Page 9

Warranties and Liabilities

Warranty & Liability Coverage

1. Peak warrants that, subject to the provisions in this statement, purchased Peak generators, whether

purchased directly from Peak or indirectly via an approved, certified and trained distributor or partner

(referred to hereafter as a “Peak Partner”) will comply in all material respects with any specifications

referred to in your customer order confirmation and, subject to installation and operational guidelines

being followed as described in applicable product manuals, shall be free from any defects in quality

of materials or workmanship for a period of one year from the date of installation, provided this takes

place within 3 months of factory dispatch.

2. Where the purchased generator is from the Precision Hydrogen series, Peak further warrants that,

subject to installation and operational guidelines being followed as described in applicable product

manuals, the hydrogen cell shall be free from any defects in quality of materials or workmanship for a

total period of three years (inclusive of warranty period specified in clause 1) from date of installation,

provided this takes place within 3 months of factory dispatch.

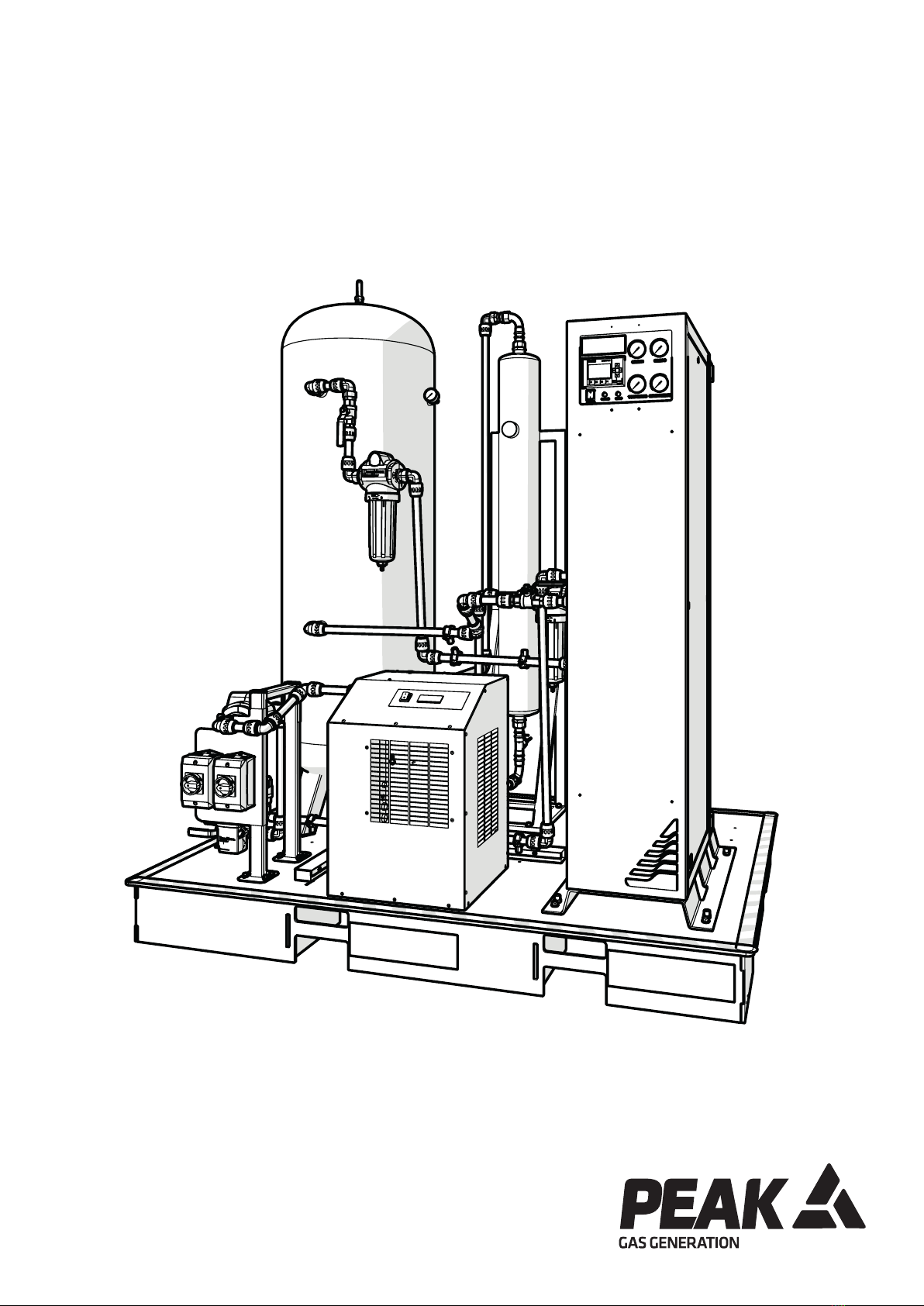

3. Where the purchased generator is from the i-Flow 6000 series and/or i-Flow skidded solution, Peak

further warrants that, subject to installation and operational guidelines being followed as described

in applicable product manuals, the generator shall be free from any defects in quality of materials

or workmanship for a total period of two years (inclusive of warranty period specified in clause 1)

from the date of installation, provided this takes place within 3 months of factory dispatch and the

following provisions have also been met:

a. you must purchase a service plan, ensuring the generator is serviced by Peak or a Peak Partner on

or before the end of the first 12 months of your ownership, and serviced at least once during each

subsequent 12 month period thereafter;

b. the generator (and any associated equipment) must have been commissioned by Peak or a Peak

Partner;

c. the feed air or inlet air supply to the generator must comply with the minimum ISO 8573-1:2010 air

class, as specified within relevant product user manual, at all times;

d. your air compressor, dryer, filtration and oil removal systems must be deemed suitable for use

by Peak or a Peak Partner, and must be changed and serviced regularly, in line with the equipment

manufacturer’s recommended guidelines; and

e. any generator failure or fault that is deemed to have been caused by the failure of any upstream

equipment, component, part or system (such as air compressor, air treatment or filtration) will be

excluded from the warranty described herein.

4. Peak also warrants that any replacement parts whether purchased (directly from Peak, or via a Peak

Partner) or supplied as part of any remedial action undertaken in line with the provisions of clauses 12

and 13, shall be free from any defects in quality of materials or workmanship for a period of 180 days

from the date of factory dispatch, provided its installation is performed by Peak or a Peak Partner.

5. This warranty does not exclude Peak’s liability in respect of any claim for death or personal injury

to any person, in so far as such can be attributed to negligence or breach of duty of care directly

resulting from failure of Peak to comply with the provisions in clauses 1, 2, 3 & 4.

Exclusions & Limitations

6. This warranty does not cover:

a. damage, deterioration or malfunction resulting from an alteration or modification to a generator

which has not been carried out by Peak or a Peak Partner;

b. damage, deterioration or malfunction resulting from what Peak reasonably believes to be abuse, or

misuse of a generator by you or any third party;

c. liability for accident or neglect (other than pursuant to clause 5);

d. maintenance or repairs which have not been carried out by Peak or a Peak Partner;

e. operation of a generator or exposure of a generator to environmental conditions that fall out-with

operational guidelines as specified in the applicable product user manual; and

f. lightning, power surges or any other acts of God or nature.

7. This warranty is non-transferrable. Only the original owner of the generator may benefit from the

terms within this statement.