TTM Energiprodukter AB reserves the right to make techical changes. We reserve the right to make printing and factual errors.

2 (3)

2023-11

TTM MAG 250 Magnetite and dirt separator

Installation, operating and maintenance instructions

EN

TTM Energiprodukter AB

Slöjdaregatan

1

|

393

66

Kalmar

|

Sweden

|

T

el.

+

46

480-41

77

40

|

[email protected] |

www

.ttmenergi.se

For latest updates visit www.ttmenergi.com.

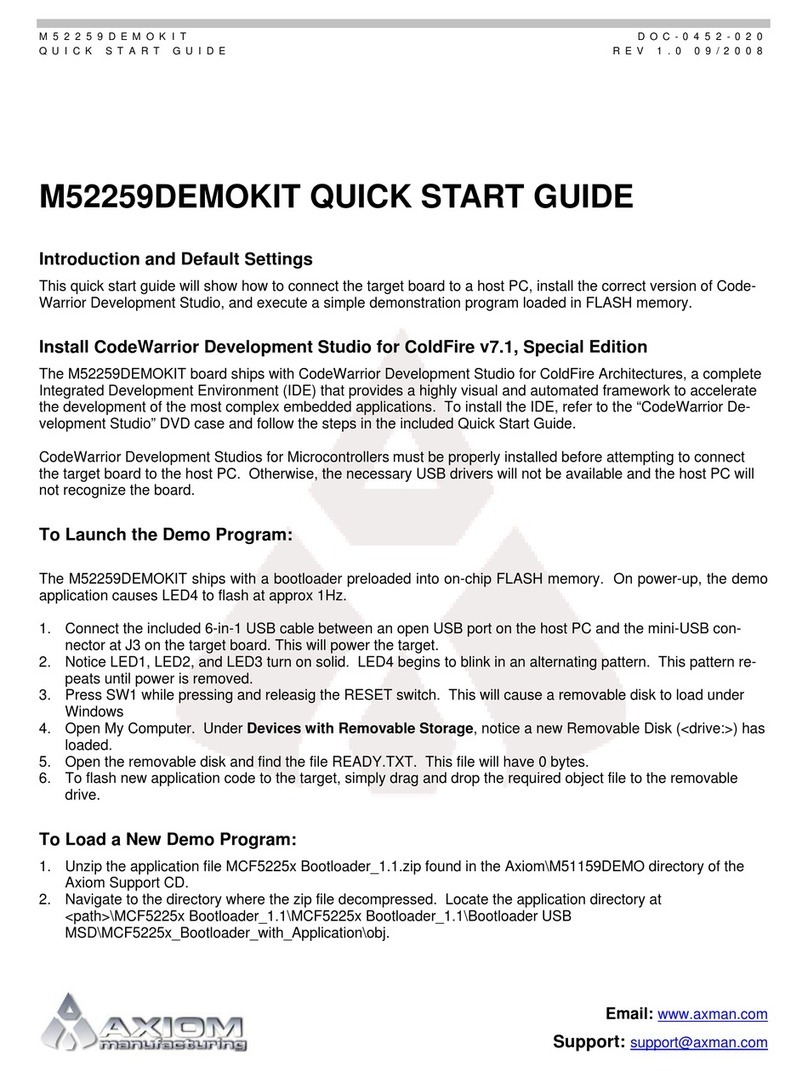

Return flow

TTM Connection

hose

Inlet

R25 int.

Pump

Return

R25 int.

Shut off valve

Shut off

valve

c/c min. 500 mm

DN20 - 25

21

3

3

3

4

Technical data

Installation

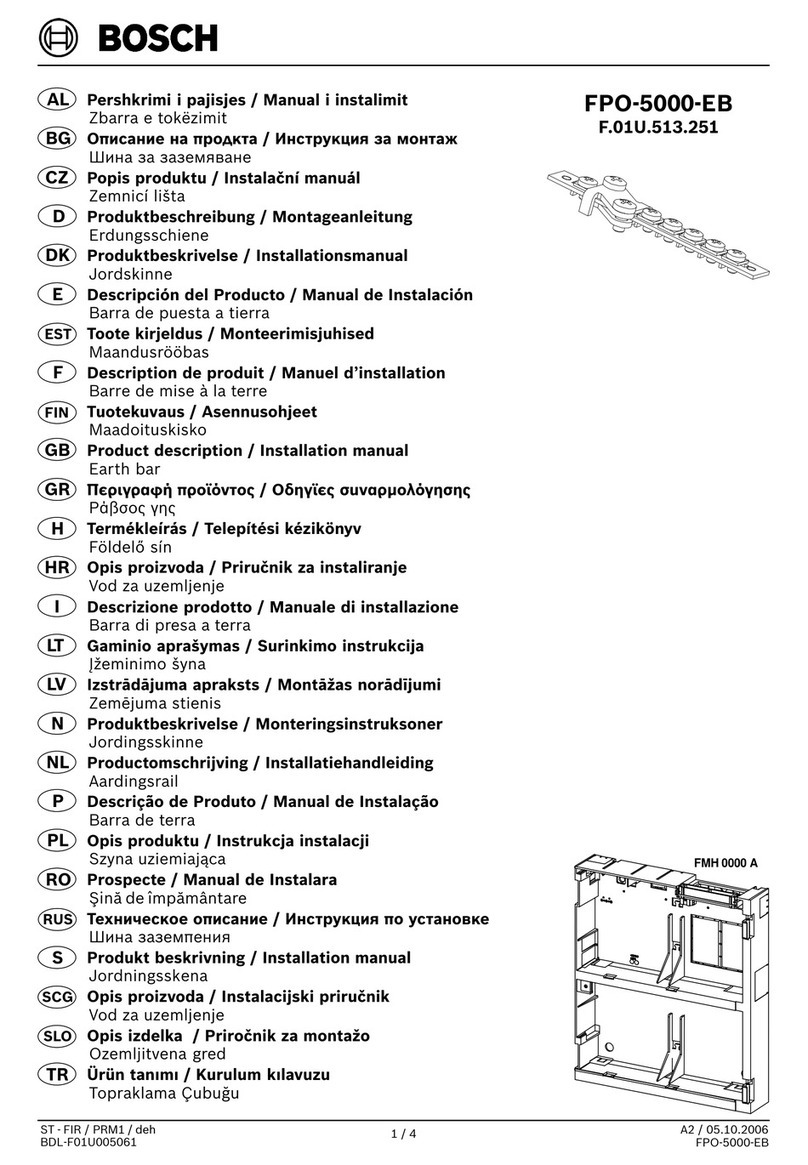

The filter is connected with TTM Connection hoses on the

system’s return conduit. Two bifurcations with ball valves with

minimum dimensions DN20 and a spacing of at least 500 mm are

installed on the bottom side of the conduit. The connections on

the TTM MAG 250 are DN25 internal thread.

• Connect a TTM Connection hose (1) from the first

bifurcation to the pump (inflow from the system)

• Connect a TTM Connection hose (2) from the second

bifurcation to the filter holder (return to the system).

• Open both ball valves (3) and wait until all the air in the filter

holder has been evacuated through the top aerator (4).

• Start the pump.

•Inspect the filter regularly and replace as needed.

The interval depends on the size of the system and

the quantity of particles in the fluid. We recommend

that an inspection be held as early as after a few

days in the event of heavily dirtied systems.

System pressure standard, total 10 bar

pressure in connection point, max.

Width x length x height (mm) 390 x 450 x 650

Medium temperature 0 – +60 ° C

Pressure class PN 10

Permissible liquids Water, glycol, alcohol

Connection dimension R25, int. thread

Magnetic insert Ø25 x 200mm

Magnetic intensity 12000GS

Power rating 1 ~ 230 V, 50 Hz

External fuse 10 A

Rated current 0.51 kW

Power 1 ~ 230V, 50Hz, power plug

Voltage 2.34 A

Protection class IP44

Weight 27 kg

Art. no. 506317

650

390450 (mm)

R25 int.