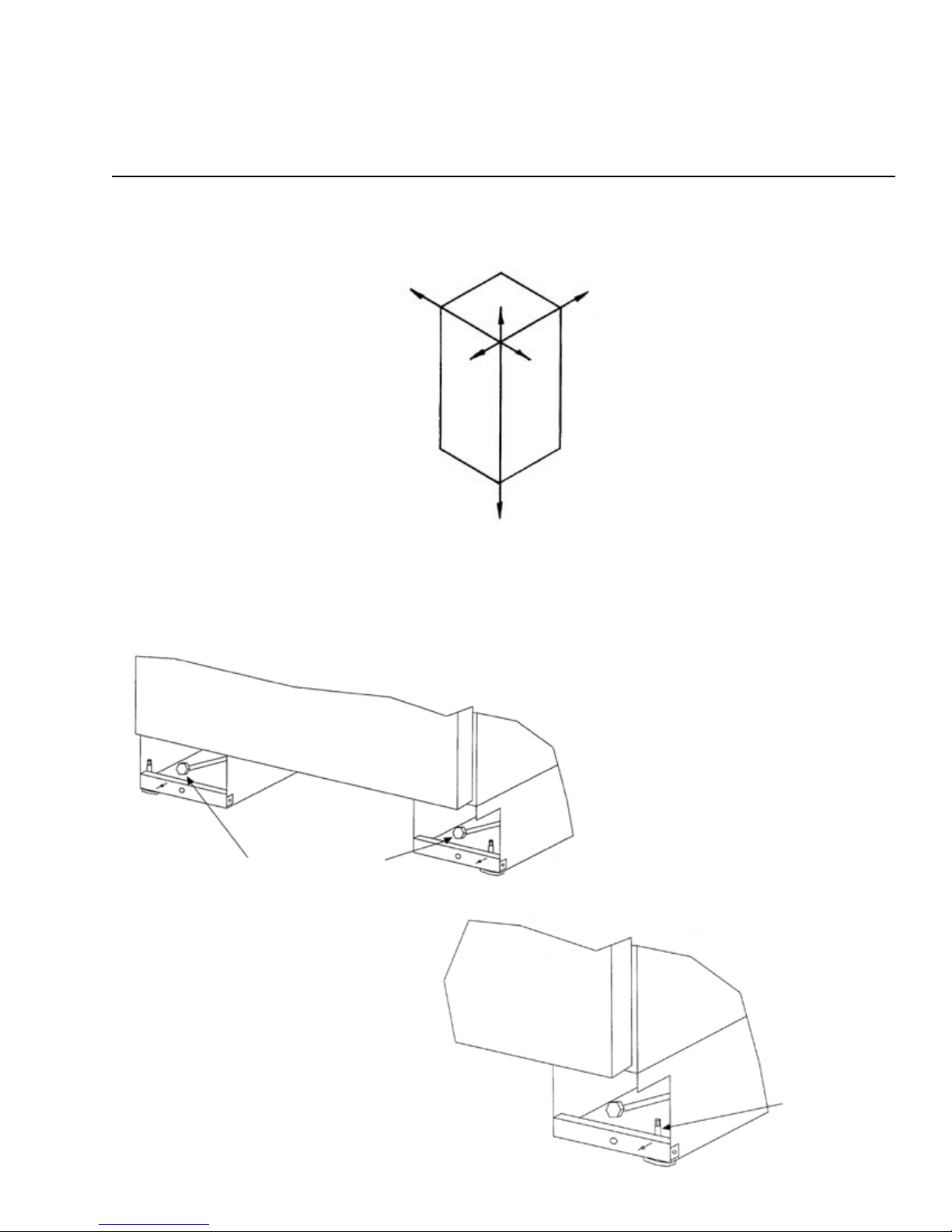

LEVELING THE UNIT

5

This unit is equipped with front and rear rollers. Rollers will aid during installation. Rear rollers are adjustable from

the front of the unit. Total adjustment is + 5/16, - 5/16. Turn adjusting bolt clockwise to raise cabinet and coun-

terclockwise to lower cabinet. Front leveling legs must be adjusted to the floor for leveling and to prevent the unit

from rolling during use.

Rear Roller Adjustment Bolt

Front leveling leg.

Use 1/4” wrench

to adjust height of

leveling legs.

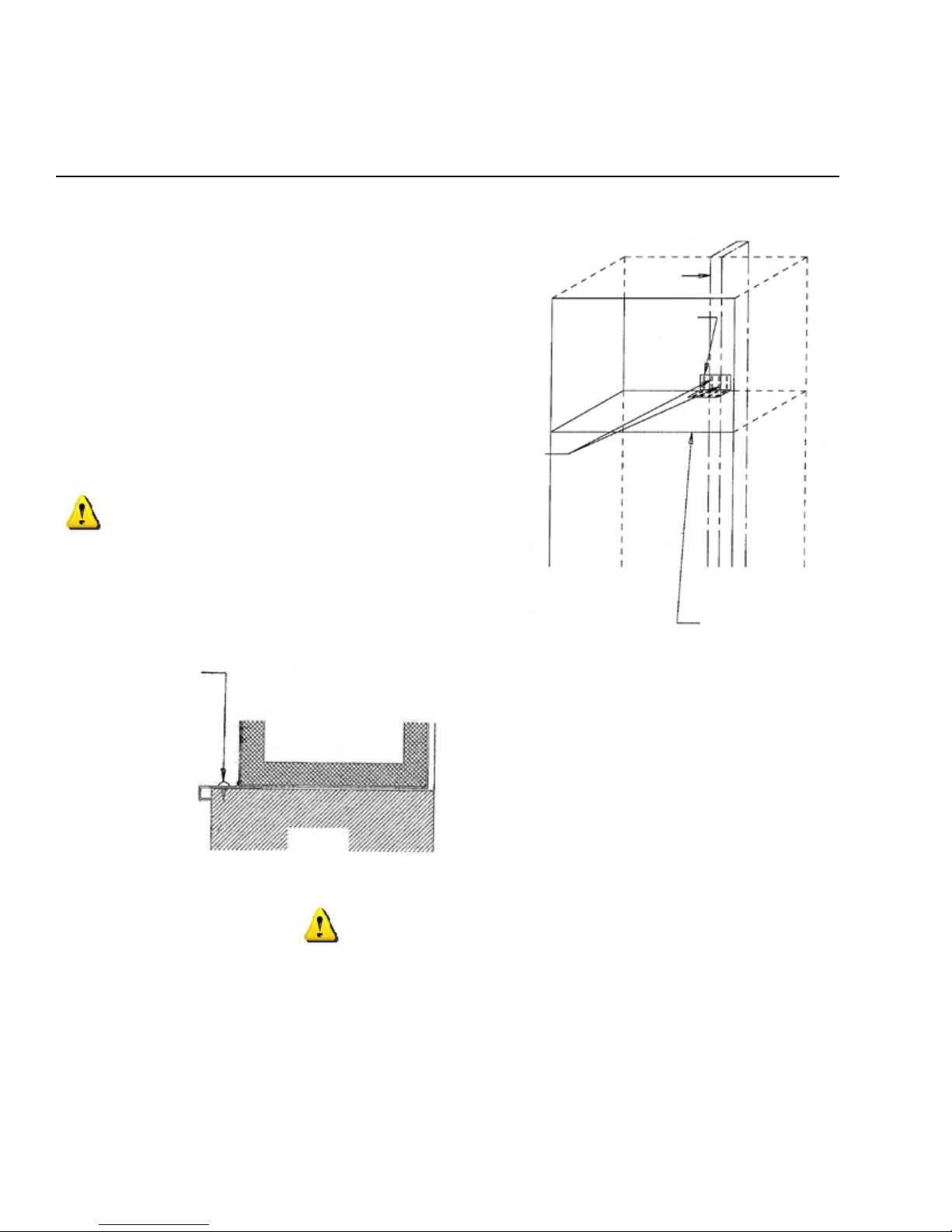

Before placing the cabinet in opening, the depth of the

cut-out opening should be at least 24 inches. If the

cut-out opening depth is more than 24 inches, then

a piece of wood must be secured crosswise on the

wall into the studs at the height of the anti-tip bracket.

Slide the cabinet into position and level the cabinet

with adjustable rear roller and front leveling legs. Lo-

cate and mark a center stud in the back of the cut-out

opening for the L-shaped anti-tip bracket- (the bracket

should fit tight to the top of the cabinet). Install at least

two screws through the bracket into the stud located

in the wall behind the cabinet. The front leveling legs

also prevent the unit from rolling during use. Check fit

of toe kick and grille.

IMPORTANT

Drill and screw through the side trim into adjoining

cabinets and/or walls for additional support.

IMPORTANT

Recheck cabinet installation for:

Proper space left for grille installation.•

Cabinet levelness.•

Door opening and closing appearance.•

SAFETY...To prevent unit from tipping forward:•

-Are screws installed securely through front trim

into adjoining cabinetry and/or walls?

-Is anti-tip mounting bracket secured to wall

studs?

After above checks have been made, proceed

with refrigeration installation.

INSTALLING THE CABINET

6

Stud

Anti-Tip

Bracket

Cabinet Top

Install at least

two (2) screws

into studs.

Do NOT install anti-tip bracket over the

top of the power module.

NOTE: 18 and 24 inch wide models have

a full anti-tip bracket across the back of

the units. The anti-tip bracket should be

attached to the wall.

Refrigerator

Cabinet

Finished

Wall or

Cabinets

Drill three (3) holes

equal distance apart

in vertical section of

aluminum frame and

install pan head screws

as shown.

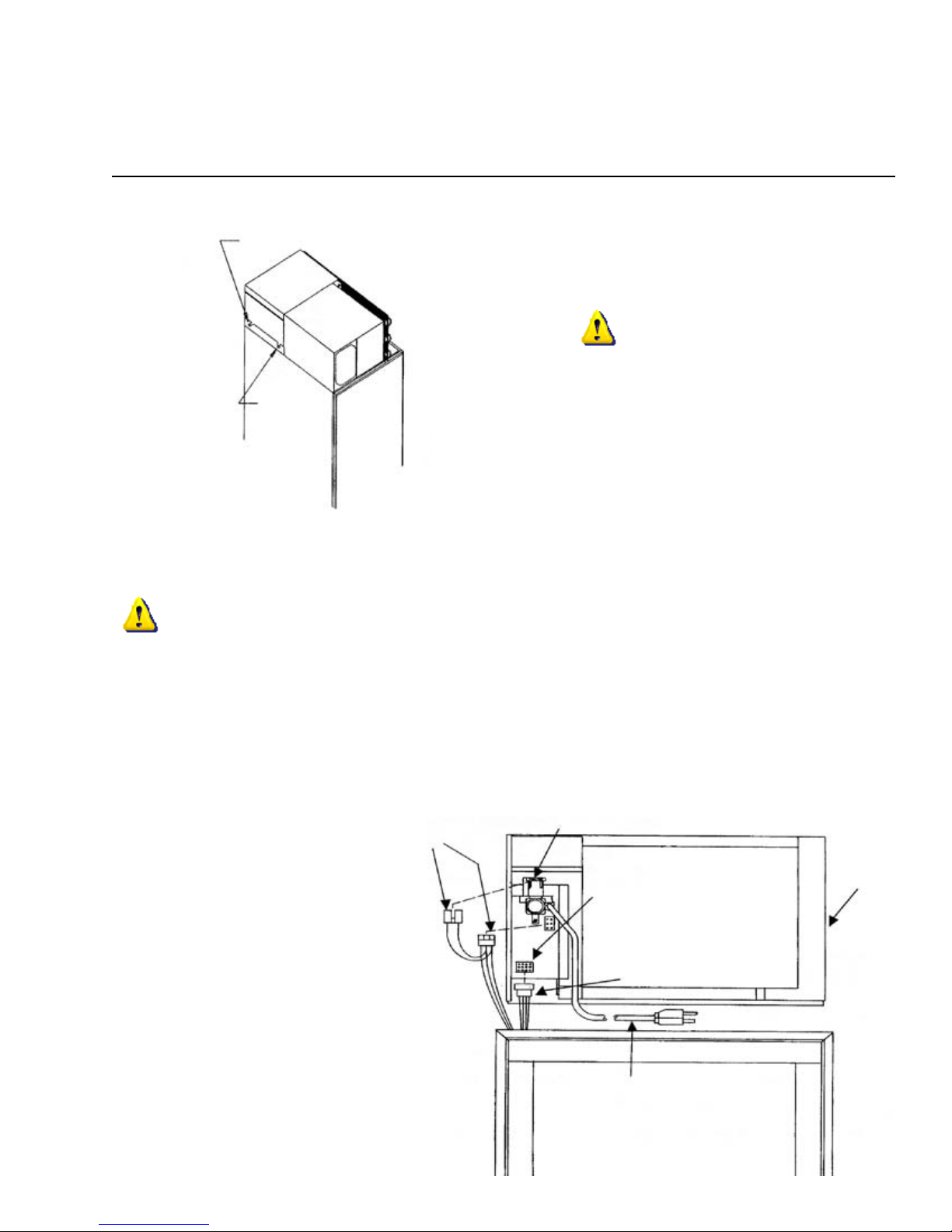

INSTALLING THE MODULE

CAUTION

Module NOT fastened to cabinet below. Remove

before tipping or transporting.

Place module on top of the cabinet with rear shoulder screws resting on the locator brackets behind the front slots.

Slide module toward the rear of the cabinet until the rear shoulder screws engage the slots in the rear of the brack-

ets. Rest the front shoulder screws into the front slots of the brackets.

IMPORTANT

Check to make sure wiring and ice maker tubing is clear and not interfering with module seal. Do NOT start prod-

uct during construction, as dust can block module condenser coils. If dust accumulates on coils, vacuum immedi-

ately, using a soft brush attachment.

Do NOT operate the refrigerator in the presence of explosive fumes.

Do NOT install the refrigerator where the temperature will drop below 60 degrees F (15 degrees C) or rise above

110 degrees F (43 degrees C). The compressor will NOT be able to maintain proper temperatures.

Make electrical connections from the top

of the lower cabinet to the junction box

at left side of module. If NO ice maker

then only one cabinet line will be pro-

tuding. With ice maker, be sure to plug

the ice maker line into the module, and

the solenoid valve as well. See module

diagram on the right.

Front

Shoulder

Screw

Rear Shoulder Screw

7

Module

Water Valve

Power Cord

Cabinet

Leads

Junction

Box

Ice Maker

Leads

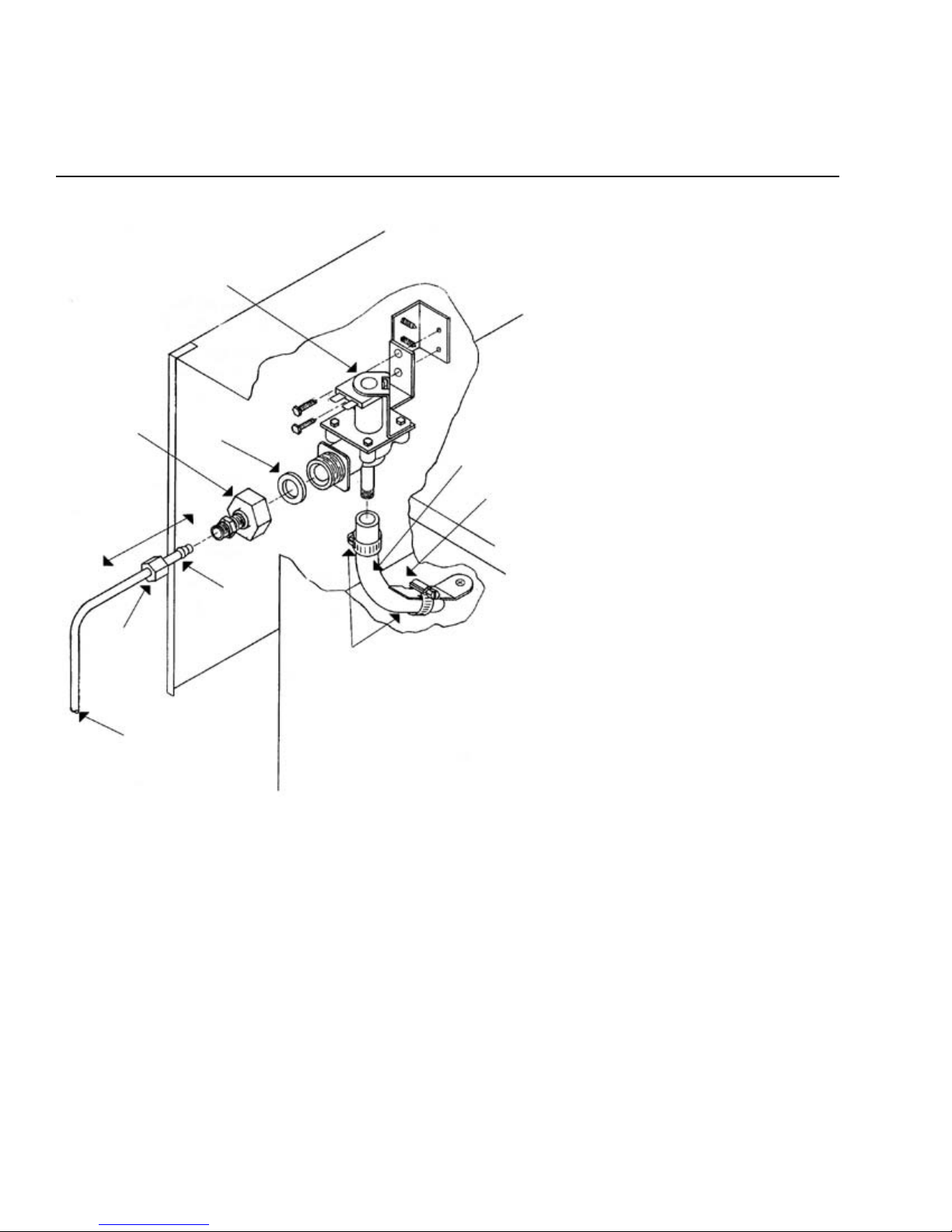

INSTALLING THE ICE MAKER WATER VALVE

Ice Maker (Solenoid) Connection

Slip solenoid valve compression nut and

compression sleeve on copper tubing

as shown in diagram. Tighten nut onto

water valve with adjustable wrench. Turn

on water supply valve. Check fittings

for leaks. Clamp ice maker line from

cabinet onto solenoid valve as shown.

Tighten clamp securely.

This clamp for tube positioning only.

Check to make sure tube is not col-

lapsed or restricted after connecting

opposite end to valve.

Fill hose to ice maker.

Tube Clamp (2)

Sleeve

Compression

Nut

Copper Tubing

(by customer)

3 1/2”

Garden Hose

Fitting Gasket

Solenoid

Water Valve

8

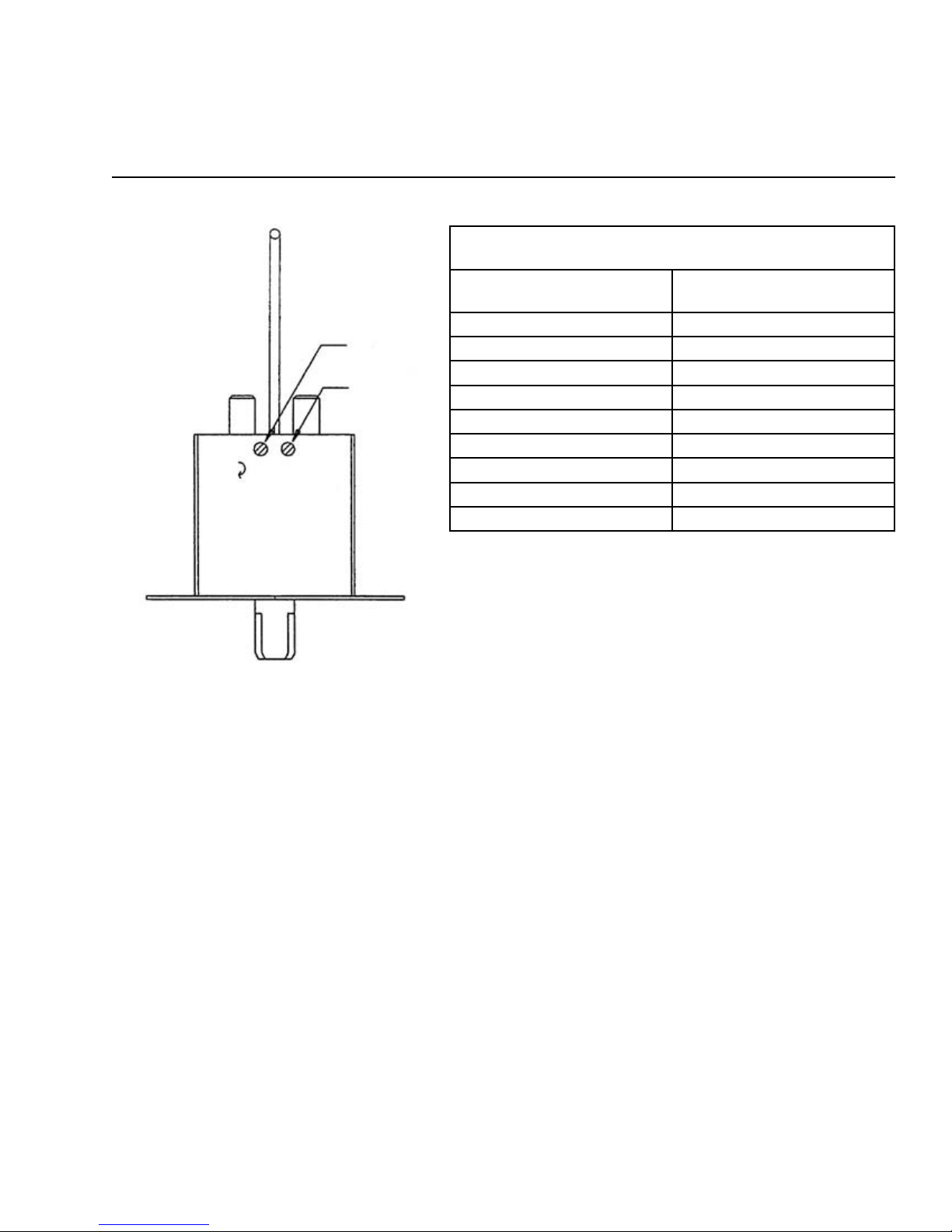

ALTITUDE ADJUSTMENT FOR FREEZER/WINE CELLAR TEMPERATURE CONTROL

ALTITUDE CORRECTION

BOTH CUT-IN & CUT-OUT SCREWS MUST BE ADJUSTED.

ALTITUDE IN FEET COUNTERCLOCKWISE

TURNS

2,000 7/60 = .12

3,000 13/60 = .22

4,000 19/60 = .32

5,000 25/60 = .42

6,000 31/60 = .52

7,000 37/60 = .62

8,000 43/60 = .72

9,000 49/60 = .82

10,000 55/60 = .92

Turn off power to refrigerator before servicing.1.

Remove screws holding freezer/wine cellar air return and drop air return grille to expose control assembly.2.

Locate cut-in and cut-out adjustment screws.3.

Determine the altitude of your location and refer to the chart above for the number of counterclockwise turns4.

to adjust the control for proper calibration. NOTE: Both cut-in and cut-out screws must be adjusted the same

amount. (NEVER exceed one full turn or damage to the control may occur.)

Reassemble the return air grille and plug in the refrigerator.5.

9

Cut-In Screw

Cut-Out Screw

In

Colder

Out

INSTALLING THE GRILLE ASSEMBLY

GRILLE MOUNTING - STYLE I BRACKET

Instructions for Installing Grille Brackets

Use the two (91180-000) screws to secure each bracket to the cabinet top.1.

Loosen the screws at the top of the mounting bracket. Leave .13 inches (2-3 screw2.

threads) sticking through the bracket.

Install the grille by aligning the screws in the top of the bracket with the slots in the3.

grille top trim.

Grille is installed when bottom of the grille fits behind the cabinet trim across the4.

front.

Pull grille forward about an inch at the top and retighten the screws in the top of the5.

bracket.

Cabinet Top Trim

Grille Top Trim

Edge of Cabinet

See Note #2.

2.06” from inside of

cabinet top trim to

centerline of holes.

Bottom of grille

shown behind top

trim. See Note #4.

Mounting Brackets

(91180-000) # 8 - 5/8 P.H. Screws

See Note #1.

Drill four (4) holes 7/64” (.109) dia.

3.81”

2.00” .45” typ. (ref.)

GRILLE MOUNTING - STYLE II SPRING

10

Instructions for Installing Grille Mounting (STYPE III) Spring

Remove screw A in mounting bracket. Mount L-bracket with screw A.1.

Hook one end of spring (81050-000) through hole in L-bracket. Holding the facia in position -2.

stretch the spring and secure the hook end to the facia through a square top hole in the facia.

GRILLE MOUNTING - STYLE II

SCREW 24”, 30” & 36” wide units will use

one (1) spring (81050-000) and

one (1) L-bracket (30483-000) to

secure the facia.

L-Bracket

(30483-000)

Anti-Tip

Bracket

Screw A

42” & 48” wide units

will use two (2) springs

(81050-000) and two (2)

L-brackets (30483-000) to

secure the facia.

Kappet Screw

(into enclosure)

Screw Cap

Module

Fasten top of grille to enclosure

with screw provided. Cover

screw head with snap-on cap.

Spring

(81050-000)

Grille Back

Facia Bracket

Facia

HINGE AND GASKET ADJUSTMENTS AND FACE MOUNTED DOOR HANDLES

11

Hinge and Gasket Adjustment

It is possible that doors may become out of adjustment

in shipment. See diagram on right.

If product is installed slightly “out of level”, doors may

not line up properly. Check this BEFORE adjusting

hinges.

NOTE: Door gaskets occasionally compress in ship-

ment. If gasket does not seal all around, warm slightly

with a hair dryer and pull outward softly until magnet

in gasket seals against cabinet.

Change or Tighten Face Mounted Door Handles

Open the door - remove the interior door shelves.1.

Remove the screws that secure the shelf mounting2.

rail and the rail.

Remove the plug buttons (exposing handle screws)3.

- make sure not to scratch the inner liner.

Remove the foam insert to expose the door handle4.

mounting screw.

Change handle/tighten screw and replace foam5.

insert, plug button, shelf rail and door shelf.

Stainless Steel Wrap Door Units

To expose concealed door hinge screws, remove plug

buttons if present. All hinge sections attached to doors

adjust left or right. Top and bottom cabinet hinges

are also adjustable in and out. See diagram (shown

without cabinet trim).

Panel Ready Doors

To expose the concealed door screws, first remove handle trim. Then slide trim over hinge toward handle side. If

your unit requires door panels, see “Custom Door Panel” section, on page 14.

All hinge sections attached to doors, adjust left or right. Top and bottom cabinet hinges are also adjustable in and

out.

Adjustable Screws

Edge of Door Trim

Door

Cabinet

Cabinet

Adjustable

Screws

Door

Foam

Shelf Mounting

Rail and Screw

Door Shelf

Plug Button

Handle Mounting

Screw

Foam Insert

Door Handle

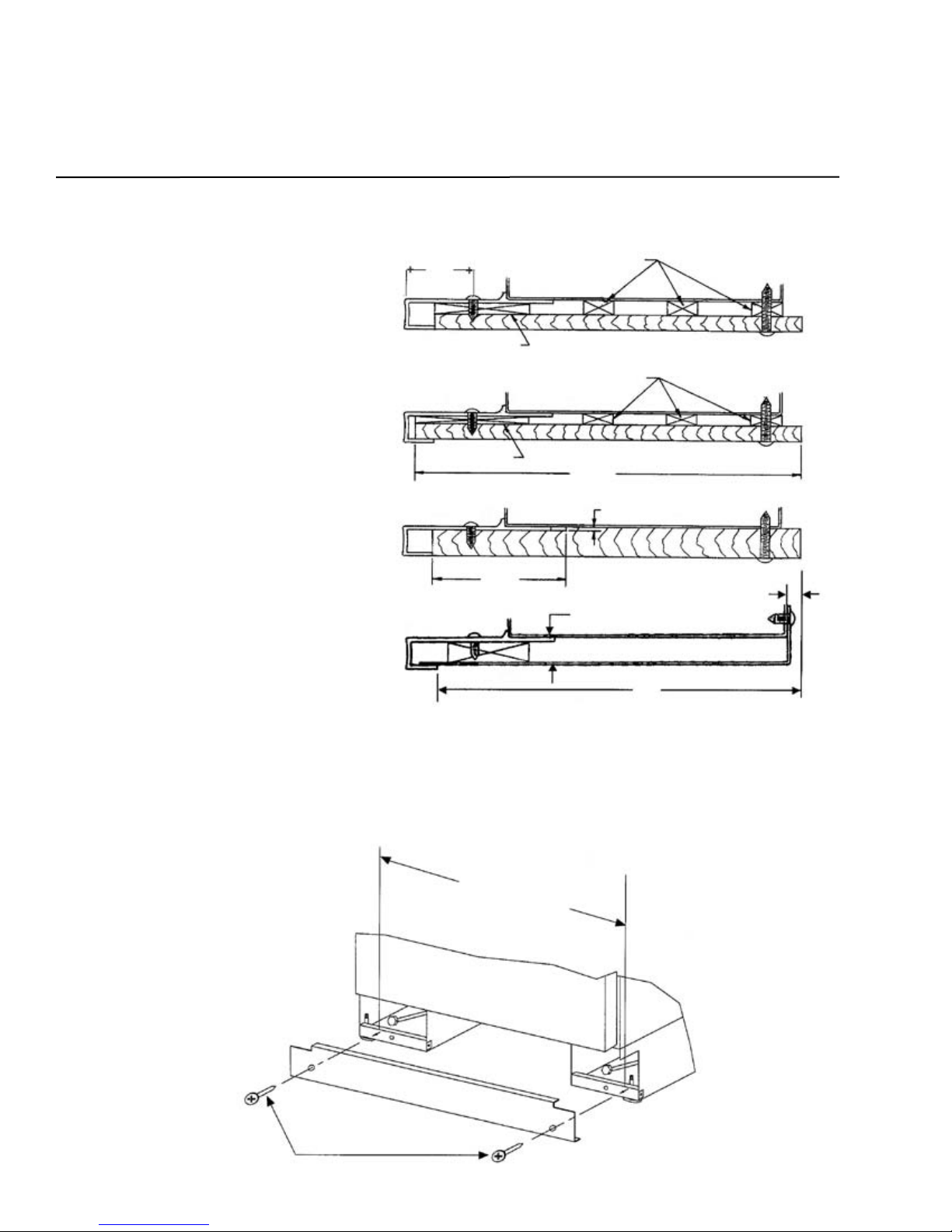

INSTALLING THE SIDE PANELS AND KICK PLATE

12

Instructions for Fastening Side Panels to

Refrigerator

Side panels should be 24 inches D (or 241.

5/16 inches D when tucked into the front

trim).

Panel height to match installation height.2.

Install the side panels per drawings on the3.

right.

NOTE: To avoid damage to panels or floor-

ing, raise panels slightly, to clear floor when

installing.

Drill three (3) holes equal distance apart in

vertical section of aluminum frame and install

pan head screws as shown.

Anchor side panel with screw as shown. Be

sure screw used goes no more than 1/2 inch

deep into product. Do NOT overtighten.

Kick Plate Installation

Use two (2) #8 sheet metal screws to facilitate holding your kick plate in place. Mount screws in holes in roller

base. Notching of upper corners may be required to clear hinges.

Typical Side Panel Installations

Measure the distance between

mounting holes on roller base.

#8 Sheet

Metal Screw

Drill three (3) holes equal distance apart in vertical section of aluminum frame and install # 6 - 3/8 pan head

screws as shown (provided).

Attach side panel to cabinet with screws as shown. Screws must not penetrate cabinet more than 1/2 inch.

24”

“D”

“A”

“B”

“C”

Typ.

1 1/8”

1/4” Thick Battens

3/16” Thick Back Up 1/4” Plywood/Panel

3/16” Thick Battens

1/4” Plywood/Panel

1/8” Thick Back Up

24 5/16”

1/16” Rout

1/2” Plywood/Panel

2 3/16”

11/32”

5/16”

Metal Side Panel

(Typ. Installation Opening)

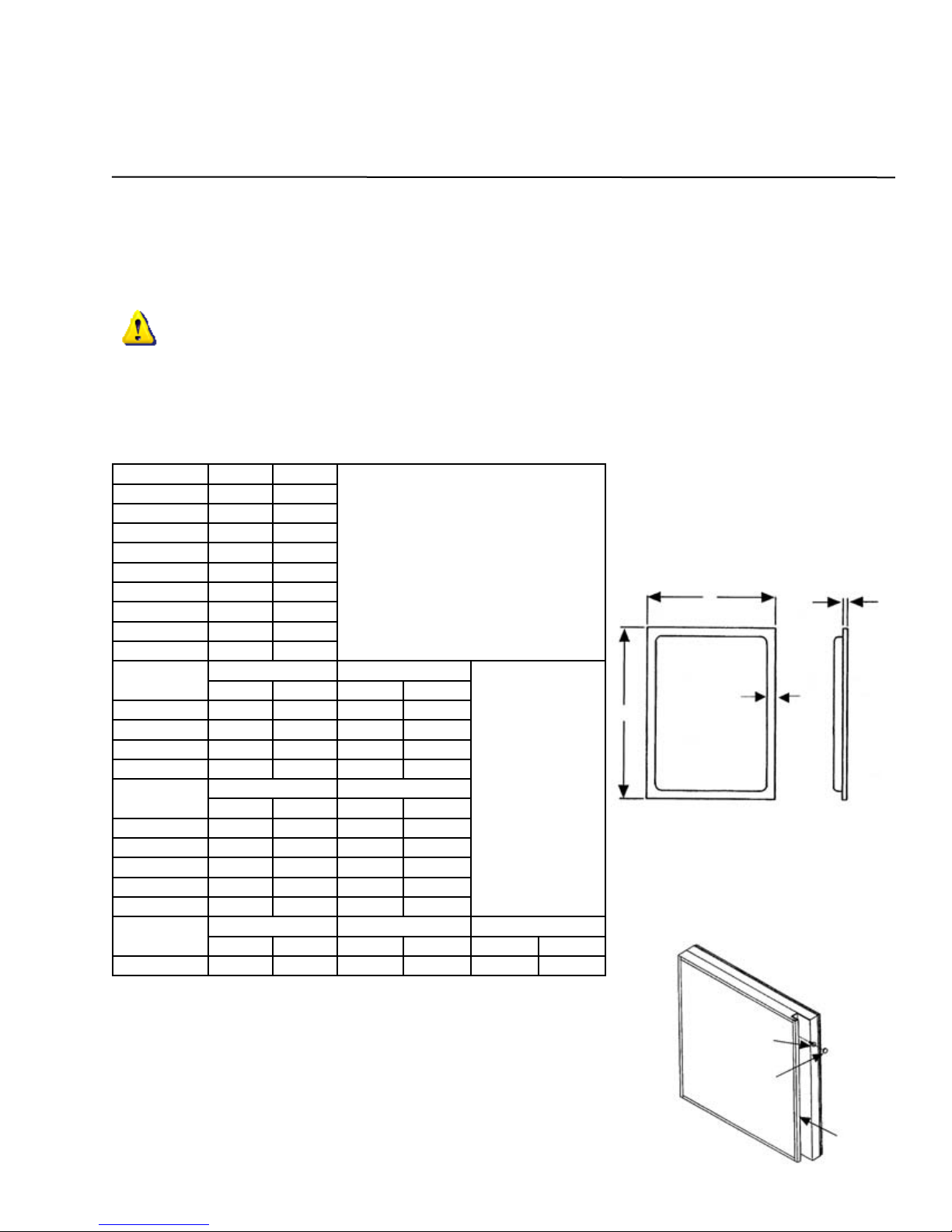

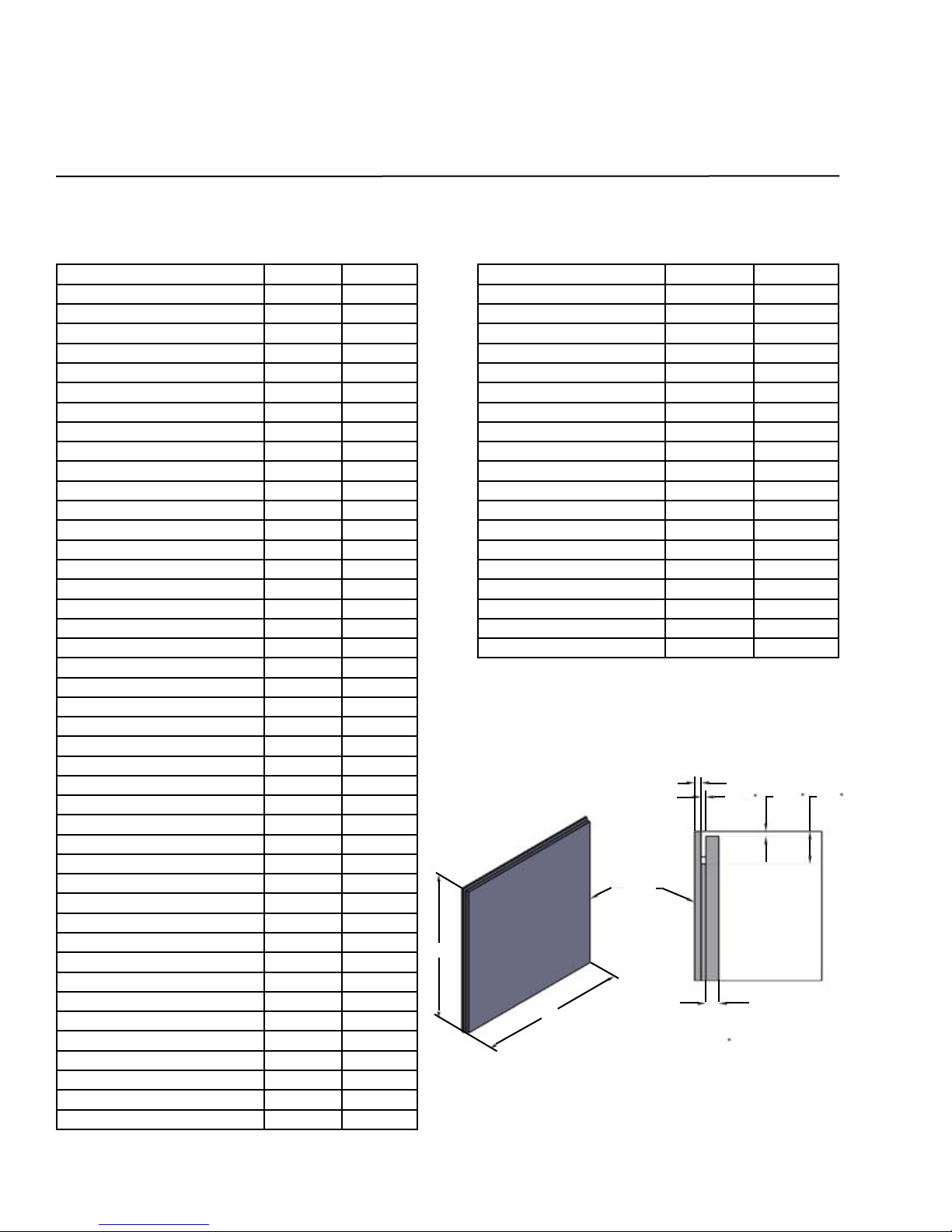

CUSTOM DOOR PANELS AND SPECIFICATIONS

The NORTHLAND Panel Ready Built-In design allows you to insert decorative material on the doors of your refrig-

erator/freezer. If a panel thinner than 1/4 inch is being used, we recommend a filler be inserted behind it for a

proper fit, as frames are designed to accept up to a 1/4 inch of material. If a raised panel is used, route edges to

fit the frame.

CAUTION

Door panels MUST NOT exceed 50 lbs. Do NOT use glass, mirrors, granite or similar heavy materials for panels.

Panels weighing more than 50 lbs. may cause product damage. We recommend that the door load (panel and

food) NOT exceed 90 lbs.

13

Model AR H W

18AR Custom Panel 68” 15 1/2”

24AR Custom Panel 68” 21 1/2”

30AR Custom Panel 68” 27 1/2”

36AR Custom Panel 68” 33 1/2”

Model AF H W

18AF Custom Panel 68” 15 1/2”

24AF Custom Panel 68” 21 1/2”

30AF Custom Panel 68” 27 1/2”

36AF Custom Panel 68” 33 1/2”

Model TF

Freezer Door Refrigerator Door

H W H W

18TF Custom Panel 22 1/4” 15 1/2” 45 1/8” 15 1/2”

24TF Custom Panel 22 1/4” 21 1/2” 45 1/8” 21 1/2”

30TF Custom Panel 22 1/4” 27 1/2” 45 1/8” 27 1/2”

36TF Custom Panel 22 1/4” 33 1/2” 45 1/8” 33 1/2”

Model SS

Freezer Door Refrigerator Door

H W H W

36SS Custom Panel 68” 15 1/2” 68” 17”

42SS Custom Panel 68” 17” 68” 21 1/2”

48SS Custom Panel 68” 17” 68” 27 1/2”

60SS Custom Panel 68” 21 1/2” 68” 33 1/2”

72SS Custom Panel 68” 33 1/2” 68” 33 1/2”

Model 3D

Freezer Door Refrigerator Door Refrigerator Door 2

H W H W H W

363D Custom Panel 22 1/4” 15 1/2” 68” 17” 45 1/8” 15 1/2”

For models:

All Refrigerator (AR), All Freezer (AF), Top Freezer (TF), Side-by-Side (SS), and Side-by-Side 3 Door (3D)

W

H

3/8”

Min.

1/4”

Max.

Removing Protective Film from Factory Installed Decorative Panels

Cabinets are shipped with protective film over the exterior surface of•

decorative panels (optional).

Do NOT remove protective film until the cabinet has been completely•

installed to prevent scratching or marring the decorative panels.

To remove the protective film, firmly grasp the loose edge of the film•

and slowly pull the film downward off the decorative panels.

Decorative panels may be removed if necessary by removing the•

handle screws and handle and then sliding the decorative panel out

of the frame.

Screw

Screw

Cap

Handle

CUSTOM GRILLE PANELS AND SPECIFICATIONS

For models:

All Refrigerator (AR), All Freezer (AF), Top Freezer (TF), Side-by-Side (SS), and Side-by-Side 3 Door (3D)

Model AR H W

18AR Grille Panel 8 9/16” 14 13/16”

24AR Grille Panel 8 9/16” 20 13/16”

30AR Grille Panel 8 9/16” 26 13/16”

36AR Grille Panel 8 9/16” 32 13/16”

Model AF H W

18AF Grille Panel 8 9/16” 14 13/16”

24AF Grille Panel 8 9/16” 20 13/16”

30AF Grille Panel 8 9/16” 26 13/16”

36AF Grille Panel 8 9/16” 32 13/16”

Model TF H W

18TF Grille Panel 8 9/16” 14 13/16”

24TF Grille Panel 8 9/16” 20 13/16”

30TF Grille Panel 8 9/16” 26 13/16”

36TF Grille Panel 8 9/16” 32 13/16”

Model SS H W

36SS Grille Panel 8 9/16” 32 13/16”

42SS Grille Panel 8 9/16” 38 13/16”

48SS Grille Panel 8 9/16” 44 13/16”

54SS Grille Panel 8 9/16” 50 13/16”

60SS Grille Panel 8 9/16” 56 13/16”

66SS Grille Panel 8 9/16” 62 13/16”

72SS Grille Panel 8 9/16” 68 13/16”

Model 3D H W

363D Grille Panel 8 9/16” 32 13/16”

14

Custom Grille Panels

CAUTION

Grille panels MUST NOT exceed 20 lbs. Panels

weighing more than 20 lbs. may cause product dam-

age.

For grille installation refer to page 11, Grille Assembly

Installation, and see separate Instruction Sheet, No.

31395-000.

Remove screws and handle.•

Slide custom panel into position in door trim•

opening.

Do ALL doors.•

Do NOT replace handle until hinge and gasket•

adjustments have been made. See page 12.

Replace handle and screws and install plastic•

screw caps provided.

NOTE: All center hinged doors CANNOT exceed 1/2

inch in panel thickness from the door trim face.

Note: 1/2” Min. (Relief)

1/4” Max.

3/8”

Min.

W

H

TRIMLESS OVERLAY DOOR PANELS AND SPECIFICATIONS

For models:

All Refrigerator (AR), All Freezer (AF), Top Freezer (TF), Side-by-Side (SS), and Side-by-Side 3 Door (3D)

Model 18AR & 18AF H W

Refrigerator or Freezer Overlay Panel 68 1/4” 15 3/4”

Refrigerator or Freezer Spacer Panel 66 3/4” 14 1/4”

Refrigerator or Freezer Backer Panel 68” 15 1/2”

Model 24AR & 24AF H W

Refrigerator or Freezer Overlay Panel 68 1/4” 21 3/4”

Refrigerator or Freezer Spacer Panel 66 3/4” 20 1/4”

Refrigerator or Freezer Backer Panel 68” 21 1/2”

Model 30AR & 30AF H W

Refrigerator or Freezer Overlay Panel 68 1/4” 27 3/4”

Refrigerator or Freezer Spacer Panel 66 3/4” 26 1/4”

Refrigerator or Freezer Backer Panel 68” 27 1/2”

Model 36AR & 36AF H W

Refrigerator or Freezer Overlay Panel 68 1/4” 33 3/4”

Refrigerator or Freezer Spacer Panel 66 3/4” 32 1/4”

Refrigerator or Freezer Backer Panel 68” 33 1/2”

Model 18TF H W

Refrigerator Overlay Panel 45 3/8” 15 3/4”

Refrigerator Spacer Panel 43 7/8” 14 1/4”

Refrigerator Backer Panel 45 1/8” 15 1/2”

H W

Freezer Overlay Panel 22 1/2” 15 3/4”

Freezer Spacer Panel 21” 14 1/4”

Freezer Backer Panel 22 1/4” 15 1/2”

Model 24TF H W

Refrigerator Overlay Panel 45 3/8” 21 3/4”

Refrigerator Spacer Panel 43 7/8” 20 1/4”

Refrigerator Backer Panel 45 1/8” 21 1/2”

H W

Freezer Overlay Panel 22 1/2” 21 3/4”

Freezer Spacer Panel 21” 20 1/4”

Freezer Backer Panel 22 1/4” 21 1/2”

Model 30TF H W

Refrigerator Overlay Panel 45 3/8” 27 3/4”

Refrigerator Spacer Panel 43 7/8” 26 1/4”

Refrigerator Backer Panel 45 1/8” 27 1/2”

H W

Freezer Overlay Panel 22 1/2” 27 3/4”

Freezer Spacer Panel 21” 26 1/4”

Freezer Backer Panel 22 1/4” 27 1/2”

Model 36TF H W

Refrigerator Overlay Panel 45 3/8” 33 3/4”

Refrigerator Spacer Panel 43 7/8” 32 1/4”

Refrigerator Backer Panel 45 1/8” 33 1/2”

H W

Freezer Overlay Panel 22 1/2” 33 3/4”

Freezer Spacer Panel 21” 32 1/4”

Freezer Backer Panel 22 1/4” 33 1/2”

Model 36SS H W

Refrigerator Overlay Panel 68 1/4” 17 1/4”

Refrigerator Spacer Panel 66 3/4” 15 3/4”

Refrigerator Backer Panel 68” 17”

H W

Freezer Overlay Panel 68 1/4” 15 3/4”

Freezer Spacer Panel 66 3/4” 14 1/4”

Freezer Backer Panel 68” 15 1/2”

Model 42SS H W

Refrigerator Overlay Panel 68 1/4” 21 3/4”

Refrigerator Spacer Panel 66 3/4” 20 1/4”

Refrigerator Backer Panel 68” 21 1/2”

H W

Freezer Overlay Panel 68 1/4” 17 1/4”

Freezer Spacer Panel 66 3/4” 15 3/4”

Freezer Backer Panel 68” 17”

Model 48SS H W

Refrigerator Overlay Panel 68 1/4” 27 3/4”

Refrigerator Spacer Panel 66 3/4” 26 1/4”

Refrigerator Backer Panel 68” 27 1/2”

H W

Freezer Overlay Panel 68 1/4” 17 1/4”

Freezer Spacer Panel 66 3/4” 15 3/4”

Freezer Backer Panel 68” 17”

Model 60SS H W

Refrigerator Overlay Panel 68 1/4” 33 3/4”

Refrigerator Spacer Panel 66 3/4” 32 1/4”

Refrigerator Backer Panel 68” 33 1/2”

H W

Freezer Overlay Panel 68 1/4” 21 3/4”

Freezer Spacer Panel 66 3/4” 20 1/4”

Freezer Backer Panel 68” 21 1/2”

Model 72SS H W

Refrigerator Overlay Panel 68 1/4” 33 3/4”

Refrigerator Spacer Panel 66 3/4” 32 1/4”

Refrigerator Backer Panel 68” 33 1/2”

H W

Freezer Overlay Panel 68 1/4” 33 3/4”

Freezer Spacer Panel 66 3/4” 32 1/4”

Freezer Backer Panel 68” 33 1/2”

Model 363D H W

Refrigerator 1 Overlay Panel 68 1/4” 17 1/4”

Refrigerator 1 Spacer Panel 66 3/4” 15 3/4”

Refrigerator 1 Backer Panel 68” 17”

H W

Refrigerator 2 Overlay Panel 45 3/8” 15 3/4”

Refrigerator 2 Spacer Panel 43 7/8” 14 1/4”

Refrigerator 2 Backer Panel 45 1/8” 15 1/2”

H W

Freezer Overlay Panel 22 1/2” 15 3/4”

Freezer Spacer Panel 21” 14 1/4”

Freezer Backer Panel 22 1/4” 15 1/2”

15

Typical Door Assembly with “Trimless” Panel

Slot - panel fits in.

3/32” 3/32” 5/8”

Custom

Door

Panel

Front

Door

1/8”

Min.

1/4”

Max.

Typical

All

Around

Panel

TRIMLESS OVERLAY GRILLE PANELS AND SPECIFICATIONS

Model 18AR & 18AF H W

Refrigerator or Freezer Grille Overlay Panel 8 7/8” 15 1/8”

Refrigerator or Freezer Grille Spacer Panel 7 5/16” 13 9/16”

Refrigerator or Freezer Grille Backer Panel 8 9/16” 14 13/16”

Model 24AR & 24AF H W

Refrigerator or Freezer Grille Overlay Panel 8 7/8” 21 1/8”

Refrigerator or Freezer Grille Spacer Panel 7 5/16” 19 9/16”

Refrigerator or Freezer Grille Backer Panel 8 9/16” 20 13/16”

Model 30AR & 30AF H W

Refrigerator or Freezer Grille Overlay Panel 8 7/8” 27 1/8”

Refrigerator or Freezer Grille Spacer Panel 7 5/16” 25 9/16”

Refrigerator or Freezer Grille Backer Panel 8 9/16” 26 13/16”

Model 36AR & 36AF H W

Refrigerator or Freezer Grille Overlay Panel 8 7/8” 33 1/8”

Refrigerator or Freezer Grille Spacer Panel 7 5/16” 31 9/16”

Refrigerator or Freezer Grille Backer Panel 8 9/16” 32 13/16”

Model 18TF H W

Top Freezer Grille Overlay Panel 8 7/8” 15 1/8”

Top Freezer Grille Spacer Panel 7 5/16” 13 9/16”

Top Freezer Grille Backer Panel 8 9/16” 14 13/16”

Model 24TF H W

Top Freezer Grille Overlay Panel 8 7/8” 21 1/8”

Top Freezer Grille Spacer Panel 7 5/16” 19 9/16”

Top Freezer Grille Backer Panel 8 9/16” 20 13/16”

Model 30TF H W

Top Freezer Grille Overlay Panel 8 7/8” 27 1/8”

Top Freezer Grille Spacer Panel 7 5/16” 25 9/16”

Top Freezer Grille Backer Panel 8 9/16” 26 13/16”

Model 36TF H W

Top Freezer Grille Overlay Panel 8 7/8” 33 1/8”

Top Freezer Grille Spacer Panel 7 5/16” 31 9/16”

Top Freezer Grille Backer Panel 8 9/16” 32 13/16”

Model 36SS H W

Side-by-Side Grille Overlay Panel 8 7/8” 33 1/8”

Side-by-Side Grille Overlay Panel 7 5/16” 31 9/16”

Side-by-Side Grille Overlay Panel 8 9/16” 32 13/16”

Model 363D H W

Three Door Grille Overlay Panel 8 7/8” 33 1/8”

Three Door Grille Spacer Panel 7 5/16” 31 9/16”

Three Door Grille Backer Panel 8 9/16” 32 13/16”

Model 42SS H W

Side-by-Side Grille Overlay Panel 8 7/8” 39 1/8”

Side-by-Side Grille Overlay Panel 7 5/16” 37 9/16”

Side-by-Side Grille Overlay Panel 8 9/16” 38 13/16”

For models:

All Refrigerator (AR), All Freezer (AF), Top Freezer (TF), Side-by-Side (SS), and Side-by-Side 3 Door (3D)

16

Model 48SS H W

Side-by-Side Grille Overlay Panel 8 7/8” 45 1/8”

Side-by-Side Grille Overlay Panel 7 5/16” 43 9/16”

Side-by-Side Grille Overlay Panel 8 9/16” 44 13/16”

Model 54SS H W

Side-by-Side Grille Overlay Panel 8 7/8” 51 1/8”

Side-by-Side Grille Overlay Panel 7 5/16” 49 9/16”

Side-by-Side Grille Overlay Panel 8 9/16” 50 13/16”

Model 60SS H W

Side-by-Side Grille Overlay Panel 8 7/8” 57 1/8”

Side-by-Side Grille Overlay Panel 7 5/16” 55 9/16”

Side-by-Side Grille Overlay Panel 8 9/16” 56 13/16”

Model 66SS H W

Side-by-Side Grille Overlay Panel 8 7/8” 63 1/8”

Side-by-Side Grille Overlay Panel 7 5/16” 61 9/16”

Side-by-Side Grille Overlay Panel 8 9/16” 62 13/16”

Model 72SS H W

Side-by-Side Grille Overlay Panel 8 7/8” 69 1/8”

Side-by-Side Grille Overlay Panel 7 5/16” 67 9/16”

Side-by-Side Grille Overlay Panel 8 9/16” 68 13/16”

Typical Grille Assembly with “Trimless” Panel

1/8”

Min.

3/32” 3/32” 5/8”

1/4”

Max.

H

W

Typical All

Around Panel

Custom

Grille

Panel

Front Grille Frame

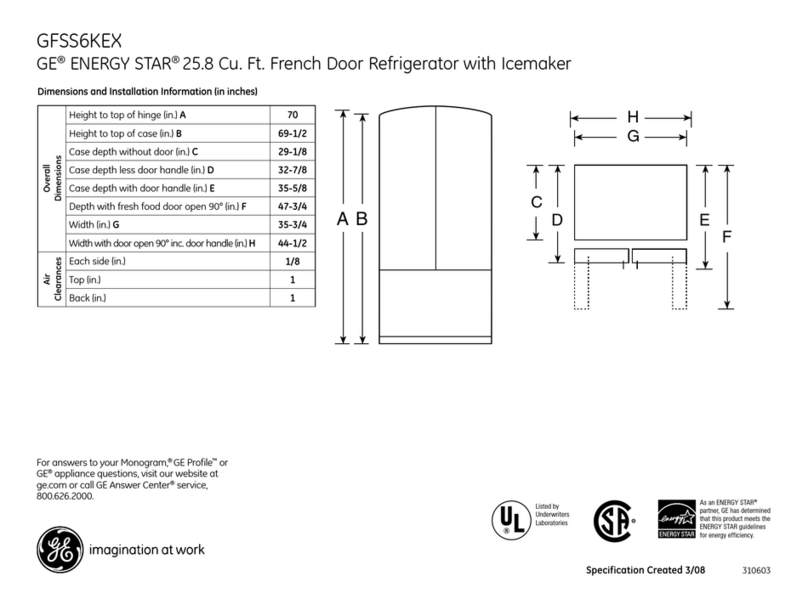

GLASS PANEL READY WOOD FRAME DOOR SPECIFICATIONS

17

Model AR H W Frame with

Min.

18AR - WGP 68 1/8” 16 1/4” 2 1/2”

18AR - SGP 68 1/8” 16 1/4” 2 1/2”

24AR - WGP 68 1/8” 22 1/4” 2 1/2”

24AR - SGP 68 1/8” 22 1/4” 2 1/2”

30AR - WGP 68 1/8” 28 1/4” 2 1/2”

30AR - SGP 68 1/8” 28 1/4” 2 1/2”

36AR - WGP 68 1/8” 34 1/4” 2 1/2”

36AR - WGP 68 1/8” 34 1/4” 2 1/2”

Model WC H W Frame with

Min.

18WC - SGP 68 1/8” 16 1/4” 2 1/2”

24WC - SGP 68 1/8” 22 1/4” 2 1/2”

Model 2Z H W Frame with

Min.

242Z - SGP 68 1/8” 22 1/4” 2 1/2”

Model BC H W Frame with

Min.

24BC - SGP 68 1/8” 22 1/4” 2 1/2”

Model SS H W Frame with

Min.

60SS - WGP 68 1/8” 34 1/4” 2 1/2”

60SS - SGP 68 1/8” 34 1/4” 2 1/2”

72SS - WGP 68 1/8” 34 1/4” 2 1/2”

72SS - SGP 68 1/8” 34 1/4” 2 1/2”

H

W

2.50” Typ.

All Around .50”

.33” Typ.

(2) Plcs.

1.38” Typ.

(2) Plcs.

INSTALLING A DOOR FRAME TO THE GLASS DOOR

18

The door frame can be mounted to the glass door with the glass door on or off the unit. The door handle needs to

be mounted to the door frame before the frame is mounted to the glass door.

Glass Door On the Unit

Lay the unit on its back.1.

Open the glass door 180 degrees and support the glass door during installation.2.

Pull the door gasket back along the top and bottom of the glass door to expose the mounting holes for the3.

door frame. There are twelve (12) total mounting holes on the door - four (4) on each side and two (2) on the

top and bottom of the door. Screws will be mounted around the outside diameter of the door on the gasket

side.

Line up the door frame that is to be mounted to the unit and mark the hole locations on the door frame. Drill4.

1/8” pilot holes, 1/4” deep to aid during mounting of the door frame.

Recommended screws to use to mount the door frame are 1 1/4” long wood screws.5.

After installing the mounting screws, press the door gasket back into the gasket retainer. Make sure the gasket6.

is seated into the corners to retain proper door gasket seal.

Glass Door Off the Unit

Remove the four (4) hinge bolts from the door- two (2) at the top and two (2) at the bottom of the door. Retain1.

the two (2) hinge spacers. One (1) at the top and one (1) at the bottom of the door.

Lay the glass door on a surface that will protect the door frame during assembly of the frame to the glass door.2.

Complete Steps 3 through 6 as listed in the above section “Glass Door On the Unit”.3.

Mount the door to the unit using the hinge spacers and hinge bolts that were removed when taking the glass4.

door off the unit.

Door Frame

Door Gasket

(shown pulled up)

Screws to mount the door

frame to the glass door.

This manual suits for next models

142

Table of contents

Other Northland Refrigerator manuals

Popular Refrigerator manuals by other brands

GE

GE GFSS6KEXSS - r 25.8 cu. Ft. Refrigerator Dimensions and installation information

Hotpoint

Hotpoint RLAV21P Instructions for installation and use

Gram

Gram BAKER 610 Instructions for use

LIBHOF

LIBHOF B-35H user manual

MPM

MPM MPM-30-MBS-06/L user manual

Whirlpool

Whirlpool WRS325FDAB Installation instructions and owner's manual