Northrock PRO 1.5+ User manual

PRO 1.5+

PRO 3+

NORTHROCK INDUSTRIES

TEL:

1-800-989-8423

3688 HORSEBLOCK ROAD

1-631-924-6130

MEDFORD, NY 11763

FAX:

1-800-315-1277

1-631-924-6369

PRO 2+

CONCRETE VIBRATORS

INSTRUCTION MANUAL

SAFETY, ASSEMBLY, AND MAINTENANCE INSTRUCTIONS FOR MODELS:

WARNING

When using concrete vibrators as with any electric tool basic safety precautions should always be followed

to reduce the risk of fire, electric shock, and personal injury, including the following:

READ ALL INSTRUCTIONS

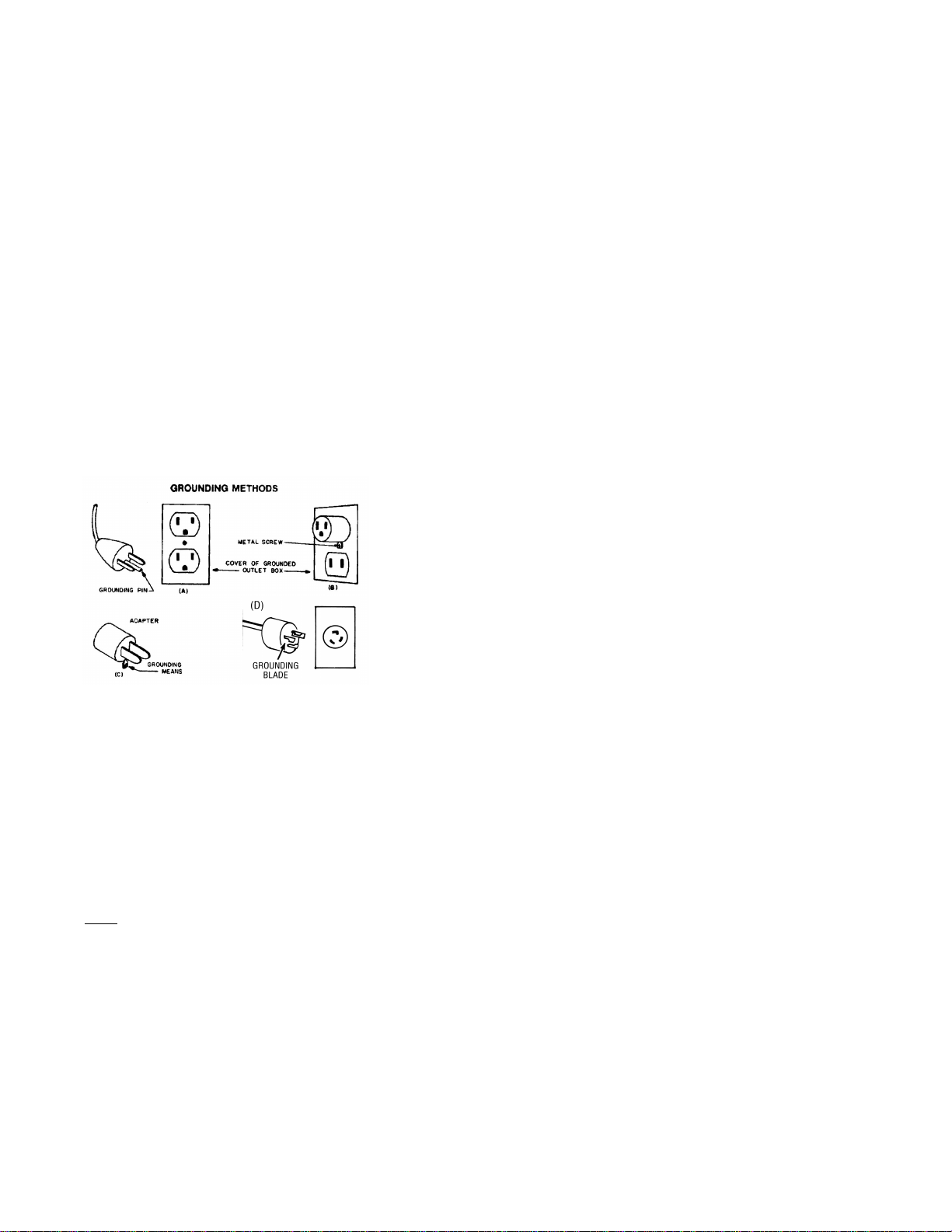

GROUNDING INSTRUCTIONS GENERAL SAFETY PROCEDURES

This tool should be grounded while in use to protect -Keep work area clean. Cluttered areas invite injury.

the operator from electric shock. The tool is equipped -Consider work area environment. Don't expose power tool to

with a three conductor cord and three prong grounding rain. Don't use POWER tools in a damp or wet location. Keep

type plug to fit the proper grounding type receptacle. area well lit. Do not use in presence of flammable liquids or gasses.

The green conductor in the cord is the grounding wire. -Guard against electric shock. Prevent body contact

Never connect the green wire to a live terminal. The plug with grounded surfaces like metal pipes.

supplied on model Pro 1.5+ and Pro 2+ look like that -Keep children away. Do not let visitors contact tool or extension

shown in sketch (A). An adapter is available for connecting cord. All visitors should be kept away from work area.

sketch (A) type plugs to two prong receptacles. See -Store tools when not in use in a dry, secure

sketch (B) and (C). The green colored rigid ear, lug area out of the reach of children.

or the like, extending from the adapter must be connected -Don't force tools, the job will be done better and safer by not

to a permanent ground such as a properly grounded exceeding the recommended max. vibrator head for the motor.

outlet box. No adapter is available to fit model Pro 3+ plug (D). -Use the right tool, don't force a small tool to do

a job meant for larger one.

-Do not use the tool for any purpose for which

it is not intended. For example do not use the vibrator

to drive posts in to the ground.

-Dress properly, do not wear loose clothing or jewelry. They

can get caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors.

Wear protective hair covering to contain long hair.

-Wear safety glasses to protect against splashing concrete,

and a dust mask if operation is dusty.

-Don't abuse electric cord, never carry the tool by the cord or

yank it to disconnect it from the receptacle. Keep the cord

EXTENSION CORDS from heat, oil, and sharp edges.

-Don't overreach, keep proper footing and balance at all times.

Use only three conductor cords that have three prong -Maintain tools by following instructions on cleaning

grounding type plugs and three pole receptacles that and lubricating. Inspect tool cords regularly, if damaged

accept the tools plug. Use only extension cords intended have repaired by authorized service facility. Inspect

for outdoor use, and so marked. For outdoor use extension extension cords and replace if damaged. Keep handles

cords shall be marked with the suffix W-A following the dry, clean, and free of oil and grease.

cord type designation, for example SOW-A indicates -Disconnect power cord when not in use, before servicing

it is acceptable for outdoor use. Use proper extension cords and when changing flexible shafts and heads.

rated to the tool as shown on the following chart. -Avoid unintentional starting. Don't carry tool with your finger on

the switch, be sure the switch is off before plugging tool in.

Extension cord AWG sizes for 120V motors: -Stay alert, be aware of what you are doing and others

AMPS 0-25' 26-50' 51-100' 101-150' around you. Do not operate the tool when you are tired.

12-16 14 12 not recommended -Check damaged parts before further use of the tool, a

16 - 20 12 10 not recommended guard or other part that is damaged should be carefully

checked to determine that it will operate properly and perform

Always use an extension cord heavy enough to carry the its intended function. Check for alignment of moving parts,

current the tool will draw, as undersized cords will cause a binding of moving parts, breakage of parts, mounting, and

drop in line voltage resulting in loss of power and overheating. any other conditions that may affect its operation. A guard

Inspect all extension cords making sure they are in good or other part that is damaged should be properly repaired

condition before using, repair or replace damaged extension or replaced by an authorized service center unless otherwise

cords. Extension cords are available from the factory, contact indicated elsewhere in this instruction manual. Have

your authorized service representative for details. defective switches replaced by authorized service center.

Do not use tool if switch does not turn it on and off.

SAVE THESE INSTRUCTIONS

Northrock flexible shaft vibrators are built to the highest standards

of both quality and function. When properly assembled and maintained you will

receive many hundred hours of service from these units. Please take a few

minutes to read the assembly, maintenance, and safety instructions before

attempting to operate the vibrator.

Assembly Instructions:

! Be sure unit is unplugged and switch is in off position before proceeding.

1- Insert inner flexible core to motor adapter and then screw outer casing

on to motor. Tighten securely using wrench flats on motor and a pipe

wrench on the metal part of the flexible casing.

2- Apply adhesive sealant to threads at the vibrator head end to prevent water

from entering and to lock the head on. Secure head to shaft using wrench flats

provided on the head and a pipe wrench on the metal part of the flexible casing.

Note: The unit is now ready for operation, but with a new flexible shaft it

will take a few minutes for the grease to run itself in. For this short period

it is normal for the flexible shaft to rattle, and the motor speed to be

somewhat slower. (3-5 minutes)

Maintenance Instructions:

Motor: - keep housing and air filter clean to allow for proper cooling

- check brushes, switch boot, and electric cord for wear and replace

when worn

- motor bearings require no additional lubrication, replace when worn

Shafts: - inspect inner cores for lubrication after approx. 50 hours of

operation as follows: remove core on to a clean surface free of dirt

and grit, inspect core for dry areas, if lubrication is required wipe

core with cloth, reinsert core into casing applying approx. 1/16"

thick coating of high quality lithium grease. (available in 1lb cans

from the factory) Do not over grease the flexible shaft as this will

cause excess drag on the motor, and the shaft to get hot.

Heads: - heads are sealed at the factory since it is extremely important to keep

contaminants out, therefore they require no field maintenance

This manual suits for next models

2

Popular Power Tools manuals by other brands

Meec

Meec 023-024 instruction manual

Emerson

Emerson Klauke EK 50/5CFM manual

Roland

Roland CAMM-3 PNC-3200 user manual

STEINEL PROFESSIONAL

STEINEL PROFESSIONAL HG 2120 E Translation of the original operating instructions

Bosch

Bosch GDS 18 V-HT PROFESSIONAL operating instructions

Berner

Berner BPT-RA 12 SD Instruction manual/safety instruction