#55-3556-1 Rev.1

Printed 10-2009

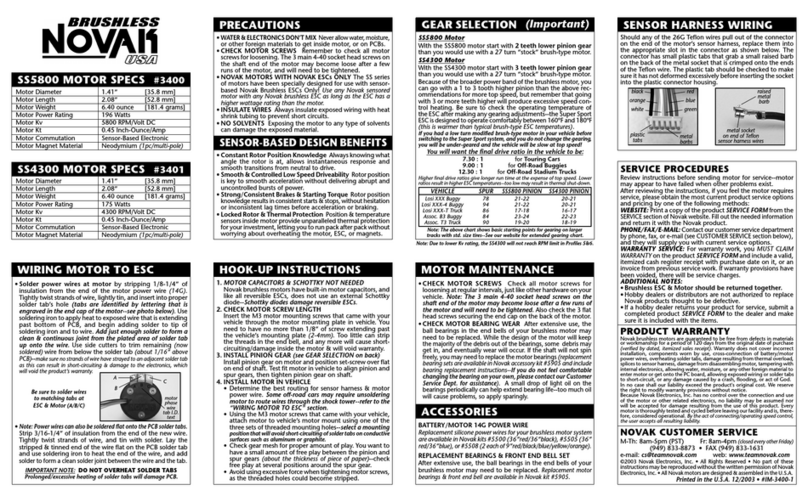

PRECAUTIONS

•WATER&ELECTRONICSDON’TMIX Never allow water, moisture,

or other foreign materials to get inside motor.

•INSULATEWIRES Always insulate exposed wiring with heat shrink

tubing to prevent short circuits.

•NOSOLVENTS Do NOT expose the motor to any type of solvents.

•MOTORCAPACITORS Brush motors generate electrical noise. Install

all 3 capacitors on the motor to help prevent radio interference.

•NOSCHOTTKYDIODESWITHREVERSIBLEESCs NEVER use Schottky

diodes on the motor with reversible ESCs–ESC damage will occur.

•SETGEARMESHPROPERLY Too tight of a gear mesh can result in

motor pinion shaft breakage–be sure to adjust mesh properly.

MOTOR MAINTENANCE

•CHECKMOTORBUSHINGS&BRUSHWEAR

After extensive use, your motor’s bushings or commutation brushes

may need replacement. A small drop of light oil on the bushings

periodically can help extend bushing life–however, too much oil will

attract dirt and will cause problems, so apply sparingly & wipe clean.

•CLEANINSIDEMOTOR

Periodically blow out the inside of the motor with compressed air.

INSTALLATION INSTRUCTIONS

1.INSTALLMOTORCAPACITORS

Electric motors generate RF noise that causes interference. The

included 0.1µF (50V) [Novak #5620] non-polarized, ceramic

capacitors must be used on all Terra Claw motors to reduce

motor noise and prevent ESC damage.

Solder 0.1µF (50V) capacitors between:

•POSITIVE(+)motortab&NEGATIVE(–)motortab.

•POSITIVE(+)motortab&MotorCan

•NEGATIVE(–)motortab&MotorCan

Positive (+) motor tab

0.1µF Capacitors

Grounded motor capacitors

Negative (-) motor tab

Motor can

Make sure NOT to touch motor capacitor leads

to motor can, except for the two motor

capacitors that are grounded to the can.

2.INSTALLPINIONGEAR

Install pinion on motor and align pinion and spur gears. Tighten

pinion’s set screw on the flat of motor shaft.

3.ADJUSTMOTORFORPROPERGEARMESH

• Adjustthemotorpositionforproperamountoffreeplay.You

NEEDasmallamountofplaybetweenthepiniongearand

thespurgear (about the thickness of a piece of paper)

–check

the free play at several positions around the spur gear to

ensure a proper mesh (just in case the gears are out of round).

MAKE SURE THE PINION/SPUR GEAR MESH IS

NOT TOO TIGHT!

If gear mesh is too tight, motor shaft breakage can occur.

• Tightenmotormountingscrews–Avoidusingexcessiveforce

that could break screws or strip the threaded holes in motor.

4.SOLDERMOTORPOWERWIRES

•Determine the best routing in vehicle for power wires.

Prepareendsofmotorpowerwires by stripping 1/8–1/4”

of insulation from end of wire. Tin wire ends with solder.

• Lay tinned end of the wire flat on the solder tab and solder

wires to proper tabs of the motor. Apply heat with soldering

iron to the power wire and solder tab–begin adding solder to

tip of iron and to wire–Add just enough solder to form a clean

& continuous joint from the solder tab up onto the wire.

5460

3AmpUniversalBEC

–6VDC/3A output Battery Eliminator Circuit for 6.3-8.4VDC input.

5463 3AHigh-VoltageUniversalBEC–

6VDC/3A output B.E.C. for up to 26.4VDC input.

5465

5AmpUniversalBEC

–6VDC/5A output Battery Eliminator Circuit for 6.3-8.4VDC input.

5466 5AHigh-VoltageUniversalBEC–

6VDC/5A output B.E.C. for up to 28.0VDC input.

5470

Smart-Stop2-cellLi-PoCut-OffModule–

Safe 2S Li-Po operation with 6.25V cut-off.

5471

Smart-Stop4-cellLi-PoCut-OffModule–

Safe 4S Li-Po operation with 12.5V cut-off.

5472

Smart-Stop3-cellLi-PoCut-OffModule–Safe 3S Li-Po operation with 9.375V cut-off.

5500 14GASuper-FlexWire–Black&Red

–3 ft each color, silicone.

5510 16GASuper-FlexWire–Black&Red

–3 ft each color, silicone.

5530 12GASuper-FlexWire–Black&Red

–3 ft each color, silicone.

5512 12GAPowerWireSet–Black,Red&Blue

–3 ft each color, silicone.

5514 14GAPowerWireSet–Black,Red&Blue

–3 ft each color, silicone.

5516 16GAPowerWireSet–Black,Red&Blue

–3 ft each color, silicone.

5620 MotorCapacitors–25pcs0.1µF(50V)

–Non-polarized ceramic capacitors.

5626 GlitchBusterCapacitor

–Stores battery power for receiver to eliminate radio cut-out.

5636 RacingSchottkyMotorModule

–36A Schottky module for forward-only ESCs.

5647 BlackCoolingFan–25x25x10mm

–All purpose cooling fan with 2-pin JST connector.

5648 ClearCoolingFan–30x30x6mm

–GTB replacement fan with 2-pin JST connector.

5832 Lead-Free3%SilverRacingSolder–15g

–Low-resistance, high-conductivity solder.

5840

Double-SidedMountingTape

–10pcs–1”x1” high-performance clear mounting tape.

ACCESSORIES

PRODUCT WARRANTY

Novak products are guaranteed to be free from defects in materials or

workmanship for a period of 120 days from the original date of purchase

(verified by dated, itemized sales receipt). Warranty does not cover incorrect

installation, components worn by use, cross-connection of battery/motor

power wires, overheating solder tabs, damage resulting from overload, wear

or damage from improper gear mesh or damage from disassembling motor,

tampering with motor, allowing water, moisture, or any other foreign material

to enter motor, allowing exposed wiring or solder tabs to short-circuit, or any

damage caused by a crash, flooding, or natural disaster. In no case shall our

liability exceed the product’s original cost. We reserve the right to modify

warranty provisions without notice.

BecauseNovakElectronics,Inc.hasnocontrolovertheconnection&useof

motor or other related electronics, no liability may be assumed nor will be

accepted for damage resulting from the use of this product. Every motor is

tested before leaving our facility and is, therefore, considered operational.

By the act of connecting motor to speed control or operating motor, the user

accepts all resulting liability.

NOvAK ELECTRONICS, INC.

P:(949)833-8873•F:(949)833-1631

©2009NovakElectronics,Inc.Irvine,CA,U.S.A.•AllRightsReserved

No part of these instructions may be reproduced without the

writtenpermissionofNovakElectronics,Inc.Motormadein

China and tested at the Novak facility in Irvine, Calif.

#55-3556-1 Rev.1

Printed 10-2009

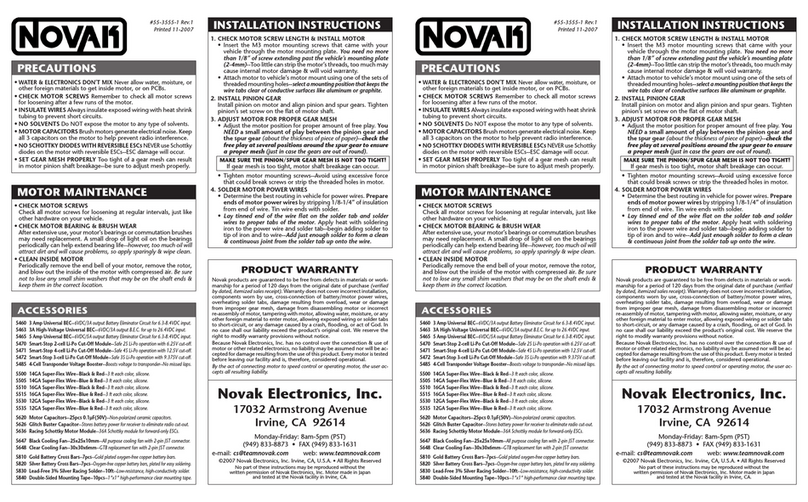

PRECAUTIONS

•WATER&ELECTRONICSDON’TMIX Never allow water, moisture,

or other foreign materials to get inside motor.

•INSULATEWIRES Always insulate exposed wiring with heat shrink

tubing to prevent short circuits.

•NOSOLVENTS Do NOT expose the motor to any type of solvents.

•MOTORCAPACITORS Brush motors generate electrical noise. Install

all 3 capacitors on the motor to help prevent radio interference.

•NOSCHOTTKYDIODESWITHREVERSIBLEESCs NEVER use Schottky

diodes on the motor with reversible ESCs–ESC damage will occur.

•SETGEARMESHPROPERLY Too tight of a gear mesh can result in

motor pinion shaft breakage–be sure to adjust mesh properly.

MOTOR MAINTENANCE

•CHECKMOTORBUSHINGS&BRUSHWEAR

After extensive use, your motor’s bushings or commutation brushes

may need replacement. A small drop of light oil on the bushings

periodically can help extend bushing life–however, too much oil will

attract dirt and will cause problems, so apply sparingly & wipe clean.

•CLEANINSIDEMOTOR

Periodically blow out the inside of the motor with compressed air.

5460

3AmpUniversalBEC

–6VDC/3A output Battery Eliminator Circuit for 6.3-8.4VDC input.

5463 3AHigh-VoltageUniversalBEC–

6VDC/3A output B.E.C. for up to 26.4VDC input.

5465

5AmpUniversalBEC

–6VDC/5A output Battery Eliminator Circuit for 6.3-8.4VDC input.

5466 5AHigh-VoltageUniversalBEC–

6VDC/5A output B.E.C. for up to 28.0VDC input.

5470

Smart-Stop2-cellLi-PoCut-OffModule–

Safe 2S Li-Po operation with 6.25V cut-off.

5471

Smart-Stop4-cellLi-PoCut-OffModule–

Safe 4S Li-Po operation with 12.5V cut-off.

5472

Smart-Stop3-cellLi-PoCut-OffModule–Safe 3S Li-Po operation with 9.375V cut-off.

5500 14GASuper-FlexWire–Black&Red

–3 ft each color, silicone.

5510 16GASuper-FlexWire–Black&Red

–3 ft each color, silicone.

5530 12GASuper-FlexWire–Black&Red

–3 ft each color, silicone.

5512 12GAPowerWireSet–Black,Red&Blue

–3 ft each color, silicone.

5514 14GAPowerWireSet–Black,Red&Blue

–3 ft each color, silicone.

5516 16GAPowerWireSet–Black,Red&Blue

–3 ft each color, silicone.

5620 MotorCapacitors–25pcs0.1µF(50V)

–Non-polarized ceramic capacitors.

5626 GlitchBusterCapacitor

–Stores battery power for receiver to eliminate radio cut-out.

5636 RacingSchottkyMotorModule

–36A Schottky module for forward-only ESCs.

5647 BlackCoolingFan–25x25x10mm

–All purpose cooling fan with 2-pin JST connector.

5648 ClearCoolingFan–30x30x6mm

–GTB replacement fan with 2-pin JST connector.

5832 Lead-Free3%SilverRacingSolder–15g

–Low-resistance, high-conductivity solder.

5840

Double-SidedMountingTape

–10pcs–1”x1” high-performance clear mounting tape.

ACCESSORIES

PRODUCT WARRANTY

Novak products are guaranteed to be free from defects in materials or

workmanship for a period of 120 days from the original date of purchase

(verified by dated, itemized sales receipt). Warranty does not cover incorrect

installation, components worn by use, cross-connection of battery/motor

power wires, overheating solder tabs, damage resulting from overload, wear

or damage from improper gear mesh or damage from disassembling motor,

tampering with motor, allowing water, moisture, or any other foreign material

to enter motor, allowing exposed wiring or solder tabs to short-circuit, or any

damage caused by a crash, flooding, or natural disaster. In no case shall our

liability exceed the product’s original cost. We reserve the right to modify

warranty provisions without notice.

BecauseNovakElectronics,Inc.hasnocontrolovertheconnection&useof

motor or other related electronics, no liability may be assumed nor will be

accepted for damage resulting from the use of this product. Every motor is

tested before leaving our facility and is, therefore, considered operational.

By the act of connecting motor to speed control or operating motor, the user

accepts all resulting liability.

NOvAK ELECTRONICS, INC.

P:(949)833-8873•F:(949)833-1631

©2009NovakElectronics,Inc.Irvine,CA,U.S.A.•AllRightsReserved

No part of these instructions may be reproduced without the

writtenpermissionofNovakElectronics,Inc.Motormadein

China and tested at the Novak facility in Irvine, Calif.

INSTALLATION INSTRUCTIONS

1.INSTALLMOTORCAPACITORS

Electric motors generate RF noise that causes interference. The

included 0.1µF (50V) [Novak #5620] non-polarized, ceramic

capacitors must be used on all Terra Claw motors to reduce

motor noise and prevent ESC damage.

Solder 0.1µF (50V) capacitors between:

•POSITIVE(+)motortab&NEGATIVE(–)motortab.

•POSITIVE(+)motortab&MotorCan

•NEGATIVE(–)motortab&MotorCan

Positive (+) motor tab

0.1µF Capacitors

Grounded motor capacitors

Negative (-) motor tab

Motor can

Make sure NOT to touch motor capacitor leads

to motor can, except for the two motor

capacitors that are grounded to the can.

2.INSTALLPINIONGEAR

Install pinion on motor and align pinion and spur gears. Tighten

pinion’s set screw on the flat of motor shaft.

3.ADJUSTMOTORFORPROPERGEARMESH

• Adjustthemotorpositionforproperamountoffreeplay.You

NEEDasmallamountofplaybetweenthepiniongearand

thespurgear (about the thickness of a piece of paper)

–check

the free play at several positions around the spur gear to

ensure a proper mesh (just in case the gears are out of round).

MAKE SURE THE PINION/SPUR GEAR MESH IS

NOT TOO TIGHT!

If gear mesh is too tight, motor shaft breakage can occur.

• Tightenmotormountingscrews–Avoidusingexcessiveforce

that could break screws or strip the threaded holes in motor.

4.SOLDERMOTORPOWERWIRES

•Determine the best routing in vehicle for power wires.

Prepareendsofmotorpowerwires by stripping 1/8–1/4”

of insulation from end of wire. Tin wire ends with solder.

• Lay tinned end of the wire flat on the solder tab and solder

wires to proper tabs of the motor. Apply heat with soldering

iron to the power wire and solder tab–begin adding solder to

tip of iron and to wire–Add just enough solder to form a clean

& continuous joint from the solder tab up onto the wire.