Need help? Call +1 (360) 764-8850 or email offic

[email protected] v4.2 Jan 2021| Page 6

1.2 Overview of CWT tagging

Mark recapture experiments using the Coded Wire Tag (CWT) consist first of implanting tags in the

specimens, verifying implantation and releasing the specimens. The second stage involves recovering

and screening the specimens for tags and reading the tags. Tag implantation sites influence which

verification and recovery procedures are used. Please refer to our CWT Project Manual

(https://www.nmt.us/wp-content/uploads/2017/11/Coded-Wire-Tag-Project-Manual-Nov-2017.pdf) for

detailed information about using CWT.

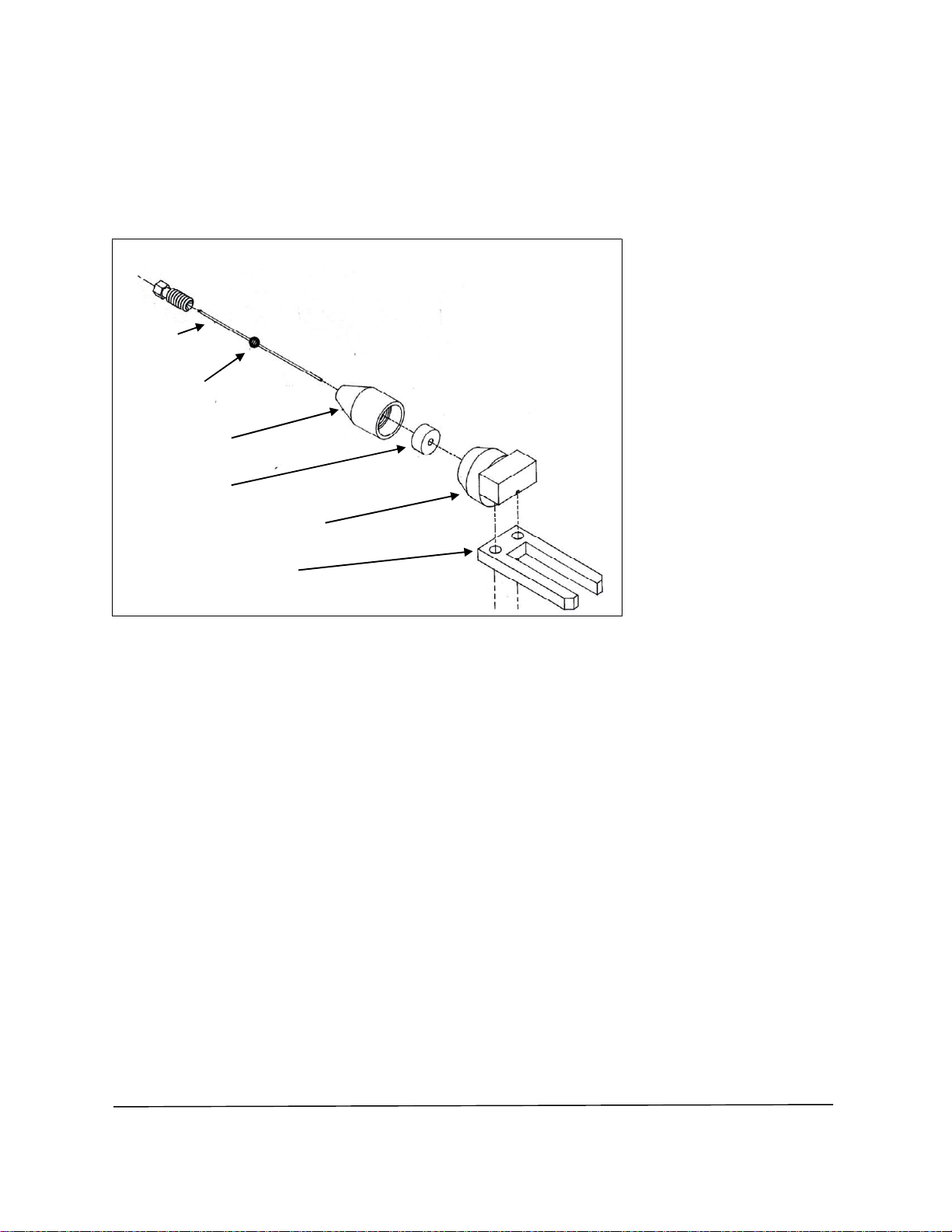

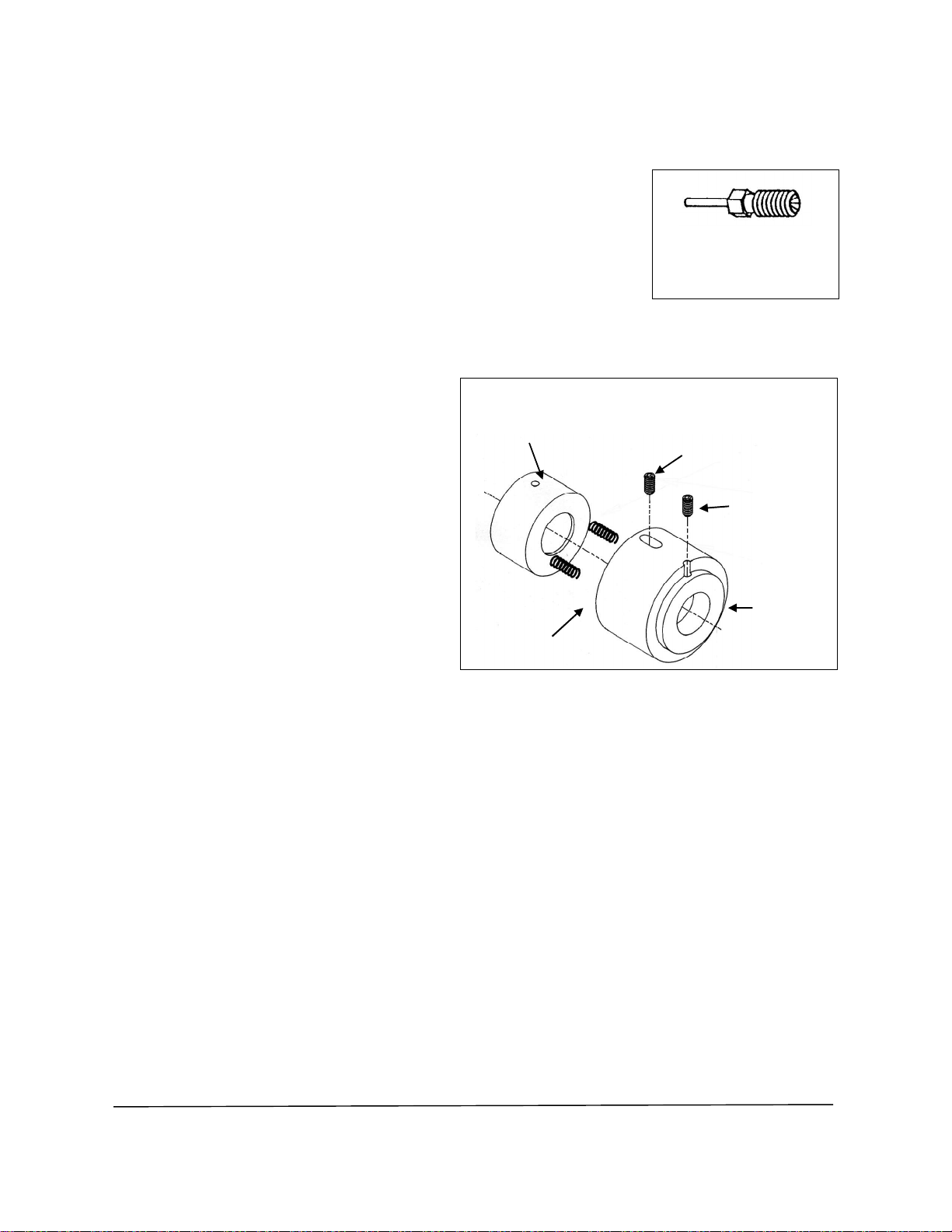

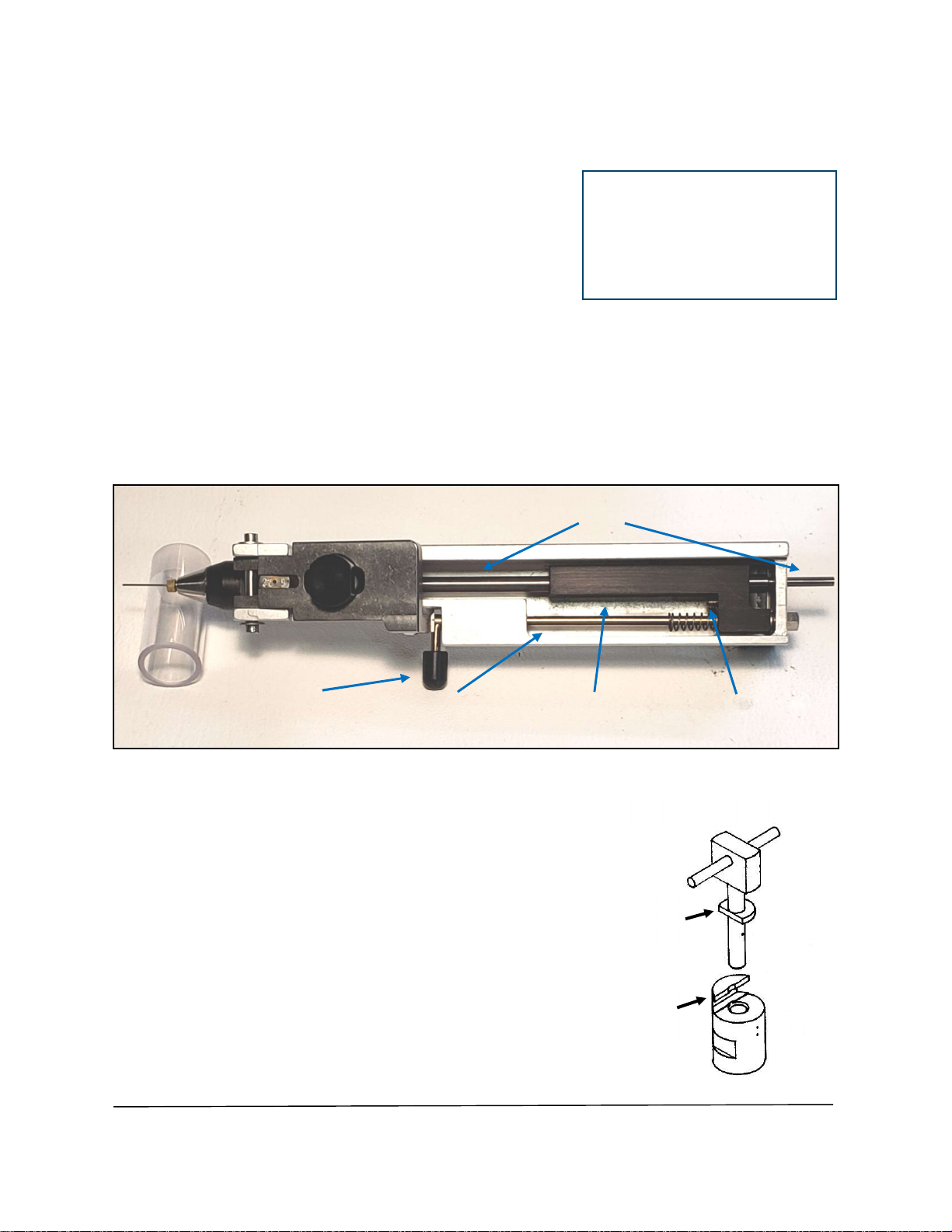

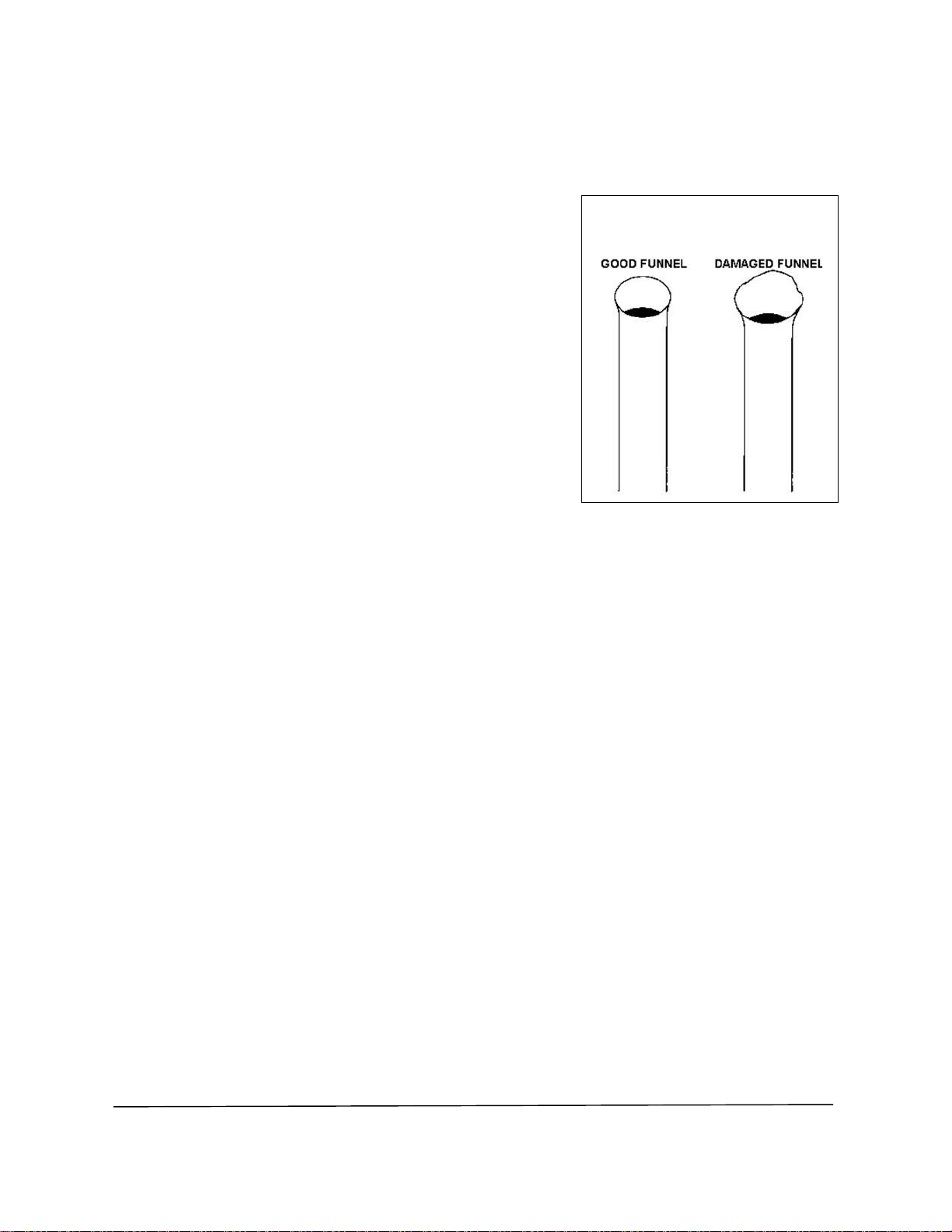

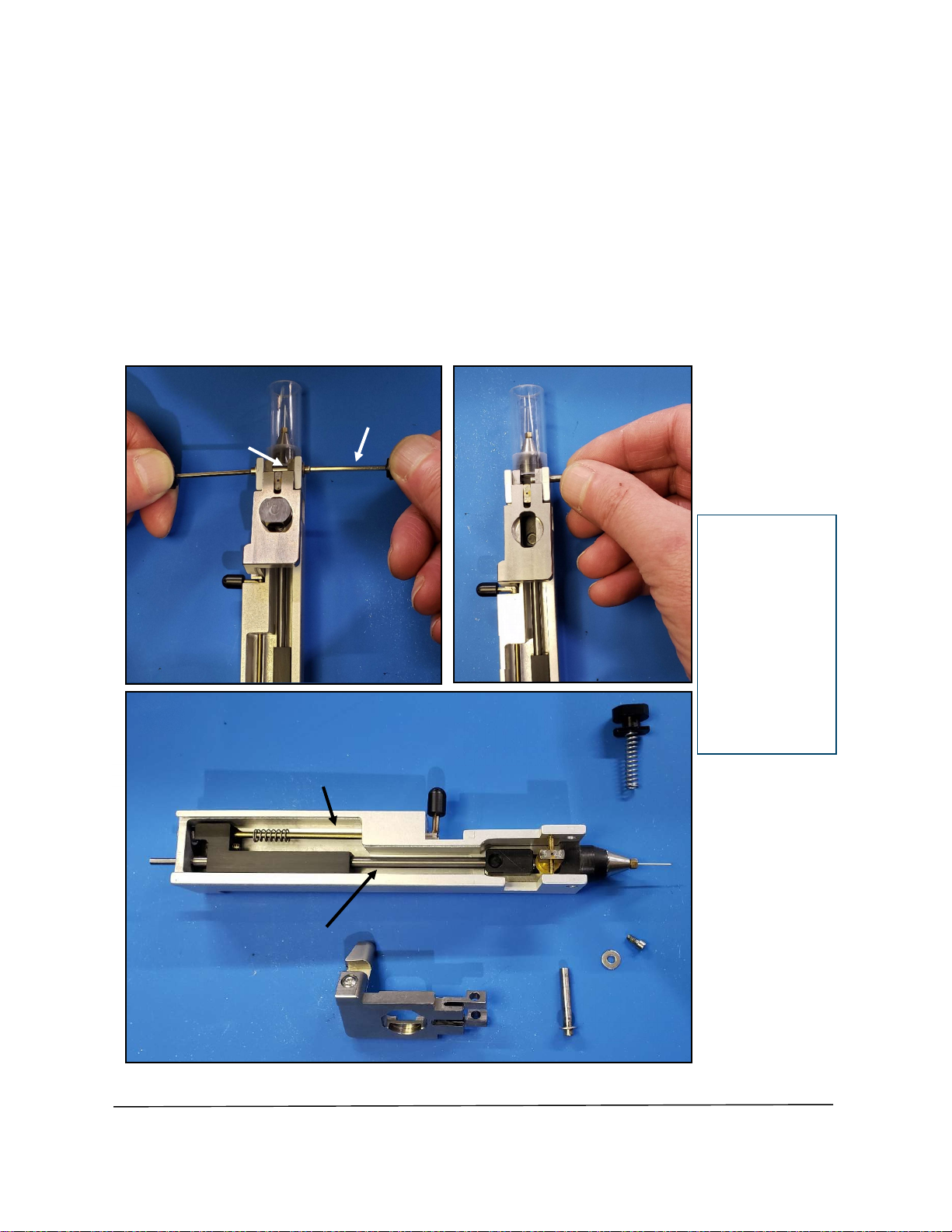

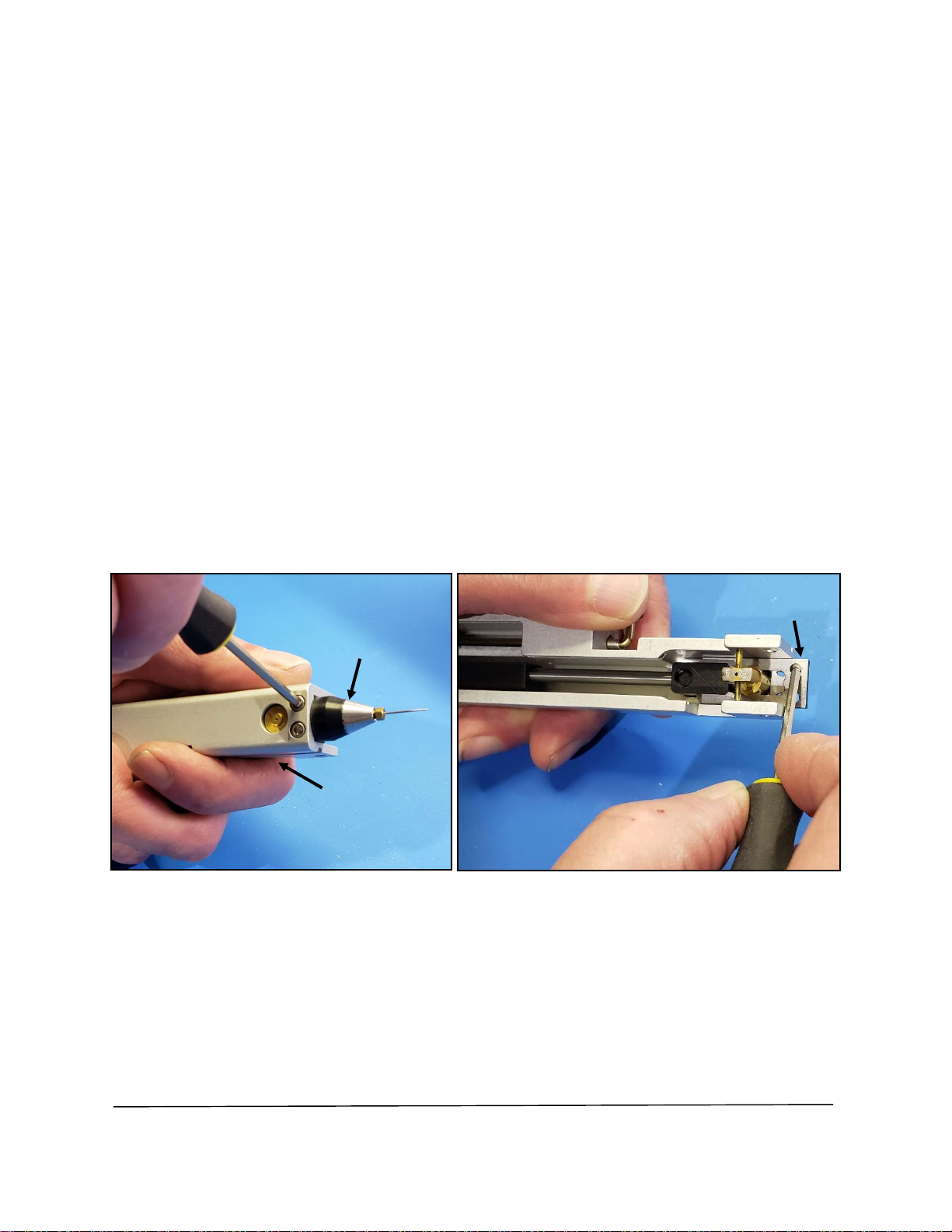

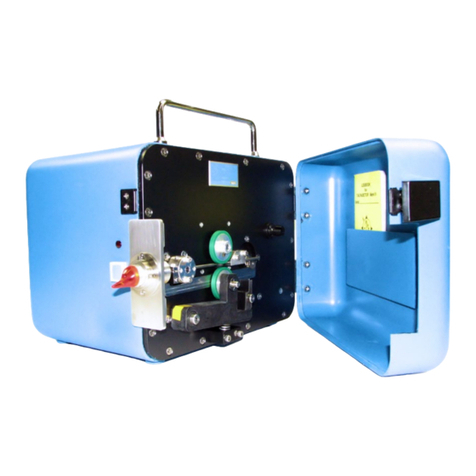

Coded Wire Tags are supplied as a spool of wire. The Multishot cuts a tag from the spool, magnetizes

the tag, and injects it into the specimen. The operator then verifies that the specimen contains a Coded

Wire Tag using one of the detectors made by NMT.

Upon recovery of the specimen, CWTs are located using one of the available detectors. CWTs are

removed from the specimen and then the tag code is read under magnification (25X or higher).

1.3 A few things to consider before tagging

Tag Type: Coded Wire Tags are available in several formats. These include different tag sizes and

coding options. The tag type you choose will depend upon specimen size, data requirements and

recovery methods.

Tag Implantation Site: The area or “target” where the tag will be implanted can vary for different

applications. While salmon and trout have traditionally been tagged in the snout, other species are

tagged in the cheek, adipose eyelid, jaw, scalp, nape, leg, etc. Choosing a suitable implantation site

is critical to tag retention, specimen health, and tag recovery.

Tag Insertion Technique: Some tagging is done with the aid of head molds to precisely position the

specimen during tagging. It is very important to use a head mold of the proper size and shape for

the particular specimen, otherwise tag retention may be poor. NMT offers a variety of head molds

for different species of fish ranging in size from 0.25 grams to 225 grams. If you are tagging a species

for which a head mold is not available, or if you wish to make your own molds, contact NMT about

the head mold fabrication kit and instructional video. Tagging can also be done without the use of

these fixtures if specimen size varies widely, the implantation site is large, or a suitable positioning

fixture is not practical. A needle support tube is available for this type of tagging.

Tag Recovery: How the tags will be recovered must be considered during program design. Specimen

size at the time of recovery, tag location, tag type, recovery site and detector technology can all

influence the method and success of tag recovery.