norweco BIO-DYNAMIC 4000 Series User manual

INSTALLATION AND OPERATION MANUAL

SERIES 4000 TABLET FEEDER

INTRODUCTION

The Bio-Dynamic Series 4000 tablet feeder is a complete dry

chemical dosing system for water or wastewater treatment.

It is designed to provide precise control over chemical

application and to maximize installation exibility. All ve

(5) models of the Series 4000 will treat liquid ows from

20,000 gallons per day (GPD) to 200,000 GPD. For non-ow

equalized wastewater applications, a peak ow factor of four

will allow the feeder to be used in treatment plants with a

design ow of up to 50,000 GPD. Constructed of heavy duty,

UV rated polyethylene for maximum strength and durability,

the feeder is entirely gravity

fed with no electro-mechanical

components. The feeder has

a variable dosage capability

depending upon general

component configuration,

the ow rate and the type of

chemical tablets used. The

Series 4000 tablet feeder is

designed to provide long-term,

unattended operation. To

insure proper performance

and maximize operational

life, please take the time to

familiarize yourself with the

contents of this manual.

SYSTEM APPLICATION

The Series 4000 tablet

feeder is designed for

treatment systems that

utilize 2

5/8" diameter molded

chemical tablets. Applications

include potable water, process

water, wastewater, irrigation,

municipal, reservoirs, water towers, cooling towers, as well as

swimming pool backush dechlorination. The system may be

installed and adjusted for long-term chemical dosage in any

of these applications. Each Bio-Dynamic has an internal fall

of 1" to insure complete drainage of liquid from the ow deck.

A built-in hydrodynamic mixing chamber provides maximum

contact between the applied chemical and the liquid. This

additional treatment step permits the Bio-Dynamic to be

installed without secondary tankage where regulations allow.

HOW THE SERIES 4000 WORKS

Each model of the Series 4000 is a ow rated proportional

feeder designed to safely apply chemicals into the ow of

any treatment system. Flow enters through the integral 6"

inlet hub and is channeled under an adjustable inlet bae.

Liquid proceeds to the ow deck where the chemicals are

contained in four feed tubes. The ow deck has three

levels (tiers) which accommodate varying hydraulic loading

rates and channel liquid to the chemical tablets. Due to the

conguration of the ow deck, the tablet feeder can eectively

treat low, sustained, variable, intermittent and surge ows.

Active chemicals are released

as the liquid erodes the tablets.

As the ow rate increases,

the liquid level rises and

contacts more tablets, thereby

providing additional chemical

release. The liquid is then

channeled through an outlet

weir or optional sluice to further

regulate chemical application

by controlling the liquid depth

within the system. Properly

treated liquid then ows out of

the tablet feeder through the

integral 6" outlet hub.

SYSTEM PERFORMANCE

A proven disinfection device for

use with any treatment system,

the Bio-Dynamic is listed as

a certied chlorine dispenser

under NSF/ANSI Standard 46.

The Series 4000 tablet feeder

is rated for ows up to 200,000

GPD, however, Standard 46

applies only to secondary euent from residential wastewater

treatment systems up to 1,500 GPD. Certication requires

the use of Blue Crystal residential disinfecting tablets or Bio-

Sanitizer disinfecting tablets and a chlorine contact tank of

at least 111/2 gallons. Contact tank retention time should be

sucient to comply with the controlling regulatory jurisdiction.

USEPA guidelines state “On the average, satisfactory

disinfection of secondary wastewater euent can be obtained

when the chlorine residual is 0.5 ppm after 15 minutes contact.”

SERIES 4000 TABLET FEEDER

GENERAL INSTALLATION INSTRUCTIONS

The Bio-Dynamic Series 4000 tablet feeder can be installed in any treatment system, including direct burial, in-line and contact

chamber mounting. The integrally molded inlet and outlet hubs allow direct connection to 6" Schedule 40 PVC piping. A

standard coupling is required to make the connection watertight. If the treatment system piping is not 6", adapter couplings

should be used. The system is self-draining and must always be installed plumb and level to insure proper operation. Place

a bubble level on the feeder before nal installation to conrm that the unit is plumb and level. For wastewater chlorination

applications, the feeder should be installed downstream of the treatment system but upstream of the chlorine contact tank.

For dechlorination applications, the feeder should be installed at a location immediately downstream of the chlorine contact

tank. The Bio-Dynamic data chart at the bottom of this page lists the dimensions of the dierent models in the 4000 Series.

INSTALLATION AT GRADE

The tablet feeder can be installed at grade, in-line, or mounted in the contact tank of a water or wastewater treatment system. The

installation should be accessible for routine maintenance. To mount the unit, use 3/8" diameter corrosion resistant bolts to secure the

four integrally molded mounting feet to the deck of the contact tank, concrete pad or mounting brackets, as required. For contact

tank installations, use PVC or aluminum mounting brackets to prevent corrosion. To protect the system from ow back-up during

a severe hydraulic surge, there must be a minimum of 3" free fall from the unit outlet to the liquid level in the tank. After bolting the

unit in place, check for level from side to side and end to end to conrm that fall through the system has been maintained. Make

sure the feeder and all other treatment processes are secured for safety and to prevent unauthorized access.

DIRECT BURIAL INSTALLATION

The tablet feeder may be installed below grade without a

manhole or secondary enclosure. The internal fall through

the system and molded outlet hub eliminate the need for an

external drop box. Safety/reinforcing struts are included in all

direct burial models to insure system safety and strength. To

install the tablet feeder in a direct burial application, prepare

the excavation to 4" below the operational depth. Install a

sand or ne gravel pad 4" thick and be sure that the pad is

level. Place the feeder in the excavation and connect the inlet

and outlet hubs using the proper couplings. Place each of

the safety/reinforcing struts in position. When only two struts

can be used, they must be side by side in the top retaining

bosses adjacent to the feeder lid. Check the system for level

and then carefully backll the installation. When complete,

the top of the tablet feeder lid must be at least 6" above grade

to prevent groundwater inltration. Remote removal systems

are included with each Model ITR 4000-S to allow access to

feed tubes in direct burial installations.

BIO-DYNAMIC®SERIES 4000 DATA CHART

2

CHAMBER MOUNTING BRACKETS

Model Length Width Feeder Body Height

Minimum Maximum

Fixed Adjustable Installation Drawing

Weir Sluice Position Number

XT 4000 35¾" 14½" 12" 18" Yes No At Grade PC-5-9503

XT 4000-S 35¾" 14½" 12" 18" Yes Yes At Grade PC-5-9503

ITR 4000-S 35¾" 14½" 30" 120" No Yes Direct Burial PC-5-9505

IT 4000-S 35¾" 14½" 24" 24" No Yes

IT 4000 35¾" 14½" 24" 24" Yes No At Grade or

Direct Burial PC-5-9504

PC-5-9504

At Grade or

Direct Burial

ACCESS RISERS

On below grade installations, 24" access risers are available that connect directly to the feeder body and utilize the standard lid. Drive

rivets and sealant are provided with each riser to properly secure and seal the riser joint. The feeder and risers have drill points for

placement of the drive rivets. Sixteen drive rivets connect the riser assembly. To install a riser, snap the riser section onto the feeder

body. Using a 1/4" bit, drill completely through the riser and feeder at the drill point on the left-hand inlet end. Install a drive rivet in

this hole and tap the stem ush. Check the feeder and riser from side to side to be sure they are vertically aligned. Drill a hole in

the right-hand inlet end, opposing the rst. Install the second drive rivet. Level the riser and feeder from end to end and drill the drill

point on the left-hand outlet end. Install the drive rivet and repeat same on right-hand outlet end. Recheck alignment side to side

and end to end. Now that the corners are secure, drill and install the remaining drive rivets along each side of the system. Seal the

joint inside and outside according to the directions on the sealant label. Bio-Dynamic sealant is specially formulated and will not

chemically react with chlorine tablets. Do not use other sealant products. Allow the sealant to cure for 24 hours before lling the

feed tubes. Multiple risers may be used to allow deeper installation. Repeat these instructions for each additional riser installed.

Four safety/reinforcing struts are installed in each riser. To insure system strength and to prevent entry into the access risers,

one strut must be located every 12" of system depth. Trim lines are located at 6" vertical increments on the feeder and riser

to allow reduction of system height. Remove the lid and feed tubes before trimming the unit. Cut only along the trim line and

remove all burrs and ash around the entire top of the unit. Reinstall any struts from the cut o section into the newly trimmed

body and riser. Two side by side struts must be installed in the top retaining bosses adjacent to the unit lid.

SELECTING COMPONENT CONFIGURATION

The anticipated ow rate and desired chemical application rate of the system should be estimated to properly congure the

tablet feeder for operation. The plant ow rate can be determined by engineering design estimates or by using a system ow

meter, lift station capacity with number of pumping cycles, ow counter or water meter records. The adjustability of an inlet

bae and outlet weir or sluice gives Bio-Dynamic Series 4000 tablet feeders much greater control over chemical application

than standard xed-weir tablet feeders. The adjustability of the Series 4000 will allow the plant operator to control chemical

application by adjusting weir width and bae height without changing the position or number of feed tubes. Once the feeder is

on-line, the primary methods used to regulate chemical dosage are to modify the weir or sluice width and/or adjust the inlet bae.

BIO-DYNAMIC®SERIES 4000 TABLET FEEDER COMPONENT CONFIGURATION

The feeder component chart above denes the preliminary conguration for inlet bae, weir and sluice to satisfy the diering

ow rates, chlorine demands and desired residuals as shown. These gures assume 70% available chlorine, as in Bio-Sanitizer

chlorination tablets. In applications other than wastewater chlorination, regulate chemical dosage by changing the system

conguration according to the results of euent samples taken. The built-in exibility of the Series 4000 tablet feeder should

be utilized for nal adjustments after the system is placed into operation and chemical dosage samples can be taken.

3

Flow

(GPD)

20,000

25,000

30,000

35,000

40,000

45,000

50,000

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1.0

1.5

2.0

1"

1"

1"

1"

1"

1"

2"

2"

2"

2"

2"

2"

2"

2"

2"

3"

3"

3"

3"

3"

3"

1½

1½

1½

1¾

1¾

1¾

2

2

2

2¼

2¼

2¼

2½

2½

2½

2¾

2¾

2¾

3

3

3

1¾

1¾

1¾

2

2

2

2¼

2¼

2¼

2½

2½

2½

2¾

2¾

2¾

3

3

3

3¼

3¼

3¼

2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

3"

3"

3"

3"

3"

3"

3"

3"

3"

1"

1"

1"

2"

2"

2"

2"

2"

2"

2"

2"

2"

3"

3"

3"

3"

3"

2"

3"

3"

3"

2-2¼"

2-2¼"

1¾-2"

2-2¼"

2-2¼"

1¾-2"

2-2¼"

2-2¼

1¾-2"

2-2¼"

2-2¼"

1¾-2"

2¾-3"

2½-2¾"

2¼-2½"

2¾-3

2½-2¾"

2¼-2½"

2¾-3"

2½-2¾"

2¼-2½"

1½-1¾"

1¼-1½"

1-1¼"

2-2¼"

2-2¼"

1¾-2"

2-2¼"

2-2¼"

1¾-2"

2-2¼"

2-2¼"

1¾-2"

2¾-3"

2½-2¾"

2¼-2½

2¾-3"

2½-2¾"

2¼-2½"

2¾-3"

2½-2¾"

2¼-2½"

1½-1¾"

1¼-1½"

1-1¼"

1½-1¾"

1¼-1½"

1-1¼"

2-2¼"

2-2¼"

1¾-2"

2-2¼"

2-2¼"

1¾-2"

2-2¼"

2-2¼"

1¾-2"

2¾-3"

2½-2¾"

2¼-2½"

2¾-3"

2½-2¾"

2¼-2½"

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

16

15

14

14

13

12

12

11

10

10

9

8

8

7

6

6

5

4

4

3

2

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

2

2

2

2¼

2¼

2¼

2½

2½

2½

2¾

2¾

2¾

3

3

3

3¼

3¼

3¼

3½

3½

3½

Less than 5 ppm Chlorine Demand

Resid Bae Weir Sluice Days Resid Bae Weir Sluice Days Resid Bae Weir Sluice Days

5 to 15 ppm Chlorine Demand More than 15 ppm Chlorine Demand

ADJUSTABLE INLET BAFFLE

All ow entering the tablet feeder is channeled under an

adjustable inlet bae. The inlet bae is held in place by

vertical support ribs molded into the body of the unit and is

provided to protect the system from hydraulic surges. The

inlet bae can be adjusted from a 1" to 31/2" height. For

most applications, the bottom of the inlet bae should be

1/4" below the average liquid level. Raising the inlet bae

will increase chemical dosage. For installations at grade,

the bae height can be set by hand with a standard tape

measure. For direct burial applications, a threaded bae

adjustment tool is available from your local Bio-Dynamic

distributor. Thread the adjustment tool into the extension

handle to adjust the bae from any installation depth.

STATIONARY INSERT

The Series 4000 has a stationary insert that holds the internal

components of the tablet feeder in place. The stationary

insert has tapered locating holes to properly position and

support the chemical feed tubes when installed. On all

models, the insert is open on the inlet end to facilitate the

adjustment of the inlet bae. For models incorporating the

standard weir plates, the stationary insert does not extend

all the way to the outlet end wall of the tablet feeder. This

section is left open to allow for the removal and replacement

of weir plates. In models incorporating the optional outlet

sluice, the insert extends completely to the outlet end

wall. The sluice sections are held in proper position by the

stationary insert. A molded hex nut on the top of each sluice

section protrudes through the insert to hold the sluice in place

and allow for adjustment. Indicator pins attached to the hex

nuts show the sluice opening in inches on a scale engraved

into the top of the stationary insert. The stationary insert is

securely riveted to the body of the Bio-Dynamic Series 4000

tablet feeder at the factory.

FIXED WEIR

The tablet feeder is supplied with interchangeable 1", 2" and

3" outlet weir plates. Decreasing the width of the weir will

raise the liquid level in the feeder and increase the chemical

dosage. The outlet weir plates slide into vertical support ribs

4

TIERED FLOW DECK

The multi-tiered ow deck of the Series 4000 tablet feeder

allows consistent chemical application to low, sustained,

variable, intermittent and surge ows. Liquid is channeled

through the three tiers of the ow deck according to the

hydraulic load. In low ows, liquid is directed toward the

feed tubes to accomplish the desired chemical dosage. In

higher ows, liquid is directed across the entire width of the

feeder to maintain the chemical dosage level. The lowest

tier of the ow deck is the inert drainage tier. The inert

drainage tier directs liquid to the feed tubes during low ow

conditions and forms a drainage channel to dry the tablets

when there is no ow. As the ow increases up to 3 gallons

per minute, the liquid is channeled through the intermediate

ow tier, contacting more tablets. The shape of this tier

causes the ow to accelerate as it passes the feed tubes.

At ow rates over 3 gallons per minute, the liquid rises to

the upper ow tier which dissipates the ow velocity and

produces a consistent chemical dosage. The ow deck

automatically channels these variable ows through the

appropriate tier as shown in the sketch on page 7.

BAFFLE ADJUSTMENT TOOL

INTERCHANGEABLE WEIR PLATES

molded into the tablet feeder body and engage into a channel

in the ow deck. There is no need for external fasteners

or adhesive to install the weir plates. The stationary

insert is open at the outlet end of the ow deck to facilitate

interchangeability of the weir plates. When installing a weir

plate, make sure the plate is completely engaged in the

support ribs and rmly against the ow deck. To change a

weir plate, lift vertically to remove the weir and push down

evenly to install the new plate.

ADJUSTABLE OUTLET SLUICE

The optional outlet sluice can be completely adjusted from

a 1" to 3" width and provides precise control over chemical

dosage. Chemical application can be customized to meet

specic treatment requirements by using the outlet sluice.

Decreasing the width of the sluice will raise the liquid level in

the unit and increase the chemical dosage. The stationary

insert extends completely to the feeder outlet to hold the

sluice in position. The right and left sections of the sluice

are synchronized by molded gears that assure accurate

adjustment. Adjust the sluice by rotating one of the molded

hex nuts that are located at the top of each sluice segment.

The hex nuts protrude through the stationary insert and

can be rotated with a standard 1" socket. Indicator pins on

the hex nuts show the sluice opening in inches on a scale

5

engraved into the top of the stationary insert. Each tablet

feeder utilizing one or more riser sections for direct burial

will include an adjustable outlet sluice. Follow these steps

to adjust the outlet sluice:

1. Remove the feeder lid.

2. Place a 1" socket with the appropriate extension handle

over one of the hex nuts that protrude through the

stationary insert.

3. Rotate the hex nut toward the outside of the feeder to

increase sluice width or toward the inside of the feeder

to decrease sluice width. The indicator pins show the

opening in inches on the engraved scale.

4. If you have rotated the hex nut too far, simply move

the socket to the other hex nut and rotate the sluice

back to the desired position.

5. Wait at least one hour and sample the euent. If

additional adjustment is necessary, repeat steps 1-4.

6. If the desired adjustment is not accomplished, see the

Chemical Application section of this manual.

7. Note setting on service record and replace lid.

FILLING AND INSTALLING FEED TUBES

Before handling any chemical tablets, carefully read the

product container label and the CAUTION section of these

instructions. When lling feed tubes, always wear rubber

gloves and safety goggles or a face shield for proper

protection. Follow all handling instructions for the chemical

tablets used. To ll the feed tube:

1. Remove feed tube from the tablet feeder.

2. Rinse feed tube and cap thoroughly with fresh water. Dry

as required.

3. Hold tube, slotted end up, at a 30° to 45° angle and slide

tablets into the open feed tube, one tablet at a time.

4. Insure that each tablet lies at, against the next and evenly

on top of one another, in the feed tube.

5. Use a gloved hand to retain the tablets inside the open

end of the inverted tube until it has been completely lled.

6. Carefully return the tube to the upright position.

7. Replace cap and slide feed tube through the stationary

insert and into the retaining rings in the ow deck.

8. Align the two vertical parting lines, one on each side of

the tube, with the direction of ow through the feeder.

9. Insure the notches in the top of the feed tube are per-

pendicular to the ow direction. The window portions at

the bottom of the feed tube will now be facing upstream

and downstream respectively.

The precise control provided by the Series 4000 tablet

feeder allows adjustment of the chemical application with

all feed tubes lled and installed. Feed tubes should be

relled at the approximate intervals suggested in the Series

4000 Component Conguration chart on page 3 of this

manual. Each installation will have an individual chemical

consumption pattern which should be monitored during the

initial weeks of operation to establish a rm rell schedule.

Utilize the Chemical Consumption Record on the back of

this manual to track your rell pattern.

FILLING FEED TUBES

CORRECT INCORRECT

OUTLET SLUICE WITH SCALE

REMOTE REMOVAL SYSTEM

A remote feed tube removal system is available for direct

burial installations to allow for safe removal, recharge and

reinstallation of the chemical feed tubes from grade. The

remote removal system consists of four top-threaded feed

tube caps, four corrosion resistant extensions and four

corrosion resistant handles. For use, replace the standard

cap with the top-threaded cap. The top-threaded cap

locks into the feed tube, then the extension and handle

are threaded onto the top of the new cap. The feed tube is

then returned to its proper position within the tablet feeder.

6

Additional extensions are available for deeper installations

and can be added or removed any time. The extensions

and handles remain in place during system operation

and standard feed tube lling instructions apply. A bae

adjustment tool is available that threads into the extension

handle in the same manner as the top-threaded caps. To

adjust the bae, remove one feed tube and extension

handle. Remove the handle from the feed tube and thread

the handle onto the bae tool. Place the hook portion of

the tool through the hole in the inlet bae. Adjust the bae

up or down as shown in the sketch on page 4.

FEED TUBE CLEANING BRUSH

A brush for cleaning the feed tubes and ow deck is available

from your local Bio-Dynamic distributor. To use the brush,

remove the extension handle from the top-threaded feed

tube cap and screw the brush into the handle. Wet the

brush with fresh water, hold the feed tubes over the tablet

feeder and gently swab the inside of each feed tube. Lower

the brush into the tablet feeder and through the openings

in the stationary insert. Clean the ow deck and inside of

the feeder. Thoroughly rinse and remove the brush, attach

the top-threaded feed tube cap to the handle and reinstall

the feed tube into the tablet feeder.

EXTENSION HANDLES WITH CAP

BIO-SANITIZER®DISINFECTING TABLETS

If the tablet feeder is to be used for the disinfection of water

or wastewater, a (10 lb., 25 lb., 45 lb. or 100 lb.) supply of

Bio-Sanitizer tablets is available from your local distributor.

Bio-Sanitizer tablets insure dependable disinfection for

water and wastewater treatment system ow and other

applications where a predictable long-term source of

chlorine is desirable. The tablets are manufactured

from pure calcium hypochlorite and contain at least 70%

available chlorine. Registered with the USEPA for water

and wastewater treatment, the tablets incorporate beveled

edges to enhance the chemical dissolution pattern, providing

eective and economical bacteria killing power. Each tablet

is 25/8" diameter, compressed to a 13/16" thickness, has an

approximate weight of 5 ounces and is white in color for easy

identication. The chemical application rate of the tablets

remains consistent at peak ow factors as high as four.

CAUTION: The improper handling of Bio-Sanitizer

tablets may cause personal injury or property damage.

Keep out of the reach of children and do not allow the

tablets or feed tubes to contact skin, eyes or clothing.

Tablets may be fatal if swallowed and tablet dust is

irritating to the eyes, nose and throat. Do not handle the

tablets or feed tubes without rst carefully reading the

product container label and/or the handling and storage

instructions. Do not add tablets to any dispensing

device or storage container containing remnants of any

other product, especially petroleum based products or

swimming pool chlorine. Do not use swimming pool

chemicals in Bio-Dynamic tablet feeders. For additional

information about Bio-Sanitizer tablets contact your

local distributor.

BIO-NEUTRALIZER®DECHLORINATION TABLETS

If the tablet feeder is to be used for the dechlorination

of water or wastewater, a (25 lb. or 45 lb.) supply of

Bio-Neutralizer tablets is available from your local distributor.

Containing 35% sodium sulte, the tablets are manufactured

to neutralize both free and combined chlorine. Bio-Neutralizer

tablets incorporate beveled edges to enhance the chemical

dissolution pattern. Each tablet is 25/8" diameter, compressed

to a 13/16" thickness, weighs approximately 5 ounces and is

green in color for easy identication. The tablets dissolve

slowly, releasing controlled amounts of chemical for the

instantaneous removal of residual chlorine from the water

or wastewater ow. The chemical application rate of the

tablets remains consistent at peak ow factors as high

as four. Bio-Neutralizer tablets are formulated to remove

chlorine residuals to non-detectable levels.

CAUTION: Bio-Neutralizer tablets or feed tubes should

not be mixed with Bio-Sanitizer tablets or the remnants

of any other product. Do not handle tablets or feed tubes

without rst carefully reading the product container

label, SDS information and the safety, handling and

storage instructions. For additional information about

Bio-Neutralizer tablets contact your local distributor.

PLACING THE BIO-DYNAMIC®ON-LINE

After adjusting the inlet bae, lling and installing the

feed tubes and selecting the outlet weir or adjusting

the outlet sluice, the tablet feeder is ready to be placed

on-line. Be sure the entire liquid stream from the facility

being served ows through the tablet feeder. Conrm

that the proper chemical tablets are being used. After the

system has been in operation for at least one hour, draw

a sample of the treated euent from the feeder outlet or

the contact chamber inlet to test the chemical application.

For chlorination applications, testing can be done using a

chlorine test kit, available from your Bio-Dynamic distributor,

or a DPD Colorimetric test as outlined in the most recent

edition of Standard Methods for the Examination of Water

and Wastewater. Multiple samples must be taken to insure

that the system has reached equilibrium. Take samples at

15 minute intervals. When three or more samples produce

the same results, the system has reached equilibrium.

OPERATIONAL ADJUSTMENT

If the chemical dosage requires alteration, the Series

4000 tablet feeder can be adjusted during operation. You

do not need to take the system o-line or to disassemble

any component of the unit. Chemical application can be

increased by decreasing the width of the weir or sluice and

also by raising the inlet bae. Conversely, chemical dosage

can be decreased by increasing the width of the weir or sluice

and by lowering the inlet bae. The precise control provided

by the Series 4000 tablet feeder allows adjustment of the

chemical dosage to almost any requirement while all feed

tubes are charged with tablets. Adjustment of the chemical

dosage and potential operational problems are covered

in this manual. If there are additional questions regarding

operation, contact your local Bio-Dynamic distributor. For

further reference, a red identication tag with the contact

information of the manufacturer is attached to the feeder.

7

ROUTINE MAINTENANCE

The tablet feeder requires very little maintenance other

than periodic cleaning and relling of the feed tubes. When

performing any maintenance, always wear rubber gloves and

safety goggles or a face shield and follow the procedures

outlined in the handling instructions for the chemicals used

in the feeder. Before relling the feed tubes, rinse each

tube and cap thoroughly with fresh water. Occasionally,

a feed tube may need to be cleaned with a brush. When

relling feed tubes, check the inside of the feeder and rinse

any residue with a low pressure hose. The liquid ow will

normally prevent accumulation of debris during routine

operation. Debris that may become lodged within the feeder

can be removed with the cleaning brush or a gloved hand.

INSUFFICIENT CHEMICAL APPLICATION

Check to see that the tablets are not jammed in the feed tube.

If the tablets are jammed, remove and properly rell the feed

tubes. Make sure the feed tubes are resting at in the ow

deck retaining rings. If the feed tubes are properly lled and

resting securely on the ow deck, check the system for a

hydraulic overload. Surges over and above the anticipated

system ow rate can cause temporary reductions in chemical

application. If adjustment of the Bio-Dynamic tablet feeder

is necessary, reduce the width of the outlet weir or sluice.

The inlet bae may also be raised to increase chemical

dosage. These adjustments can be made during system

operation. Test the chemical application after adjustment

to conrm the system is performing as desired.

OVER APPLICATION OF CHEMICAL

Too much chemical can be applied if the outlet is restricted.

Check the feeder for blockage. If the outlet is not obstructed,

increase the width of the outlet weir or sluice. The inlet

bae can also be lowered to reduce chemical application.

These adjustments can be made during system operation.

If the outlet weir or sluice is at its maximum width and the

inlet bae is at its lowest setting, chemical application can

be reduced even further by leaving one or more feed tubes

empty. Empty tubes must still be installed within the tablet

feeder to maintain the hydraulic ow pattern. The lowest

application of chemical is accomplished by placing the lled

feed tubes closest to the system outlet. If this application

is too low, the lled feed tubes can be placed closest to the

system inlet. Test the chemical application after adjustment

to conrm the system is performing as desired.

INTERMITTENT USAGE

If a period of intermittent use or extended period of

non-use is anticipated, the feed tubes should be removed

and stored in a well-ventilated, dry, secure location. Refer to

the tablet container label for detailed safety, storage and/or

disposal instructions for the chemical tablets. Reinstall the

feeder lid securely for the period of time that the system

will be unattended. If a cable locking device has been

installed, it should be locked during the period of non-use.

TIERED FLOW DECK

A) DRAINAGE TIER B) INTERMEDIATE TIER C) UPPER TIER

SYSTEM SAFETY

All installations not protected by a safety fence or locked

grating should be equipped with an optional cable locking

device as available from the manufacturer. The locking

device will assure that only authorized personnel have access

to system components. Conned space entry equipment

(Occupational Safety and Health Regulations OSHA

29,CFR1910.146) is not required for a properly installed

Series 4000 tablet feeder with optional riser. Maintenance

of the tablet feeder can be performed from grade. Under no

circumstances should operating personnel put their face,

head or torso into the tablet feeder or risers. Toxic fumes

present in wastewater and/or tablets may accumulate within

the feeder and cause personal injury or death. Thoroughly

read chemical container label before use. Safety/reinforcing

struts are provided for unit integrity as well as to restrict

means of entry into the tablet feeder. Feeders should not

be buried without these safety struts securely in place. If

struts are removed during the installation process, they

must be reinstalled at the very top of the nal installation.

BIO-DYNAMIC®LIMITED WARRANTY

SERIES 4000 CHEMICAL CONSUMPTION RECORD

For your reference, please document component setting, chemical consumption and maintenance on the following chart:

The Bio-Dynamic Series 4000 tablet feeder is backed

by a comprehensive ten year limited warranty. The

purchaser is protected from defects in material and

workmanship, under normal use and service, for a

period of ten years from the date of original purchase.

The Bio-Dynamic Series 4000 distributor will provide a

warranty registration card, as well as detailed warranty

and exchange information, to each purchaser. This

warranty is not eective unless the warranty registration

card is returned to the factory within 30 days of

purchase. If the tablet feeder or components require

service or replacement, do not use or dismantle the unit.

Contact your local, authorized Bio-Dynamic Series 4000

distributor to arrange for service or replacement of the

system or component. After inspection, the distributor

will return the tablet feeder or component, as required,

to the factory and replace the necessary items according

to the terms of the limited warranty.

DATE DESCRIPTION

220 REPUBLIC STREET

NORWALK, OHIO, U.S.A. 44857-1156

TELEPHONE (419) 668-4471

FAX (419) 663-5440

www.norweco.com

DISTRIBUTED LOCALLY BY:

Norweco®, Norweco.com®, Singulair®, Modulair®, Travalair®, Singulair Green®, Ribbit Rivet®, Hydro-Kinetic®, Hydro-Kinetic Bio-Film Reactor®,

Evenair®, Lift-Rail®, Microsonic®, Bio-Dynamic®, Bio-Sanitizer®, Bio-Neutralizer®, Bio-Kinetic®, Bio-Static®, Bio-Gem®, Bio-Max®, Bio-Perc®,

Blue Crystal®, Phos-4-Fade®, Enviro-C®, ClearCheck®, ChemCheck®, Tri-Max®, Hydra-Max®, Service Pro®, MCD®, TNT®, WASP®, Grease Buster®and

“BUSTER” logo®are registered trademarks of Norwalk Wastewater Equipment Company, Inc.

©MMXI NORWECO, INC.

Popular Laboratory Equipment manuals by other brands

Teledyne Cetac Technologies

Teledyne Cetac Technologies ASX-560 Alignment Guide

Ametek Land

Ametek Land Fti-E installation guide

Macherey-Nagel

Macherey-Nagel NucleoMag SEP user manual

Selecta

Selecta STERILBIO quick start guide

Adam Equipment

Adam Equipment ANTI-VIBRATION TABLE Assembly instruction

MCi

MCi C Series Operation manual

Hach

Hach PHOSPHAX sigma High Range user manual

ScanSpeed

ScanSpeed Mini Service manual

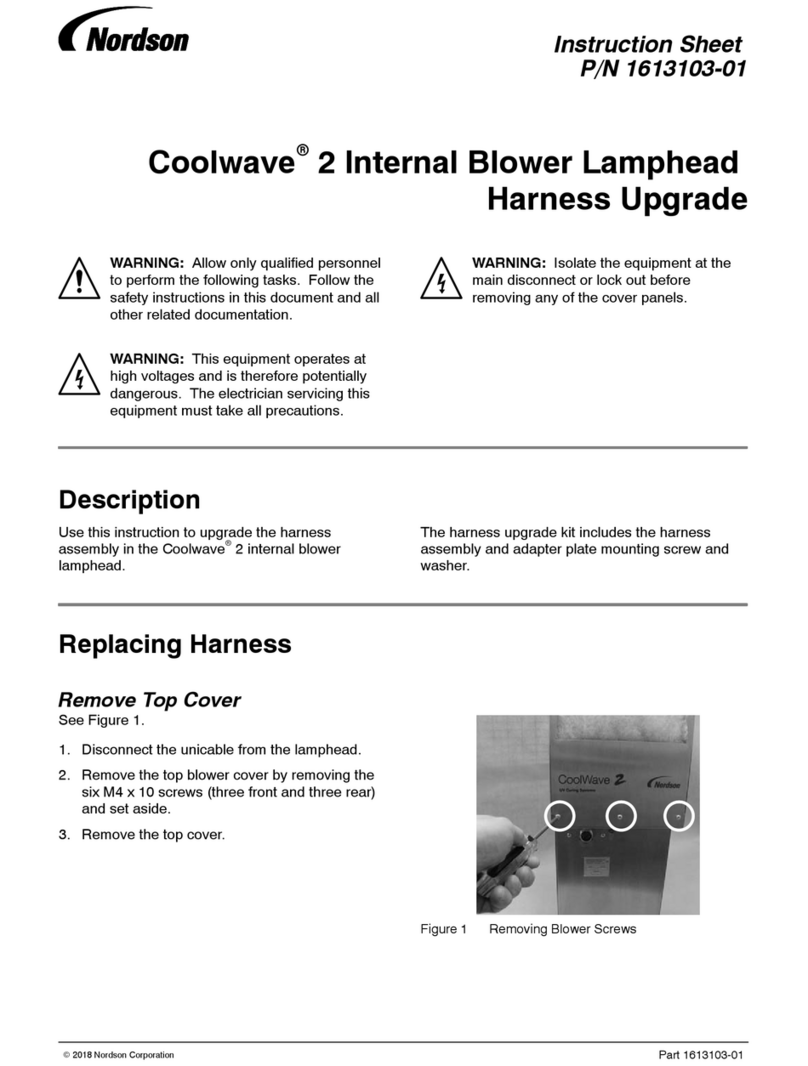

Nordson

Nordson CoolWave 2 instruction sheet

D&H

D&H Lifelabs AquaSolvo Eco AAE-5005 Series instruction manual

ThermoFisher Scientific

ThermoFisher Scientific Q Exactive GC quick start guide

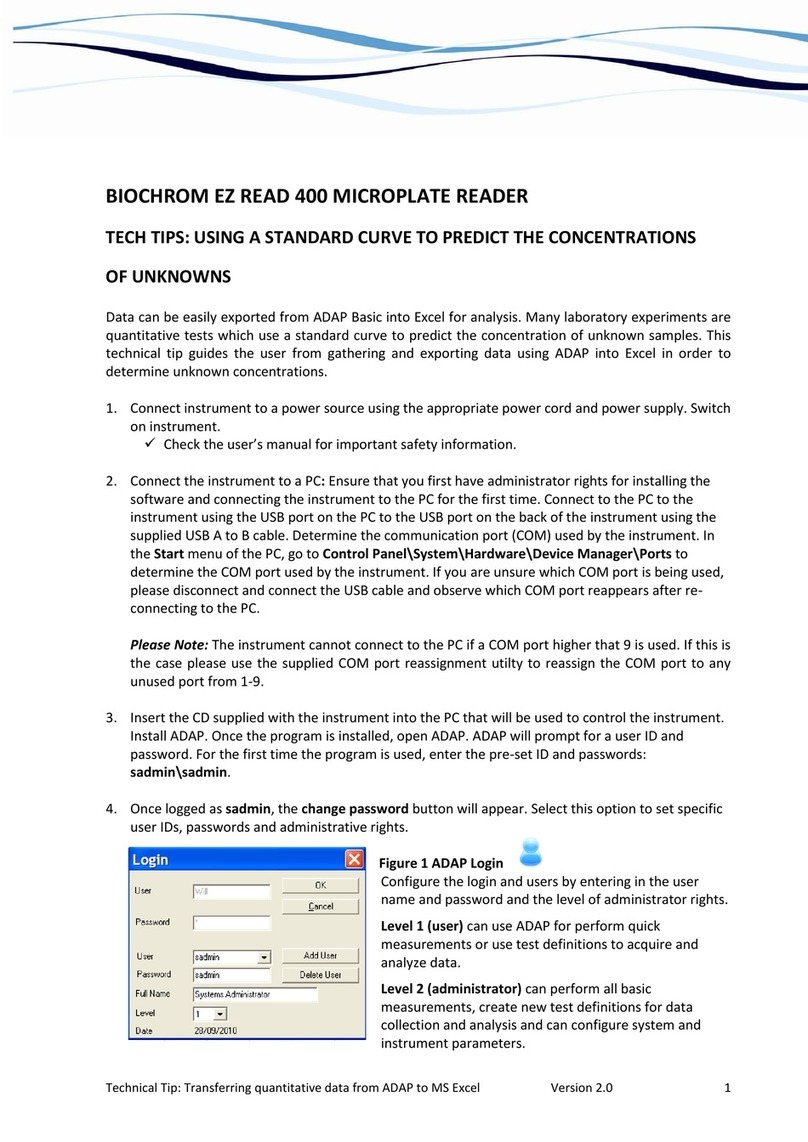

biochrom

biochrom EZ Read 400 quick start guide