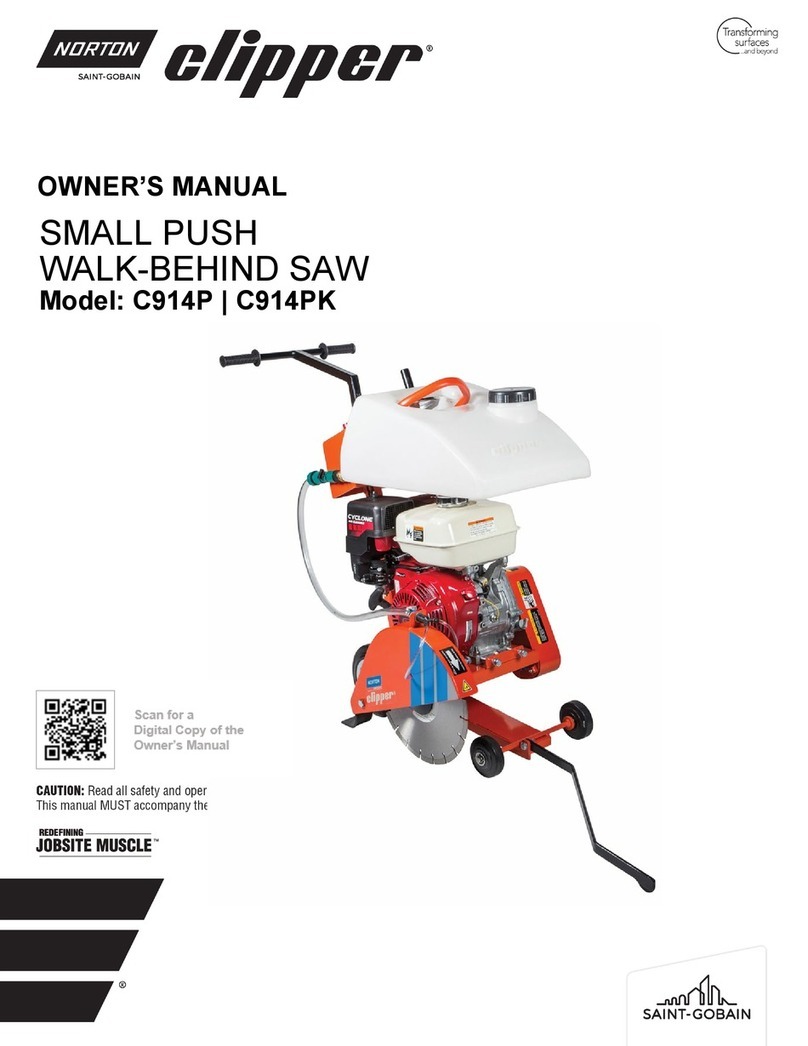

Norton Clipper C914P User manual

1

OWNERS

MANUAL

Small Concrete Saw

Models:

C914P

FORM: C914P rev 8-2020

2

WARRANTY

Norton warrants all products manufactured by it against defects in

workmanship or materials for a period of one (1) year from the date of

shipment to the customer.

The responsibility of Norton under this warranty is limited to

replacement or repair of defective parts at Norton's Gainesville,

Georgia factory, or at a point designated by it, of such part as shall

appear to us upon inspection at such point, to have been defective in

material or workmanship, with expense for transportation borne by the

customer.

In no event shall Norton be liable for consequential or incidental

damages arising out of the failure of any product to operate properly.

Integral units such as gasoline engines, electric motors,batteries,

tires, transmissions, etc., are excluded from this warranty and are

subject to the prime manufacturer's warranty.

This warranty is in lieu of all other warranties, expressed or implied,

and all such other warranties are hereby disclaimed.

Important: Before placing equipment in operation, record the following

information.

MODEL:_________ SERIAL NO.___________

PURCHASE FROM: _____________________

ADDRESS: ____________________________

CITY_______ STATE ______ ZIP ________

TELEPHONE NO. ______________________

Before using this equipment, make sure that any person using it

reads and understands the instructions in this owner’s manual.

3

Table of Contents

CONTENTS PAGE

I. Preparation 4-11

A. Safety Precautions 4-6

Dust and Silica Warning 5

B. Assembly 7-9

C. C914P Series Concrete Saw Specifications 10

D. Engine Precautions 11

E. Pointer Alignment 11

II. Operation 12-20

A. Blade Installation 12-16-

B. Starting The Engine 16-18-

C. Water Supply 18-19

D. Operating The Saw 19-20

E. Cutting Technique 20

III. Maintenance 21-

A. Engine 21-23

B. Wiring Diagram C914P 9 HP Honda 24

C. Bearings 25

D. V-Belts 25-32

Adjust The C914P Belt Tension 26-29-

Belt Alignment 29

Main Causes of Belt Failures 30

E. Depth Control 31-32

F. Inspection and Cleaning 32

IV. Parts List Section 32-48

A. Ordering Information 33

B. Parts Drawing and Service Parts List 34-48

Depth Control Group 34-35

Blade Guard Group 36-37

Blade Shaft and Engine Group 38-39

Main Frame and Pivoting Frame Group 40-41

Belt Guard Group 42

Handle Bar Group 43

Pointer Group 44

Water Tank Group 45-46

Decals 47-48

Read Owner’s Manual Before Use

Safety Alert Symbol: Information Following This Symbol Is

Very Important.

Use Only Norton Diamond Blades

4

I. PREPARATION

A. Safety Precautions

Important! The following safety precautions must always be observed.

Hazard Symbols

Fuel (gasoline) is extremely flammable and its vapors can

explode if ignited. Store gasoline only in approved containers,

in well-ventilated, unoccupied approved areas, and away from

sparks or flames. Do not fill the fuel tank while the engine is hot

or running. Do not start the engine near spilled fuel. Never use

the fuel as a cleaning agent

Engine components can get extremely hot from operation. To

prevent burns, do not touch the engine or related parts while the

engine is running or immediately after it is turned off. Never

operate the engine with any heat shields or guards removed.

Keep all guards in place when operating any piece of equipment

Keep hands, feet, hair, and clothing away from all rotating parts

Lethal Exhaust Gas: use only in well ventilated areas. Engine

exhaust gases contain poisonous carbon monoxide, which is

odorless, colorless, and can cause death if inhaled. Avoid

inhaling exhaust fumes, and never run the engine in a closed

building or confined area.

Never tamper with the governor components of settings to

increase the maximum speed. Severe personal injury and

damage to the engine or equipment can result if operated at

speed above maximum. Always obey the maximum speed

rating of blade.

DO NOT LIFT THE SAW BY THE HANDLE

BARS

5

Dust and Silica Warning

Grinding/cutting/drilling of masonry, concrete, metal and other materials can

generate dust, mists and fumes containing chemicals known to cause serious or

fatal injury or illness, such as respiratory disease, cancer, birth defects or other

reproductive harm. If you are unfamiliar with the risks associated with the

particular process and/or material being cut or the composition of the tool being

used, review the material safety data sheet and/or consult your employer, the

material manufacturer/supplier, governmental agencies such as OSHA and

NIOSH and other sources on hazardous materials and make certain to comply

with all product warnings and instructions for the safe and effective use of the

material being cut. California and some other authorities, for instance, have

published lists of substances known to cause cancer, reproductive toxicity, or

other harmful effects.

Control dust, mist and fumes at the source where possible. In this regard use

good work practices and follow the recommendations of the manufacturer/supplier,

OSHA/NIOSH, and occupational and trade associations. Water should be used

for dust suppression when wet cutting is feasible. When the hazards from

inhalation of dust, mists and fumes cannot be eliminated through engineering

controls such as vacuum and/or water mist, the operator and any bystanders

should always wear a respirator approved by NIOSH/MSHA for the material being

cut.

Use Approved:

Eye Protection Hearing

Protection

Respiratory

Protection

Head Protection

6

1. Before mounting any blade on the saw, the blade should be inspected for

any damage which might have occurred during shipment, handling or

previous use.

2. The blade collars and arbors should be cleaned and examined for damage

before mounting the blade.

3. The blade must be properly fitted over the arbor with the drive pin on the

outside collar projecting through the drive pin hole on the blade and

inside collar.

4. The blade shaft nut, which is a left-hand thread nut, must be tightened

securely against the outside blade shaft collar.

5. The blade must be operated within the specified maximum operating

speed listed on the blade.

6. Turn water control valve to full to provide adequate coolant (4 to 6 gallons

per minute) for diamond blades and wet cutting abrasive blades.

Insufficient coolant could result in severe blade breakage or diamond

segment separation.

7. The blade guard must be in place with the nose guard down and locked

when the saw is running.

8. The operator should wear safety glasses and any other appropriate safety

equipment.

9. When starting the saw, the operator should stand away and to the side of

the blade.

10.If for any reason the saw should stall in the cut, raise the blade out of the

cut. Check the outside blade shaft collar and nut for tightness. Inspect

the blade for damage before restarting the saw. Use caution when

resuming a cut. Be certain that the blade is in alignment with the previous

cut.

11.During cutting operations do not exert excess side pressure on the

handles as a method of steering. Do not force the blade into the cut by

lowering the blade too fast or by pushing the saw too fast.

You Are Responsible For Your Safety!!!

7

I. PREPARATION

B. Assembly

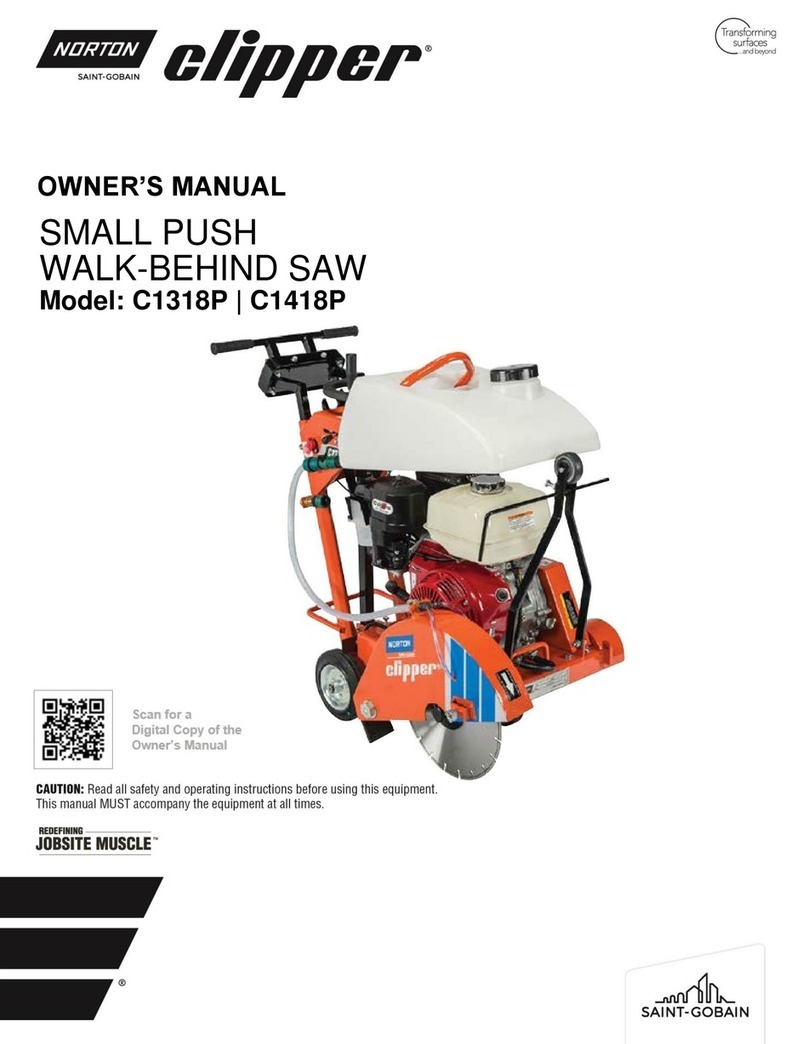

The C914P compact concrete saw is shipped completely assembled and ready

for use except for Handle Bar, Diamond Blade, Gasoline, and Engine Oil.

Inspect the saw for shipping damage. If any damage is found, contact the

shipper immediately and file a freight claim. Norton Clipper is not responsible

for any freight-related damages.

Handle Bar Lifting Bale

Depth Adjustment

Hand Wheel

Front Pointer

(

Cuttin

g

Guide

)

Belt Guard

Blade Guard

Engine On/Off

Switch

Water Tank

Engine Choke,

Fuel Shut Off, and

Throttle Controls

Engine Air Cleaner

8

Remove the saw from the pallet. Inspect the machine for concealed shipping

damaged. Read and understand ALL instruction included in this manual.

Failure to understand and follow the instruction covered in this manual can

result in injury to persons or damage to the machine.

DO NOT LIFT THE SAW BY THE HANDLE BARS

Loosen the Handle Bar Retaining Jam Nuts and Bolts. Remove the Handle

Bars from the Frame and rotate 180° so that the Hand Crips will be towards the

Operator. Slide the Handle Bar Assembly into the frame, adjust to the

Operator’s desired height, and align the nearest Hole in the Handle Bar

Assembly with the top Retaining bolt. Tight both Handle Bar Retaining Bolts

and Tighten the Jam Nuts. See Figure: Handel Bar Assembly

¾” Garden Hose

Fitting

Quick Detach

Water Fitting with

Valve

Handle Bar Attachment

Hardware

En

g

ine On/Off Switch

Wrench and

Wrench Holder

Serial Number Plate

Water Tank Quick

Detach Fittin

g

s Blade Guard Water

WYE and Nozzels

9

Handle Bar Assembly

Level the cutting frame and check the engine oil level and add if required (See

Engine Manual) and add fuel (See Engine Manual). NOTE: Do not install the

blade until it is time to use the saw. ANSI regulations prohibit the

transportation of any concrete saw with the blade installed.

Handle Bar Installation;

DO NOT LIFT THE SAW BY THE HANDLE BARS

Handle Bar Assembly

Handle Bar Attachment

Hardware

Handle Bar Attachment

Hardware

10

C. C914P Series Concrete Saw Specifications

C914P

Dimensions/Weight

Length (Working) – in (mm) 57-55/64" (1,469)

Length (Transport) – in (mm) 35-37/64" (929)

Pointer Length – in (mm) 12-47/64" (323)

Width – in (mm) 37-59/64" (963)

Height – in (mm) 21-9/32" (541)

Weight Created – lbs. (kg) 198.4 (90.6)

Weight Uncreated – lbs. (kg) 169.4 (77)

Engine

Engine Mfg. Honda

Model GX370

Spec No. GX270QXC

Engine Type Single Cylinder 4 Cycle

Horse Power – Gross hp (kW) 9 HP (6.7kW) @ 3,500 RP<

Max Torque – Gross – ibf-ft (Nm) 14 (19) @ 2,500 RPM

Cooling System Air

Oil Capacity – US qt (l) 0.29 (1.1)

Fuel Capacity – US qt (l) 5.6 (1.1)

Fuel Type Unleaded Gasoline (86 pump octane)

Low Oil Sensor Yes

Air Filtration Three Stage Cyclone

Characteristics

Max Blade 14" (350)

Depth of Cut 14” (356 mm) – in (mm) 4-5/8 (117)

12” (305 mm) – in (mm) 3-5/8 (92)

10” (254 mm) – in (mm) 2-5/8 (67)

1-5/8 (41)

Arbor Bore – in (mm) 1” (25.4 mm)

Blade Shaft Locking Device Machined Into Flats On Blade Shaft

Blade Shaft Speed – RPM 2,840

Blade Shaft Diameter – in (mm) 7/8" (22)

Depth Control Hand Wheel With Screw Feed

Depth Lock Standard

One (1) Revolution of Hand Wheel ¼” (6.4mm) Change of Depth

Front Wheel DxWxB – in (mm) 3-15/16 x 1-3/8 x 0.59 (100 x 35 x 15)

Rear Wheel DxWxB – in (mm) 7-7/8 x 1-49/64 x 0.79 (200 x 45 x 20)

Number Of Belts Three (3) XPZ610 Belts

Blade Guard Type Hinged, All Steel Construction

Side of Cut Right

Lifting Bale Yes

Water Hose Connector Standard Garden Hose With Flow Control Valve

Water Tank Capacity – gal (l) 6.6 (25)

Recessed Rear Wheels Standard

Adjustable Handle Bars – in (mm) Yes 9-29/64 (245)

Stay Level Handel Bar System Yes

* = Horse power and Torque ratings are Gross Horse power and are supplied by the engine manufacturer. Actual output of the engine will vary due to many

factors including operational speed of engine, environmental conditions, maintenance, fuel, and other variables. Saint-Gobain Abrasives, Inc. makes NO

claim to actual or gross horse power and torque ratings.

11

D. Engine Precautions

Prior to attempting to operate the engine, read the information

contained in the engine owner's manual. An engine owner’s manual is

supplied with every gasoline powered concrete saw.

1. Check Oil: Add oil if low. Refer to the engine owner's manual for the

recommended SAE viscosity grades. Capacity of oil is 1.16 US quarts (1.1

liters)

2. Check Fuel: Fill if low. Use only unleaded gasoline with a pump sticker

octane rating of 86 or higher is recommended. Never use an oil and

gasoline mixture!

3. Air Cleaner: Never run the engine without the air cleaner! Rapid engine

wear will result from contaminants being drawn through the carburetor and

into the engine.

4. Engine Starting: Refer to the engine owner's manual additional proper

engine starting procedure.

E. Pointer Alignment

1. Use a straight edge, and carefully mark a line 12 feet long on a smooth level

surface.

2. Place the saw blade on the marked line, move the saw to the center of the

marked line and then lower the blade until it is about 1/16” above the

marked line

3. Measure from each end of the saw frame to insure that the frame is parallel

to the marked line. Adjust the saw as needed.

4. With the blade centered on the marked line and the saw frame parallel to

the marked line, lower the front pointer.

5. Adjust the pointer by bending it until is aligned with the marked line.

12

II. OPERATION

A. Blade Installation

1. Disconnect the spark plug.

2. Pull the Blade Guard Locking Pin Way from the Blade Guard and Pivot

the Blade Guard out of the Way see Figure: Blade Guard Locking Pin

for details. NOTE: The Blade Guard Locking Pin is under spring

tension and will automatically move towards the Blade Guard, if it does

not immediately replace the Blade Guard Locking Pin before using the

saw.

Blade Guard Locking Pin

3. Pivot Blade Guard UP to provide access to Blade Shaft Nut and Blade

Collars see Figure: Blade Attachment Components for details.

Blade Guard Locking Pin

Blade Guard

Pull Pin Away from Blade Guard to UNLOCK

Move Towards Blade Guard to LOCK

13

Blade Attachment Components

4. Remove the blade shaft nut, (Turn clockwise),and remove the outside

collar. NOTE: The Blade Shaft has a flat for use with a 19mm wrench

to prevent rotation.

5. Clean off any foreign particles on the clamping surfaces of both collars and

on the mounting surface of the blade.

6. Place the blade on the blade shaft, lining up the drive pin hole in the blade

with the drive pinhole in the inside collar. The C914P will only accept

Diamond Blades with a Maximum Diameter of 14” (350mm) and a Bore of

1” (25.4mm) and a maximum core thickness of 1/8” (3.1mm) see Figure:

Blade Installation for details. NOTE: Maximum 14” (350mm) Blade can be

used with the C914P, if the blade does not fit under the Blade Guard then

the diameter is greater than 14” (350mm). ALL Diamond Blades have a

direction of rotation indicated on the blade either, install the blade so that

the direction of rotation is clock wise. Use only Norton Diamond Blades

Loose Collar

Blade Shaft Nut

Left Hand Thread

Blade Shaft

Blade Guard

Tight Collar

14

Blade Installation

For Best Performance Use Only Norton Diamond Blades

Specified For the Material Being Cut.

7. Slide the outside blade shaft collar onto the blade shaft. The drive pin

on the outside collar must project through the drive pin hole in the blade

and into the inside collar.

8. Tighten the blade shaft nut (counter-clockwise) securely against the

outside collar. See Figure: Blade Installed on C914P for details.

Diamond Blade

14” (350mm) Max

Diamete

r

Loose Collar

Blade Shaft Nut

Left Hand Thread

Direction of Rotation

Drive Pin Hole

Blade Shaft

Tight Collar

15

Blade Installed on C914P

9. Lower the Blade Guard, verify that the Blade Guard Locking Pin Aligns

with the Slot in the Blade Guard Bayonet and Reattach the Blade Guard

Locking Pin by pushing the Locking Pin Towards the Blade Guard see

Figure: Locking The Blade Guard for details. NOTE: The Blade

Guard Locking Pin is under spring tension and will automatically move

towards the Blade Guard, if it does not immediately replace the Blade

Guard Locking Pin before using the saw.

16

Locking The Blade Guard

10. Reconnect the spark plug.

One Revolution of the Hand Wheel equals ¼” (6.4mm) change of cut depth

B. Starting the Engine

1. Refer to the engine owner's manual for detail starting procedures.

2. Always cut with engine rpm in the full throttle setting.

Before starting, insure that the blade is properly installed,

all guards are in place and in safe operating condition, and

that the Blade is not in contact with any surface or object.

Also verify that the area where the work is to be performed

is clean, safe, and has proper ventilation and lighting.

Always located and properly mark all water, gas, and

electrical services before beginning any work.

Never transport any machine with the Blade installed.

Move Towards Blade Guard to LOCK

Blade Guard Locking Pin

Blade Guard

Blade Bayonet

17

Turn the Fuel Control To the ON Position

Move the choke lever to the CLOSED position.

NOTE: The Choke may not be needed if the engine

is warm or the air temperature is high.

Move the Engine Throttle Slightly to the Left

Turn the ON/OFF Switch to the ON position. NOTE:

The Emergency Stop Switch is located on the

machine’s Console.

Pull the starter grip lightly until you feel resistance,

then pull briskly. CAUTION: Do not allow the starter

grip to snap back against the engine. Return it gently

to prevent damage to the starter.

As the engine warms up, gradually move the choke

lever to the OPEN position (fully to the right)

Position the throttle control lever for the maximum

engine speed (fully to the Left).

18

To stop the engine, move the Throttle Control Lever fully to the Forward

Position (fully to the right) and Engine Switch to the OFF position. Turn the fuel

valve to the OFF position.

Never transport the machine with the Fuel Valve in the ON

position. Never Store the machine with the Fuel Valve in the

ON position.

Never Transport a machine with the blade installed.

C. Water Supply

The C914P is designed for use with either a ¾” Garden Hose Fitting and

pressurized water source or by using the included Water Tank.

Pressurized source:

A Pressurized Water Source such as a city water supply off of a building or

external water tank with a water pump capable of providing 4 to 6 gallons (15.1

to 22.7 liters) of water per minute will provide the best dust control and cooling

of the blade. Using a Pressurized Water source providing 4 to 6 gallons (15.1

to 22.7 liters) of water per minute meets all OSHA Silica control requirements.

¾” Garden Hose

Fitting

Quick Detach

Water Fitting with

Valve

Water Tank Quick

Detach Fittings

Water Tank

Water Tank Cap

19

1. Verify that the Quick Detach Fitting with Valve is connected to the ¾”

Garden Hose connector.

2. Turn the Water Control Valve to full "ON" when using wet cutting blades.

The required flow rate is 4 to 6 gallons (15.1 to 22.7 liters) per minute.

3. Follow ALL instructions under the Section “D. Operating The Saw”

Water Tank source:

The C914P included Water Tank is designed to provide some dust control for

when a Pressurized Water source is not available. The Water Tank also

increases the machine overall weight which assist at cutting at deeper depths.

It is preferred to use the Pressurized Water source as it will provide the

required water flow rates over a longer time period than the Water Tank.

Please note that when using the Water Tank it is recommended that the

operator use a OSHA approved respirator to protect from Silica Dust.

1. Fill the Water Tank to the bottom of the filler neck with Water.

2. Replace the Water Tank Cap

3. Verify that the Quick Detach Fitting with Valve is Connected to the Water

Tank Fittings

4. Follow ALL instructions under the Section “D. Operating The Saw”

5. Adjust the Quick Detach Fitting with Valve’s water control valve so that

enough water is covering the blade to reduce the water to your required

level. NOTE: The Operator and anyone around the machine MUST wear a

respirator that meets OSHA Silica Control Requirements and follow ALL

OSHA Silica Control Regulations.

D. Operating the Saw

1. For blade installation instructions see section II. Operation sub heading

A. Installing the Blade. For the engine starting instructions, see the

Engine manual and follow the instructions located in section II. Operation

sub heading B. Starting the Engine.

2. Check the Engine Oil level. See Engine Manual for details.

3. Raise the saw to the full upright position. Do not let the blade come in

contact with the ground.

4. Maneuver the saw to the desired starting point.

5. If wet cutting, connect the water supply to the saw. See section B. Water

Connections for details.

6. Follow the instructions for starting the engine found in the Engine manual.

7. If wet cutting, turn on the water supply at the source and then open the

water valves on the saw. Make sure that there is a minimum of 4-6 gallons

(15.1 to 22.7 liters) per minute of water flow!!

8. Be sure the engine is running at full throttle!!!

20

9. Slowly lower the blade by rotating the hand wheel clockwise until the

desired depth of cut is reached. Use a reasonable rate of feed. Do not

force the blade into the cut!!

10. When the end of the cut is reached, slowly raise the blade out of the cut by

rotating the Hand Wheel counter-clockwise until the blade is at least one

(1) inch above the ground.

11. Only move the saw in reverse with the blade in the raised position.

13. When moving the saw to a new location, be sure the blade is not touching

the ground. Always pay close attention to where you are moving and

where the blade is at all times.

E. Cutting Technique

Lower the blade into the concrete to the required depth by turning the hand

wheel clockwise.

Reduce the forward pressure if the saw begins to stall.

Note: For deeper cuts of 3: (76mm) or more, several cuts should be made in

incremental steps of 1-1/2 to 2 inches until the desired depth of cut is reached

this is known as Step Cutting. The C914P has a 4-5/8” (117.5mm) with a 14”

(355.6mm) blade many blades that are marketed as a 14” blade are 350mm

(13-3/4”) which will produce shallower cuts due to the overall diameter NOT

being 14” (355.6mm). NEVER cut full depth in a single path as this will cause

damage to any concrete saw blade, and damage drive belts. Burning of drive

belts is due to cutting full depth and is not covered under warranty.

Push the saw steadily forward using the front pointer as a guide. Exert enough

forward pressure so that the engine begins to labor, but does not slow down. If

the saw begins to stall, reduce the forward movement until full rpm is restored

to the blade. If the saw stalls, raise the blade out of the cut before restarting.

Avoid excessive side pressure or twisting of the blade in the cut.

Additional Guide Lines For Sawing:

Understand and follow all of the instructions in this owner’s manual.

If wet cutting, turn on the water supply so that there is a minimum of 4-6

gallons (15.1 to 22.7 liters) per minute of water flow!!

In critically hard aggregate, more than a single pass may be needed to cut

the desired depth.

If the saw stalls in the cut, immediately stop the forward speed and raise the

blade out of the cut. If this is not done the belts can fail or the blade may be

damaged.

Go slowly with a new blade until it opens up, that is, until the diamonds can

be seen and felt.

Other manuals for C914P

1

Table of contents

Other Norton Clipper Saw manuals

Norton Clipper

Norton Clipper CB 511 User manual

Norton Clipper

Norton Clipper CE414-350SS User manual

Norton Clipper

Norton Clipper C1316SS User manual

Norton Clipper

Norton Clipper CM 601 User manual

Norton Clipper

Norton Clipper CM 41 User manual

Norton Clipper

Norton Clipper CWT 450 User manual

Norton Clipper

Norton Clipper Pro-Cut BBM307 User manual

Norton Clipper

Norton Clipper CST 120 UNO User manual

Norton Clipper

Norton Clipper C914P User manual

Norton Clipper

Norton Clipper CE414-350 User manual