nosstec 8344 User manual

Bending Roll Machine 8344

Operating instructiOns

8344 English, rev 2 3

Table of conTenTs

Main components ............................................................4

Installation ....................................................................5

Safety..........................................................................7

Operation ................................................................... 12

Programming ............................................................... 28

Service and maintenance .................................................. 30

Lubrication / Grease chart ................................................. 32

Fuses and motor protection ............................................... 34

Technical data .............................................................. 35

Machine plates and stickers ............................................... 36

Declaration of conformity.................................................. 37

Contact information................................................. See back

Note: We reserve the right to alter specifications without prior notice.

For copyright reasons all reproduction and copying of the texts, tables and illustrations within this manual is

prohibited without written permission from Nosstec AB.

Operating instructiOns 8344

42013-03-01

Emergency stop

Emergency stop

Emergency stop

Control panel

Top roll Prebending roll

Bending roll

Safety equipment

Safety equipment

Electrical cabinet

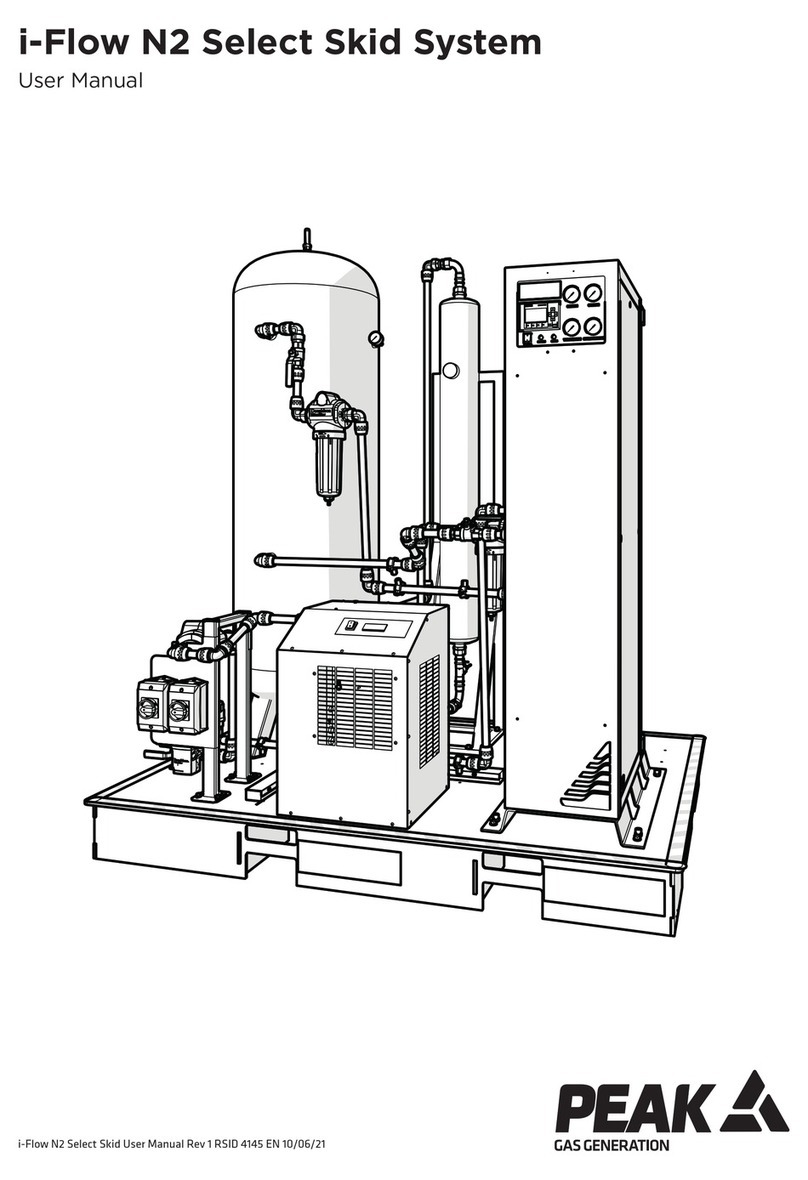

Main coMponenTs

Front side

Back side

Disclaimer: The machine pictured on this page is not necessarily representative of the actual product

as delivered. Differences in sizes, options and/or accessories may or may not be pictured here.

Foot switch

Foot switch

connector

Main switch

Left side

(fixed side)

Right side

(openable

side)

Left side

(fixed side)

8344 English, rev 2 5

insTallaTion

Installation

The machine must be placed on firm ground e.g. cemented floor. The ground must be level in order to

avoid tensions in the machine when fixing it to the floor. The machine must be bolted to the floor with

4pcs expansion shell bolts diameter 16 mm.

Check that the motor is branched to the right voltage. Also check the direction of rotation. Plates with

“Forward” and “Reverse” are mounted on the protection cover of the foot switch.

Lifting instructions

This machine must be lifted by truck as long as it is

packed in a crate or a wooden case. When lifting it

from the packing to the permanent working site a

fork lift must be used.

When lifting, place the forks under the lowest part

of the framework. The centre of gravity lies just in

the middle of the machine.

Regarding weights: see technical data.

Approximate placement

of lifting forks

Operating instructiOns 8344

62013-03-01

insTallaTion

Electrical connection

Always check the sign on the machine, or the wiring diagram (located in the door to the electrical

cabinet), that explains the electrical data for the specific machine. Follow local regulations for electrical

connection

Authorised personnel only to carry out connecting and repair work to the electrical equipment of the

machine!

Foot switch

Connect footpedal to the multiconnector. The machine cannot be opera-

ted if this is not connected.

Protective equipment

Check that all protective and emergency functions are mounted and in

working order.

Start

Turn the main switch, situated on the back right side (seen from the back) of the machine, to position 1.

When not in use, the machine should be secured from unauthorized use with a padlock that locks the

main switch in the off position.

8344 English, rev 2 7

safeTy

General

This bending roll machine is designed with a view to eliminating personal injuries provided that the in-

structions in this manual are being followed.

Only authorized and trained staff is allowed to use the machine. Read the whole instruction manual and

make sure that you understand the contents before the machine is taken into use. It is important that

you read the safety instructions below.

Keep the instruction manual of the machine in a safe place

The instruction manual contains important information that besides the safety information also give im-

portant information regarding operation, service, maintenance etc.

Safety instructions in connection with the installation

The machine must be bolted to the floor with 4 pcs expansion shell bolts diameter 16 mm.

Electrical installation of the machine must be carried out by authorized staff.

Protective clothing

Important! Never use gloves when bending, as this considerably in-

creases the risk of getting pinched between the rolls. For other handling

of the workpieces use gloves. The operator must not carry belts, rings or

necklaces.

Working shoes with steel inserts must be used.

Loose hanging clothes must not be used.

If the operator has long hair, this must not hang loose.

Dangerous area

The dangerous area of the machine is described in the figure.

This area shall in an appropriate way be marked in the floor.

The operator must make sure that nobody comes into the

danger zone while the machine is in progress. Should this

occur then the machine must be stopped immediately.

Area for maintenance and service.

There should always be a free space of at least 2 meters in

front of the machine and at least 1 meter on the remaining three sides of the machine for service and

maintenance.

1 meter behind and

to both sides

2 meter in front of

machine

Operating instructiOns 8344

82013-03-01

safeTy

Check that the environment around the machine is suitable

• Do not expose the machine to rain.

• Do not use the machine in wet or damp premises.

• Check that the lighting of the premises is satisfactory.

• The floor must be clean, dry and free from oil and grease spots.

• Never use easily inflammable material close to the machine.

• Dirty working sites increase the risk of accidents.

Main switch

The machine should be equipped with a padlock for the main switch, and the operator must take cau-

tion to check the machine before powering it on that the padlock is secured and locked before removing

it and switching the machine on.

When leaving the machine for any length of time where it is not under supervision, the main switch

should always be turned off and the padlock securely locking it to prevent unauthorized use.

Application

Never use the machine for material which is outside the capacity range of the machine. Check

the machine plate and the section “Technical data”.

Before the machine is operated the following steps must be taken:

Check that all safety devices function and that they are not damaged. Also check that moveable parts are

not exposed to obstacles e.g. owing to incorrectly mounted guards or parts. Broken parts or safety com-

ponents must be changed by authorized staff. Contact Nosstec in case spare parts are needed. The ma-

chine has a 24 month applicable warranty from date of delivery. The warranty is only applicable as long

as original spare parts are used.

Avoid unstable working positions

Check that the operator always has a secure and stable working position.

Do not keep tools on the machine

Remove all tools from the machine before it is operated.

8344 English, rev 2 9

safeTy

Danger zone

In connection with production work check that no part of

the body comes too close to the infeed side of the clamping

rolls of the machine (see figure).

Note: The infeed side may vary owing to the direction of

rotation of the rolls.

Airborne noise

The following noise level has been measured at the operator’s place:

Equivalent noise level Leq, idle running 62 dB(A)

Equivalent noise level Leq, operation 63 dB(A)

Falling work pieces

The work piece is ejected and can fall to the floor when

it has been rolled. This means you should take care while

working, especially in the case of large work pieces.

If necessary, use a lift table, overhead crane or other

lifting device.

Moving work pieces

While the bending roll is working, the work piece moves up

and down. Take care and do not stand too close to the work

piece – there is a risk of injury to your torso, arms, legs or

face. The machine is fast working, which means the move-

ments are correspondingly fast.

Pinching risk of the workpiece

Note that there is a pinching risk between the ends

of the workpiece, see figure.

Pinching risk

While it is being rolled, the work piece may

move forwards, backwards, up and down in the

machine.

The work piece can exit the machine from the front

or from the back.

Operating instructiOns 8344

10 2013-03-01

safeTy

Deburring of the workpiece

Burrs and sharp edges must be removed from the workpiece before bending.

Jamming

If for some reason the machine stops while

bending a workpiece, proceed as follows:

• Crank down the bottom roll and possibly also the bending roll.

• Remove the workpiece. Identify the trouble reason. If the motor protection is released,

wait for some minutes before it is reset. The machine is then ready for use again.

• If the trouble is mechanical or electrical: Cut the current and contact the supervisor.

Regular checking

Daily check the function of the foot switch as well as the condition of the electric cable of the foot switch.

Also check that the emergency stop works. Carry also out the regular service, which is described in the

chapter Service and Maintenance in the instruction manual.

Modification of the machine

All conversion, modification or change of this machine is strictly forbidden with the exception of

• Original spare parts

• Optional equipment supplied by the manufacturer.

All repairs must be carried out by authorized staff

The machine and its electrical equipment has been made according to valid safety rules. All

repairs must be carried out by trained and qualified staff. Only original spares must be used.

Cut the power

Cut the current before touching live parts. This is done either by disconnecting the main

switch of the machine or by disconnecting the voltage of the electrical cabinet.

Note: Do not put the main switch or the safety switch of the machine out of operation. The

main switch must be locked with a padlock when the machine is not in use (recommended

during all repair and maintenance).

8344 English, rev 2 11

safeTy

Emergency stop

The machine has a number of safety switches and emergency stop devices:

• Thefootpedalhasanemergencystopfunction,whichyoucanactivateby

pushing down very hard.

• Youcanactivatetheemergencystopontherightsideofthemachineby

pressing it.

• Youcanactivatetheemergencystopontheleftsideofthemachinebypressingit.

• Youcanactivatetheemergencystopontherearsideofthemachinebypressingit.

• Thesafetylineinthelowerpartoftherearofthemachineisactivatedbymovementorifitis

broken.

To reset the emergency stop, rotate the button anticlockwise, in the direction of the arrow.

Foot switch

To reset the stop function of the foot pedal, push down the button on the

pedal side.

Safety line

To reset the safety line, press the button on the safety switch at the end

of the line. The machine cannot be restarted until the Reset key on the

control panel has been pressed.

Important:

The operator must know the location of all the stop and emergency stop functions and

how to operate them.

All protective devices must be fitted and the transmission doors must be locked.

Reset button

Safety line

Emergency stop

Reset

Emergency stop

Emergency stop switch

Reset

Foot pedal

Operating instructiOns 8344

12 2013-03-01

operaTion

Outline of control panel functions

The operating system is run from the control panel. The panel is logically designed to simplify operation.

Function keys Display Mode selector

KeypadArrow keys and ESC

Reset

Auto

Manual

Run

Program

8344 English, rev 2 13

operaTion

Mode selector

The mode selector consists of five keys with various functions.

Reset

If an emergency stop or other stop function has been activated, the machine and con-

trolpanelwillnotrestartuntilyoupresstheResetkey.YoualsoneedtopresstheReset

key if the main power supply has been disconnected. See also Emergency stop in the

Security section.

Auto

Auto mode means that the selected program can be started using the foot pedal.

Program

Program mode is used to find specific items, select the language, adjust the display,

program new items, change existing items and review existing settings.

Manual

Manual mode is used for the manual bending of special formats, for test runs and for

calibration.

Run

The ”Run” light illuminates while the machine is running a program in Auto mode.

Important:

In “Auto” mode, bending takes place automatically when you press the foot switch. Check

the shape of the item before running the program so that you know which movements the

machine will make. This means there will be no surprises, which may lead to injury.

Control system

The control system can store up to 99 programs. With a USB memory stick there is virtually no limit to

the amount of storage. Each program contains 50 program lines. In standard design the system consists

of four axis. The four functions controlled by the control system are: Feeding, bending, holding and lock-

ing of upper roll. Parts can be made through stepless radius change. This is made possible by the feeding

and bending axis working simultaneously.

Operating

The four rolls are driven by an electric motor situated on the left side of the machine. Raising and

lowering of the lower bending-rolls is carried out with the help of 2 separate electric motors. Operation

is carried out via a drive shaft with worm gear motors.

Operating instructiOns 8344

14 2013-03-01

operaTion

Display window

The display of the machine provides the ope-

rator with the necessary information about the

current operation and the settings. The display

shows various screens depending on the cur-

rent mode of the machine.

Marker

The display contains a marker indicating where

your input will go. The marker looks like a line

underneath the character, or else like a rectang-

le.

Function keys

Above and below the display, there are two rows of five function keys. The keys have different functions

depending on the current screen in the display. The top and bottom rows of the screen show the fun-

ction of each button.

Arrow keys and Esc

The arrow keys are used to move the cursor around the display, and for run-

ning the machine functions manually.

8344 English, rev 2 15

operaTion

Keyboard

The keypad is used to enter numbers (and letters) at the location indicated by the marker.

Delete key

To delete the value you have just entered or the text

you have just typed.

Shift key

YoucanpressShift toswitchtolettermode(see be-

low).

Enter key

Press Enter to confirm the value you have just entered.

Using letters

YoucanpressSHIFTtousethelettersshownonthenumberkeys.TotypeA,pressandholddownSHIFT

andpressthenumberkey0.TotypeB,firstpressandreleaseSHIFTonce,thenpressSHIFTagainand

holditdownwhilepressingthenumberkey0.SototypeC,pressandreleaseSHIFTtwice,thenpress

SHIFTathirdtimeandholditdownwhilepressingthenumberkey0.

Two special cases are comma and space, which are produced with the dot key (see example below).

Example:

0 = 0 SHIFT + . = , (comma)

SHIFT+0 =A SHIFT+SHIFT + . = (space)

SHIFTSHIFT + 0 = B

SHIFTSHIFTSHIFT + 0 = C

WhereSHIFTisunderlined,pressandholddownthekeywhilepressingtherelevantletterkey.

Password

The keyboard can be protected with a 5-digit code that the machine supervisor receives from Nosstec.

The machine can otherwise only be run without any program changes unless the code is entered.

Delete key

Shift key

Enter key

Operating instructiOns 8344

16 2013-03-01

operaTion

Program

Menu structure, Program mode

Use the relevant function key to change the screen shown on the display.

8344 English, rev 2 17

operaTion

Manual

Menu structure, Manual mode

The display shows how the function keys are used. Note that the pedal must be held in

the operating position for any movement to take place. The calibration function is illus-

trated below. All movements are performed at lower speeds than in Auto mode.

Start

Use the main switch to connect the power supply. If the Reset key on the control panel is not illuminated,

you must check and reset the emergency stop functions and the stop function in the foot pedal.

Checking functions

Check the function of all rolls using the relevant function key with the pedal pressed down to the opera-

tion position.

< >

Operating instructiOns 8344

18 2013-03-01

operaTion

Manual

Manual mode

Use the relevant function keys for feed, prebending and bending.

Feed position

Indicatesthecurrentfeedpositionoftheworkpiece.Youcanre-

set the value by pressing the number key 0.

Bending/prebending rolls

Indicates the current position of the prebending and bending

rolls.

Pinch roll

Indicates the current roll opening.

If you are running a test operation that you will be programming later, read the values and make a note

of them so you can use them as a starting point for programming

Warning!

The feed, prebending and bending movements start slowly, but switch to a higher speed

after one second.

Top roll

Prebending

roll

Bending

roll

Pinch

roll

Feed + Feed –

8344 English, rev 2 19

operaTion

Program

Program mode

With the mode selector in ”Program” mode, you can select, create and change programs.

Youcanalsoreviewstoredprogramsandchangethemachinesettings.

Program storage in general

Each "storage folder" (a data file on the memory stick) can handle up to 99 different programs, and

each program can consist of up to 50 rows of instructions, 0-49. The control system allows up to 99

storage folders.

The machine comes equipped with a 2GB USB-connected memory stick. This will be sufficient for

normal use. If there is a need for another memory stick for some reason, choose a version with a

max storage capacity of 4GB and dedicate its use to the machine and its programs. Any other form

will drastically slow down the read- and write speed of the control system.

Handling the program library

From the BASIC DATA screen, select "Library" to

enter the program management section of the

control system. This is where you manage the

library of programs, and you have the option of

loading and saving the current program.

Load

Using the arrow keys you can select which program you want to load. The currently loaded

program is marked with an asterisk (*, see screen above). Press the "Load" function key to load

the selected program. To load programs stored in other folders, see under USB on how to

change storage folder.

Save

When you want to save (or copy) the current

program, use the arrow keys to select the program

number you want to save to and press "Save". If the

program number you have selected is in use, you

will get a message (see screen shown) notifying

that the position is occupied and you can then press

"Save" again to overwrite the program already stored at that position (the previously stored

program will be lost and can not be recovered). To save programs in other folders, see under

USB on how to change storage folder.

A..Z

This function key toggles the sorting of the stored

programs between the program number ("Prog")

and the drawing number/name ("drawing-no")

stored.

Operating instructiOns 8344

20 2013-03-01

operaTion

Program storage in general, continued

USB

Pressing this function key opens the storage

folder management. When you use the "Load"

and "Save" functions within the USB storage folder

management, you load/save an entire library of

up to 99 programs in one go. The currently loaded

storage folder is marked with an asterisk (*).

Note: Loading another storage folder does not affect the currently loaded program.

The control system allows for upto 99 different storage folders (PA001.MY – PA099.MY), each

with up to 99 programs – allowing for a total of 9801 programs to be stored on the USB memory

stick.

Load: Loads the currently selected storage folder

and all of its up to 99 programs from the USB

memory stick. If there are any programs in the

loaded storage folder, the names of program 0 in

each folder is displayed in the "Status" column. By

setting/changing the name for program 0 in the

storage folder, you can set/change the name

displayed for each storage folder.

If the current program hasn't been saved, you will be prompted to save the program as well as

the entire storage folder.

Save: Saves or copies the currently loaded storage

folder (up to 99 programs) to selected folder (PA001.

MY–PA099.MY).Ifyouwanttosavechangestothe

currently loaded storage folder, press "Save" with the

currently loaded storage folder selected (marked

with an asterisk, *).

If the current program hasn't been saved, you will be prompted to save the program with

another press on "Save", or ignore the warning by pressing both "Ignore" buttons at the same

time.

A...Z: As with programs, this function key toggles

the sorting of the storage folders by order ("File

name") or by name ("Status" column).

Table of contents

Popular Industrial Equipment manuals by other brands

Hammer

Hammer HNC 47.82 manual

Trane Technologies

Trane Technologies V-Traq BAYTRAQ001 Series installation instructions

Buchi

Buchi ProxiMate Operation manual

PGR

PGR PH Series Maintenance and operation instructions

Siemens

Siemens SIRIUS ACT 3SU19 operating instructions

Samoa

Samoa LARIUS PNEUMATIC HOIST 200 Operating and maintenance manual