Norwood Kwik-Till HSD2575 User manual

2015

OWNER’S MANUALOWNER’S MANUAL

55-5-00002 01/01/2015 (Rev A)2

Read this manual before operating your Norwood equipment. The information presented will

prepare you to do a better and safer job. Keep this manual handy for ready reference. Require all

operators to read this manual carefully and become acquainted with all the adjustment and operating

procedures before attempting to operate. Replacement manuals can be obtained from your dealer.

The equipment you have purchased has been carefully engineered and manufactured to

provide dependable and satisfactory use. Like all mechanical products, it will require cleaning and

upkeep. Lubricate the unit as specied. Observe all safety information in this manual and safety

decals on the equipment.

Use only genuine Noorwood service parts. Substitute parts will void the warranty and may

not meet standards required for safe and satisfactory operation. Record the model number and serial

number of your equipment in the spaces provided:

!!

!

!!

!!

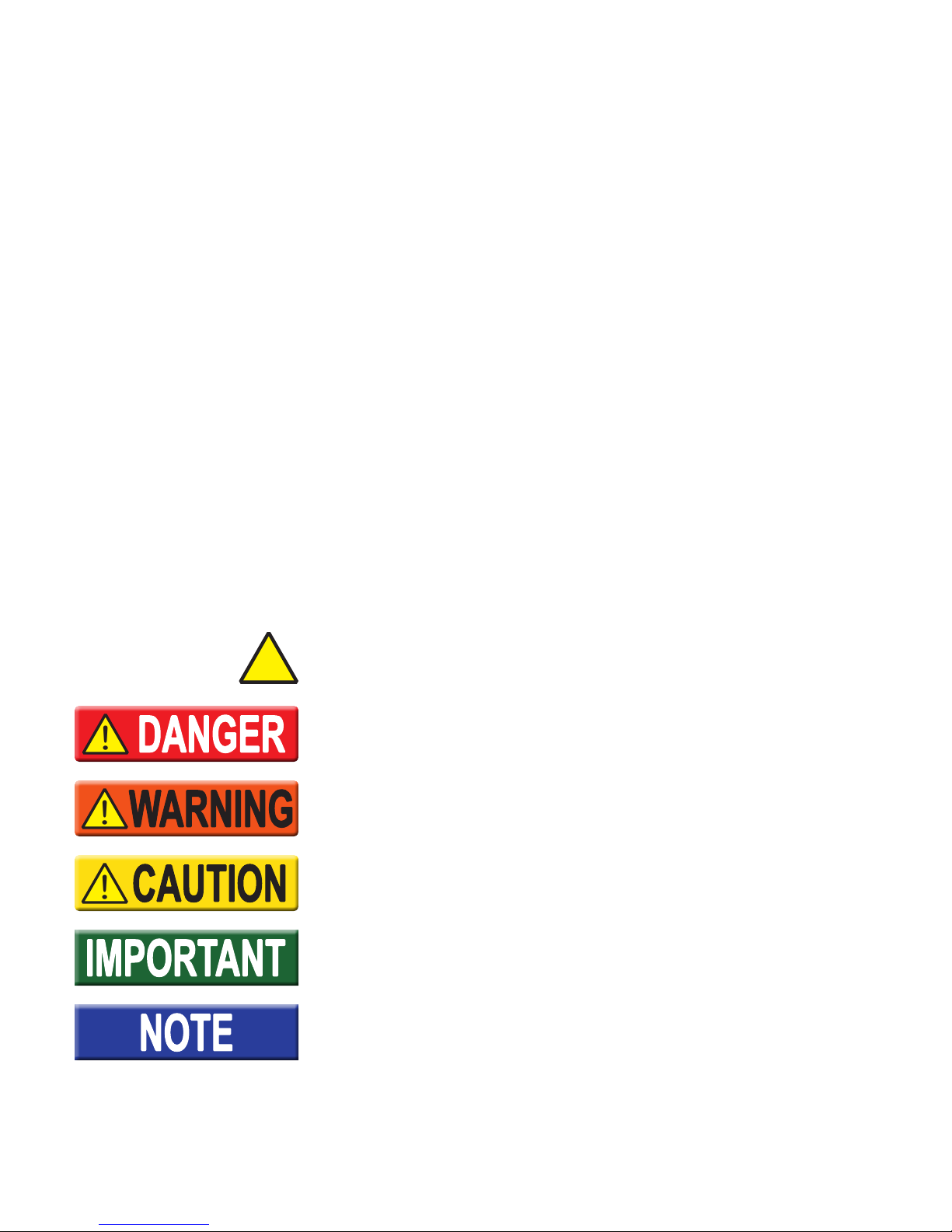

This Safety-Alert Symbol indicates a hazard and means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could

result in death or serious injury, and includes hazards that are exposed

when guards are removed

Indicates a potentially hazardous situation that, if not avoided, may re-

sult in minor or moderate injury.

Indicates that failure to observe can cause damage to equipment.

Indicates helpful information.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can

cause damage to equipment. The terms CAUTION, WARNING and DANGER are used in conjunction

with the Safety-Alert Symbol, (a triangle with an exclamation mark), to indicate the degree of hazard

for items of personal safety.

Model: __________________________ Date of Purchase: __________________________

Serial Number: __________________________

Provide this information to your dealer to obtain correct repair parts.

55-5-00002 01/01/2015 (Rev A)3

Quick Reference Guide

I. Insert the males ends into the couplers on the tractor, Be sure to match pressure and return

lines to one valve bank and make sure they are locked in place. See Below for Color Code Chart

1

1

2

2

12

1

2

3

3

4

4

1

2

3

4

5

5

Wing

Frame Lift

Connect Hydraulics1.

Unfold Machine into Field Postion

3.

I. Remove wing transport pins from wings and place into holder holes.

II. Slightly raise the transport cylinders (#4) to remove pressure from wings

from transport rest. DO NOT fully extend cylinders at this point.

III. Extend wing cylinders (#3) to unfold wings. When last wheel touches

ground place wing cylinders in oat.

IV. With wings fully opened and wing cylinders in oat, extend transport

cylinders (#4) to lower machine fully to the ground. When machine is

completely on the ground place transport cylinders into oat position.

≈ 2 in.

3

3

3

3

4

4

4

4

Before operating machine MAKE SURE

both wing cylinders (#3) and transport

cylinders (#4) are in FLOAT position

or damage to cylinders or machine may

occure.

Transporting

2.

I. Use clevis style hitch on the tractor. Use hardened draw

bar pin with a mechanical retainer.

II. Attach safety chain around draw bar or cage to prevent

unexpected separation.

* * Refer to Owner’s Manual for complete safety and operating instructions * *

II

III

IV

55-5-00002 01/01/2015 (Rev A)4

Field Operation

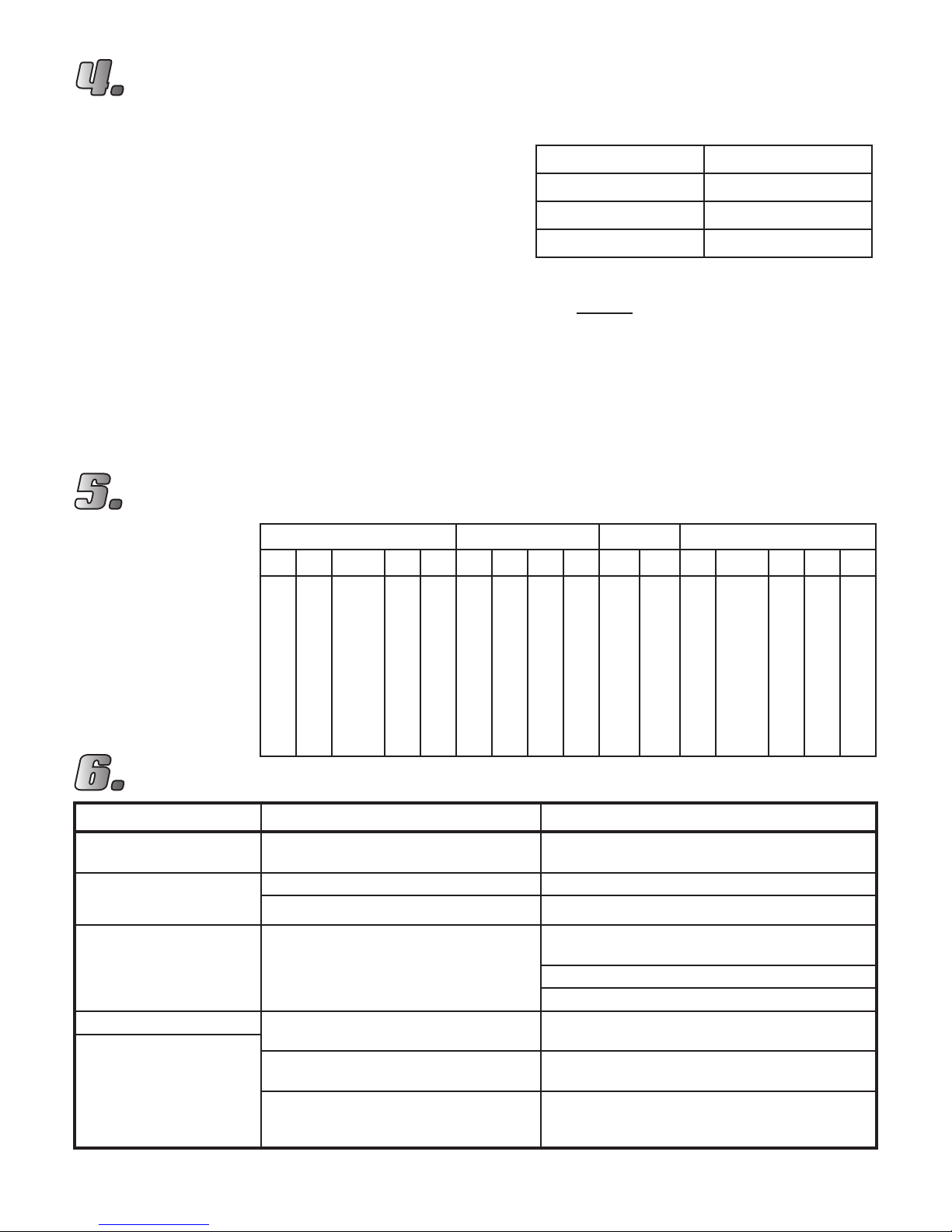

4.

I. After placing machine in eld position retract

wheel cylinders (#1) and packer cylinders (#2)

to the cylinder stops.

II. It may be necessary to adjust digging depth,

this is done by extending wheel cylinders (#1)

and packer cylinders (#2) and adding cylinder

stops for shallower, or removing stops for deeper

depth.

III. Be sure transport cylinders and wing cylinders are in FLOAT position before operating the

machine, This ensures machine follows contour of ground. Otherwise damage may occur to

hydraulic cylinders or other components.

IV. For best performance the recommended operating speed is between 9 and 14 MPH and a

depth of 2 1/2”, depending on eld conditions.

V. When making headland turns thats are sharp, the operator may need to raise discs slighting

using the wheel cylinders (#1).

Problem Cause Solution

Machine doesn’t

track straight Machine not level from front to back Add or Remove cylinder stops as needed to

level machine

Entire machine plugs

Ground speed too slow Increase speed as specied in operations

Working depth too deep Add cylinder stops as needed

Wings plug Wings not level

Verify same number of cylinders stop on

main frame and wings

Reduce digging depth

Add weights to wings

Machine moves slowly Low hydraulic pressure/ow from

tractor Increase ow/pressure to SCV in tractor

Machine doesn’t move

Hydraulic hoses from equipment not

connected

Verify all hoses are securely connect to

tractor

Hydraulic hoses from equipment not

connected in correct pairs

Refer to color code diagram and connect

hoses of the same color to the same SCV

on tractor

Depth Stop Size Digging Depth

3/4” 5/8”

1” 3/4”

2” 1 1/2”

Maintenance5.

12 Hours or Daily 25 Hours 40 Hours Anually

L

C

C

C

C

L

L

L

L

L

L

C

C

C

C

C

Roller Packer Bearing

Hydraulic Leaks

Damaged Hoses,

Fittings, and Valves

Check Tire Pressure

Scraper Alignment

Roller Packer Pivot

Wing Pivot

Hitch Pivot

Strut Pivot

Wing Transport Roller

Wheel Hub

Loose Hardware

Damage or Excessive

Wear to Discs

Wheel Bearings

Disc Hubs

Rubber Cord Alignment

Trouble Shooting6.

L = Lubricate C=Check

NOTE:

Recommendations

are based on

normal operating

conditions.

Severe or unusual

conditions may

require more

frequent lubrication

or oil changes.

* * Refer to Owner’s Manual for complete safety and operating instructions * *

55-5-00002 01/01/2015 (Rev A)5

Table of Contents

Introduction ................................................................................................. Inside Front Cover

General Information .............................................................................................................. 5

Dimensions & Specications ................................................................................................... 6

Safety & Instructional Decals ................................................................................................. 7

Safety ............................................................................................................................... 11

Operation .......................................................................................................................... 15

Maintenance ...................................................................................................................... 23

Trouble Shooting ................................................................................................................ 28

Index to Parts List .............................................................................................................. 29

Bolt Torque Chart ............................................................................................................... 50

Abbreviations ..................................................................................................................... 51

Index ................................................................................................................................ 52

Warranty Registration & Inspection Report ............................................................................. 54

Warranty Policy .................................................................................................................. 55

General Information

The purpose of this manual is to assist you

in operating and maintaining your Kwik-Till. Read it

carefully. It furnishes information and instructions

that will help you achieve years of dependable

performance. These instructions have been compiled

from extensive eld experience and engineering data.

Some information may be general in nature due to

unknown and varying operating conditions. However,

through experience and these instructions, you

should be able to develop procedures suitable to your

particular situation.

The illustrations and data used in this manual

were current at the time of printing, but due to possible

in-line production changes, your machine may vary

slightly in detail. We reserve the right to redesign and

change the machines as may be necessary without

notication.

Throughout this manual, references are made

to right and left direction. These are determined by

standing behind the equipment facing the direction of

forward travel.

!!

Some illustrations in this manual show the

Kwik-Till with items removed to provide a

better view. The Kwik-Till should never be

operated with any items removed.

This manual suits for next models

1

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

Sunforce

Sunforce SOLAR user manual

GARDEN OF EDEN

GARDEN OF EDEN 55627 user manual

Goizper Group

Goizper Group MATABI POLMINOR instruction manual

Rain Bird

Rain Bird 11000 Series Operation & maintenance manual

Cub Cadet

Cub Cadet BB 230 brochure

EXTOL PREMIUM

EXTOL PREMIUM 8891590 Translation of the original user manual

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

Snapper

Snapper 1691351 installation instructions