NOTTINGHAM ANALOGUE STUDIO Deco User manual

Nottingham

Analogue Studios

Dealer Manual

Table of Contents

1. Essential tools

2. Set up Specs

Distance from Tone arm center to spindle

Effective Mass of Tonearms

Nottingham Cartridge specs

3. Set up tips

The meaning of tight

Thoughts on VTA

Thoughts on Bias (anti-skate)

Motor height

Getting the tone arm position right

Installing and positioning the cartridge

Getting the right amount of oil in the bearing

Positioning your table – (including leveling, mains connection)

What about the plinth?

4. Maintenance & Service

Cleaning Belts

Changing Oil

Leveling the platter

5. Manuals

Horizon

Space Deck

Dais

Heavy Kit

Wave Mechanic

6. General Specs

Weights

Dimensions

7. Prices

8. Warranty information

Essential tools

Included

Allen Keys (metric)

Spirit Level

Protractor

Additional tools

Stylus Pressure Gauge - The Shure SFG gauge works well

Small Electric Screwdriver - With a clutch so you won’t over tighten

Cartridge Mounting Screws - Spares are helpful so when you drop them you don’t

have to go crazy looking for them

A Good pair of Needle Nosed Pliers Not Tweezers!

A Ruler w/ Metric scale - At least 12 inches long

A Good pair of Ears - Nothing will tell you more than listening to music

Set up Specs

Distance from Tone arm center to spindle

Interspace and RB-250 - 222 mm

Space Arm - 210 mm

Anna (10”) - 222 mm

Anna (12”) - 294 mm

Effective Mass of Tone arms*

RB-250 - 11.25 grams

Interspace - 11.25 grams

Space Arm - 12.5 grams

Anna (10”) - 13 grams

Anna (12”) - 15.5 grams

* All measurements are approximate

Nottingham “Tracer One” cartridge specs

Cartridge Type - Moving Magnet

Output - 5 millivolt – 5 cm/sec at 1KHz

Recommended Loading - 47 K Ohm

Tracking Force - 1.5 to 2.5 grams: Optimal 2.0 grams

Channel Balance - within 1.5 db at 1KHZ

Channel Separation - More than 18 db at 1000 KHz

Dynamic Compliance - 10 x 10-6th cm/dyne

Stylus Tip - .6 mil Elliptical Diamond Stylus

Impedance - 3200 ohms at 1000 Hz

DC Resistance - 480 ohms at 1000 Hz

Weight - 5 grams

Frequency Response - 15 – 25,000 cycles

Set up tips

The meaning of tight

There is a great deal of debate about how tightly you should tighten all of the little

screws and bolts when setting up a turntable. While we will not offer our thoughts on

other manufacturers recommendations, we thought you should know about our

recommendations for our turntable.

Tom Fletcher (Founder and head designer at Nottingham Analogue) says: “You

should tighten just enough to hold in place. Our turntables are generally on the warm

side of neutral, by tightening you have the ability to raise frequencies slightly. There are

not many situations where this will help.” Over tightening things will raise the frequency

of the turntable thereby exaggerating surface noise and making the table bright and

strident.

Thoughts on VTA

Setting VTA causes a great deal of anxiety. I’ve never really understood why in

light of the fact that no records are really the same thickness. Take a variety of records

and listen.

Tom says: “Start with the arm parallel to the record. No diamond on the end of

the styli is where it should be, so adjust the VTA up /down until you hear the best

possible compromise. This is done in conjunction with the bias. Test records will not do

the job for you, they may get you to the right haystack, but you will have to find the

needle.”

Thoughts on Bias (anti-skate)

A good place to start is to set the stylus on the blank space between the lead out

grooves. Adjust the bias weight until the stylus runs neither to the inside nor to the

outside of the record. The dynamics of blank plastic are not the same as when the stylus

is in the groove, so once you’ve done this add some bias, subtract some bias and listen.

Tom says: “On some cartridges, the bias mechanics can be used more beneficially

if there are two small bias weights on the end of the lever. Some moving coils can need

two bias weights, but these are the exception rather than the rule.” Call us at Audiophile

Systems if you need additional weights.

Motor height

The motor height is adjustable and it is important to line up the grooves on the

pulley with the grooves on the platter. Make sure the table is leveled first. If you need to

raise or lower the motor, do so by pushing on the motor itself. It is snug in its housing,

but it will move.

DO NOT PUSH ON THE PULLEY!

Installing and positioning the cartridge

My suggestion is to install the cartridge on the tone arm while the tone arm is free

from the table. It will be much easier to attach wires and get the mounting screws

threaded while the arm is free and on its back. Get the screws just snug enough to hold

the cartridge in place but loose enough so that you can move it when you are lining things

up with the protractor. Position the cartridge using the protractor, and then remove the

tone arm again to snug the screws up (see section on “The meaning of tight”).

Getting the tone arm position right

Set the position of the tone arm using the distances listed in the chart found in set

up specs. Do this before adding oil to the bearing well due to the fact that on some of the

tables you will need to remove the platter to re-position the arm and tighten the arm pod

back in place.

You may find that with certain cartridges you can optimize their set up by slightly

repositioning the arm. This again is more easily done before the oil is added to the

bearing.

Getting the right amount of oil in the bearing

Follow the recommendations on the set up sheet. Remember, though, that too

much oil is better than too little. I take an absorbent paper towel, fold it, tear it half way

across and position it around the spindle. Then, when the platter lowers into the bearing

well (and some oil spills out), most of the overflow of oil will be caught by the towel. I

usually spin the platter while it is settling. This seems to speed things up just a bit.

Positioning your table – (including leveling, mains connection)

Positioning your turntable (for that matter, your whole system) can have a major

effect on your outcome. You must make sure that it is level. You should take care not to

plug equipment into wall sockets that are connected to circuits that have dimmers,

fluorescent lights or low voltage lighting (with its attendant transformers). Also be

careful with fancy line conditioners. Some actually work, but most do not. Whenever

you add anything to your system, listen carefully and judge by what you hear and feel,

not by what you read in a magazine.

Tom says: “Sensible positioning of the turntable is required – special

stands/platforms are sold for this very purpose but few succeed in any way shape or

form! However, a few work very well – finding them can be difficult though. A wooden

table will do the job very well. Try to divorce the turntable (physically and electrically)

from big amps/transformers so you don’t undo all the work the turntable manufacturer is

trying to do. Keep the table still and you will hear the music!”

What about the plinth

A plinth is supplied with each table. In the case of the Space Deck and the

Horizon this is done to supply a platform with a predictable behavior. It is possible to use

the tables without the plinth, but be careful! As we mentioned in the section above, many

things that claim to do a “better” job, don’t. So listen.

The Dais requires the use of the plinth. There is a cutout for the motor that allows

the motor to sit on the shelf below the plinth. This provides further isolation between the

motor and the turntable. If you leave out the plinth, you will not be able to get proper

height for the motor or proper isolation.

The other thing to keep in mind is that if you get way too much oil in the bearing

it may overflow and drip onto your furniture. (Yeh, yeh, we all get the joke about British

machinery leaking oil. Why do you never drive a British car without an oil spot under it?

Because it must be out of oil.)

Maintenance & Service

Cleaning Belts

The belt should last a very long time. Occasionally you may want to clean it

(especially if you have smokers in the house or if the house is dusty). All you have to do

is wash it in some gentle liquid hand soap, rinse it carefully and let it dry.

Changing Oil

Tom Fletcher says: “Oil wears out under rotation – if the turntable is used very

frequently, then change the oil every six months. If it is used once or twice a week (how

most turntables are used) oil change is required only every 18 months to two years.”

You may also want to change oil if you haven’t tried the new Special

Nottingham Analogue Kinetic Enhancement oil. Believe it or not, this oil will

improve the performance of your turntable. It has improved the performance of every

turntable on which we have tried it.

Leveling the platter

Rarely, you may run across a platter that seems to wobble ever so slightly as it

turns. On the Space Deck and the Horizon turntables the platter is held in place by three

screws that are found under the mat and right around the spindle. You can correct these

minor wobbles by tightening or loosening the three screws. Adjust to level the platter but

be careful not to over-tighten. If you do not feel comfortable attempting this operation,

contact Audiophile Systems.

NOTTINGHAM ANALOGUE STUDIO

128 CORDY LANE, UNDERWOOD, NOTTINGHAM NG16 5FD

Design and Manufacture of Quality Audio Equipment

Telephone: +(44) (0) 1773 762947

Fax: +(44) (0) 1773 533566

V.A.T. REGISTRATION NO. 667 3729 92

ASSEMBLY INSTRUCTIONS FOR THE HORIZON TURNTABLE

Put approximately ½ of a capful of oil into the bearing well. Lower the platter assembly into the

bearing well and allow it to settle. This may take a few minutes.

Place the drive belt provided around the platter and pulley using the appropriate grooves for the

desired speed.

Fit the arm into the armbase and adjust using the protractor provided after you have fitted your

choice of cartridge.

Happy Listening!

NOTTINGHAM ANALOGUE STUDIO

128 CORDY LANE, UNDERWOOD, NOTTINGHAM NG16 5FD

Design and Manufacture of Quality Audio Equipment

Telephone: +(44) (0) 1773 762947

Fax: +(44) (0) 1773 533566

V.A.T. REGISTRATION NO. 667 3729 92

ASSEMBLY INSTRUCTIONS FOR THE HORIZON SE TURNTABLE

Put approximately ½ of a capful of oil into the bearing well. Lower the platter assembly into the

bearing well and allow it to settle. This may take a few minutes. Attach pulley onto motor

spindle.

Place the motor/pulley assembly on the left side of the plinth with the cutout to the front and cable

to the rear. The height can be adjusted by gently pushing the motor cassette up/down as

required using hand pressure. Do not adjust by pushing/pulling the pulley.

VERY CAREFULLY lower the main body/platter assembly over the motor/pulley assembly. The

cutout of the motor assembly base should be in line with the left leg of the main body, but not

touching it. Using a combination of adjusting the motor cassette height and leveling feet, the

platter and pulley can be lined up and leveled. Place the drive belt provided around the platter

and pulley using the appropriate grooves for the desired speed.

Fit the arm into the armbase and adjust using the protractor provided after you have fitted your

choice of cartridge.

Gently push the platter to start the turntable. It will adjust itself to the correct speed.

Happy listening!

NOTTINGHAM ANALOGUE STUDIO

128 CORDY LANE, UNDERWOOD, NOTTINGHAM NG16 5FD

Design and Manufacture of Quality Audio Equipment

Telephone: +(44) (0) 1773 762947

Fax: +(44) (0) 1773 533566

V.A.T. REGISTRATION NO. 667 3729 92

SPACEDECK INSTRUCTIONS

Place the turntable on a level surface. Half fill the bearing hole with oil. Carefully lower the

platter assembly into the bearing well centrally and allow to sink slowly under it’s own weight.

This can take several minutes. Level the turntable by the two adjusting feet. Place the motor up

to the platter and align the two motor pulley grooves to coincide with the two bottom grooves in

the platter by pushing the motor housing into the body up or down. If pushing down, do not push

from the top of the pulley as motor damage may result. Place the belt around the bottom grooves

of the platter and motor pulley. The bottom groove is 33 1/3 rpm and the top is 45 rpm.

Place the motor cut out groove by the static leg of the turntable without touching it and pull the

motor body away from the leg to leave a gap of 6mm between the top of the pulley and the

player. Always use the turntable with the mat on. The plastic cover is a dust cover only. Do not

touch the three caphead bolts on the top of the platter.

To start the turntable, give the platter a push by the thick rubber band. If pushed to fast, it will

adjust to the correct speed in a few seconds. To stop the platter, gently place your hand on the

thick rubber band.

Attach the cartridge to the arm and place the arm into the hole. The headshell should face directly

to the front when the arm is ‘parked’. Place the mat and an old record onto the platter. Position

the arm so that it sweeps the whole of the record before hitting the ‘stop’. Adjust the height and

level with the small spirit level on top of the headshell. Tighten the two grub screws in the arm

pillar. Align the cartridge and playing weight in the usual way. When using scales, place them

directly onto the mat, not on the record. The adjustment of the playing-weight is set by moving

the heavy bronze inner-weight. The bias is set by ear, but a rough guide is to lower the arm onto

the runout groove of the record. It should stabilize before running gently into the center of the

record. If the stylus moves quickly to the inside or outside of the record, the bias needs to be

increased or decreased.

Note: if unable to get the correct cartridge adjustment, the armboard satellite can be adjusted by

removing the platter and undoing the cap head bolt on the right side of the baseboard.

NOTTINGHAM ANALOGUE STUDIO

128 CORDY LANE, UNDERWOOD, NOTTINGHAM NG16 5FD

Design and Manufacture of Quality Audio Equipment

Telephone: +(44) (0) 1773 762947

Fax: +(44) (0) 1773 533566

V.A.T. REGISTRATION NO. 667 3729 92

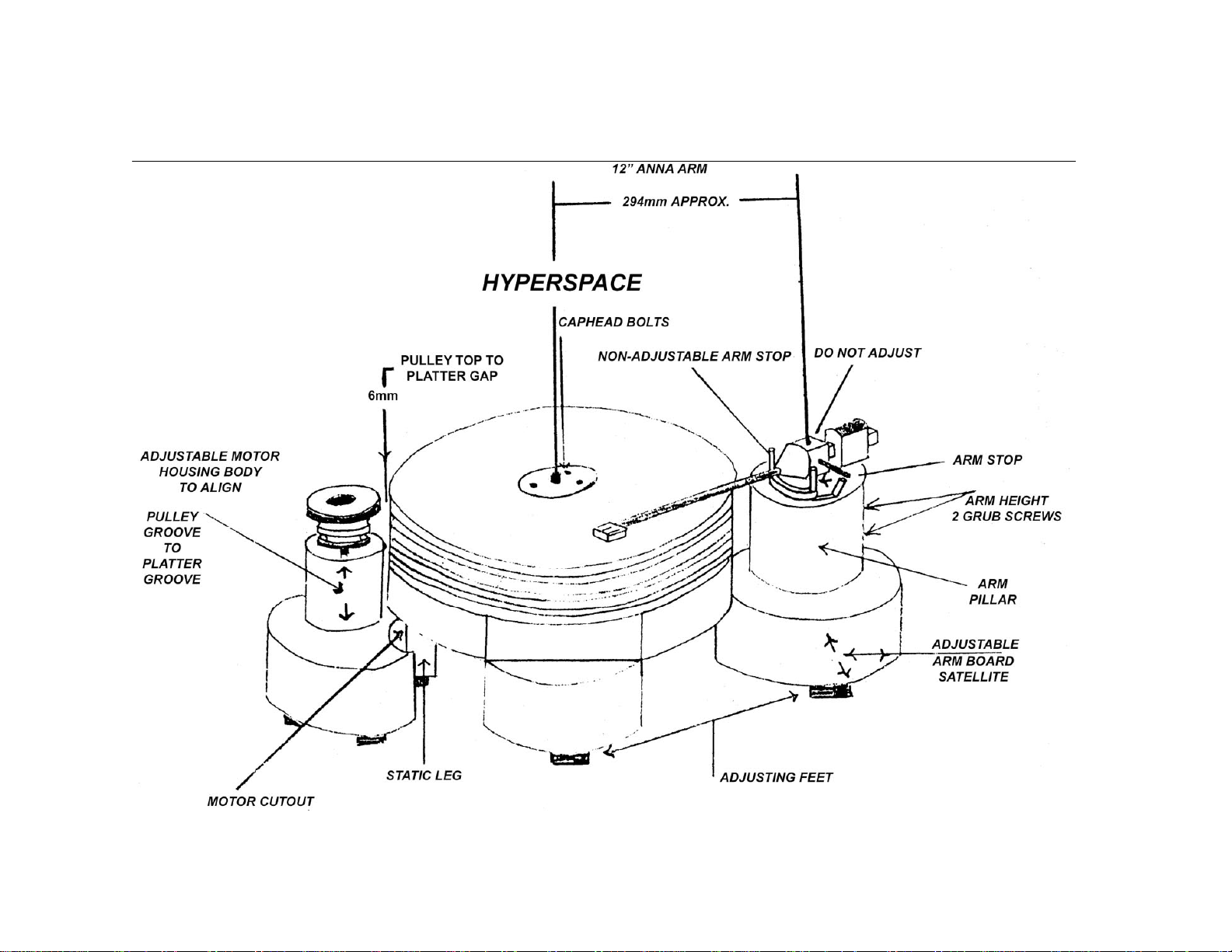

SPACEDECK DIAGRAM

ADJUSTABLE

ARM BOARD

ARM

HEIGHT:

2 GRUB SCREWS

ARM PILLAR

ARM STOP

DO NOT

ADJUSTING FEET

ARM STOP

PULLEY TOP

TO PLATTER

PULLEY TOP

TO PLATTER

PULLEY TOP

TO PLATTER

CAPHEAD BOLTS

NON ADJUSTABLE

PULLEY TOP

TO PLATTER

STATIC LEG

ADJUSTABLE MOTOR

HOUSING TO ALIGN

PULLEY GROOVE TO

PLATTER GROOVE

MOTOR

CUTOUT

NOTTINGHAM ANALOGUE STUDIO

128 CORDY LANE, UNDERWOOD, NOTTINGHAM NG16 5FD

Design and Manufacture of Quality Audio Equipment

Telephone: +(44) (0) 1773 762947

Fax: +(44) (0) 1773 533566

V.A.T. REGISTRATION NO. 667 3729 92

HYPERSPACE INSTRUCTIONS

Place the turntable on a level surface. Put two capfuls of oil into the bearing well. Carefully lower

the platter assembly into the bearing well centrally and allow to sink slowly under its own weight.

This can take several minutes. After placing the main platter into the bearing well fit the plastic

spacer over the spindle shaft, then gently lower the graphite top onto the main platter. Place the

second rubber band in the groove between the main platter and the graphite top/ Level the

turntable by the two adjusting feet.

Place the motor up to the platter and align the two motor pulley grooves to coincide with the two

bottom grooves in the platter by pushing the motor housing into the body up or down. If pushing

down, do not push from the top of the pulley as motor damage may result. Place the belt around

the bottom grooves of the platter and motor pulley. The bottom groove is 33 1/3 rpm and the top

is 45 rpm.

Place the motor cut out groove by the static leg of the turntable without touching it and pull the

motor body away from the leg to leave a gap of 6mm between the top of the pulley and the

player. Always use the turntable with the mat on. The plastic cover is a dust cover only. Do not

touch the three caphead bolts on the top of the platter.

To start the turntable, give the platter a push by the thick rubber band. If pushed to fast, it will

adjust to the correct speed in a few seconds. To stop the platter, gently place your hand on the

thick rubber band.

Attach the cartridge to the arm and place the arm into the hole. The headshell should face directly

to the front when the arm is ‘parked’. Place the mat and an old record onto the platter. Position

the arm so that it sweeps the whole of the record before hitting the ‘stop’. Adjust the height and

level with the small spirit level on top of the headshell. Tighten the two grub screws in the arm

pillar. Align the cartridge and playing weight in the usual way. When using scales, place them

directly onto the mat, not on the record. The adjustment of the playing-weight is set by moving the

heavy bronze inner-weight. The bias is set by ear, but a rough guide is to lower the arm onto the

runout groove of the record. It should stabilize before running gently into the center of the record.

If the stylus moves quickly to the inside or outside of the record, the bias needs to be increased or

decreased.

Note: if unable to get the correct cartridge adjustment, the armboard satellite can be adjusted by

removing the platter and undoing the cap head bolt on the right side of the baseboard.

NOTTINGHAM ANALOGUE STUDIO

128 CORDY LANE, UNDERWOOD, NOTTINGHAM NG16 5FD

Design and Manufacture of Quality Audio Equipment

Telephone: +(44) (0) 1773 762947

Fax: +(44) (0) 1773 533566

V.A.T. REGISTRATION NO. 667 3729 92

DAIS INSTRUCTIONS

Well done, you have found the instructions! Now, carefully unpack both boxes. OK – we know it

looks like a ‘kit’ to build a turntable. Put the plinth onto the surface you are going to use for your

turntable with the ‘U’ shape cut out facing away from you. Put the motor into the ‘U’ shape with

the lobe of the motor inside. Lift up the bearing chassis and you will find at the back a small ‘u’

shape cut out. This has to fit centrally around the motor, approximately 3mm away. With the

spirit level provided, level the chassis with the three leveling feet. Carefully remove the sealing

tape from around the bottom of the bearing. This will allow you to take the ‘male’ out of the

‘female’ part of the bearing. Half fill the bearing with the oil provided (do not worry if you slightly

over fill it). Gently lower the male spindle into the hole and let it settle slowly down for a few

minutes – it may take a long time to go right down, but it will reach its final level when the platter

is put on.

Before placing the platter onto the bearing, make sure the mating surfaces are clean. Then,

using the lifting handles provided, lower the platter very gently onto the bearing. Once the platter

has settled, check the level again with the spirit level on top of the platter. Unscrew the lifting

handles and gently place the graphite ‘mat’ on top of the platter. Place the drive belt around the

platter and motor (top groove for 45rmp, bottom for 33 1/3rpm). Now you can fit your arm in the

usual way. It is self-explanatory how to adjust the armboard ‘lobes’ with the tools provided.

Happy listening!

NOTTINGHAM ANALOGUE STUDIO

128 CORDY LANE, UNDERWOOD, NOTTINGHAM NG16 5FD

Design and Manufacture of Quality Audio Equipment

Telephone: +(44) (0) 1773 762947

Fax: +(44) (0) 1773 533566

V.A.T. REGISTRATION NO. 667 3729 92

ASSEMBLY INSTRUCTIONS FOR ‘HEAVY DUTY KITS’

Remove the arm from the turntable.

Position the turntable satellite over the edge of a table. With the standard Allen key, undo the two

headscrews under the armbase. Place the 25mm spacer in and re-connect the armbase to the

satellite using the longer bolts provided.

Position the centre adapter in the middle of the turntable and gently lower the graphite platter

onto the original platter. The damping ring is then placed in the groove between the original and

the new graphite platters.

Replace and set up the arm.

Happy listening.

PLEASE NOTE: Due to the nature of the platter material, you may often find small

imperfections in the top or bottom of the platter. This will make no difference to the function or

the sound.

NOTTINGHAM ANALOGUE STUDIO

128 CORDY LANE, UNDERWOOD, NOTTINGHAM NG16 5FD

Design and Manufacture of Quality Audio Equipment

Telephone: +(44) (0) 1773 762947

Fax: +(44) (0) 1773 533566

V.A.T. REGISTRATION NO. 667 3729 92

WAVE MECHANIC POWER SUPPLY

Why a power supply? But first, why an AC turntable motor?

Nottingham Analogue turntables excel by virtue of their almost elemental simplicity, relying as

they do on the fact that a rotating platter will continue to do so at absolutely constant speed

unless acted upon by outside forces. By coupling this steadily rotating mass to an arm base that

is stable around the axis of rotation of the platter, the result is a truly integrated unit.

By giving the platter adequate moment of inertia, the effects of any variability in outside forces are

minimized. However, the most important force, bearing friction, should if the bearing is correctly

made and lubricated remain essentially constant; hence, all that is required is to supply a small

amount of energy to the platter at a constant rate – just sufficient to counter the friction and

maintain a steady speed.

DC motors and their highly developed control systems may rightly dominate the small motor

market for “movement and placement” applications such as robotics, but are they what we need

in order to maintain this steady state? For this purpose, an AC synchronous motor backed by the

“mass” of the National Grid should be the answer. Unfortunately, although the laws of mechanics

show no sign of changing, electricity supplies are – and apparently always for the worse. There

are four main areas of concern.

1. Voltage variations

As a case in point, since “harmonizing” with the rest of the EC, the nominal UK domestic supply

voltage has fallen from 240V to 230V, but the permissible range of voltage has increased vastly,

now being from –6% (216.2V) to +10% (253V). This whole range will not be seen in any one

locality, but wide variations do occur between different areas.

For an AC synchronous motor, such voltage variations will not affect its overall speed, but will

affect its torque: not what we need for constant energy input (torque x speed = power). In

addition, the absolute voltage level has a very distinct effect on the dynamics and detail of the

music, with a clearly audible optimum voltage range. We need, then, to be able to optimize the

motor supply voltage and to hold it stable.

2. Frequency variations

These, by definition, will directly affect the speed of a synchronous motor. Supply frequency

variations are generally slow, but are easily demonstrated using an independent precision strobe

illuminator such as the “Zapper”.

Permissible variation in the UK is +/- 1% (6% equates to a semitone). Over 24 hours the

frequency must average exactly 50Hz to satisfy users of synchronous clocks, so that if the

frequency is slow at one point in the 24 hours, it must be fast at some other point as night follows

day (sometimes literally!). For a power supply, some slight adjustment of frequency is desirable

for pitch purposes but once set, it must remain stable.

3. Supply waveform

This is an aspect that has been becoming universally and insidiously more of a problem over the

years largely as a result of the “switched mode” power supplies that have generally supplanted

transformers in much modern electronic equipment.

The supply waveform does not now have a clean sinusoidal shape, but shows drastically clipped

peaks – the equivalent of adding numerous high order harmonics to the fundamental 50 or 60 Hz.

These can be shown to exist at significant levels far up into the audio frequency range, and even

if attenuated by damping in the drive belt will still feed through to the platter. We need to

synthesize a new clean waveform; “filtering” is not an answer.

4. Voltage spikes, and other “hash”

These are another part of the fallout from the volume and complexity of modern consumer

demands, and are sufficiently worrying to have provoked restrictive regulations on equipment

manufacturers. Our AC motor supply needs to be free of all such intrusions.

THE WAVE MECHANIC

The “Wave Mechanic” power supply addresses all of these issues, and provides a clean

waveform, stable in voltage and frequency even when run off voltages well below the permissible

level. The output voltage is pre-set internally to be in the optimum range, and there is a single

control on the front panel to allow minor adjustment of the frequency for pitch control. Other than

for this purpose it will probably remain untouched.

Both 50Hz and 60Hz version are available configured to suit local frequency and voltage.

For a Turntable speed reference to partner the “Wave Mechanic” power supply, the “Zapper”

hand-held battery-operated strobe illuminator is ideal. This is available in 50Hz and 60Hz

version, either with the power supply or separately for more general use.

The audible benefits of the power supply are very clear. Detail, dynamics and sound stage are all

much improved, but perhaps the most evident feature is the way that the whole pace and rhythm

of the music sound natural and true. Pitch stability is impeccable, giving complete confidence

and much deeper involvement in the musical performance.

The benefits should not be expected to replace those from upgrading the turntable, but rather to

complement them. Al of the Nottingham Analogue turntables will benefit, whether your current

one or your next upgraded one!

Specifications:

Supply voltage/frequency: Version for 230V/50Hz, 115V/60Hz, 100V/50Hz, 100V60Hz

Power consumption: 6.5W

Fuse: Ceramic HRC 5mm x 20mm T250mA (230V), T500mA (115V and 100V)

Output frequency: 50Hz or 60Hz (depending on model) with control in center position.

Case Dimensions: (H x W x D) 2.55” x 4.13” x 11.22”

Weight: (w/ packaging) 5.6 lbs.

NOTTINGHAM ANALOGUE STUDIO

128 CORDY LANE, UNDERWOOD, NOTTINGHAM NG16 5FD

Design and Manufacture of Quality Audio Equipment

Telephone: +(44) (0) 1773 762947

Fax: +(44) (0) 1773 533566

V.A.T. REGISTRATION NO. 667 3729 92

Pulley Installation

An adjustment has been made to the packing of Nottingham’s turntables to ensure that

the motor/pulley assembly can better withstand the rigors of shipping in the United

States. Follow these steps to properly affix the pulley to the motor:

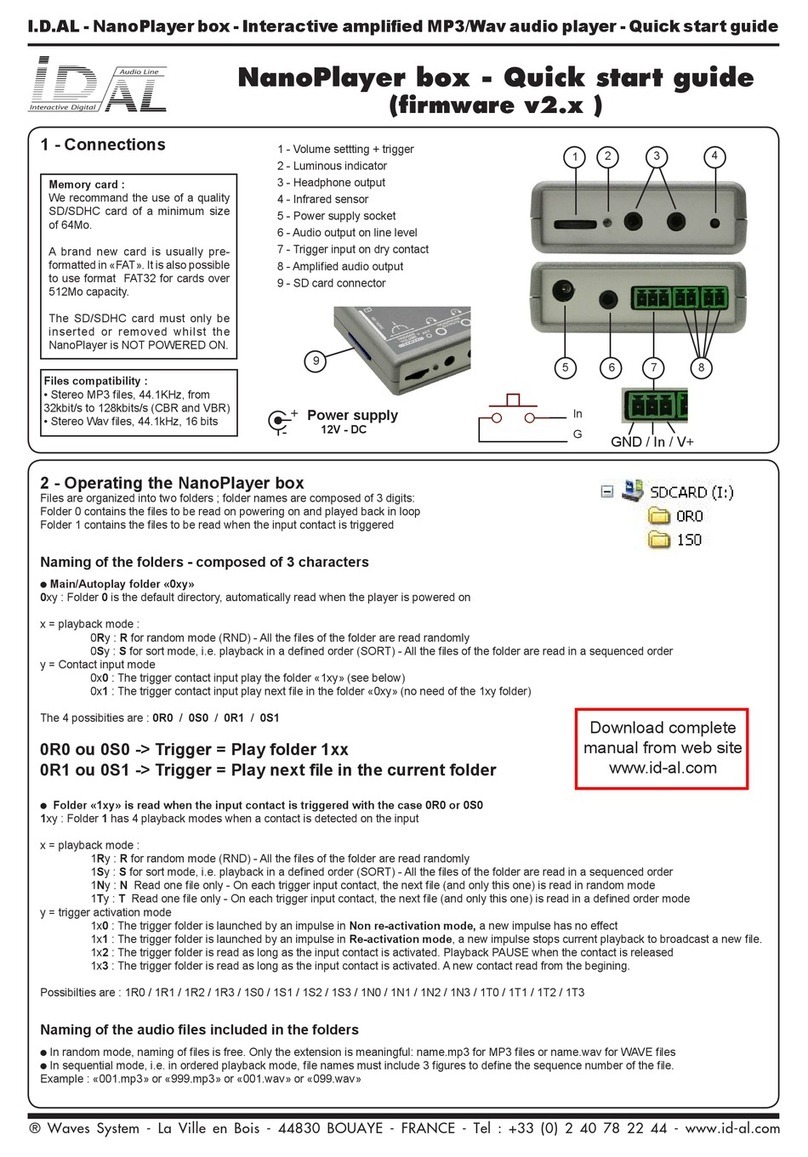

1. Locate the pulley (fig. 1)

2. Locate the motor (fig. 2)

3. Slide the hole in the bottom of the pulley (fig. 3) over the post at the center of the

motor, and press down until the pulley stops.

When the turntable is spinning, if you notice rubbing at the bottom of the pulley, simply

pull up on the pulley to eliminate any contact with the motor housing.

Figure 1

Figure 2

Figure 3

Completed motor assembly

NOTTINGHAM ANALOGUE STUDIO

128 CORDY LANE, UNDERWOOD, NOTTINGHAM NG16 5FD

Design and Manufacture of Quality Audio Equipment

Telephone: +(44) (0) 1773 762947

Fax: +(44) (0) 1773 533566

V.A.T. REGISTRATION NO. 667 3729 92

Rega Tonearm Instructions

With the cartridge fitted and aligned using the alignment

protractor supplied, ensure that the bias adjustment

slider is set to zero. Screw the balance weight along its

shaft until the stylus is ‘floating’ just 1mm clear of the

record.

The recommended tracking force can now be applied by

rotating the balance weight so that it moves toward the

front of the arm. One half-turn gives 1g of tracking force.

The green plastic plugs on the weight can be used as a

visual aid to achieve this. Always use a force that

corresponds to the upper limit of the cartridge maker’s

recommended range.

Set the bias adjustment slider to the same number as

the tracking force control, i.e.

1 ½g tracking force=1 ½ on the bias slider.

This manual suits for next models

6

Table of contents

Other NOTTINGHAM ANALOGUE STUDIO Turntable manuals