Northwest Marine Technology MKIV User manual

Northwest Marine Technology, Inc.

4003 Airport Road, Anacortes, WA 98221, USA

Phone: +1 (360) 764-8850 Email: office@nmt.us

www.nmt.us

MKIV Coded Wire Tag Injector

Instruction Manual

Page 3 Need help? Call +1 (360) 764-8850 or email of[email protected]

Table of Contents

1. Introduction ................................................................................................................... 7

2. Setup.............................................................................................................................. 9

2.1 Contents Checklist......................................................................................................................... 9

2.2 Assembly ....................................................................................................................................... 9

3. Quick Start ................................................................................................................... 11

4. Getting Ready to Tag .................................................................................................... 15

4.1 Needle Selection .........................................................................................................................15

4.2 Needle Positioning Jig Selection .................................................................................................16

4.3 Tag Length................................................................................................................................... 17

4.4 Common Menu Settings ............................................................................................................. 19

4.4.1 Using a head mold and 2.5 inch needle.................................................................................................19

4.4.2 Using a needle support tube and a 3.5 inch needle ..............................................................................19

4.4.3 Using a needle support tube and a 3.5 inch needle (alternate) ............................................................19

4.5 Needle Penetration..................................................................................................................... 19

4.6 Tag Placement Depth.................................................................................................................. 20

4.7 Final Check .................................................................................................................................. 21

5. Configuration ............................................................................................................... 23

5.1 Keyboard ..................................................................................................................................... 23

5.1.1 Key: [TOTAL] ..........................................................................................................................................24

5.1.2 Key: [BATCH] ..........................................................................................................................................24

5.1.3 Key: [CLeaR] ...........................................................................................................................................24

5.1.4 Key: [BATTery] .......................................................................................................................................25

5.1.5 Key: [LOAD]............................................................................................................................................25

5.1.6 Key: [SHOW] ..........................................................................................................................................26

5.1.7 Key: [*] ...................................................................................................................................................26

5.1.8 Key: [-10], [+10], [-1], [+1]......................................................................................................................27

5.1.9 Key: [TAG] ..............................................................................................................................................27

5.1.10 Key: [ESCape].....................................................................................................................................27

5.1.11 Key: [OK]............................................................................................................................................28

5.1.12 Key: [STEP].........................................................................................................................................28

5.1.13 Key: [ADJustment] .............................................................................................................................29

5.2 Adjustment Menu ....................................................................................................................... 30

Item: SETUP...................................................................................................................................................................... 30

Item: TAG LENgth ............................................................................................................................................................. 30

Item: WIRE........................................................................................................................................................................ 31

Item: QCD THRESHold ...................................................................................................................................................... 31

Item: STOP........................................................................................................................................................................ 31

Item: NEEDLE MOVe......................................................................................................................................................... 32

Item: MIN. TIME ............................................................................................................................................................... 33

Item: QCD BEEP................................................................................................................................................................ 33

Item: QCD DELAY.............................................................................................................................................................. 33

Item: CUT EDGE................................................................................................................................................................ 34

Item: TAG CREDIT............................................................................................................................................................. 35

Item: US-EURopean.......................................................................................................................................................... 35

6. Quality Control Device (QCD)........................................................................................ 37

Page 4 GEV v 4.0 Feb 2021

6.1 Overview .....................................................................................................................................37

6.2 General Assembly (Mechanical and Water Jet Versions) ........................................................... 39

6.3 Mechanical Diverter Gate Assembly...........................................................................................41

6.4 Separator (Water) Jet Adjustments ............................................................................................43

7. Maintenance ................................................................................................................ 47

7.1 Injector Disassembly ...................................................................................................................47

7.2 Injector Assembly........................................................................................................................ 50

7.2.1 Needle Carrier Installation.....................................................................................................................50

7.2.2 Needle Installation.................................................................................................................................52

7.3 Parts Inspection ..........................................................................................................................54

7.3.1 Needle Inspection and Maintenance.....................................................................................................54

7.3.2 Cutter.....................................................................................................................................................55

Cutter Inspection.............................................................................................................................................................. 57

7.3.3 Needle Carrier........................................................................................................................................58

7.3.4 Drive Rollers...........................................................................................................................................59

7.3.5 Touch Switch..........................................................................................................................................59

7.3.6 QCD Solenoid Valve (Water jet version QCD only) ................................................................................60

Removal and Installation.................................................................................................................................................. 60

7.3.7 Solenoid Valve Cleaning.........................................................................................................................60

7.3.8 QCD Filter Assembly (Both QCD versions) .............................................................................................62

Filter Cleaning................................................................................................................................................................... 62

7.4 Cleaning and Disinfection ........................................................................................................... 63

7.4.1 Equipment and Supplies ........................................................................................................................64

7.4.2 Injector...................................................................................................................................................64

7.4.3 Quality Control Device (QCD) ................................................................................................................65

8. System Messages.......................................................................................................... 67

BAD DRIVE XY......................................................................................................................................................67

BAD MEMORY .....................................................................................................................................................67

CHECK ALL ADJ ....................................................................................................................................................67

CHECK NEXT TAG.................................................................................................................................................67

CUTTER STUCK ....................................................................................................................................................67

INT ERROR...........................................................................................................................................................67

NEEDLE STUCK ....................................................................................................................................................67

NO QCD OK .........................................................................................................................................................67

NO WIRE OR STUCK ............................................................................................................................................67

POWER LOW .......................................................................................................................................................67

READY VX.X .........................................................................................................................................................68

*RELOAD WIRE....................................................................................................................................................68

WEAK MEMORY ..................................................................................................................................................68

9. Troubleshooting the MKIV Injector ............................................................................... 69

9.1 Injector displays “NO WIRE OR STUCK” ......................................................................................69

9.2 Injector displays “INT ERROR”....................................................................................................70

9.3 Injector displays “CHK NEXT TAG” ..............................................................................................70

9.4 Tag wire unthreads and backs out when leaving LOAD mode. .................................................. 70

9.5 Tag length varies. ........................................................................................................................ 71

9.6 Injector indicates “CUTTER STUCK” ............................................................................................71

9.7 A tag is not ejected from the needle. ......................................................................................... 72

9.8 Injector cycles continuously........................................................................................................72

Page 5 Need help? Call +1 (360) 764-8850 or email of[email protected]

9.9 Injector indicates “NEEDLE STUCK” ............................................................................................73

9.9.1 Needle stuck on the return stroke.........................................................................................................73

9.9.2 Needle stuck on the forward stroke ......................................................................................................73

9.10 The tag wire jams........................................................................................................................ 74

9.11 Injector indicates "POWER LOW" ............................................................................................... 77

9.12 Nothing happens when Injector is turned on. ............................................................................ 77

9.13 The display reads “* RELOAD WIRE”...........................................................................................78

10. Troubleshooting the QCD .......................................................................................... 79

10.1 The QCD is not detecting tags..................................................................................................... 79

10.2 The QCD detects a tag but tagged fish is not diverted. .............................................................. 79

10.3 The QCD is sorting fish to the opposite side from before. .........................................................79

10.4 The QCD diverter is working, but fish are not sorted properly. ................................................. 80

10.5 The QCD activates erratically, even with no tagged fish present............................................... 81

10.6 Water leaks from the QCD’s filter housing. ................................................................................ 82

10.7 QCD reject count is negative.......................................................................................................82

11. Appendix A: Tool Kit Components ............................................................................. 83

12. Appendix B: Main-Plate Parts List .............................................................................. 85

13. Appendix C: Adjustment Menu.................................................................................. 87

14. Appendix D: Setups ................................................................................................... 89

15. Appendix E: Size Conversion Table for Salmonids....................................................... 91

16. Appendix F: Spare Parts and Accessories ................................................................... 93

17. Equipment Specifications .......................................................................................... 95

17.1 MKIV Tag Injector........................................................................................................................ 95

17.2 Quality Control Device ................................................................................................................95

17.3 Power Supply .............................................................................................................................. 95

18. Index......................................................................................................................... 97

Page 7 Need help? Call +1 (360) 764-8850 or email of[email protected]

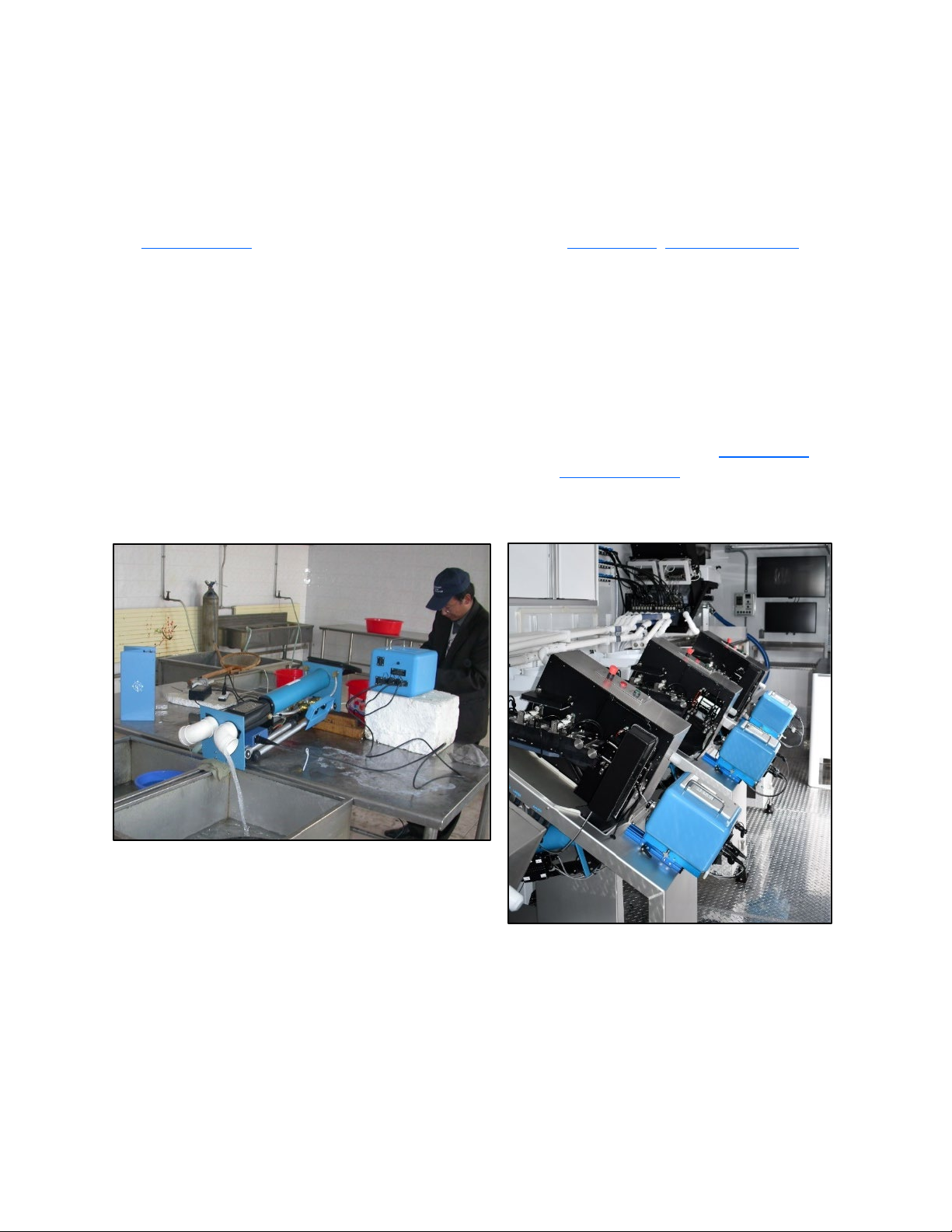

1. Introduction

Northwest Marine Technology (NMT) designs

and manufactures Coded Wire Tags and their

associated injection and detection equipment.

The Coded Wire Tag (CWT) identification

system provides an accurate and versatile

method for assessing and researching natural

and hatchery reared fish populations. Coded

Wire Tags have been implanted in hundreds of

different marine and freshwater species.

Reliability of the equipment and data allow for

application in many areas of fisheries research

and management.

The MKIV Tag Injector is designed to give years

of reliable performance. Please read and

understand the operating and maintenance

instructions so you can obtain the maximum

service from this product. The most up-to-date

version of this manual is available on our

website (www.nmt.us; NMT User Manuals).

The MKIV Injector comes in various

configurations:

1. MKIV Tag Injector only (a V-detector or

T-Wand for quality control is

recommended).

2. MKIV Tag Injector with a Quality

Control Device (QCD), Figure 1.

3. MKIV Tag Injector in an AutoFish trailer

(Figure 1)- refer to the AutoFish SCT

Operator Manual).

Figure 1: MKIV with QCD for manual tagging (left) and installed in AutoFish System for automated

tagging.

Page 9 Need help? Call +1 (360) 764-8850 or email of[email protected]

2. Setup

2.1 Contents Checklist

A MKIV Tag Injector is shipped with the

following items in a transit case:

•MKIV Tag Injector

•Power Supply

•Touch Switch or Foot Switch

•3 non-custom head molds

•3,000 tag spool of test wire

•Tool Kit (see Appendix A: Tool Kit

Components)

•Instruction Manual

A MKIV Tagging Unit includes these additional

items:

•Quality Control Device (QCD)

•Interconnect Cable

•Funnel

•Quick disconnect with a water filter.

Remove all items from the boxes and make sure

nothing has been left in the packing materials.

2.2 Assembly

1. Place the Injector on a stable,

flat surface near the power

source. The tagging equipment

operates on 12-28 volts DC

(about 50 watts). The Injector

comes with a power supply

which converts 110-240 volts AC

to 24 volts DC. Plug the power

supply into a grounded AC

power outlet.

2. Alternate DC power sources

such as a 12 V automobile

battery can also be used when

AC power isn’t available.

Adapters for use with alternate

power sources are available

from NMT.

3. Connect the cable from the power supply to the 4-pin connector on the back of the Injector.

Touch switch

QCD

interconnect

cable

Power supply

On/off switch and

circuit breaker

Figure

2: Back view of the MKIV Injector

Page 10 GEV v 4.0 Feb 2021

4. Attach the cable from your touch switch or foot

switch to either of the two large connectors on the

back of the Injector.

5.

6. If you are using a QCD, connect it to the other large

connector on the back of the injector (

7. Figure 3). See (Quality Control Device (QCD), page 37)

for more information about setting up your QCD.

Figure 3: Cable connections for a mechanical gate QCD.

MKIV Injector

QCD Detection Head

Separator

Gate Actuator

Gate Box

QCD Electronics Box

24 VDC

Power

Supply

110-220

VAC

Touch Switch

The two large connectors

on the back of the Injector

are interchangeable. Keep

the protective caps closed

on any unused

connector(s).

WARNING! To avoid

damaging the

electronics

,

do not connect the QCD

while the Injector is

turned on.

Page 11 Need help? Call +1 (360) 764-8850 or email of[email protected]

3. Quick Start

After the equipment is assembled, follow these steps for initial testing and familiarization. The steps

below confirm that the equipment is operating and ready for the remaining adjustments. Completing

these steps does not mean that everything is ready for tagging.

Step 1: Open the latch on the front of

the Injector (Figure 4) and swing

the door open.

Figure 5 shows the parts on the Injector main plate with the door open.

Figure

5: MKIV Injector main plate.

Spool retainer

Actuator arm

Drive roller latch

Idler roller arm

Pressure

spring

Shoulder

bolt

Entry wire guide

E-clip

Magnetizer

Idler roller

Drive

roller

Cutter block

wire guide

Cutter

Needle carrier

clamp

Needle carrier

Head

mold

base

LED

Door

lh

Head

mold base

Blue

tag

LED

Figure

4:

Front of MKIV Injector,

AutoFish

version left, standard

version, right.

Page 12 GEV v 4.0 Feb 2021

Step 2: Turn on system power by pressing the rubber-covered On/Off button on the back of the Injector

(Figure 2). When the Injector is turned on, a self-test sequence will take place and the display

will show a "READY VX.X" message where “X.X” is the firmware version number.

The Injector has a built-in circuit breaker and protective fuse. If the circuit breaker is tripped, the

Injector will shut off. The circuit breaker will automatically reset after about one minute. If the

circuit breaker does not reset, the internal protective fuse is most likely blown and the Injector

must be returned to NMT for servicing.

If a QCD is not connected, or if the self-test detects a problem with the QCD, the display will

show the message "NO QCD OK?". If you see this message and the QCD is connected, check to

make sure the QCD Interconnect Cable is properly installed.

If you are not using a QCD, press any key on the keyboard to confirm this status and clear the

message.

Step 3: The Injector is shipped with a spool

of test wire installed. If there is not

a spool of wire on the machine,

install one on the spool retainer

before proceeding.

Step 4: Locate the idler roller arm and move the drive roller latch so that the rollers are engaged (Figure

6).

Step 5: Load the tag-wire by

pressing [LOAD] (page 25)

on the keyboard. The

display will show “LOAD

100" and the drive rollers

can be rotated easily by

hand. The Injector may

make a hissing sound

when in the LOAD

position. This is normal.

tag wire

drive roller

Engage the

drive roller

latch

rotate

Figure

6: Loading tag wire.

The MKIV Injector ships with a 2.5 inch

needle installed which is protected by a

head mold base. If a needle is not

installed or a 3.5 inch needle is required,

see Needle Installation, page 54.

Page 13 Need help? Call +1 (360) 764-8850 or email of[email protected]

Step 6: Insert the tag-wire into the entry wire guide and push it forward until it reaches the drive rollers.

Rotate the top roller clockwise by hand to feed the wire into the cutter block wire guide (Figure

6). Continue turning the top roller until the tag wire extends slightly beyond the tip of the

needle.

Step 7: Press the [OK] key. The Injector will retract and cut the tag wire. Cycle the Injector once by

pressing either the Touch Switch button, the [TAG] key, or the blue tag switch on the front of the

Injector if equipped (Figure 4, page 11). Any of these three switches will cycle the Injector. The first

piece of wire ejected will be longer than a standard tag. Cycle the Injector a few more times to see how

it operates and confirm the Injector is making the proper length tags. Each cycle will produce one tag.

If a QCD is attached, the red error light and tone will be activated as determined by the tag

credit value (page 35). This indicates that tagged specimens are not being detected by the

QCD, and is normal for this sequence.

Page 15 Need help? Call +1 (360) 764-8850 or email [email protected]

4. Getting Ready to Tag

Before tagging, please read NMT’s Coded Wire Tag Project Manual, available at www.nmt.us . It

provides a comprehensive overview of coded wire tagging projects and discusses appropriate setups for

a variety of species and environments.

The following MKIV Tag Injector adjustments need to be made or checked before tagging:

•Needle selection (page 15)

•Needle Positioning Jig Selection (for example a head mold) (page 16)

•Tag Length (page 17)

•Common Menu Settings (page 19)

•Needle Penetration (page 19)

•Tag Placement Depth (page 20)

If you are using a Quality Control Device (QCD) you will also check or adjust:

•Water flow and General Assembly (Mechanical and Water Jet Versions) (page 39)

•Separator (Water) Jet Adjustments (water jet version only) (page 43)

or

•Mechanical Diverter Gate Assembly (mechanical gate version only) (page 41)

•Item: QCD DELAY (page 33)

•Item: QCD THRESHold (page 31)

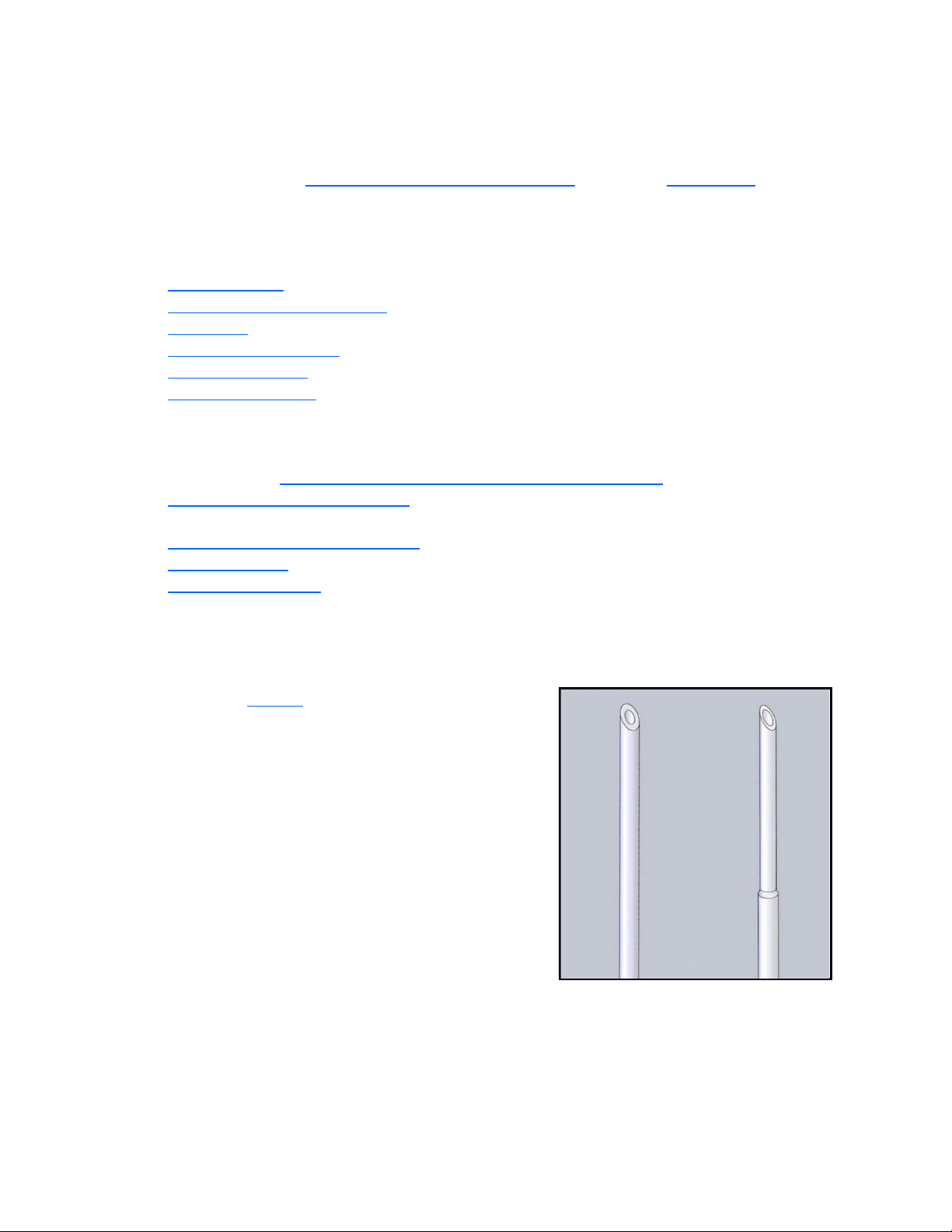

4.1 Needle Selection

Four needle styles (Figure 7) are offered for the MKIV Tag

Injector:

•2.5 inch (63.5 mm), etched or non-etched

•3.5 inch (89 mm), etched or non-etched

Non-etched needles do not have a reduced outside diameter

near their tip, making them better suited for larger animals or

tagging into tougher tissue because of their added strength.

Etched needles have a reduced outside diameter near the tip,

making them better suited for smaller animals, where a

smaller incision is required or for tagging into soft tissue. The

trade-off with etched needles is reduced strength in the tip.

Non-etched

Etched

Figure

7: Needle styles

Page 16 GEV v 4.0 Feb 2021

4.2 Needle Positioning Jig Selection

The most common type of positioning jig used with a MKIV Tag Injector is the head mold (Figure 8). NMT

sells head molds for a wide variety of size and species fish (see Table 1). A custom head-mold kit is also

available from NMT to allow the end user to create unique head molds.

Table 1: NMT stock head mold sizes.

Species

Head Mold Size (fish/lb); CMS=Closed Mouth Style

Coho/Chinook

5, 10, 15, 20, 30, 45, 65, 90, 120, 200, 300 (CMS), 550, 1100

Steelhead

(Rainbow)

2(5), 3(8), 5(12), 7(18), 11(27), 20(50), 36(90), 80(200)

Pink

2000 (CMS)

Atlantic Salmon

7, 9, 11, 15, 25, 30, 50, 100, 120

Lake Trout

5, 8, 12, 18, 27, 50, 90

Chum

700

Head Mold Size (length in mm);

CMS=Closed Mouth Style

Sockeye

60 (CMS), 90

Walleye

55, 65, 125

Mullet

60-70, 70-80, 100, 120, 140

Paddlefish

Not size designated, but for ~ 6 inch fish

Tagging can be done without a positioning jig. Many fishes,

crustaceans, and other animals have tag locations which

don’t need or aren’t conducive to, the use of a positioning

jig. The operator would manually impale the specimen on a

non-moving needle (see Item: NEEDLE MOVe, page 32) and

then inject the tag. Without a jig, is still desirable to have

some depth control so that you know how much of the

needle has penetrated the specimen. The needle support

tube (available as an accessory) makes a good depth stop.

Figure 8: Positioning jigs – tagging with a head mold (top)

and with a needle support tube (bottom).

Page 17 Need help? Call +1 (360) 764-8850 or email [email protected]

4.3 Tag Length

There are two ways to set the tag length of the Injector:

1) Under Item: SETUP (page 30) in the

Adjustment menu (ADJ), select

Standard (otherwise known as single

length tags), Half, 1 ½, or Double.

2) Choose the appropriate tag length in

the Adjustment menu under the

option Item: TAG LENgth (page 30).

Using the TagLength option will

automatically display Special if other

options, for example Needle Move, are

changed in the Adjustment menu. You can

also store 2 different adjustment settings

using Custom1 and Custom2 (page 30).

If the MKIV Tag Injector is set up to cut

tags SHORTER than that specified on the

spool, then the code(s) will be

unreadable.

Page 18 GEV v 4.0 Feb 2021

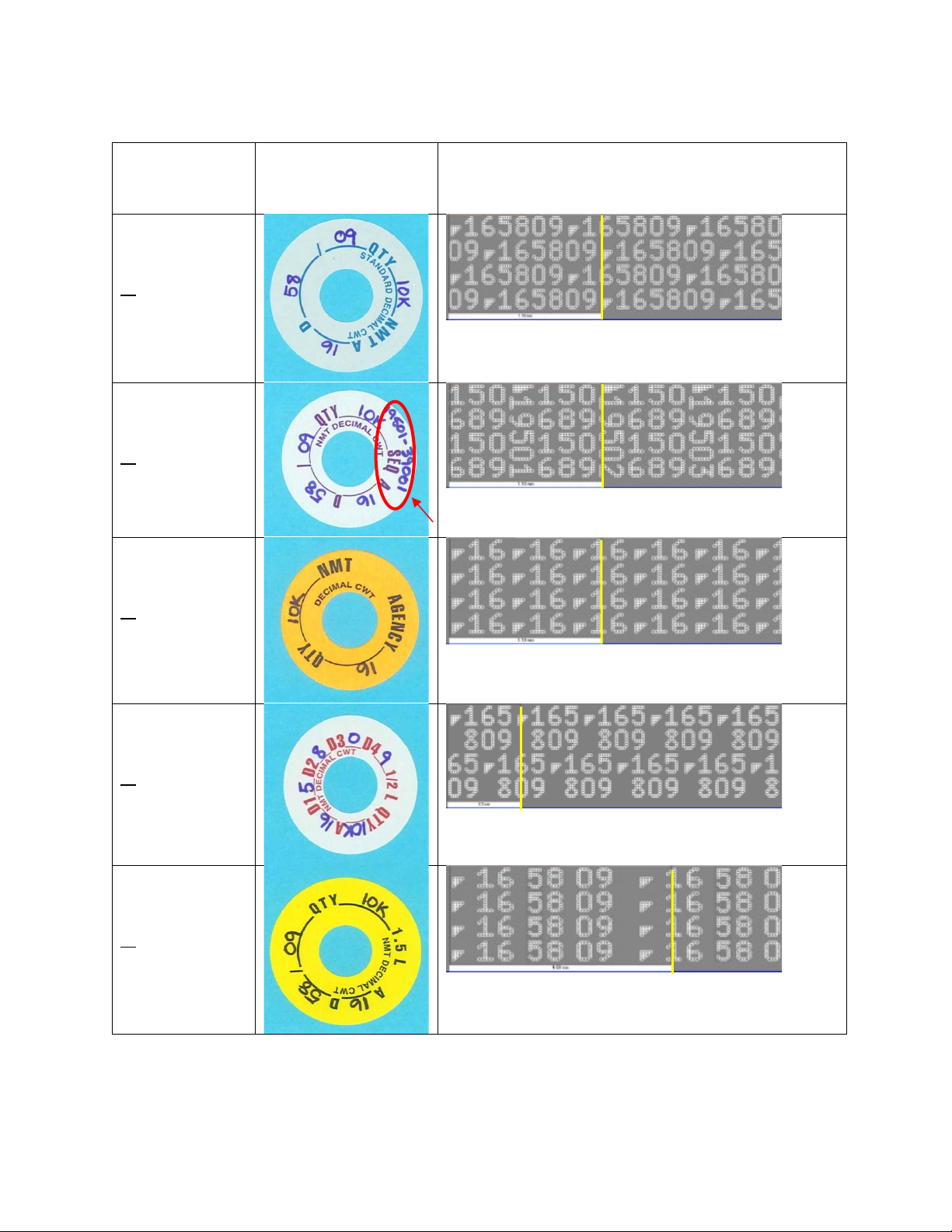

Table 2: Coded Wire Tag formats

CWT format and

MKIV Injector

setting

Spool label

Layout: If a 2 mm piece of wire were unrolled and

magnified, it would look like this. The yellow bars show

where tags of each format might be cut by the injector.

Standard CWT:

TAG LEN [SGL]

or

SETUP

[STANDARD]

Sequential CWT:

TAG LEN [SGL]

or

SETUP

[STANDARD]

Sequence numbers

Agency CWT:

TAG LEN [SGL]

or

SETUP

[STANDARD]

½ Length CWT:

TAG LEN[1/2]

or

SETUP[HALF]

1 ½ Length CWT:

TAG LEN[1 1/2]

or

SETUP[1 1/2]

Page 19 Need help? Call +1 (360) 764-8850 or email [email protected]

4.4 Common Menu Settings

4.4.1 Using a head mold and 2.5 inch needle

•Item: SETUP [STANDARD/HALF/1 1/2] (page 30)

•Key: [SHOW] [96] (page 26)

4.4.2 Using a needle support tube and a 3.5 inch needle

•Item: SETUP [SPECIAL/CUSTOM 1/CUSTOM 2] (page 30)

•Item: NEEDLE MOVe [NO] (page 32)

•Item: STOP [1] (page 31)

•Key: [SHOW] [171] (page 26)

4.4.3 Using a needle support tube and a 3.5 inch needle (alternate)

This setup using Stop 2 and a small amount of Needle Move is recommended over no

Needle Move (section 4.4.2) and Stop 1 if poor tag retention is an issue.

•Item: SETUP [SPECIAL/CUSTOM 1/CUSTOM 2] (page 30)

•Item: NEEDLE MOVe [S5-S23] (page 32)

•Item: STOP [2], the needle starts in the extended position (page 31)

•Item: MIN. TIME [0-255] (page 33)

•Key: [SHOW] [172-180], dependent on the amount of Needle Move (page 26)

4.5 Needle Penetration

Needle penetration refers to the depth the

needle will penetrate the specimen. Proper

penetration depth is very important for tag

retention and depends on the size and species

of the specimen being tagged. Penetration

depth is controlled with the use of a head mold

or positioning jig.

To set the needle penetration depth, put the

Injector in the SHOW mode which will move the

needle to its fully extended position. Loosen the

set screws in the head-mold holder and slide

the appropriate head mold or needle

positioning jig in or out to adjust the distance

the needle will extend into the specimen.

Gently tighten the set screws to hold the head

mold in place.

Page 20 GEV v 4.0 Feb 2021

4.6 Tag Placement Depth

Tag placement depth refers to the position of

the tag with respect to the tip of the needle.

Tag placement depth can be estimated by

measuring the distance from the end of the

wire to the surface of the head mold while

the Injector is in SHOW mode (see Key:

[SHOW], page 26). In all cases correct tag

placement depth must be confirmed by

dissection of tagged test specimens. Figure 9

shows the preferred placement for Coded

Wire Tags in salmonids.

There are instances when the tag must be

extended beyond the tip of the needle, and

other cases when the tag should not be

extended beyond the tip of the needle.

Examples of these cases are given below.

Tag placement depth beyond the tip of the

needle: If the tag implantation site does not

lend itself to the use of a head mold, you may

wish to manually impale the specimen on a

non-moving needle. Since the needle will not

be retracting to leave the tag in the

specimen, the tag must be pushed past the

tip of the needle. Otherwise, the tag will not

reach the tip of the needle until subsequent

tags accumulate to push it out. The

approximate SHOW value using a standard

length needle with "NEEDLE MOVe (NO)" is

78.

Tag placement depth behind the tip of the needle:Whenever the target area is very hard (e.g., the

head of steelhead trout), trying to inject the tag into tissue which has not been penetrated by the

needle will cause a wire jam or slippage of the drive rollers. In this case, use a tag placement depth

which does not extend any part of the tag beyond the tip of the needle. This way the needle can

penetrate the hard tissue and, upon retracting, leave the tag in the target area.

NMT’s Coded Wire Tag Project Manual (available for download at www.nmt.us) has more details about

correct tag placement.

Figure 9

: Typical tag placement for salmonids.

Coded Wire Tag

In SHOW mode, the tip of the uncut

tag wire will move to the same

position as the leading end of the tag

at implantation. Thus, the end of the

uncut tag wire represents the tag's

deepest point of penetration.

Table of contents

Other Northwest Marine Technology Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

SKC

SKC Sioutas Cascade Impactor operating instructions

NuAire

NuAire LabGard NU-640-400 Operation and maintenance manual

AMX

AMX PS-POE-AT-TC quick start guide

D-Link

D-Link DPE-101GI Quick installation guide

BioLAB

BioLAB BHMS-104 Operation manual

Velp Scientifica

Velp Scientifica DLH F201A0157 instruction manual

Snow Performance

Snow Performance Boost Cooler 210 instructions

VWR

VWR PerfectBlue Maxi S instruction manual

Agilent Technologies

Agilent Technologies 1260 Infinity II user manual

CORNING

CORNING Lambda EliteTouch instruction manual

TESTO

TESTO 872s instruction manual

InnovaPrep

InnovaPrep CP Select quick start guide