Norton Clipper CST 100 User manual

CST

OPERATING INSTRUCTIONS

Translation of the original instructions

VERS.2016.01.12 CST 100/120/150_MAN_EN

2

VERS.2016.01.12 CST 100/120/150_MAN_EN

3

The undersigned manufacturer:

SAINT - GOBAIN ABRASIVES S.A.

190, BD. J. F. KENNEDY

L-4930 BASCHARAGE

Declares that this product:

Masonry saw: CST 100 230V - 350MM -2.2 KW - 2800RPM Code : 70184613977

CST 120 230V - 350MM -2.2 KW - 2800RPM 70184614032

CST 150 230V - 350MM -2.2 KW - 2800RPM 70184614025

is in conformity with the following directives:

"MACHINES" 2006/42/CE

"LOW VOLTAGE" 2014/35/UE

"ELECTROMAGNETIC COMPATIBILITY" 2014/30/UE

"NOISE" 2000/14/CE

and the European standard

EN 12418 –Masonry and stone cutting-off machines - Safety

Valid for machines with serial number from: 160175030

Storage location of the technical documents:

Saint-Gobain Abrasives 190, Bd. J. F. Kennedy 4930 BASCHARAGE, LUXEMBOURG

This declaration of conformity loses its validity when the product is converted or modified without

agreement.

Bascharage, Luxembourg, 01/01/2016.

Olivier Plenert, executive officer.

Déclaration of conformity

VERS.2016.01.12 CST 100/120/150_MAN_EN

4

VERS.2016.01.12 CST 100/120/150_MAN_EN

5

CST: OPERATING INSTRUCTIONS

TABLE OF CONTENTS

1BASIC SAFETY INSTRUCTIONS...............................................................................................6

1.1 Symbols..................................................................................................................................6

1.2 Machine plate..........................................................................................................................7

1.3 Safety instructions for particular operating phases ............................................................7

2MACHINE DESCRIPTION ..........................................................................................................8

2.1 Short description....................................................................................................................8

2.2 Purpose of use .......................................................................................................................8

2.3 Layout .....................................................................................................................................8

2.4 Technical data.......................................................................................................................10

2.5 Statement regarding the vibration emission ......................................................................11

2.6 Statement regarding noise emission..................................................................................12

3ASSEMBLY ANDCOMMISSIONING...........................................................................................13

3.1 Tool assembly ......................................................................................................................13

3.2 Feet mounting.......................................................................................................................13

3.3 Electrical connections..........................................................................................................13

3.4 Starting the machine............................................................................................................13

3.5 Water cooling system ..........................................................................................................14

4TRANSPORT AND STOCKING................................................................................................15

4.1 Securing for transport..........................................................................................................15

4.2 Transport procedure............................................................................................................15

4.3 Long period of inactivity......................................................................................................15

5OPERATING THE MACHINE ...................................................................................................16

5.1 Site of work...........................................................................................................................16

5.2 Cutting material....................................................................................................................16

5.3 General advice for the cutting .............................................................................................17

6MAINTENANCE AND SERVICING...........................................................................................18

7FAULTS: CAUSES AND CURES .............................................................................................19

7.1 Fault-finding procedures.....................................................................................................19

7.2 Trouble-shooting guide........................................................................................................19

7.3 Circuit diagram......................................................................................................................20

VERS.2016.01.12 CST 100/120/150_MAN_EN

6

1 BASIC SAFETY INSTRUCTIONS

The CST is exclusively designed for the cutting of abrasive materials with NORTON diamond

blades, mainly on construction sites.

Uses other than the manufacturer's instructions shall be considered as contravening the regulations.

The manufacturer shall not be held responsible for any resulting damage. Any risk shall be borne

entirely by the user. Observing the operating instructions and compliance with inspection and

servicing requirements shall also be considered as included under use in accordance with the

regulations.

1.1 Symbols

Important warnings and pieces of advice are indicated on the machine using symbols. The following

symbols are used on the machine:

Read operator's instructions

Ear protection must be worn

Hand protection must be worn

Eye protection shall be worn

Rotation direction of the blade

Danger: risk of cut

VERS.2016.01.12 CST 100/120/150_MAN_EN

7

1.2 Machine plate

Important data can be found on the following plate located on the machine:

1.3 Safety instructions for particular operating phases

Before commencing work

Before commencing work, make yourself familiar with the working environment at the place of

use. The working environment includes: obstacles in the area of work and manoeuvre, the

firmness of the floor, necessary protection at the site relating to public thoroughfares and the

availability of help in the event of accidents.

Install the machine balanced on a flat and stable ground.

Check for correct mounting of the blade regularly.

Immediately remove damaged or badly worn blades, as they endanger the operator whilst

rotating.

Only fit NORTON diamond blades to the machine! The use of other tools can damage the

machine!

Firmly press the part to be cut against the machine abutting to prevent it from moving during

cutting operation.

Use the machine only with closed and fixed blade guard.

Please use dust mask during dry cutting to minimize the dust effects.

Check carefully the documentation about diamond blades to find the one who best meet the

requirement with your application.

Machine with electric motor

Turn off the power of the CST and disconnect it from the network before any work on the

machine itself.

Avoid contact of electrical connections with water projections or moisture.

The CST must be absolutely correctly grounded. In case of doubt, have the electrical

connections checked by a qualified electrician.

Turn off the CST main power supply if it stops with no apparent reason. Only a qualified

electrician is authorized to investigate and resolve the issue.

To shut down the machine in case of danger, push the red button on the switch.

Machine model

Machine code

Year of production

Max. blade diameter

Bore diameter

Machine type

Serial number

Blade speed

Power

Safety standard

Weight

VERS.2016.01.12 CST 100/120/150_MAN_EN

8

2 MACHINE DESCRIPTION

Any modification, which could lead to a change in the original characteristics of the machine, may

be done only by Saint-Gobain Abrasives who shall confirm that the machine is still in conformity with

the safety regulations.

2.1 Short description

CST type Masonry saw is a machine with fixed table and mobile head. Robust and powerful, it

allows precise cuts in a wide variety of building materials. It can be used on construction and also

on industrial sites. Combined with NORTON diamond blades, it offers a high degree of performance

and cutting quality for large tiles, window sills or stair steps.

2.2 Purpose of use

The machine is designed for wet cutting of a large range of building and refractory materials, or tiles.

It is not designed for cutting wood or metals.

2.3 Layout

VERS.2016.01.12 CST 100/120/150_MAN_EN

9

Frame (1)

Jig-welded steel construction, the frame is robust and resistant. The side posts of the machine

ensure that the rail is parallel to the table. The rails (4) assembly can also be tilted to 45º to make

bevel cuts. The rail (2) guides the cutting head over the table.

Blade guard (3)

Jig-welded steel construction with 350mm-diameter blade capacity, which offers maximum operator

protection and increased visibility of the work piece.

Incorporated in the blade guard is an outer metal cover, which can be easily hinged open. This

allows easy access to shaft for inspection and blade replacement when motor is switched off, while

fully protecting the blade when in operation. An arrow on the blade guard indicates the direction of

the blade rotation.

Emergency stop button (5)

The red button stops the motor. It is also an emergency stop button.

VERS.2016.01.12 CST 100/120/150_MAN_EN

10

2.4 Technical data

Code

70184613977

70184614032

70184614025

Description

CST100

230V

CST120

230V

CST150

230V

Power

2,2 kW

Voltage

230V 1~

Motor protection

IP 54

Sound pressure level

73,5 dB (A) (selon ISO EN 11201)

Sound energy level

88,5 dB (A) (selon ISO EN 3744)

Cutting length

1000 mm

1200 mm

1500mm

Max. cutting depth

110 mm

Blade speed (RPM)

2800 min-1

Blade diameter

350mm

Blade bore

25.4 mm

Flanges diameter

110 mm

Length

1270 mm

1600 mm

1970 mm

Width

660 mm

Height (with feet)

1350 mm

Height (without feet)

780 mm

Water pan capacity

62 L

71 L

85L

Weight (total)

105 kg

160 kg

180 kg

VERS.2016.01.12 CST 100/120/150_MAN_EN

11

2.5Statement regarding the vibration emission

Declared value of vibration emission following EN 12096.

Machines

Modèle / code

Measured value of

vibration emission at

m/s2

Uncertainty K

m/s2

Tool used

Model / code

CST 100 / 70184613977

CST 120 / 70184614032

CST 150 / 70184614025

<2.5

0.5

Duo Granit

The vibration value is lower and does not exceed 2.5 m / s.

Values determined using the procedure described in the standard EN 12418.

The measurements are made with new machines. Actual values may vary with site conditions, in

terms of:

Materials worked

Wear Machine

Lack of maintenance

Inappropriate tool for application

Tool in poor condition

Unskilled operator

Etc…

The exposure time to vibration is based on the performance of work (related to the adequacy

Machine / Tool / worked material / operator)

When evaluating risks due to hand-arm vibration, you need to take into account effective usage at

rated power of machine during a full day of work; quite often you will realise that effective utilisation

time represents around 50% of overall duration of work. You have to consider, of course, breaks,

water feeding, preparation of work, time to move the machine, disk mounting…

VERS.2016.01.12 CST 100/120/150_MAN_EN

12

2.6 Statement regarding noise emission

Declared value of noise emission following EN ISO 11201 and NF EN ISO 3744.

Machine

Modèle / code

Sound

Pressure

level LPeq

EN ISO

11201

Uncertainty K

(Sound

Pressure level

LPeq

EN ISO 11201)

Sound power level

LWeq

NF EN ISO 3744

Uncertainty K

(Sound power level

LWeq

NF EN ISO 3744)

CST 100 / 70184613977

CST 120 / 70184614032

CST 150 / 70184614025

73.5 dB(A)

2.5 dB(A)

88.5 dB(A)

4 dB(A)

Values determined using the procedure described in the standard EN 12418.

The measurements are made with new machines. Actual values may vary with site conditions, in

terms of:

Wear Machine

Lack of maintenance

Inappropriate tool for application

Tool in poor condition

Unskilled operator

Etc…

Measured values relate to an operator in normal use, as described in the manual position.

VERS.2016.01.12 CST 100/120/150_MAN_EN

13

3 ASSEMBLY ANDCOMMISSIONING

The machine is delivered fully equipped. It is ready for operation when you mount the diamond

blade, the handles and the conveyor cart and after you connect to the appropriate power supply.

3.1Tool assembly

Only NORTON blades should be used.

All tools used must be selected with regard to their maximum permitted cutting speed for the

machine’s maximum permitted rotation speed. Before mounting a new blade into the machine,

switch off the machine and isolate it from the main source of electricity.

To mount a new blade, follow these steps:

Loosen the screw in front of the blade guard and disconnect the water hose on its the left side

and open it.

Loosen the hexagonal nut on the blade shaft (attention: left threaded), which holds the

removable outer flange, with the supplied wrench.

Remove the outer flange.

Clean the flanges and blade shaft and inspect for wear.

Mount the blade on arbour ensuring that direction of rotation is correct. Wrong direction of

rotation blunts the blade quickly.

Replace outer blade flange.

Tighten the hexagonal (attention: left threaded), nut with the supplied wrench.

Close the blade guard, retighten the screw on the front of the blade guard and reconnect the

water hose.

ATTENTION: The blade bore must correspond exactly to the diameter of the blade shaft. Cracked

or damaged bore is dangerous for the operator and for the machine.

3.2Feet mounting

Use the provided screws to mount the feet on the frame.

3.3Electrical connections

Check that,

The voltage/phase supply corresponds to the information indicated on the motor plate.

Available power supply must have ground connection in conformity with safety regulations.

The connecting cables should have at least a 2. 5mm2-section per phase.

3.4Starting the machine

Press the green button to start the machine. Press the red one to stop it. The red button is also an

emergency stop button.

VERS.2016.01.12 CST 100/120/150_MAN_EN

14

3.5Water cooling system

Fill the water pan with clean water to approximately 1cm from top (ensure that bottom of pump is

fully immersed in water).

Open water-tap at blade guard (note that handle on water-tap should be in line with water-flow).

Ensure that water is flowing freely in the circuit and is delivered adequately to both sides of the

blade, as insufficient water supply may result in premature failure of the diamond blade.

The water pump must never run without water. Always make sure that there is enough water in

the pan and refill if necessary.

In case of frost, empty the water cooling system from its water.

VERS.2016.01.12 CST 100/120/150_MAN_EN

15

4 TRANSPORT AND STOCKING

4.1Securing for transport

Before transporting or lifting the machine, always remove the blade and empty the water pan. Also

lock the cutting head on the rail. To do so, move the head in the middle of the rail and tighten the

knob screw until the cutting head is secured on the rail.

4.2Transport procedure

Conform yourself to work regulations, in order to transport the machine safely. The machine is fitted

with 4 foldable handles. Fold these out of the machine to transport it easily. The machine is

designed to be raised using a crane with hooks of lifting on the corners. The machine can also be

transported by a forklift truck while passing the forks under the water vat.

4.3Long period of inactivity

If the machine is not going to be used for a long period, please take the following measures:

Completely clean the machine

Empty the water system

Take the water pump out of the slurry and clean it thoroughly.

The storage site must be clean, dry and at a constant temperature.

VERS.2016.01.12 CST 100/120/150_MAN_EN

16

5 OPERATING THE MACHINE

In this part, you will find some safety tips to use the machine.

5.1Site of work

5.1.1 Sitting the machine

Remove from the site anything, which might hinder the working procedure!

Make sure the site is sufficiently well lit!

Observe manufacturer's conditions for connecting to power supplies!

Place electric cables in such a way that damage by the device is excluded!

Make sure you have a continual adequate view of the working area so you can intervene in the

working process at any time!

Keep other staff out of the area, so you can work securely.

5.1.2 Space required for operation and maintenance

Leave 2 m around the machine for usage and maintenance of the CST.

5.2Cutting material

To use the CST correctly, you must face it with one hand on one of the 3 handles of the cutting

head, and the other ready to shut the machine down in case of emergency. Always keep your hands

away from the moving blade.

In full depth or fixed cutting, the cutting head is locked in a fixed position and the material is pushed

into it as shown.

Lower the cutting head thanks to the hand wheel to the desired cutting depth. In “through

cutting”, lower cutting head until blade periphery reaches max. 3mm under the surface of the

conveyor cart (for maximal cutting depth).

Put the material on the table and maintain it firmly against the butting. (or the cutting guide when

appropriate).

Pull the cutting head slowly and without undue pressure towards the material.

You can tilt the head for bevel cuts. For this purpose, untighten the two black buttons on each

side of the frame, and tilt the head to the desired position (from 0 to 45º). Tighten then the two

buttons.

To cut thicker materials, you can cut a first side, and then reverse it to cut the total depth. You

can cut materials until 220mm depth. (370mm for the 500mm blade versions).

VERS.2016.01.12 CST 100/120/150_MAN_EN

17

5.3General advice for the cutting

The CST is designed to cut materials with maximal dimensions of :

Machine

CST 100

CST 120

CST 150

Ødisc

350 mm

350 mm

350 mm

Maximal dimensions

(L x W x h)

1000

x660

x120

1200

x660

x120

1500

x660

x120

Maximal weight of

materials

66 kg

80 kg

99 kg

The width of the table and of the material can be increased by adding a table extension.

Before commencing work make sure tools are firmly seated!

Select the right tools as recommended by the manufacturer depending on the material to be

worked, the working procedure (wet cut) to be carried out and the required efficiency.

Apply cooling water continuously whilst cutting and in good time! Make sure the water pan

contains enough water.

When dry cutting, ensure sufficient dust extraction and wear a dusk protection mask!

If the thermal protection trips, allow the thermal protection to cool down. Wait a few minutes to

allow the motor to cool down before restarting the machine.

VERS.2016.01.12 CST 100/120/150_MAN_EN

18

6 MAINTENANCE AND SERVICING

To ensure a long-term quality from the cutting with the CST, please follow the maintenance plan

below:

Begin of the day

During the changing of tool

End of the day

or more often if required

Every week

After a fault

After a damage

Whole machine

Visual control (general aspect,

watertightness)

Clean

Flange and blade fixing devices

Clean

Motor cooling fans

Clean

Water pump

Clean

Water pan

Clean

Cutting table

Clean

Water hoses and nozzles

Clean

Water pump filter

Clean

Rail

Clean

Motor housing

Clean

Reachable nuts and screws

Tighten up

Maintenance of the motor

Always perform the maintenance of the motor with the machine isolated from the electrical supply.

Cleaning of the machine

Your machine will last longer if you clean it thoroughly after each day of work, especially water

pump, water pan, cutting head rail, motor and blade flange. To easily clean the water pan, open the

table. Always clean the machine when any cutting dust and debris is still fresh; never allow the

deposits to solidify.

Lubrication

The CST uses life-lubricated bearings. Therefore, you don’t need to lubricate the machine at all.

VERS.2016.01.12 CST 100/120/150_MAN_EN

19

7 FAULTS: CAUSES AND CURES

7.1 Fault-finding procedures

Should any fault occur during the use of the machine, turn it off, and isolate it from the electrical

supply. Any works dealing with the electrical system or supply of the machine can only be carried

out by a qualified electrician.

7.2Trouble-shooting guide

Trouble

Possible source

Resolution

Motor is not running

No electricity

Check the electrical supply

(fuse for example)

Connection cable section too

small

Change connection cable

Defective connection cable

Change connection cable

Defective switch

CAUTION : can only be solved

by qualified electrician

Defective motor

Change motor or contact motor

manufacturer

Motor stops during the cutting,

but can be restarted after a

short period (overload

protection)

Cutting advance too quick

Cut slowly

Blade is blunt or glazed

Sharpen the blade in

calcareous stone

Defective blade

Change blade

Wrong blade specification for

the application

Change blade

No water on the blade

Not enough water in the pan

Refill the water pan

Water tap is closed

Open tap on blade guard

Water supply system is blocked

up

Clean water supply system

Water pump is not working

Change the pump

VERS.2016.01.12 CST 100/120/150_MAN_EN

20

7.3 Circuit diagram

230V Motor

This manual suits for next models

5

Table of contents

Other Norton Clipper Saw manuals

Norton Clipper

Norton Clipper Pro-Cut BBM307 User manual

Norton Clipper

Norton Clipper C914P User manual

Norton Clipper

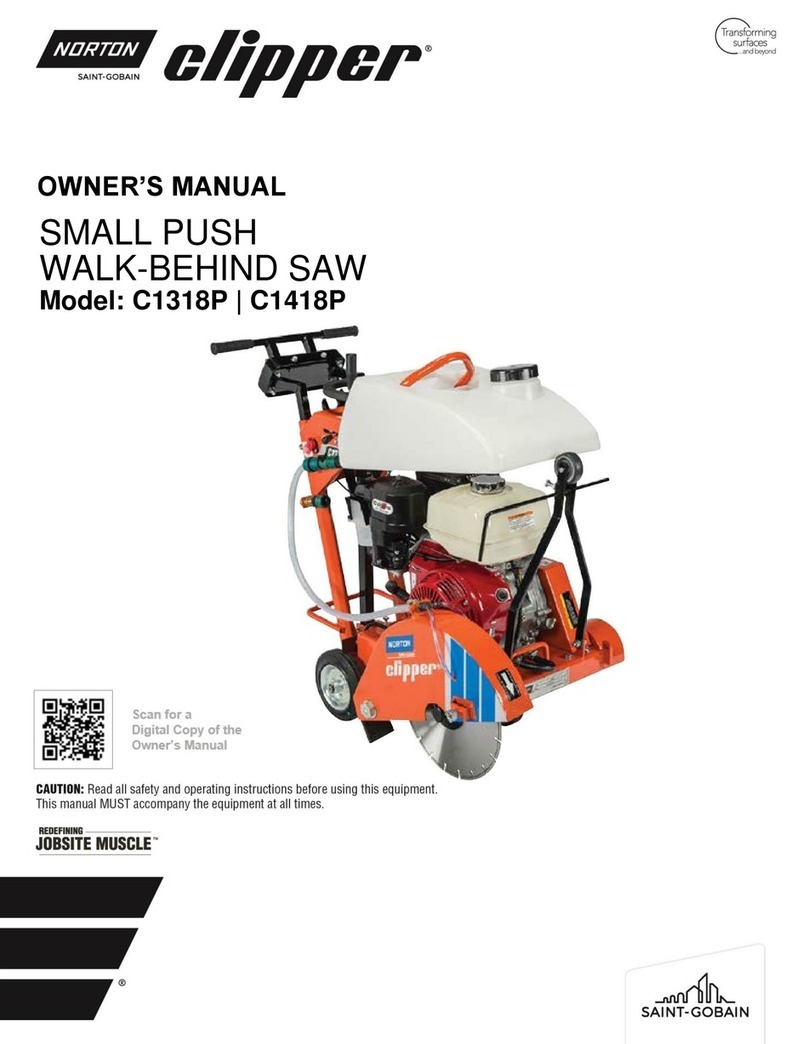

Norton Clipper C1318P User manual

Norton Clipper

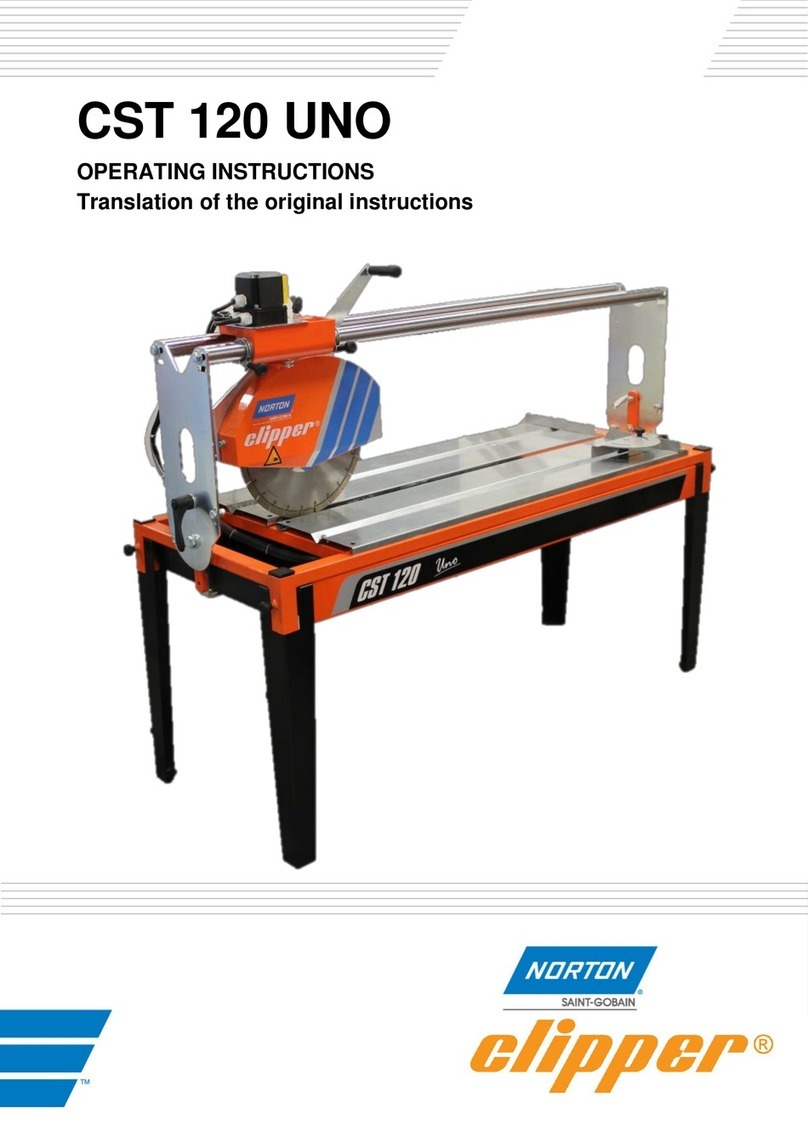

Norton Clipper CST 120 UNO User manual

Norton Clipper

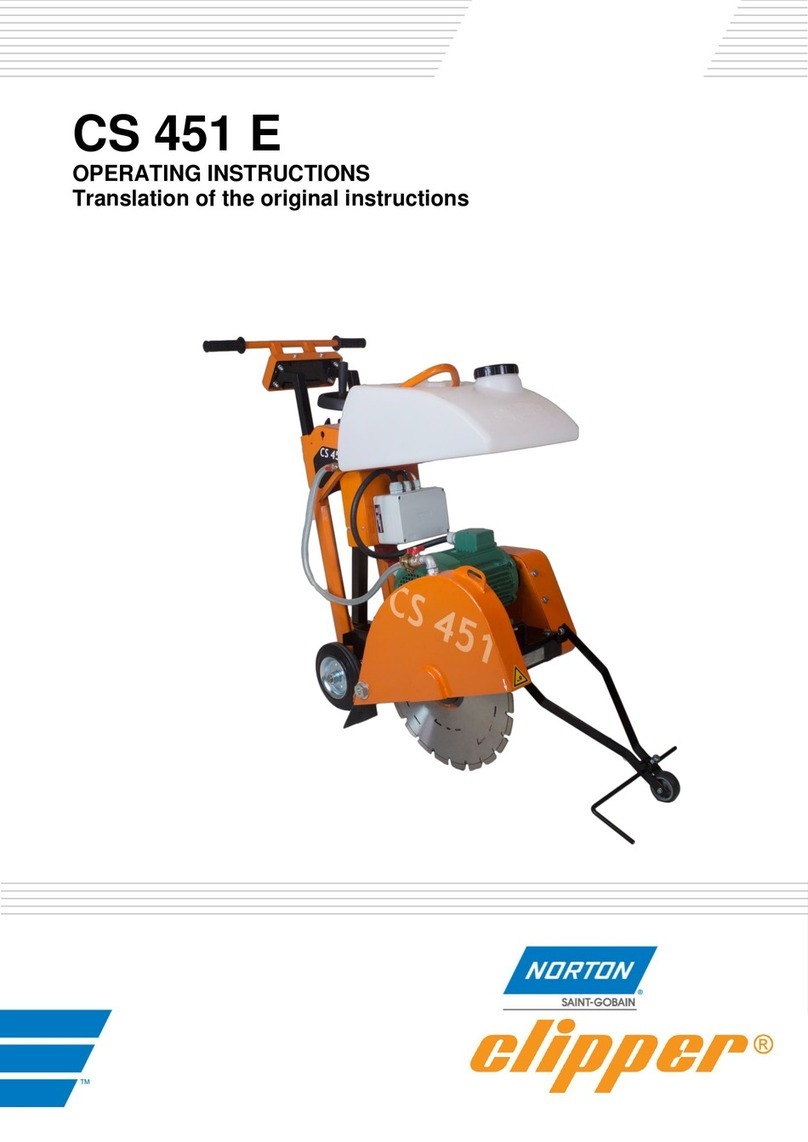

Norton Clipper CS 451 E User manual

Norton Clipper

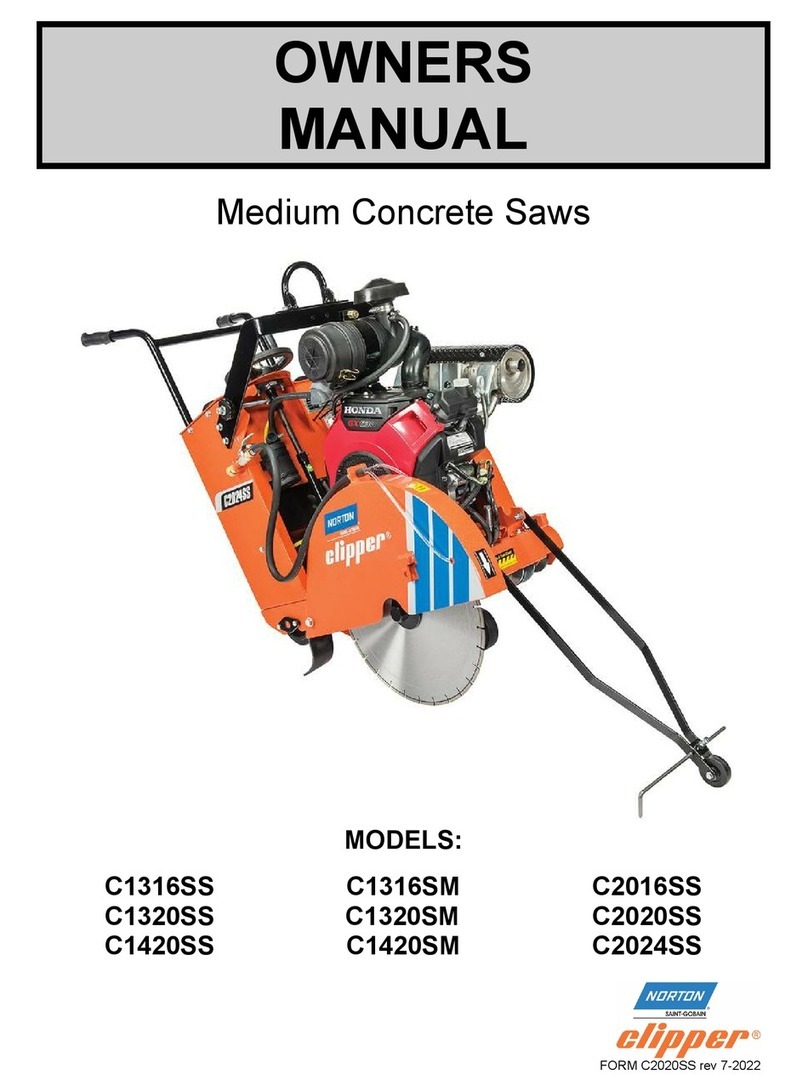

Norton Clipper C1316SS User manual

Norton Clipper

Norton Clipper C914P User manual

Norton Clipper

Norton Clipper CM 601 User manual

Norton Clipper

Norton Clipper CE414-350 User manual

Norton Clipper

Norton Clipper CM 41 User manual