NovaFlex Z-Flex DVO User manual

Model DVO

Z-Flex Flexible Insulated Direct Vent System for Oil Burning Appliances

INSTALLATION AND MAINTENANCE INSTRUCTIONS

PRODUCT Flexible Insulated Direct Vent System for oil burning appliances

MANUFACTURER Z-Flex (US) Inc.

20 Commerce Park North

Bedford, New Hampshire 03110-6911 Telephone 603.669.5136

Facsimile 603.669.0309 Toll Free 800.654.5600

COMPONENTS Part # Description

2OILVNT0305 Insulated Flex Vent pipe, 3" inner dia. - 5' long

2OILVNT0310 Insulated Flex Vent pipe, 3" inner dia. - 10' long

2OILVNT0315 Insulated Flex Vent pipe, 3" inner dia. - 15' long

2OILVNT0320 Insulated Flex Vent pipe, 3" inner dia. - 20' long

2OILVNT0405 Insulated Flex Vent pipe, 4" inner dia. - 5' long

2OILVNT0410 Insulated Flex Vent pipe, 4" inner dia. - 10' long

2OILVNT0415 Insulated Flex Vent pipe, 4" inner dia. - 15' long

2OILVNT0420 Insulated Flex Vent pipe, 4" inner dia. - 20' long

2OILCON03 Vent Adaptor, 3" to 3" Flex

2OILCON43 Vent Adaptor, 4" to 3" Flex

2OILCON43IP Vent Adaptor, 4" to 3" Flex /w Inspection Port

2OILCON53IP Vent Adaptor, 5" to 3" Flex /w Inspection Port

2OILCON04 Vent Adaptor, 4" to 4" Flex

2OILCON04IP Vent Adaptor, 4" to 4" Flex /w Inspection Port

2OILCON54IP Vent Adaptor, 5" to 4" Flex /w Inspection Port

2OILCON64IP Vent Adaptor, 6" to 4" Flex /w Inspection Port

2OILCON74IP Vent Adaptor, 7" to 4" Flex /w Inspection Port

2OILTRM404 DVO Termination (Flex -L CFT-4), concentric, 4" exhaust, 4" intake

2OILTRM604 Aerocowl Termination, concentric, 4" exhaust, 4" intake

2OILTRM605 Aerocowl Termination, concentric, 5" exhaust, 4" intake

2OILRISE04 Riser Terminal 36"

1TLXXX0305 3" x 5' Air Intake Flex

1TLXXX0310 3" x 10' Air Intake Flex

1TLXXX0315 3" x 15' Air Intake Flex

1TLXXX0320 3" x 20' Air Intake Flex

1TLXXX0405 4" x 5' Air Intake Flex

1TLXXX0410 4" x 10' Air Intake Flex

1TLXXX0415 4" x 15' Air Intake Flex

1TLXXX0420 4" x 20' Air Intake Flex

4RA43 Adaptor, Reillo BF 3" to 4"

4RA44 Adaptor, Beckett AF 4" to 4"

7HS48XX 3" Clamp

7HS72XX 4" Clamp

4FCVRVX04 4" VRV, Vacuum Relief Valve / Tee

2SILRRTV106X Z-Flex RTV High Temp. Sealant 500F 3oz

2SILRRTV106 Z-Flex RTV High Temp. Sealant 500F 10oz

2SILUC Permatex Ultracopper Sealant 700F 3oz

2SILUC10 Permatex Ultracopper Sealant 700F 8.75oz

APPROVAL AND USE

Consult the appliance manufacturers’ Installation Instructions for approval and guidelines

concerning proper installation. Attention should be paid to the following:

1. Termination a. location b. clearance to combustibles

2. Vent Pipe a. minimum & maximum lengths b. clearance to combustibles c. slope

INSTALLATION NOTES

1. Vent pipe bend radius is 12”

2. Support vent pipe with metal strapping every 36”

3. Maximum wall thickness 14”. Call Z-Flex for recommendations on thicker walls.

4. Kit or system may be based on the specific appliance.

5. System is not designed for common venting. Use for single appliance only.

6. Appliance adaptor test port is for combustion testing required by appliance manufacturer.

7. Follow National Codes for the installation of oil burning appliances. In USA – NFPA 31 In

Canada CAN/CSA B139 and local regulations.

MAINTENANCE

Z-FLEX recommends that the entire heating system, including the appliance and venting

system, be checked annually by a qualified heating professional.

JOINT ASSEMBLY

1. Apply sealant to “threaded” end of vent adaptor.

2. Insert the threaded end in to the vent pipe. Screw the adaptor into the vent pipe in a counter

clockwise direction. The adaptor should be inserted fully until it is tight. If it doesn’t completely

screw into the vent, unscrew and repeat.

3. If the vent needs to be cut to length, use a fine tooth hacksaw. Remove any burrs before

installing adaptor.

2

TERMINATION INSTALLATION

1. Determine location for termination.

2. Cut an 8½” hole through the wall.

3. Pull apart the inner and outer termination sections.

4.Slide the outer wall plate over the outer section of the termination until it rests against the

bead.

5. From the outside the building, insert the outer section through the wall until it rests against

the wall.

6. From the inside, slide the inner wall plate over the outer section and secure it to the wall with

four (4) screws.

7. Position the outer section so that the seam on the flue collar is on the top and the air intake

is on the bottom. Secure to the outer section by tightening the gear clamp around it.

8. Seal with a weather proof sealant around the the bead and edge of the outer wall plate to

avoid water from entering.

TERMINATION CONNECTION

1. Slide the inner section over the vent pipe.

2. Attach the adaptor as per joint assembly.

3. Apply a bead of sealant around the flue collar and slide on adaptor and tighten gear clamp.

4. Seal the seam on the adaptor.

5. Slide the inner section over the outer section and secure by tightening the gear clamp.

6. Stretch the intake flex to the desired length and slide over intake collar and secure by

tightening the gear clamp.

7. Seal the gap between the vent pipe and the inner section with silicone sealant.

3

APPLIANCE CONNECTION

1. Connect the appliance adaptor to the appliance collar as per joint assembly.

2. Apply sealant around the appliance flue collar.

3. Slide the appliance adaptor over the flue collar.

4.Tighten the gear clamp around collar.

5. Install the burner air adaptor. Tighten integral clamp.

6. Put the gear clamp over the intake flex and slide flex over large end of adaptor. Tighten

clamp.

7. A vacuum relief device may be required as per appliance manufacturers’ installation

instructions.

0INSTDVO 3.31.2008

4

The information provided within is for informational purposes only. We have made every effort to ensure the accuracy of the provided information and assume no responsibility for any loss

or damage due to errors or omissions or to the use or misuse of any information supplied. It is impossible to test all products under all conditions to which they might be subjected in the

field. It is therefore the buyer and/or end users’ responsibility to test all products under the conditions that duplicate the service conditions prior to installation. All improvements, all

specifications are subject to change without prior notice. It is the buyer and/or end users’ responsibility to review our complete Terms and Conditions of Sale located on our web sites at:

www.novaflex.com | www.z-flex.com | www.flexmaster.com.

Table of contents

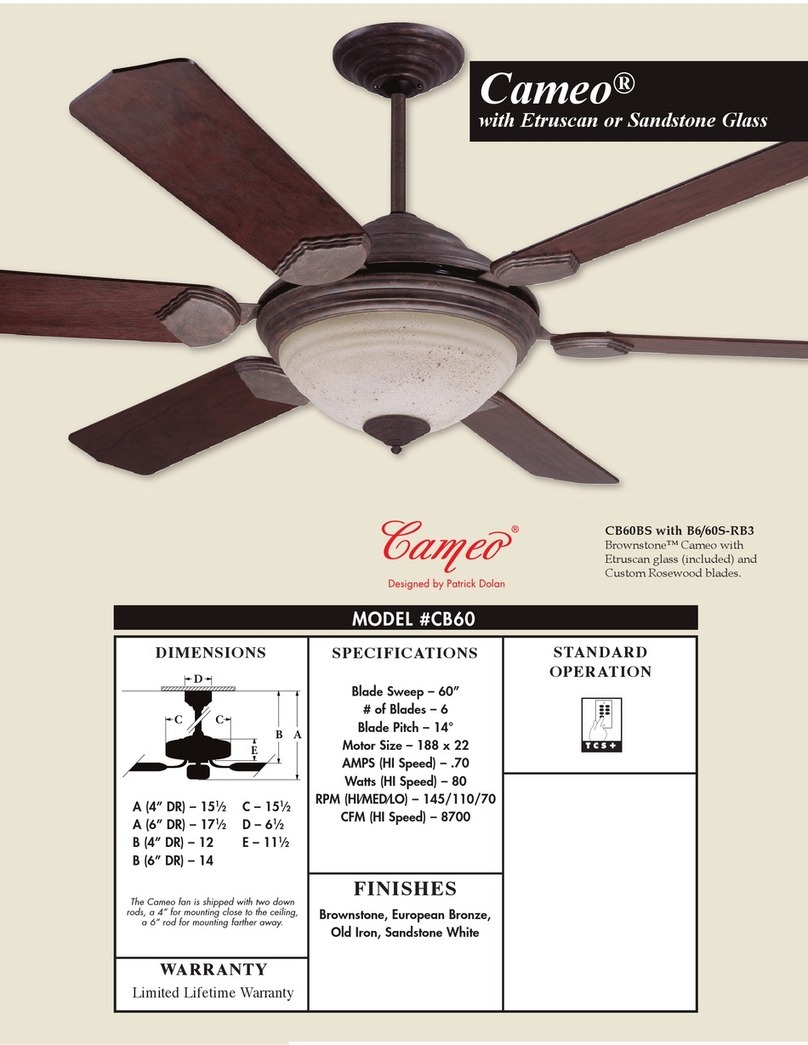

Popular Fan manuals by other brands

Craftmade

Craftmade Cameo CB60 Specifications

S&P

S&P OZEO E ECOWATT Series installation manual

Omega Altise

Omega Altise OD152W Operation, maintenance and safety instructions

McQuay

McQuay IM-WM1W-0704 installation manual

Martec

Martec DISCOVERY II AC Series installation guide

Brink

Brink Flair 325 2-2 Installation regulations

Alpha Fan

Alpha Fan AX20-5B/56 instruction manual

Hinkley

Hinkley MARIN instruction manual

Alpina

Alpina YH-40R-0 instruction manual

Bionaire

Bionaire BWF0910AR Instruction leaflet

Monte Carlo Fan Company

Monte Carlo Fan Company 5AB52XX Series Owner's guide and installation manual

Commercial Electric

Commercial Electric HVFF16CE Use and care guide