Black Splitter S2 User manual

Black Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

Original Operating

Instructions

Black Splitter

Type: S2

Keep next to the Black Splitter for future use!

Year of manufacture: 2012

Manufacturer: Black Splitter GmbH Zum Ritzenhagen 9a 34508 Willingen, Germany

Date of issue: 27.12.2011 Change index: 02

S. 1

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

TABLE OF CONTENTS

PAGE

1.0 Safety

1.1General 3

1.2 Significance of symbols 4-5

1.3 Dangers of non-observance of safety information 6

1.4 Personal safety equipment 6

1.5 Safety information 7-8

• Safety regulations

• Precautionary measures

• General information and actions

• Machinery-specific regulations

1.6 Correct use of equipment 9-10

1.7 Hazards caused by accessories 10

1.8 Residual hazards 11

1.9 Workplace Black Splitter 12

1.10 Authorized persons 13

1.11 Confirmation of operatives 13

1.12 Operator 14

1.13 Safety precautions at the Black Splitter 15

1.14 Safety equipment 16

1.15Noiselevel 16

1.16 Checking safety equipment 17

1.17 Black Splitter safety equipment checklist 17

1.18 Unapproved modification and spare parts manufacture 18

1.19 Storage place for the operating instructions 18

2.0 Transport/installation

2.1 Layout diagram 19

2.2 Technical data 19

• Data Black Splitter

• Hydraulic motor

• Important connection information

2.3 Goods incoming check 19

2.4 Safety information for transport 20

2.5Transport/storage 21

2.6 Set up and connection 21

2.7 Welding the mounting plate with excavator attachment 22

2.8 Operating the Black Splitter for the first time 22

2.9 Removal the Black Splitter 23

S. 2

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

TABLE OF CONTENTS

SEITE

3.0 Operation

3.1 Overview diagram 24

3.2 Safety information for operation 25

3.3 Before commissioning 26

3.4 Set up 27

3.4.1 Replacing the screw cone 27

3.5 Functional description 28

4.0 Faults

4.1 Safety instructions for troubleshooting 29

4.2 Troubleshooting 29

4.3 Malfunction checklist 30

4.4Faultlist 30

5.0 Care and maintenance (operative)

5.1 Maintenance schedule 31

6.0 Repair/maintenance (operative)

6.1 Safety information for repair and maintenance 32

6.2 Maintenance schedule 33

7.0 Repair/maintenance (maintenance list)

7.1 Maintenance record 34

8.0 Hydraulics

8.1 Safety instructions for the hydraulics 35

8.2 Hydraulics plan with parts list 36

9.0 Replacement and consumables list

9.1 Spare parts order and customer service 37

9.2 Spare part list and consumables list (part list) 38-39

10.0 Conformity declaration

10.1 Proof of conformity 40-41

S. 3

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety _______________________________________

1.1 General

This operating instruction manual contains basic instructions which must

be observed during installation, operation and maintenance. They must

therefore be read by operatives, specialist workshop and set up technicians

before commissioning.

The Black Splitter has undergone a safety and acceptance inspection.

Nevertheless when using it dangers can arise for the user or third parties,

respectively the Black Splitter and other material property can be damaged

in the following cases:

* use by untrained or uninstructed personnel

* incorrect use of equipment

* incorrect maintenance or repair

Improper operation or misuse poses a risk for

* the operative (danger of injury)

* the Black Splitter and other property of the operator

* the efficiency of the machine

Along with the general information listed in this "Safety" section,

the specific safety instructions included in other sections shall also be

observed.

.

The operating instruction manual must always be available at the

place of use of the machine.

All those involved with the installation, commissioning, operation

maintenance and repair of the machine shall

• follow this operating instruction manual exactly.

For your safety!

S. 4

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety ________________________________________

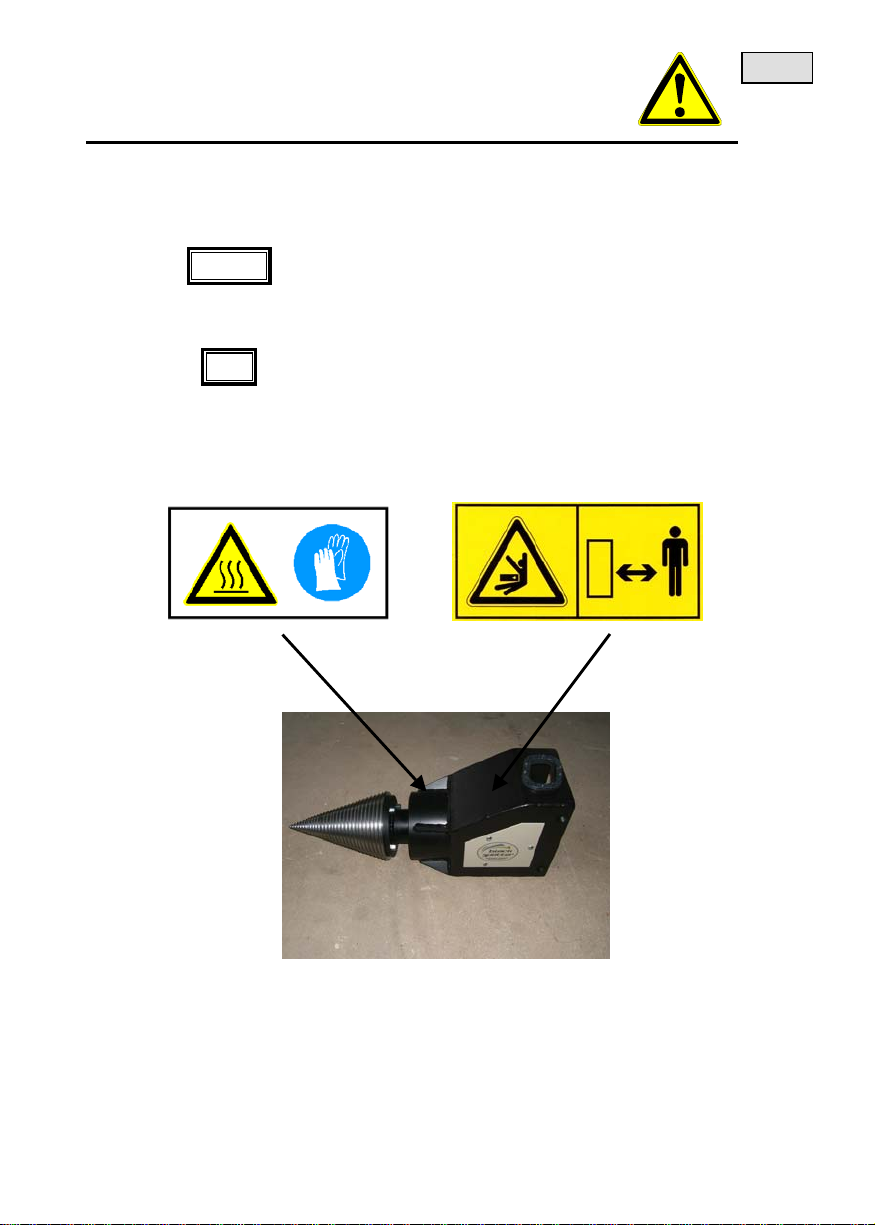

1.2 Significance of symbols

The safety instructions included in the

operating instruction manual which can

result in a risk to persons if ignored are

identified with the general hazard

symbol.

Caution: hot surface

Keep a sufficiently safe distance from the

swivel zone of the machine

Wear enclosed footwear

Wear protective gloves

Operating instruction manual

S. 5

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety ____________________________________

1.2 Significance of symbols

Caution

You will find this symbol on safety

instructions which, if ignored, can result in

risks for the machinery and its functions.

Note Represents advice or instructions which

will make work easier and ensure safe

operation

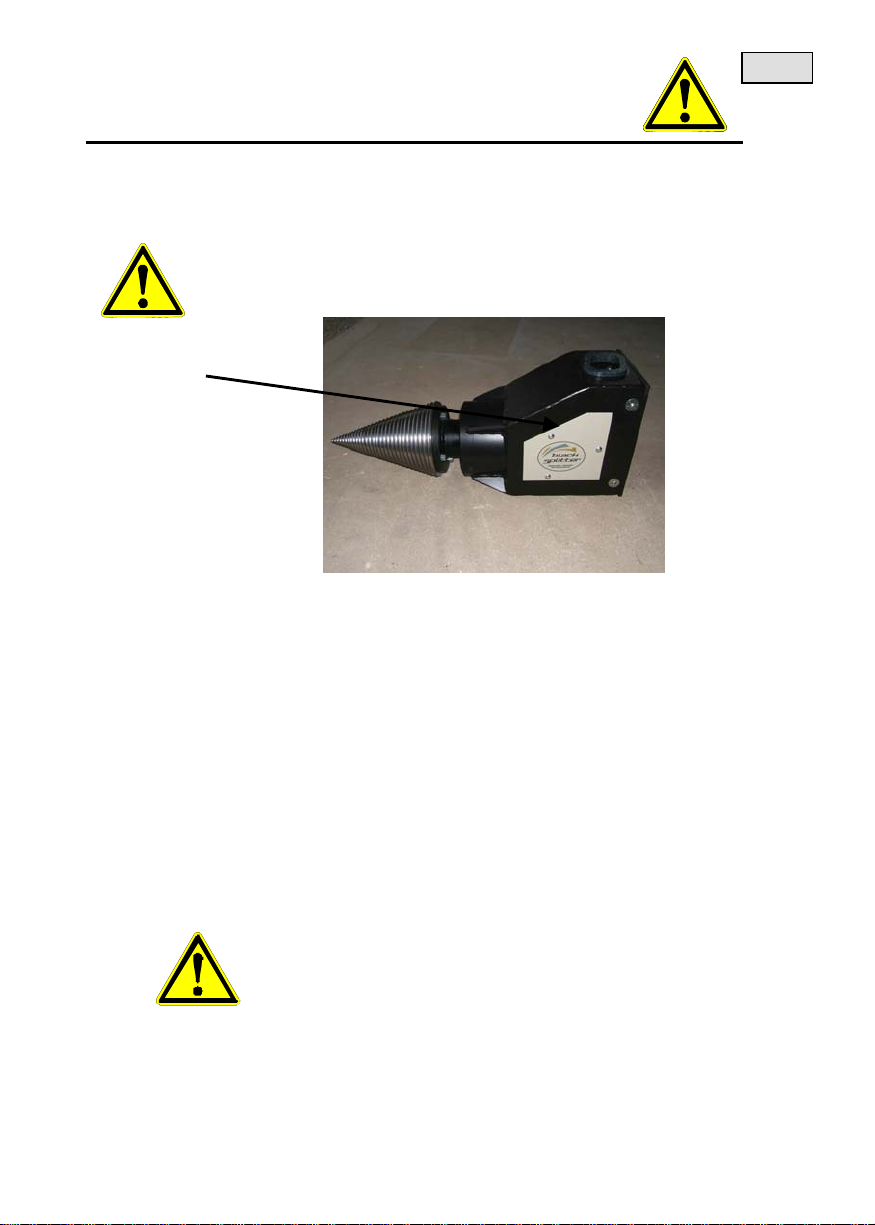

Figure 1: Black Splitter

S. 6

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety ____________________________________

1.3 Danger of non-compliance with safety notes

Non-compliance with safety information can invalidate any damage

compensation claims.

In individual cases non-compliance can, for instance, cause the following

dangers:

* failure of important machinery functions

* mechanical and electrical risk for personnel

1.4 Personal safety equipment

On the Black Splitter the setting up work, the commissioning and

the operating of the machine is only allowed to be carried out with

the stipulated protective gear.

Enclosed footwear must always be worn

when working with the Black Splitter.

Protective gloves must always be worn

when changing the screw tip.

S. 7

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety ____________________________________

1.5 Safety instructions

Safety regulations

1. Avoid damage to hydraulic lines.

2. Protect the hydraulic lines against sharp edges.

3. If the machine is not being used, interrupt the hydraulic supply.

4. Always disconnect the hydraulic supply to the machine if,

testing and maintenance tasks have to be carried out.

5. Do not remove the protective covers and screws.

Safety precautions

1. The Black Splitter is only allowed to be operated with the stipulated pressure.

2. All repair and maintenance work on the machine must be carried out by a

specialist workshop.

3. Set up work may only be carried out by a set up technician.

4. All operating and fitting personnel are only allowed

to commission the Black Splitter with closed footwear.

S. 8

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety ____________________________________

1.5 Safety instructions

General information and precautions

1. Use the Black Splitter exclusively for the purpose described in section

"1.6 Correct use of equipment".

2. Never work with a damaged Black Splitter.

Have the Black Splitter checked for faults immediately. All maintenance

and repairs must be carried out by a specialist workshop.

3. Store the Black Splitter only in a clean dry place.

Machine-specific regulations

1. The Black Splitter is only suitable for splitting and transporting logs.

2. The Black Splitter must only be operated with hydraulic oil.

3. Always observe safety instructions.

4. It is compulsory to read the operating instruction manual before assembling or

removal the Black Splitter.

5. The correct set-up of the Black Splitter is described in detail in the operating

instruction manual in section "3.0 Operation".

6. The care - and maintenance of the machine is described in detail

in the operating instruction manual in section

5.0 Care and maintenance (operator)

6.0 Maintenance/repair (operator)

S. 9

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety ____________________________________

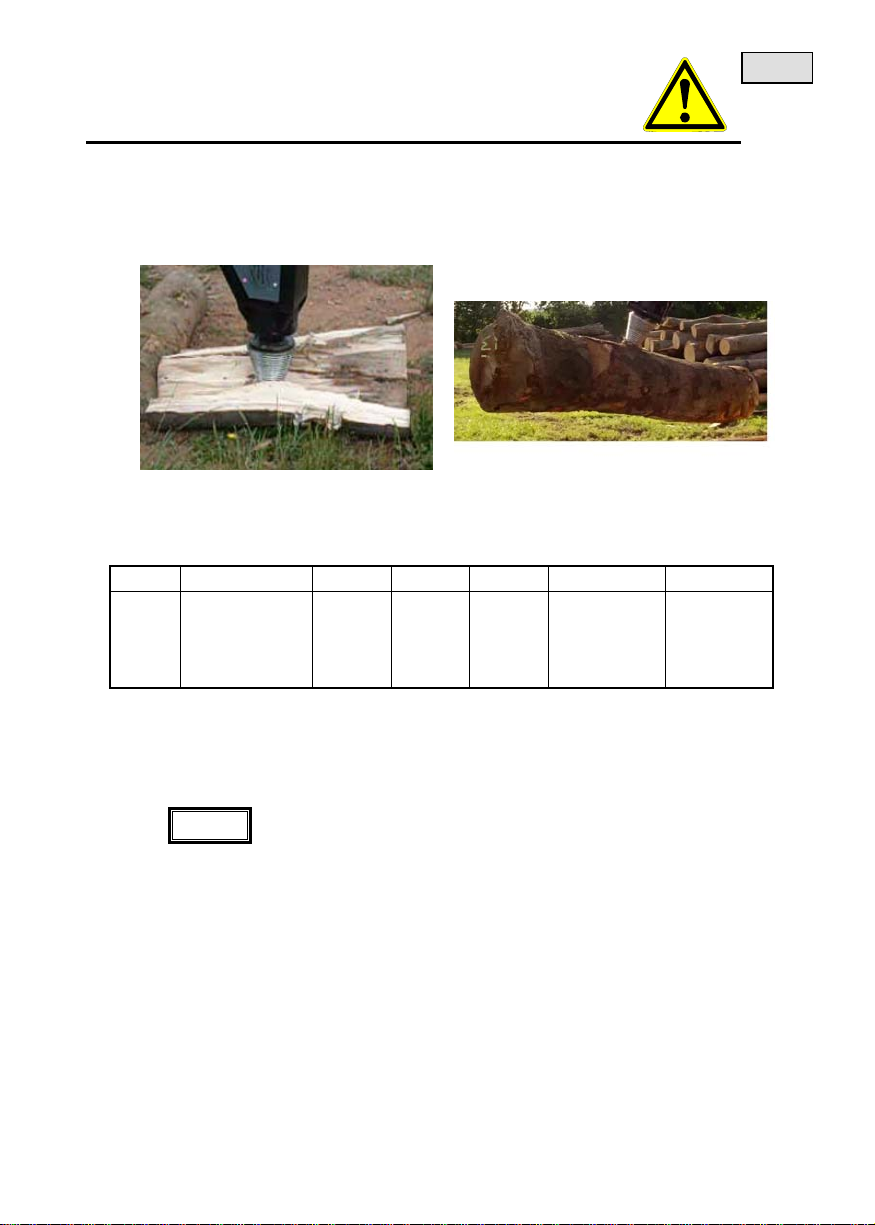

1.6 Correct use of equipment

The Black Splitter is only suitable for splitting and transporting logs.

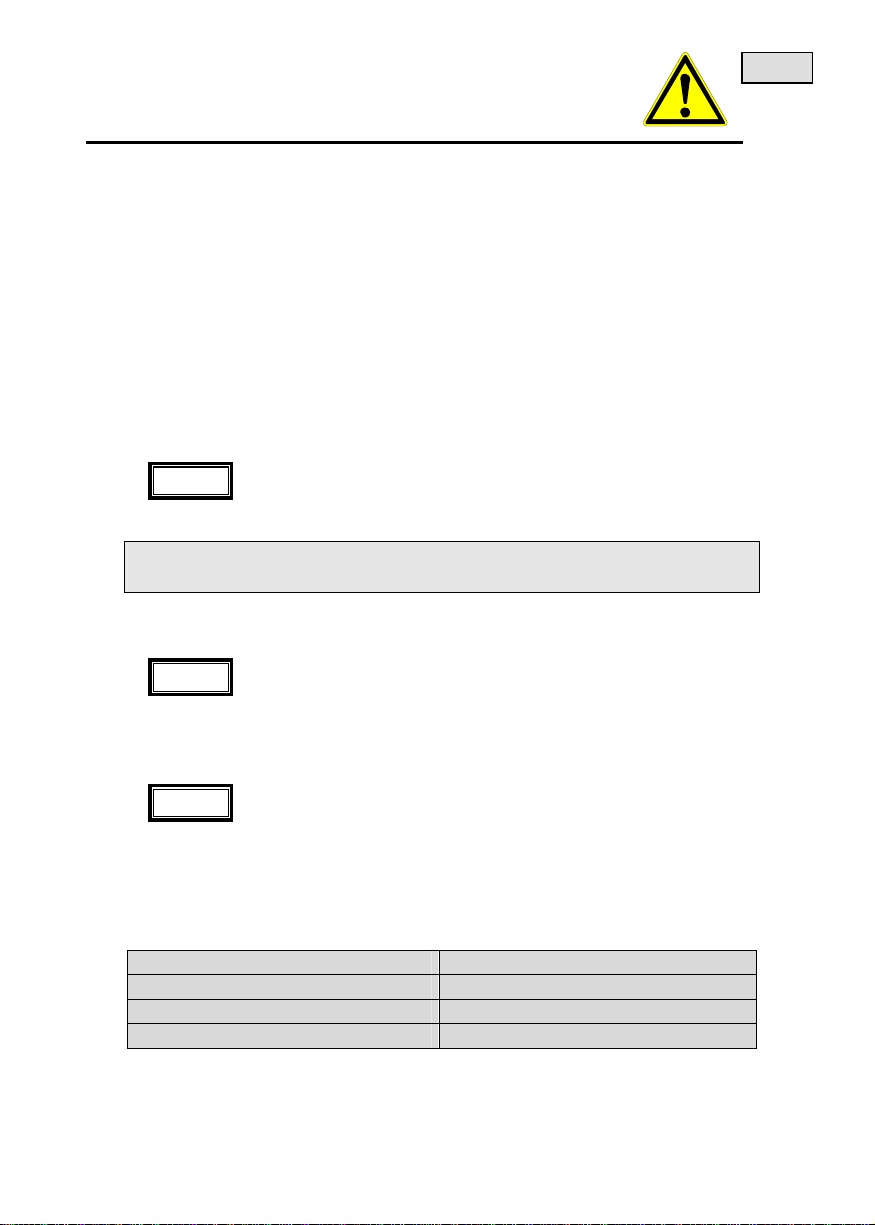

Figure 2: Splitting logs Figure 3: Transporting logs

Type max. pressure Length Width Height Volume Weight

S2 180-260 bar

180-230 bar

180-210 bar

180-380 bar

80 cm 23 cm 35 cm 518 cm3/rev

666 cm3/rev

801 cm3/rev

801 cm3/rev

ca. 109kg

The Black Splitter is connected with the carrier, e.g. forklift truck, tractor,

wheel loader, yard loader or excavator, by means of a mounting plate.

Caution When splitting, high forces must not be applied

by the carrier.

Any alternative or additional use is considered improper use of the Black

Splitter.

The operative/operator is responsible for any damage to the machine.

The same applies for unauthorised changes or manipulations of the Black

Splitter.

S. 10

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety ____________________________________

1.6 Correct use of equipment

Correct use of equipment also includes compliance with

instructions for

∗ safety

∗ operation

∗ maintenance, repair and troubleshooting

as described in this operating instruction manual.

Caution The Βlack Splitter must be repaired exclusively by a

specialist workshop.

The Black Splitter has undergone a safety inspection and a final inspection.

Unauthorised conversion or changing of the machine is prohibited on safety

grounds!

The conditions for use, maintenance and repairs in this operating instruction

manual shall be strictly adhered to.

1.7 Hazards caused by accessories

The addition of accessories must not disable any safety equipment on the Black

Splitter.

The safety equipment must always be in place.

S. 11

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety ____________________________________

1.8 Residual hazards

Despite compliance with all safety conditions, use of the Black Splitter

may still involve residual hazards.

Everyone who works on and with the machine must be aware of these

dangers, and must follow the instructions which prevent these residual

risks leading to accidents or damage.

Never remove protective covers or

disable them by modifying the Black

Splitter.

Caution: hot surface on the screw tip

Keep a sufficient distance from the

swivel zone of the machine.

Protective gloves must always be worn

when changing the screw tip.

S. 12

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety ____________________________________

1.9 Workplace Black Splitter

Zone 1: The operative is responsible that there are no persons within a sufficient

distance of the Black Splitter’s workplace.

Zone 1

Figure 4: Workplace Black Splitter

Keep a sufficiently safe distance from the

swivel zone of the machine.

S. 13

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety ____________________________________

1.10 Authorized persons

The minimum age for operatives is 18 years.

The responsibilities for different operations on the Black Splitter

shall be clearly defined and complied with.

Unclearly defined responsibilities are a safety risk.

Operatives may not start the Black Splitter unless they have read, understood

and signed the operating instruction manual.

Operatives => Persons who have read and understood

the operating instruction manual.

Maintenance personal => Operatives

Repair personnel => Persons from a specialist workshop

Any personnel under instruction of any kind must be under the constant

supervision of an experienced qualified staff member while working on

the machine!

1.11 Confirmation of the operators

The signature of the operator is confirmation of familiarity with the basic

occupational safety and accident prevention regulations and that instruction

has been received in the handling of the machinery and that s/he has read.

Date:__________ (Signature):___________

Date:__________ (Signature):___________

Date:__________ (Signature):___________

Date:__________ (Signature):___________

Date:__________ (Signature):___________

S. 14

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety ____________________________________

1.12 Operator

The operator is obliged to ensure that persons working on the Black Splitter

are familiar with the basic occupational safety and accident prevention

regulations and have received instruction in the handling of the machinery.

The operator shall additionally ensure that all maintenance and assembly

is carried out by maintenance personnel who have studied the operating

instructions carefully and are sufficiently well-informed.

The operator must

∗ ensure all operatives have constant access to the operating

instruction manual.

∗ make sure, and have this confirmed with a signature, that

the operating personnel have read the operating

instructions and understood them.

∗ instruct the operatives, the set up technicians the

maintenance personnel and the electrical engineers about

the Black Splitter and document this instruction.

∗ complete the faults list in section 4.4 and make this

available to Black-Splitter GmbH.

∗ provide personal safety equipment for use and

maintenance of the Black Splitter.

∗ provide additional instruction about residual hazards of the

Black Splitter.

∗ check at regular intervals that operatives are working

safely.

∗ at least every two years check that the Black Splitter safety

markings comply with regulations.

S. 15

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety ____________________________________

1.13 Safety precautions at the Black Splitter

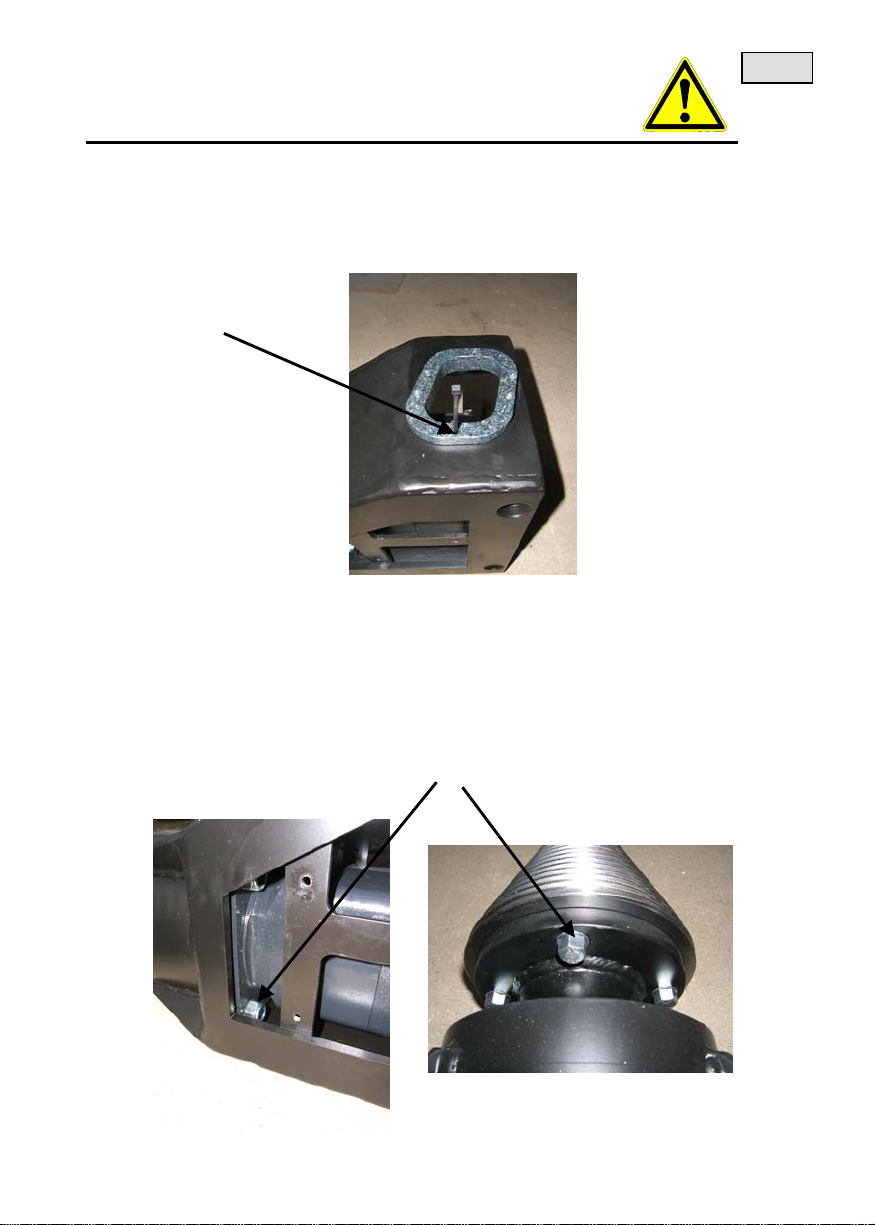

The hydraulic lines connected to the Black Splitter must be attached to

the upper opening using the cable ties supplied.

Figure 5: Attachment of the hydraulic hoses

In addition, after the first splitting operation (after approx. 2 - 3 hours

of splitting operation), the bolts on the hydraulic motor and on the screw cone

have to be checked and retightened. In order to access the bolts on the hydraulic

motor, the protective cover on the side has to be disassembled.

Cable tie

Mounting bolts

S. 16

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety ____________________________________

1.14 Safety equipment

Safety equipment

* must not under any circumstances be altered, removed or

* circumvented by modifications to the Black Splitter.

Figure 6: Side protective cover on Black Splitter

1.15 Noise level

The noise measurement on the Black Splitter was measured for the workplace

at a distance of 1 m from the machine surface and 1.60 m above the ground.

The sound pressure level of the Black Splitter is below 80 dB(A).

During the working process a higher sound-pressure level is generated.

At a sound-pressure level of between 80 dB(A) and 85 dB(A)

the operator shall

∗ provide hearing protection information and instruction.

∗ provide the operative with ear protectors.

∗ at regular intervals carry out precautionary medical check-

ups to monitor the operator’s hearing.

Protective cover

S. 17

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety ____________________________________

1.16 Checking safety equipment

Use the checklist for regular inspections of the safety equipment:

1.17 Checklist for safety equipment

Before starting up the machine, check that all safety equipment is correctly

fitted and fully operable.

Safety equipment may only be removed

∗ after stopping the machine

∗ securing the machine against restarting

Caution The general inspection instructions and function

tests shall be carried out without production

material.

Ensure immediate remedy of any faults found on

lines and safety equipment!

Checking intervals

Caution ∗ at the start of each shift

∗ after any maintenance or repair

Check the following

Caution

∗ prescribed condition

∗ secure attachment

∗ prescribed function

1.17 Black Splitter safety equipment checklist

General checks

Side protective cover Fitted and screwed tight

Screw connection Fitted and screwed tight

Hydraulic lines Fitted and screwed tight

Cylinder Fitted and screwed tight

Check date:__________ Checked by (Signature):___________

S. 18

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

1.0 Safety ____________________________________

1.18 Unapproved modification and spare parts manufacture

Refurbishment or changes to the Black Splitter are only admissible by

arrangement with the manufacturer. The manufacturer is Black-Splitter GmbH.

Original spare parts and manufacturer-authorised accessories contribute to safety.

There can be no liability accepted for the consequences of using other parts.

1.19 Storage place for the operating instructions

The operating instructions must be always kept

available next to the Black Splitter.

S. 19

Black-Splitter GmbH Zum Ritzenhagen 9 34508 Willingen, Germany Tel.: 05632 / 4594 Fax: 05632 / 966621

2.0 Transport/installation/dismantling _________________

2.1 Layout diagram

Figure 7: Black Splitter Figure 8: Black Splitter with excavator

attachment

2.2 Technical data

Data Black Splitter

Dimensions L 80 cm x B 23 cm x H 35 cm

Screw cone diameter 200 mm or 245 mm

Weight approx. 109 kg

Hydraulic motor

Hydraulic motor CPMV 500 Displacement 518cm3/rev 180-260 bar

Hydraulic motor CPMV 630 Displacement 660cm3/rev 180-230 bar

Hydraulic motor CPMV 800 Displacement 801cm3/rev 180-210 bar

Hydraulic motor EPMV 800 Displacement 801cm3/rev 180-380 bar

Important connection information

When connected to a depressurised line (leakage oil line), the max. pressure has

to be reduced by 30 bar. The screw tip can then only be turned in one direction.

2.3 Goods incoming check

Check the packaging for visible damage.

If the Black Splitter is supplied with visibly undamaged packaging but with

concealed damage, contact Black-Splitter GmbH immediately and document

the damage. (Pictures)

Table of contents