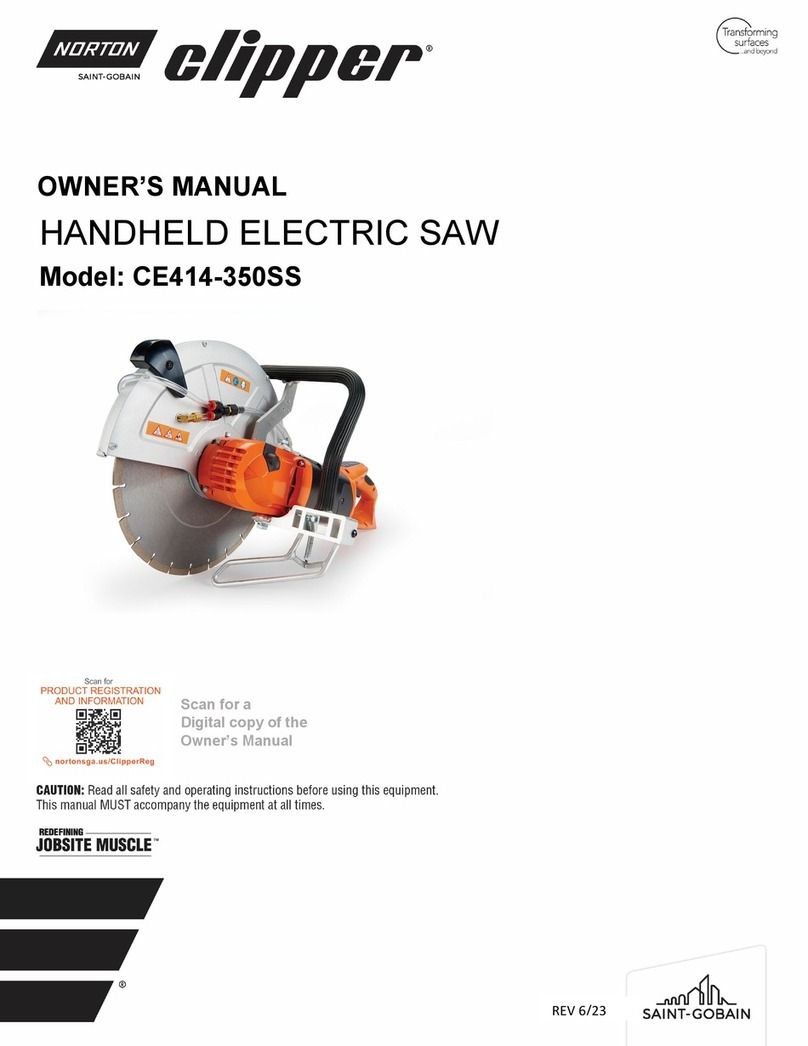

Norton Clipper CE414-350 User manual

ENGLISH 1

OWNERS

MANUAL

High Speed Hand Held Electric

Models:

CE414-350

FORM: CE414-350 rev 5-2016

ENGLISH 2

WARRANTY

Norton warrants all products manufactured by it against defects in workmanship

or materials for a period of one (1) year from the date of shipment to the

customer.

The responsibility of Saint-Gobain Abrasives under this warranty is limited to

replacement or repair of defective parts at Saint-Gobain’s, Plainfield Indiana

facility, or at a point designated by it, of such part as shall appear to us upon

inspection at such point, to have been defective in material or workmanship, with

expense for transportation borne by the customer.

In no event shall Saint-Gobain Abrasives be liable for consequential or incidental

damages arising out of the failure of any product to operate properly.

This warranty is in lieu of all other warranties, expressed or implied, and all such

other warranties are hereby disclaimed.

Important: Before placing equipment in operation, record the following information:

MODEL:_________ SERIAL NO.___________

PURCHASE FROM: _____________________

ADDRESS: ____________________________

CITY_______ STATE ______ ZIP ________

TELEPHONE NO. ______________________

Before using this equipment, make sure that any person using it

reads and understands the instructions in this owner’s manual.

ENGLISH 3

Instruction Manual Electric Hand Held High Speed Saw CE414-350

Dear customer

Thank you for purchasing this quality product from Saint-Gobain Abrasives.

For many decades, we have been a producer of professional duty construction equipment. Each of

our products has been rigorously tested to withstand use of the everyday professional operator and to

meet all safety regulations.

With the main body composed primarily of high quality aluminium and reinforced plastic components

our products promise long service life with minimal down time.

We know you will be satisfied with your purchase because we have put a lot of care and attention to

the assembly and testing of your product.

Before operating this machine, read and fully understand these operating instructions and

always observe all safety regulations and instructions. If you have any further questions

after reading these operating instructions, contact Saint-Gobain Abrasives customer service

at 800-554-8003.

Observe the maintenance guidelines closely to ensure the long service life and safe

operation of your equipment

Table of Contents

ENGLISH 4

1Information about these operating instructions .............................................................................. 5

1.1Notational conventions used in the operating instructions ........................................................... 5

2Warning, Instruction and Notice Icons.............................................................................................. 5

3Safety Provisions ................................................................................................................................ 8

3.1Correct Use .................................................................................................................................. 8

3.2General Safety Notes................................................................................................................... 8

Dust and Silica Warning............................................................................................................... 7

3.3Prescribed Work Clothing / PPE (Personal Protection Equipment).............................................. 8

3.4In Transport.................................................................................................................................. 9

3.5Before Use.................................................................................................................................... 9

3.6Electrical Safety............................................................................................................................ 9

3.7During Work.................................................................................................................................. 9

4Power Tool Description and Features............................................................................................. 13

4.1Technical Data............................................................................................................................ 13

4.2Scope of Delivery ....................................................................................................................... 14

4.3Important Operating and Function Features............................................................................... 14

4.4Power trigger usage ................................................................................................................... 15

4.5Electrical safety system.............................................................................................................. 16

5Preparing for Use .............................................................................................................................. 17

5.1Installing/Removing the Blade.................................................................................................... 17

5.2Adjusting the Blade Guard.......................................................................................................... 18

5.3Water Connection for Wet Cutting.............................................................................................. 18

6Power Tool Use ................................................................................................................................. 19

6.1Cutting Blades............................................................................................................................ 18

6.2Permissible Cutting Area and Danger From Kickback or Drawing Along................................... 20

6.3Working Behaviour and Working Technique.............................................................................. 21

6.4Cutting Metal .............................................................................................................................. 21

6.5Cutting Concrete/Masonry Materials.......................................................................................... 21

7Operating and Maintenance Notes .................................................................................................. 22

7.1Cleaning and Care...................................................................................................................... 22

7.2Replacing the Carbon Brushes................................................................................................... 23

7.3Using the Kick Stand.................................................................................................................. 24

8Warranty............................................................................................................................................. 25

9Service Parts...................................................................................................................................... 25

Table of Contents

ENGLISH 5

These operating instructions are an integral part of the motor device.

They contain important information and instructions for handling the motor device. Always

follow any specified safety regulations and instructions, as they are a prerequisite for

ensuring that you are working safely with the equipment.

These operating instructions must be kept available at the place of use of the equipment at all

times, and they must be read carefully by everybody who works on or with the equipment

(including for maintenance, care and repairs).

These operating instructions must only be used as operating instructions for the motor device

CE414-350. Any utilisation of the contents (text and graphics illustrations) – even in excerpts –

without our prior written consent shall be forbidden and may be prosecuted.

Text highlights

Xxxxx Underlined text marks interim headlines.

Xxxxx Text in italics marks advice and notes that facilitate use of the motor device for the user.

1 Xxxxx Numbered text with a black background marks main chapter headlines.

1.1 Xxxx Numbered text with a grey background marks main subchapter headlines.

Xxxxxxx Frames mark especially highlighted sections.

Structure

The operating instructions are structured by numbered main and subchapters. The table of contents

on page 4 shows an overview of the structure.

Header

To make it easier for the user to find the chapters, the header names the main chapter to which the

content on the respective page belongs.

Pictures and diagrams

Some graphical illustrations in these operating instructions are schematic illustrations or principle

illustrations and may not show exactly your device model. The conveyed contents, however, are

binding in any case.

Important: If one or several icons in these operating instructions are centred and directly below a

chapter header the notice applies for the entire chapter.

1 Information About These Operating Instructions

1.1 Notational Conventions Used in the Operating Instructions

2 Warning, instruction and Notice Icons

ENGLISH 6

Warning, Instruction and Notice Icons used in the Operating Instructions and on the Equipment:

Danger! Failure to comply with the instructions could cause accidents with potentially life-

threatening injuries

Caution! Failure to comply with the instructions could result in damage to the equipment or other

material damage

Carefully read the operating instructions. This applies before taking the equipment into operation

and before any cleaning, maintenance or assembly work.

Always wear the prescribed clothing. Chap. 3.3, page 9

Always wear sturdy shoes with good grip.

Wear safety gloves. This applies to all work with or on the equipment

Before use, put on helmet, ear defenders and a visor.

Switch off the motor!

Noise level LWA= 100 dB(A).

Never continue work with damaged cutting discs.

Only use cutting discs approved for a speed of ≥3.900 rpm (min-1)

Attention: Kickback!

Notes in chap. 6.2 as of page 20 must be observed under all circumstances!

Attention: Danger of fire from sparks.

Wear breathing protection.

Do not use circular saw blades.

ENGLISH 7

Dust and Silica Warning

Grinding/cutting/drilling of masonry, concrete, metal and other materials can generate dust, mists

and fumes containing chemicals known to cause serious or fatal injury or illness, such as respiratory

disease, cancer, birth defects or other reproductive harm. If you are unfamiliar with the risks

associated with the particular process and/or material being cut or the composition of the tool being

used, review the material safety data sheet and/or consult your employer, the material

manufacturer/supplier, governmental agencies such as OSHA and NIOSH and other sources on

hazardous materials and make certain to comply with all product warnings and instructions for the

safe and effective use of the material being cut. California and some other authorities, for instance,

have published lists of substances known to cause cancer, reproductive toxicity, or other harmful

effects.

Control dust, mist and fumes at the source where possible. In this regard use good work practices

and follow the recommendations of the manufacturer/supplier, OSHA/NIOSH, and occupational and

trade associations. Water should be used for dust suppression when wet cutting is feasible. When

the hazards from inhalation of dust, mists and fumes cannot be eliminated through engineering

controls such as either vacuum and/or water mist, the operator and any bystanders should always

wear a respirator approved by NIOSH/MSHA for the material being cut.

California Proposition 65 Message

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contain chemicals known (to the State of California) to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• Lead, from lead-based paints

• Crystalline silica, from bricks and cement and other masonry products

• Arsenic and chromium, from chemically treated lumber

For Addition Information Consult The Following Sources:

http://www.osha.gov/dsg/topics/silicacrystalline/index.html

http://www.cdc.gov/niosh/consilic.html

http://oehha.ca.gov/prop65/law/P65law72003.html

http://www.dir.ca.gov/Title8/sub4.html

Use Approved:

Eye Protection Hearing Protection Respiratory

Protection

Head Protection

ENGLISH 8

This power tool must only be used to cut/shorten metals (hot cut) and mineral materials, such as

concrete, masonry products (brick, block, pavers), with the cutting blade approved for the material

and only for the working situation indicated in chap. 6 on page 19.

For specifically trained users in rescue missions, other approved cutting discs are also offered that

can be used to cut various composites. These special applications are only permitted to specifically

trained users.

This power tool can be used for indoor or outdoor work.

Use of this power tool for any other purpose, such as sawing of wood and to remove/grind off a

material with the side surfaces of the blade is forbidden. Use of cutting tools, such as wood saw

blades (which have a positive rake angle) or knives, must not be installed or used with this product

disc.

WARNING Read all safety warnings and all instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b. Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the

dust or fumes.

c. Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric shock.

b. Avoid body contact with earthed or grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is increased risk of electric shock if your body is

earthed or grounded.

c. Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e. While operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f. If operating a power tool in a damp location is unavoidable, use a ground fault

circuit interrupter (GFCI) protected supply. Use of an GFCI reduces the risk of

electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools

may result in serious personal injury.

3 Safety Provisions

3.1 Correct use

3.2 General Power Tool Safety Warnings

ENGLISH 9

b. Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

c. Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have

the switch on invites accidents.

d. Remove any adjusting key or wrench before turning the power tool on. A wrench

or a key left attached to a rotating part of the power tool may result in personal injury.

e. Do no overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f. Dress properly. Do no wear loose clothing or jewellery. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewellery or long hair can be

caught in moving parts.

g. If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b. Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventative safety measures reduce the risk of starting the power

tool accidentally.

d. Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e. Maintain power tools. Check for misalignment or bindings of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g. Use power tool, accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from these intended could

result in hazardous situation.

5. Service

a. Have your power tool serviced by a qualified repair person using only identical

replacement parts. This ensure the safety of the power tool is maintained.

In order to prevent injuries, please make sure that you wear the prescribed clothing and protective

equipment.

Clothes should be tight-fitting (no labels), but not hindering. When performing any work,

wear a working suit of firm materials with sufficient flame resistance so that cannot catch fire

by sparks flying (materials of leather, cotton after flame-inhibiting treatment or heavy close-

meshed linen fabrics).

Check the information in the work clothes and ensure that no flammable materials and no easily

melting materials like polyester or nylon are contained in the clothes. The working clothes must

never be contaminated with flammable substances such as petrol or similar.

3.3 Prescribed Work Clothing / PPE (Personal Protection Equipment)

ENGLISH 10

Never wear scarves, ties, jewellery or other clothes that may get caught in the cutting disc or blade,

or objects in the environment, or the power tool. Tie back long hair and secure it under a helmet.

Wear a protective helmet during any work. Use personal hearing protection.

Eye/face protection is mandatory pursuant to ANSI Z 87.1.

Wear firm safety shoes with steel toes and a good grip.

Wear protective gloves with non-slip palms.

Use breathing protection for dry cutting as protection from dust.

Before carrying the power tool (even for short distances), always switch off the motor, wait until

the cutting disc has stopped, and disconnect the power supply. Carry the power tool by the top

handle and have the cutting blade facing down and to the rear. Never carry the power tool by the

power cable.

Never carry or transport the power tool with the cutting disc or blade turning.

Advice: We recommend that you keep the original packaging in order to protect the equipment

against transport damage in case you ever need to ship it or transport it.

Before starting, check the entire power tool for operationally safe condition such as:

The power trigger must move freely and return automatically to the idle position where the auto

lock can engage fully. It must not be possible to operate saw without pushing (unlocking) the

power trigger.

The cutting blade/disc must be attached firmly to the spindle.

In case of irregularities, recognisable damage, improper settings or limited function, the power unit

must not be started. In such cases, have the power tool inspected by specialist workshops

authorised by us.

Only use the power tool if it is in completely assembled condition.

All guards/cowl should be in place. Never use the machine if they have been removed!

Keep at least 3 metres distance from any flammable material when operating this machine.

Plug the power tool into the appropriate matching grounded outlet. Do not attempt to adapt the

plug head to use with a non matching outlet.

Avoid contact with earthed or grounded surfaces to avoid electric shock.

3.4 In Transport

3.5 Before Use

3.6 Electrical Safety

ENGLISH 11

Keep the power tool away from water. Do no leave the machine outside where it may be rained

upon. Water exposure will increase the risk of electric shock.

Do not pressure wash or wash the machine. Water exposure will increase the risk of electric

shock.

Do not carry the tool by the power cord. Do not use the machine if the cord is damaged. A

damaged cord will increase the risk of electric shock. If damaged have the cord repaired by a

certified technician immediately.

Use extension cables with the correct length and gauge. Refer to section 4.1 and view the

recommended extension cable chart if not known what type of extension cable to use.

Keep extension cables unravelled during use to maintain the power tool’s efficiency.

Only use undamaged extension cables to reduce the risk of electric shock.

When operating the power tool, make sure the power cable is always behind you.

Do not use the power tool if the power trigger does not turn on the motor. A malfunctioning power

switch should be repaired by a certified technician.

ENGLISH 12

In addition to the safety provisions already listed, the following safety provisions also apply when

working with the motor device:

Secure the workplace against accidental access by third parties, e.g. with warning signs. Only

persons involved and wearing protective clothes must be present within 100’ (30 m) around the

working area.

Check the site of deployment for possible dangers.

– If spark created during cutting work must never be performed close to potentially explosive

gases of liquids, or easily flammable objects.

– No electrical lines must be placed in the area to be cut.

– Objects that may fall off or topple over during work must be secured or removed from the

working environment first.

– Prepare the workplace so that secure backing away is possible.

The work piece to be cut must be free of foreign bodies such as screws, nails or stones.

When working in residential areas, observe the noise protection provisions.

Work carefully, considerately and calmly and do not endanger any other persons.

– Ensure good vision and light conditions.

– Always remain within calling distance of other persons who may administer first aid in

emergencies.

– Put in working breaks in time.

– Be attentive towards possible danger sources and take the corresponding preventive

measures. Consider that use of hearing protection limits perception of sounds. Signal

sounds, calls, etc. that announce danger may also be missed.

– Observe tripping dangers and obstacles. Never work on unstable surfaces.

– Always hold on to the power tool with both hands and always ensure a safe and firm stance.

– Never cut standing on a ladder.

– Guide the power tool so that no body part is located in the extended swivel range of the cutting

disc.

– Only process the work piece to be cut with the cutting disc running; never touch the floor or

other objects with the cutting disc running.

– Do not use the power tool to lever off and shovel away objects.

Switch off the motor when the power tool starts to behave noticeably differently.

Danger of hearing damage!

3.7 During Work

ENGLISH 13

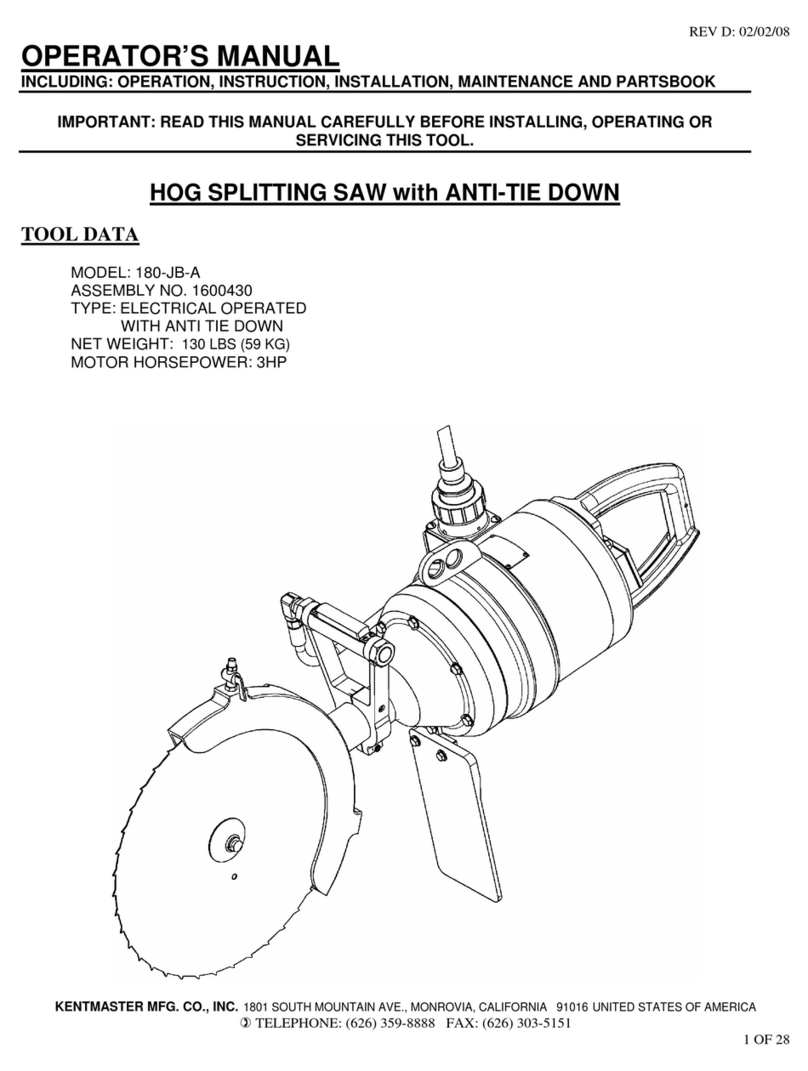

Model C414-350

Motor Brush Motor

Power Amp 15

Voltage V 115

Hertz hz 60

Spindle Diameter in / mm 0.787 (20mm)

Spindle Diameter with Bushing in / mm 1 (25.4)

Blade Shaft Speed rpm 3,900

Blade Flange Diameter in / mm 4 (100)

Sound of Motor Without Cutting Blade dB 100 dB

Maximum Blade Diameter in / mm 14 (350)

Cutting Depth in / mm 5 (125)

Dimensions Height x Width x Length in / mm 11.1 (282) h x 11.3 (286) w x 28.7 (730) l

Weight without cutting disc lb / kg 22.4 (10.2)

Recommended Extension

Cables

12 AWG 50’

10 AWG 75’

8 AWG 100’

4 Power Tool Description and Features

4.1 Technical data

ENGLISH 14

Machine CE414-350

Tool: Universal Wrench

Operating instructions

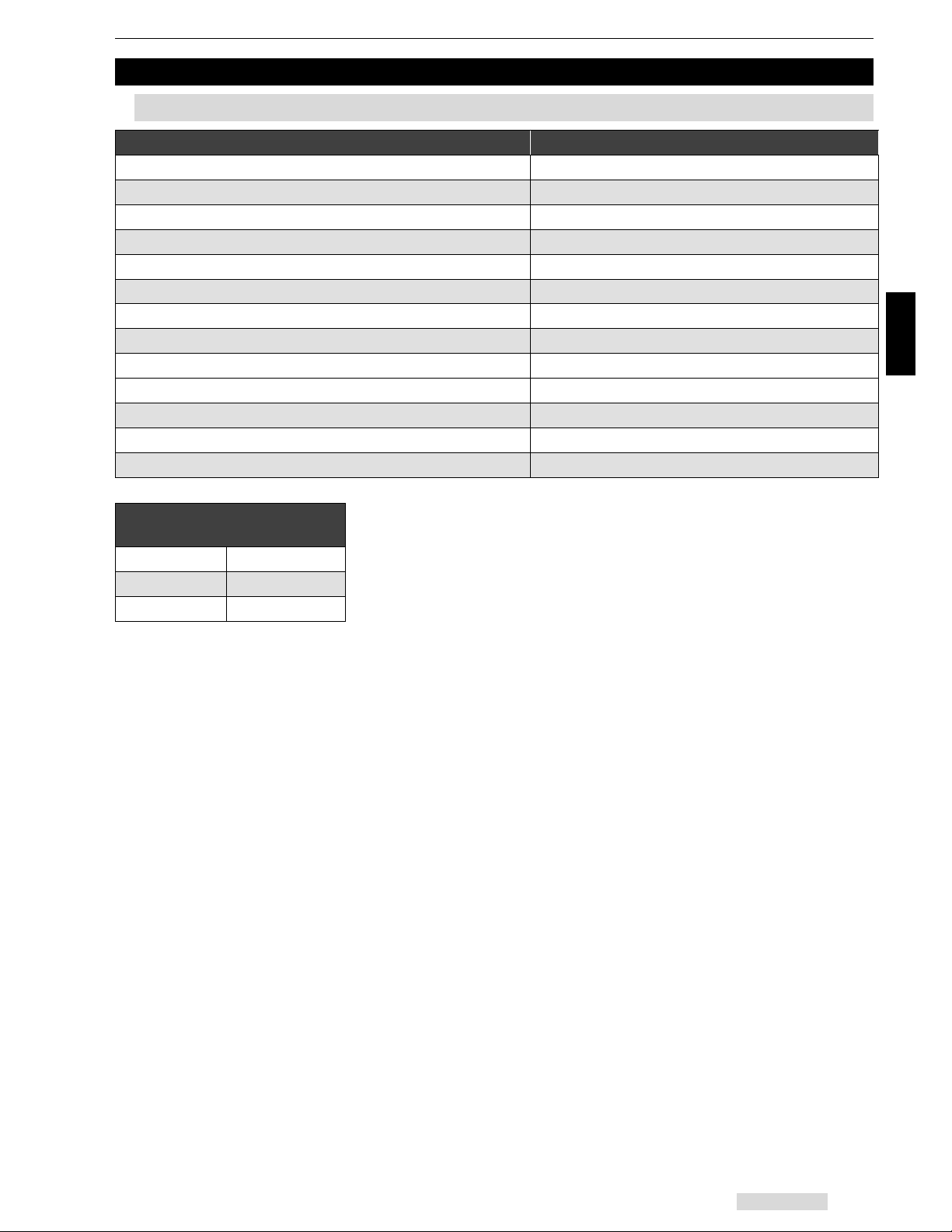

1. Cutting Blade 10. Carbon Brush Cover

2. Blade Guard 11. Blade Shaft Screw

3. Grip for Blade Guard Adjustment 12. Power Cable

4. Top Handle 13. Water Hose to Coupling

5. Water Hose 14. Water Coupling Connection (Wet Cutting)

6. Rear Handle 15. Power and Overload Indicator

7. Spindle Lock Button 16. Circuit Breaker

8. Kick Stand 17. Power Trigger Lock

9. Trigger Assemble 18. IC Board

4.2 Scope of Delivery

4.3 Important Operating and Function Features

1

3

5

2

8

10

7

4

15

6

9

13

8

ENGLISH 15

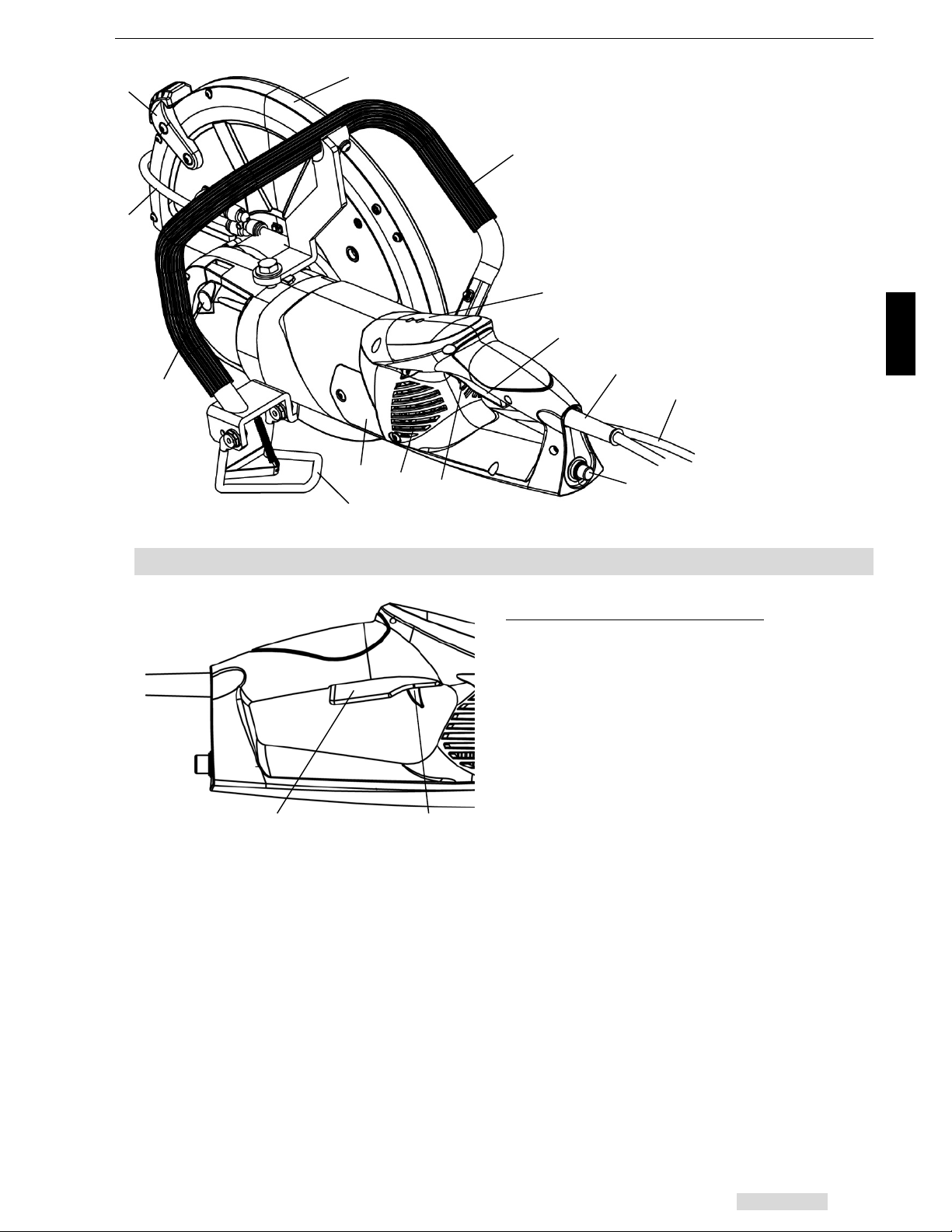

Testing functionality of power trigger

To test the power trigger, connect the machine to

the correct power supply, grasp the handle to

position your fingers next to the power trigger.

Using the index finger and push to disengage the

lock trigger (17), shown on the left. With the lock

disengaged, pull the power trigger up (9) and

then release. The motor should turn on and then

off when the trigger is released.

If the motor does not turn off or blade does not

stop spinning, have the switch assembly serviced

immediately by a certified technician. In the

mean time discontinue use of the power saw.

The power trigger lock should also be tested.

This time pull the power trigger only (9). If the

motor turns on then the lock trigger is damaged

and needs to be serviced. Have the switch

assembly serviced by a certified technician. In

the mean time discontinue use of the power saw.

4.4 Power Trigger Usage

9 17

3

5

2

7

4

16

9

13

8

10

15

12

17

18

ENGLISH 16

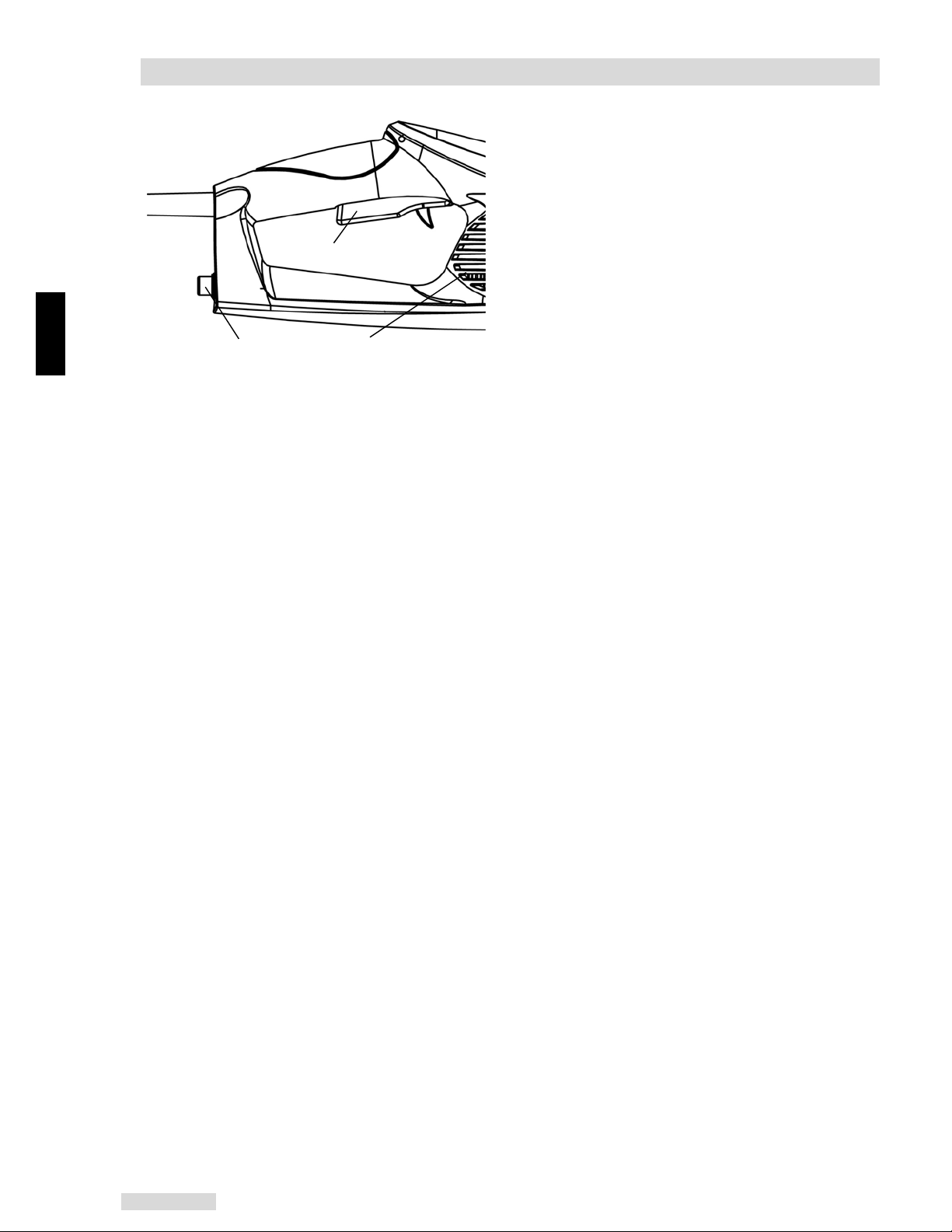

The heavy duty power switch in the power saw is

coupled with two safety features. A soft start

system (18) which prevents unintentional power

trips during start-up, and overloads. Source of

overload can be from user applying too much

cutting force or from the blade jamming. The

overloaded state has to be reset by releasing the

power trigger (a) and then depressing it once again

to return power to the motor. Before performing the

reset, the source of overload should be corrected.

A second safety device that runs in tandem with

this system is a traditional non fuse circuit breaker

(b). To reset this breaker the user must release the

power trigger and depress the circuit breaker

button located below the power cable. Now power

can be sent to the motor once again.

4.5 Electrical Safety System

16 18

9

ENGLISH 17

The cutting discs used must correspond to the specifications from chap. Error! Reference

source not found. on page Error! Bookmark not defined.!

The power tool uses a 20mm spindle is paired with an adapter blade adapter for use with 1

inch (25.4mm) bore cuttings blade. The components are assembled as shown below, along

with the universal wrench (e) included with the power tool to remove the blade bolt (d).

For blade installation, the power tool must be put securely on the ground and unplugged. With the

power tool handle facing you place left arm on the power tool body and use the correlating hand

to press the spindle lock button (7) shown below. With the free hand use the universal wrench (e)

to turn the blade bolt (d) clockwise, or away from you. Apply slight downward force from the left

arm onto the motor body to keep the tool from moving, if it should:

Remove the blade bolt (d), its washer (c) and outer flange (b). Install the cutting disc (1), and

make sure the bore of the disc slides onto the adapter (a) all the way. Also locate the spinning

direction of the disk and match it with the diagram above’s note. If you are facing the blade guard,

facing the side you are installing the cutting disc from. The disc must rotate clockwise.

Once the cutting disc (1) is properly seated, reinstall the outer flange (b), washer (d) and blade

bolt. Press the spindle lock button (7) again and this time use the universal wrench (e) to turn the

blade bolt counter-clockwise until tight.

5 Preparing for Use

5.1 Installing/Removing the Cutting Disc

1

a

b

c

de

7

Rotating direction

of the cutting disc

ENGLISH 18

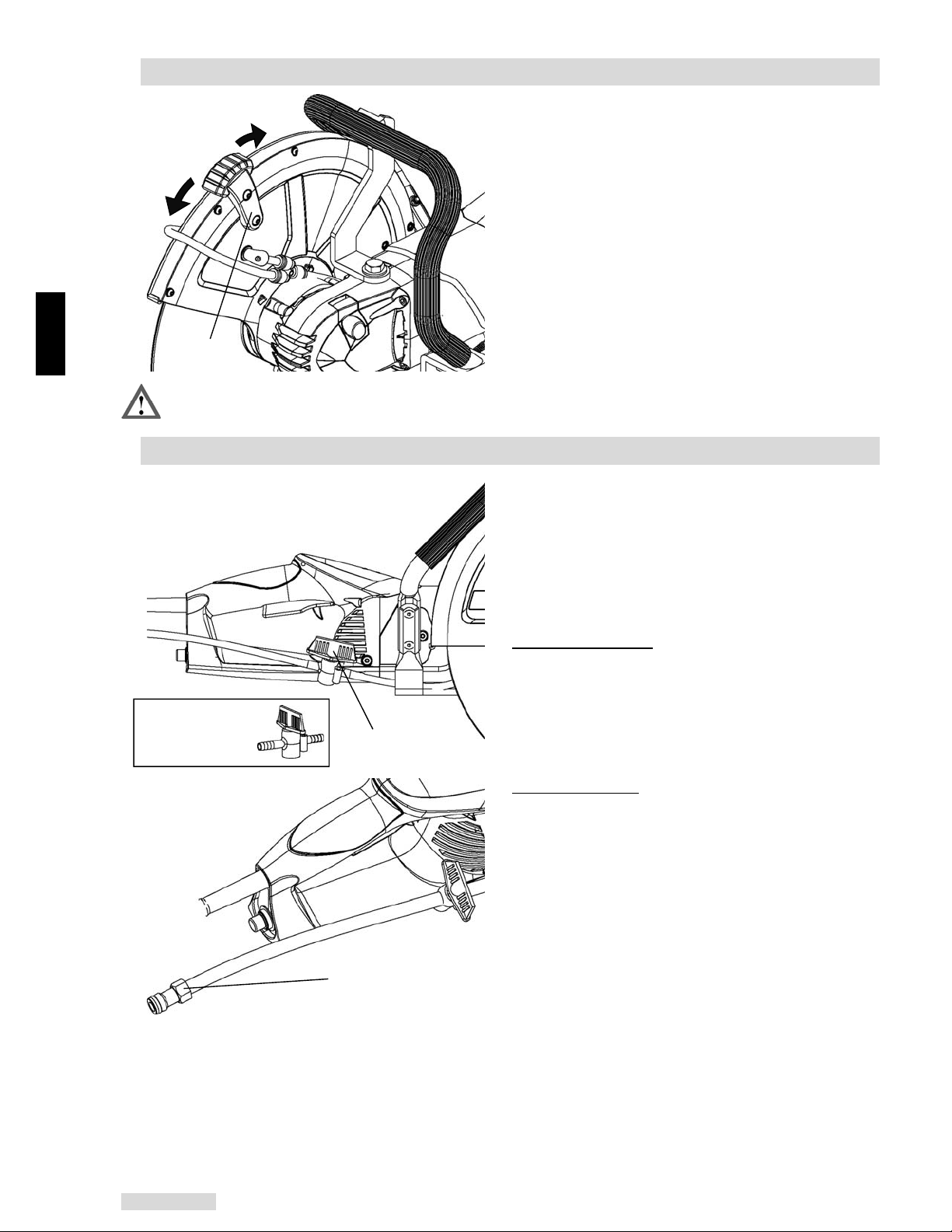

The blade guard shown on left can be swivelled

forward and backward in a limited area.

For adjustment of the blade guard, the power tool

must be put securely on the ground with the power

supply disconnected. Securely hold the power tool

at the top handle (4) with the one hand and push it

firmly onto the ground. With the other hand at the

handle for the blade guard adjustment (2), swivel

the protective cowl accordingly.

To keep sparks and particles from being thrown at

the operator, the blade guard should always be

swivelled forward as far as the working situation

permits.

When adjusting the blade guard ensure that the water supply line is not crimped and that

blade does not contact water supply line.

Lots of fine dust occurs when cutting mineral based

materials. We recommend using the water

connection when using diamond blades suitable for

the material and rated for wet cutting. When cutting

with the water, visibility of the material is improved,

and blade life can increase due to the cooling effect

of the water.

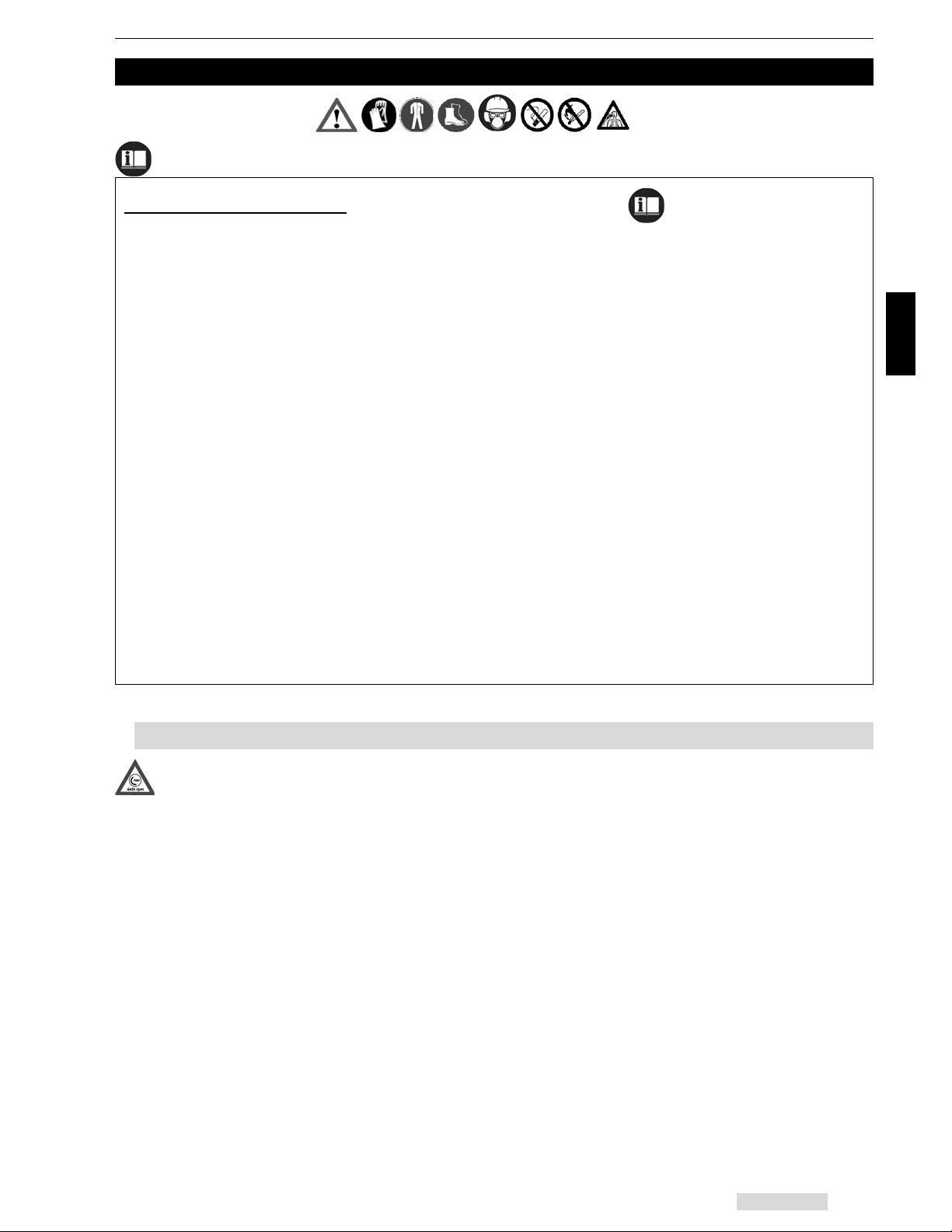

Before Wet Cutting:

Connect suitable water line (maximum 80 PSI) or

suitable pressure tank to the coupling connection

(g).

Operate the valve lever (f) to open or close the

water supply to the desired flow rate.

After Wet Cutting:

Close the water supply, i.e. put the valve lever

perpendicular to the valve body.

Let the cutting disc run at high speed for another

approx. 30 seconds to completely remove the

water.

5.2 Adjusting the Blade Guard

5.3 Water Connection for Wet Cutting

2

f

Rotate to close

the valve (valve

lever across)

g

ENGLISH 19

Always observe all safety instructions and all information in this document before using this

machine!

Check list for use (keywords only!) ...........................................................

Before start-up:

– Power tool in an operationally safe condition! ................................. Operating instructions complete

– Prescribed work clothes ................................................................. Chap. 3.3, page 9

– Working area inspected and secured ............................................. Chap. 3.2, page 8, and

Chap. 3.7, page 9

– Blade installed Correctly ................................................................. Chap. 5.1, page 17, and

Chap.

Error! Reference source

not found.

, page 19

– Blade Guard in best position .......................................................... Chap. 5.2, page 18

During work – generally safe work: ....................................................... Operating instructions complete

– Inspecting the working environment ............................................... Chap. 3.7, page 9,

Chap. 6.2, page 20, and

Chap. 6.3, page 21

– Water connection for wet cutting ..................................................... Chap. 5.3, page 15

– Proper cutting technique ................................................................ Chap. 6.3, page 21,

Chap. 6.4, page 21, and

Chap. 6.5, page 21

After work: ............................................................................................ Operating instructions complete

– Cleaning and care .......................................................................... Chap. 0, page 22

– Replacing the carbon brushes ........................................................ Chap. 7.2, page 20

– Using the flip stand ......................................................................... Chap. 7.3, page 22

–

Maintenance ................................................................................... Operating instructions complete

Only use Diamond Blades that correspond to the standards EN 12413 and EN 13236

and that are perfectly undamaged. The approved maximum speed of the cutting disc

must be ≥4,450 rpm (min-1).

For cutting of metals (hot cutting) and cutting of mineral based materials – block, brick, concrete,

stone (cold cutting), different cutting discs are offered. Use only the blades that are approved for the

material to be cut.

Diamond cutting blades are only approved for cutting mineral based materials. When installing the

diamond blade, always observe the rotating direction indicated on the diamond blade; otherwise, the

cutting effect will reduce quickly from diamond loss.

Rotating direction of the blade in the installation process see: Chap. 5.1, page 17

Synthetic resin based thin wheel cut of blades must not be exposed to moisture. The water

connection for wet cutting must not be used when using synthetic resin cut off blades. Synthetic

resin blades must not be used in high humidity or in rain. Only use synthetic resin blades until the

end of the best-before date imprinted on the blade blotter or shipping box.

The power tool's spindle is designed for cutting discs with an inner bore of 20 mm.

Blades with an 1" inner bore must only be installed with the spindle adapter provided with the

CE414-350. Using other spindle adapters may not allow the blade to be properly secured to the

machine.

Installation of blades with 1" inner bore see: Chap. 5.1, page 14

Blades with other inner bores must not be installed!

6 Power Tool Use

6.1 Blades

ENGLISH 20

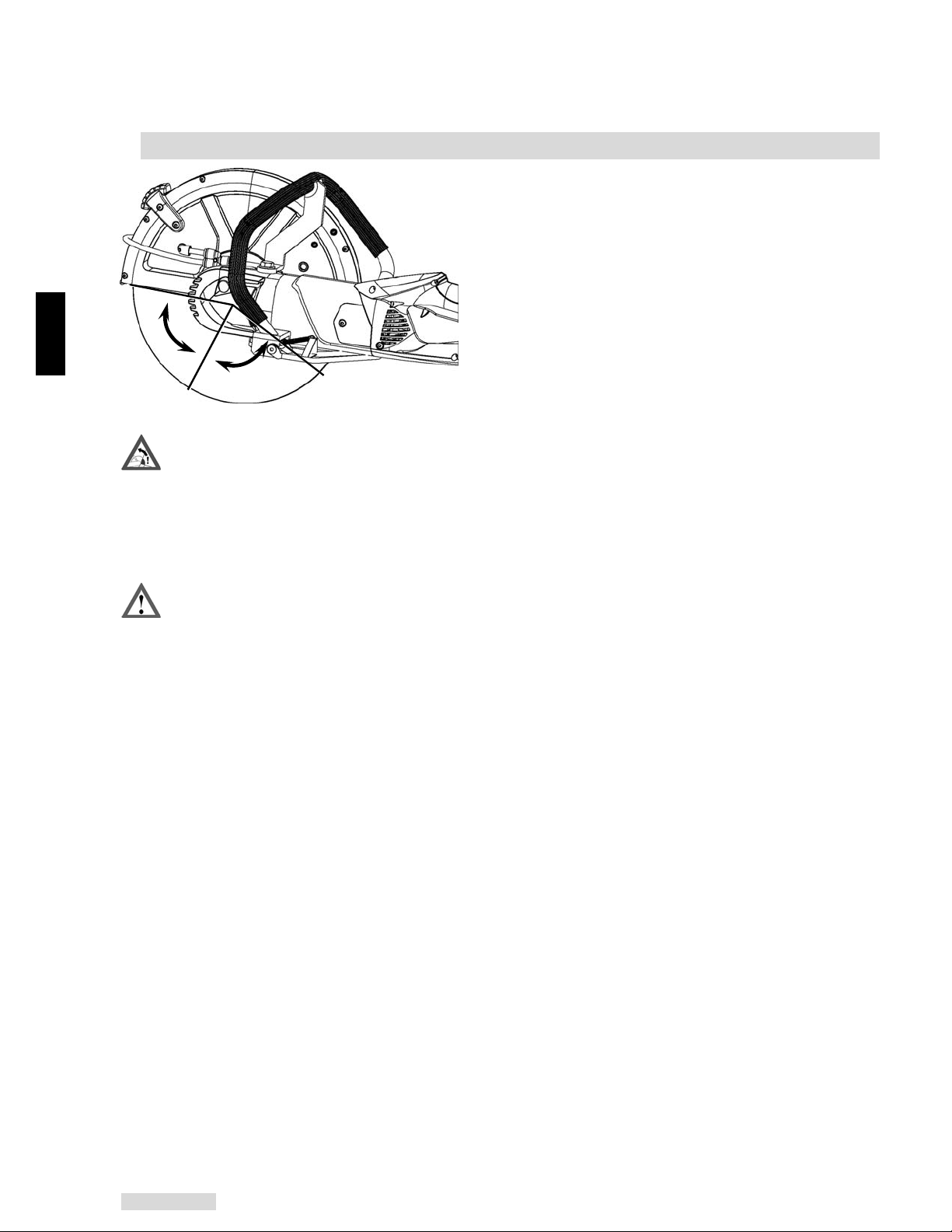

New blades must be tested for at least 60 seconds at the indicated maximum speed before the first

cutting process. Take care that no body parts are in the path of the blade.

The upper part of the blade must not be

used for cutting!

Only the lower part of the blade can be used

for cutting!

Danger of injury from kickback!

Kickback results when the upper part of the blade is used for cutting.

The power tool is can be pushed towards the user's causing lost of operator control which can

result in injury.

Never cut with the upper area of the blade!

Take special care at insertion into cutting areas already started!

Danger of injury from drawing along!

Drawing along results when the cutting path becomes very narrow or from pinching the blade

and the power tool is pulled away from the operator.

The power tool can accelerate away from the operator at high speeds and can result in injury.

Always perform cutting at full rpm and repeated insertion into the cut at points already started.

Always support the work piece so that the cutting point does not move and so that the cutting

blade is not clamped or pinched.

When starting a cut, always carefully move the cutting blade to the work piece; do not force the

blade into the work.

Only cut one item at a time!

Ensure that no other work piece is touched when cutting.

6.2 Permissible Cutting Area and Danger From Kickback or Drawing Along

ok

Table of contents

Other Norton Clipper Saw manuals

Norton Clipper

Norton Clipper C1316SS User manual

Norton Clipper

Norton Clipper C914P User manual

Norton Clipper

Norton Clipper CS 451 E User manual

Norton Clipper

Norton Clipper CM 601 User manual

Norton Clipper

Norton Clipper CB 511 User manual

Norton Clipper

Norton Clipper C914P User manual

Norton Clipper

Norton Clipper CST 100 User manual

Norton Clipper

Norton Clipper C1318P User manual

Norton Clipper

Norton Clipper CWT 450 User manual

Norton Clipper

Norton Clipper CE414-350SS User manual