Novanta ATI Axia80 User manual

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-2

Foreword

Information contained in this document is the property of ATI IndustrialAutomation, Inc. and shall not be reproduced in

whole or in part without prior written approval of ATI IndustrialAutomation, Inc. The information herein is subject to

change without notice and should not be construed as a commitment on the part of ATI IndustrialAutomation, Inc. This

manual is periodically revised to reect and incorporate changes made to the F/T system.

ATI IndustrialAutomation, Inc. assumes no responsibility for any errors or omissions in this document.

Copyright© (2022) by ATI IndustrialAutomation, Inc., Apex, North Carolina USA. All Rights Reserved.

Published in the USA.

ATI F/T Sensing Systems are considered components/ semi-nished goods intended for use in larger system/

device/ nished good.

In consideration that ATI Industrial Automation, Inc. (ATI) products are intended for use with robotic and/or automated

machines, ATI does not recommend the use of its products for applications wherein failure or malfunction of aATI

component or system threatens life or makes injury probable. Anyone who uses or incorporates ATI components within

any potentially life threatening system must obtain ATI’s prior consent based upon assurance to ATI that a malfunction

of ATI’s component does not pose direct or indirect threat of injury or death, and (even if such consent is given) shall

indemnify ATI from any claim, loss, liability, and related expenses arising from any injury or death resulting from use of

ATI components.

All trademarks belong to their respective owners. Windows®is a registered trademark of Microsoft Corporation.

Note:

Please read the manual before calling customer service, and have the following

information available:

1. Serial number (e.g., FT01234)

2. Sensor model (e.g., Axia90-M50)

3. Calibration (e.g., US-15-50, SI-65-6, etc.)

4. Accurate and complete description of the question or problem

• For the status code bit map; refer to Section 5.5—Status Code.

• For checking the system’s status, issue a “Status” command (refer to Table 8.1) or

view the System Information webpage (refer to Section 6.8—System Information

Page (manuf.htm)).

5. Computer and software information (operating system, PC type, drivers, application

software, and other relevant information about the application’s conguration)

Be near the F/T system when calling (if possible).

Please contact an ATI representative for assistance, if needed:

Sale, Service and Information about ATI products:

ATI Industrial Automation

1031 Goodworth Drive

Apex, NC 27539 USA

www.ati-ia.com

Tel: +1.919.772.0115

Fax: +1.919.772.8259

Application Engineering

Tel: +1.919.772.0115, Extension 511

Fax: +1.919.772.8259

E-mail: [email protected]

24/7 Support: +1 855 ATI-IA 00 (+1 855-284-4200)

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-3

Table of Contents

Glossary........................................................................................................................................C-7

1. Safety....................................................................................................................................C-10

1.1 ExplanationofNotications................................................................................................... C-10

1.2 General Safety Guidelines...................................................................................................... C-10

1.3 Safety Precautions...................................................................................................................C-11

2. Product Overview................................................................................................................C-12

3. Installation ...........................................................................................................................C-13

3.1 Installation of the Sensor to the Robot................................................................................. C-13

3.2 CableConguration ................................................................................................................ C-14

3.3 PinandWireAssignmentsforConnectors .......................................................................... C-14

3.3.1 Pin Assignment for theAxia F/T Sensor....................................................................... C-15

3.3.1.1 Axia80 6-Pin M8 Male Connector................................................................. C-15

3.3.1.2 Axia80 and Axia90 8-pin M8 Male Connector............................................... C-15

3.3.1.3 Axia130 8-pin M12 Male Connector ............................................................. C-15

3.3.2 Axia80 Sensor Cable (P/N 9105-C-ZC22-ZC28-X)...................................................... C-16

3.3.3 Axia80 and Axia90 Sensor Cable (P/N 9105-C-ZC27-ZC28-X)................................... C-16

3.3.4 Axia130 Sensor Cable (P/N 9105-C-ZC28-ZC28-X).................................................... C-17

3.3.5 Ethernet Cable (P/N 9105-C-ZC28-U-RJ45S-X).......................................................... C-18

4. ConnectingThroughEthernet ...........................................................................................C-19

4.1 IPAddressCongurationforEthernet.................................................................................. C-19

4.2 ConnectingTotheATIWebpagesUsingaWindowsComputer ......................................... C-20

4.3 FindingtheEthernetAxiaSensoronaNetwork .................................................................. C-23

5. Operation .............................................................................................................................C-25

5.1 LED Self-Test Sequence ......................................................................................................... C-25

5.2 LED Normal Operation............................................................................................................ C-26

5.2.1 Sensor Status LED....................................................................................................... C-26

5.2.2 Diag LED...................................................................................................................... C-26

5.2.3 Ethernet Link/Activity LED............................................................................................ C-26

5.3 Sample Rate............................................................................................................................. C-27

5.3.1 Sample Rate Versus Data Rate ................................................................................... C-27

5.4 Low-Pass Filter........................................................................................................................ C-27

5.5 Status Code ............................................................................................................................. C-31

5.5.1 Status Code: Sensing Range Exceeded...................................................................... C-32

6. ATIEthernetAxiaWebpagesInterface..............................................................................C-34

6.1 WelcomePage(index.htm)..................................................................................................... C-34

6.2 SnapshotPage(rundata.htm) ................................................................................................ C-35

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-4

6.3 DemoPage(demo.htm) .......................................................................................................... C-36

6.4 ADCSettingsPage(setting.htm) ........................................................................................... C-36

6.5 ThresholdingPage(moncon.htm) ......................................................................................... C-37

6.6 F/T CongurationsPage(cong.htm) ................................................................................... C-41

6.7 CommunicationPage(comm.htm) ........................................................................................ C-42

6.8 SystemInformationPage(manuf.htm) ................................................................................. C-44

6.9 StatusLogPage(status.htm)................................................................................................. C-45

6.10 InterfaceExamplePage(examples.htm)............................................................................... C-46

6.11 ATI Website Menu Item ........................................................................................................... C-47

7. Java®Demo Application .....................................................................................................C-48

7.1 StartingtheDemo ................................................................................................................... C-48

7.2 Data Display with the Demo................................................................................................... C-50

7.3 CollectingDatawiththeDemo............................................................................................... C-50

7.4 Demo CSV File Format............................................................................................................ C-52

7.5 The Errors Field Display of the Demo................................................................................... C-54

7.6 DevelopingaCustomizedJava®Application........................................................................ C-54

8. ConsoleInterfaceThroughTelnet .....................................................................................C-55

8.1 SettingUpaConsoleInterfaceThroughTelnet ................................................................... C-55

8.2 Console Commands................................................................................................................ C-56

8.3 Console “CAL” | “SET” Command Fields and Values......................................................... C-58

8.4 Query Commands: “S” or “C” ............................................................................................... C-63

8.4.1 Converting Counts Per Force/Torque to FT Values...................................................... C-64

8.4.2 Secondary Commands for the Query “C” or “S” Command......................................... C-64

8.4.3 ExamplesofSecondaryCommands(Speciers)......................................................... C-65

8.4.4 HowtoInterprettheOutputfrom“!”Specier .............................................................. C-67

8.5 ExampleofToolTransformationFunctionalityThroughTelnet ......................................... C-68

9. CommonGatewayInterface(CGI) .....................................................................................C-70

9.1 URLSyntaxConstruction:.................................................................................................................. C-70

9.1.1 Assigning New Values to a Variable............................................................................. C-70

9.2 CGIVariable:Settings(setting.cgi) ....................................................................................... C-71

9.3 ThresholdingCGI(moncon.cgi)............................................................................................. C-71

9.4 CGIVariable:Congurations(cong.cgi) ............................................................................. C-72

9.4.1 Example of Tool Transformation Functionality Through CGI........................................ C-73

9.5 CGIVariable:Communications(comm.cgi).......................................................................... C-74

10. TCP Interface .......................................................................................................................C-75

10.1 Command Codes..................................................................................................................... C-75

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-5

10.2 Read F/T Command................................................................................................................. C-75

10.3 Read F/T Response................................................................................................................. C-75

10.4 Read Calibration Info Command............................................................................................ C-76

10.5 Read Calibration Info Response............................................................................................ C-76

10.6 Write Tool Transform Command............................................................................................ C-77

10.7 Write Monitor Condition Command....................................................................................... C-77

10.8 Write Response ....................................................................................................................... C-77

11. XML Interface.......................................................................................................................C-78

11.1 SystemandCongurationInformation(netftapi2.xml) ....................................................... C-78

11.2 CalibrationInformation(netftcalapi.xml) .............................................................................. C-80

12. UDPInterfaceUsingRDT....................................................................................................C-81

12.1 RDT Protocol ........................................................................................................................... C-81

12.1.1 RDT Request For Records Structure ........................................................................... C-82

12.1.2 RDT Records Sent Structure........................................................................................ C-82

12.2 CalculatingF/TValuesforRDT .............................................................................................. C-83

12.3 Multiple Clients........................................................................................................................ C-83

12.4 NotesonUDPandRDTMode ................................................................................................ C-83

12.5 Example Code.......................................................................................................................... C-83

13. Troubleshoot........................................................................................................................C-84

13.1 LED Errors ............................................................................................................................... C-84

13.2 Ethernet Communication Questions and Errors.................................................................. C-85

13.3 EthernetAxiaWebpageErrors............................................................................................... C-86

13.4 Java®Demo Errors.................................................................................................................. C-86

13.5 BasicGuidanceforTroubleshooting .................................................................................... C-87

13.6 ReducingNoise ....................................................................................................................... C-92

13.6.1 Mechanical Vibration.................................................................................................... C-92

13.6.2 Electrical Interference................................................................................................... C-92

13.7 ImprovingEthernetThroughput ............................................................................................ C-92

13.7.1 Direct Connection between Axia Ethernet and Host .................................................... C-92

13.7.2 Choice of Operating System ........................................................................................ C-92

13.7.3 Increasing Operating System Performance ................................................................. C-92

13.7.4 Avoid Logging the Host to a Company Network........................................................... C-93

13.7.5 Use a Dedicated Network............................................................................................. C-93

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-6

14. Specications ......................................................................................................................C-93

14.1 ElectricalSpecications ......................................................................................................... C-93

14.2 CableSpecications ............................................................................................................... C-93

14.2.1 P/N 9105-C-ZC22-ZC28-X........................................................................................... C-93

14.2.2 P/N 9105-C-ZC27-ZC28-X........................................................................................... C-93

14.2.3 P/N 9105-C-ZC28-ZC28-X........................................................................................... C-94

14.2.4 P/N 9105-C-ZC28-U-RJ45S-X ..................................................................................... C-94

15. Terms and Conditions of Sale............................................................................................C-95

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-7

Glossary

Term Denitions

ActiveConguration Thecongurationthatthesystemiscurrentlyusing.

ADC Analog-to-digital converter

Bias

Biasingisusefulforeliminatingtheeectsofgravity(toolweight)orotheracting

forces. When the bias function is used, the software collects data for the forces and

torques that are currently acting on the sensor and use these readings as a reference

for future readings. Future readings will have this reference subtracted from them

before they are transmitted. Bias may also be referred to as “zero out” or “tare”

the sensor.

Calibration Denesaspecicmeasurementorsensingrangeforagivensensor.Calibrationis

also the act of measuring a transducer’s raw response to loads and creating data

used in converting the response to forces and torques.

CGI Common Gateway Interface (CGI) is the method of using web URLs to communicate

data and parameters back to a web device.

Complex Loading Any force or torque load that is not purely in one axis.

Conguration User-denedsettingsthatincludewhichforceandtorqueunitsarereportedand

which calibration is to be used.

Control Panel A feature on a personal computer operating system where a user can adjust

system settings.

Coordinate Frame See Sensor Reference Frame Origin.

Data Rate How fast data can be output over the network.

DHCP DynamicHostCongurationProtocol(DHCP)isanautomaticmethodforEthernet

equipment to obtain an IP address. The EthernetAxia system can obtain its IP

address using DHCP on networks that support this protocol.

DINT Signed double integer (32 bit)

ENABL Boolean that uses Enabled to represent 1 and Disabled to represent 0

Ethernet A family of computer networking technologies commonly used in local area networks.

Fieldbus A generic term referring to any one of a number of industrial computer networking

standards. Examples include: Ethernet, CAN, Modbus, and PROFINET.

FT or F/T Force and Torque.

Fxy The resultant force vector comprised of components Fxand Fy.

Force A force is a push or pull action on an object caused by an interaction with another

object. Force = mass X acceleration

HEXnHexadecimal number of nbits,prexedwith0x

HTTP GET Method Astandardandcommonmethodthatausercanrequestdatafromaspecied

resource such as a sensor. HTTP works as a request-response protocol between

client (web browser) and server (the sensor).

Hysteresis Asourceofmeasurementerrorcausedbytheresidualeectsof

previously applied loads.

INT Signed integer (16 bit)

Interface Plate

A separate plate that attaches the sensor to another surface. Interface plates are

often used if the bolt pattern on the sensor doesn’t match the bolt pattern on the

robot arm or customer tooling. The interface plate has two bolt patterns, one on either

side of the plate. One side is for the sensor. The other side is for the robot arm or

customer tooling.

IP64 Ingress protection rating “64” designates protection against dust and splashing of

water. An IP64 rating does not guarantee protection when a user submerges a device

inwateroranytypeofuid.

IP67 Ingress protection rating “67” designates protection against dust and submersion

under 1 m of fresh water.

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-8

Term Denitions

IPAddress An IP Address (Internet Protocol Address) is an electronic address assigned to an

Ethernet device so that it may send and receive Ethernet data. IP addresses may be

either manually selected by a user or automatically assigned by the DHCP protocol.

Java™ Java is a programming language often used for programs on webpages. The

Ethernet Axia demo is a Java application. Java is a registered trademark of Sun

Microsystems, Inc.

MAC Media Access Controller is the hardware that implements the lowest sub-layer of the

data link layer.

MAC Address MAC Addresses (Media Access Control Addresses) are the unique addresses

given to every Ethernet device when it is manufactured, to be used as an electronic

Ethernet serial number.

MAC ID MediaAccessCodeIdentier(MACID)isauniquenumberthatisuserassignedto

each device on an Ethernet network. Also called Node Address.

Measurement Uncertainty

Commonly referred to as “accuracy”, “measurement uncertainty” is the worst-

case error between the measured value and the true load. The measurement

uncertaintyisspeciedasapercentageofthefull-scalemeasurementrangefor

a given sensor model and calibration size. This value takes into account multiple

sourcesoferror.Thesensor’scalibrationcerticateliststhemeasurement

uncertainty percentage. For more information, refer to Section 2.2: Measurement

Uncertainty in the Frequently Asked Questions (FAQ) document located at:

https://www.ati-ia.com/library/documents/FT_FAQ.pdf.

Mechanical Coupling When an external object such as customer tooling or utilities contacts a sensor’s

surface between the sensor’s mounting side and tool side.

N/A Not Applicable

NVM Non-Volatile Memory. Storage of information or device memory that can be retrieved

even after the device goes through a power cycle.

Overload The condition where more load is applied to the sensor than the rated measurement

range that can be applied to the sensor. Overloads result in reduced accuracy and

potentially reduced sensor life.

Plug-in Technology A customized program that when downloaded and installed onto a host device adds

aspecicfeaturetoanexistingcomputerprogram.

P/N Part Number

Power Cycle When a user removes and then restores power to a device.

REAL Floating-point number (32 bit)

RDT The rate per second at which the sensor sends streaming RDT data to a

host. Raw Data Transfer (RDT) is a fast and simple Ethernet protocol for control and

data transfer via UDP.

RDTBuerSize

A mode where the sensor sends more than one data package per sample. Multiple

datapackagesarebueredandsentinoneblock.Bueringreducestheamountof

overheaddatasentfromthesensorandreducestheoverallnetworktrac.

Sensor Reference Frame Origin The point on the sensor from which all forces and torques are measured.

Sensor System (or

conguration)

The entire assembly consisting of a sensor body and a system interface to translate

forceandtorquesignalsintoaspeciccommunicationinterface/protocol.

Resolution The smallest change in load that can be measured.

Sample Rate How fast the ADCs are sampling inside the unit.

Sensor The component that converts a detected load into electrical signals.

SINT Signed short integer (8 bit)

STRINGnString of ncharacters

Status Bit A unit of computer data sent from the ATI F/T sensor.

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-9

Term Denitions

TCP Transmission Control Protocol (TCP) is a low-level method of transmitting data over

Ethernet. TCP provides a slower, more reliable delivery of data than UDP.

Thresholding A software function of the sensor that performs a simple arithmetic comparison of a

user-denedthresholdtotheloadingonatransduceraxis.

Torque The application of a force through a lever or moment arm that causes something to

want to turn. For example, a user applies torque to a screw to make it turn.

Torque = force x moment arm length

Txy The resultant torque vector comprised of components Txand Ty.

UART Universal asynchronous receiver transmitter.

UDINT Unsigned double integer (32 bit)

UDP UDP (User Datagram Protocol) is a low-level method of transmitting data over

Ethernet. While UDP is faster than TCP, unlike TCP lost UDP data is not resent.

UINT Unsigned integer (16 bit)

USINT Unsigned short integer (8 bit)

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-10

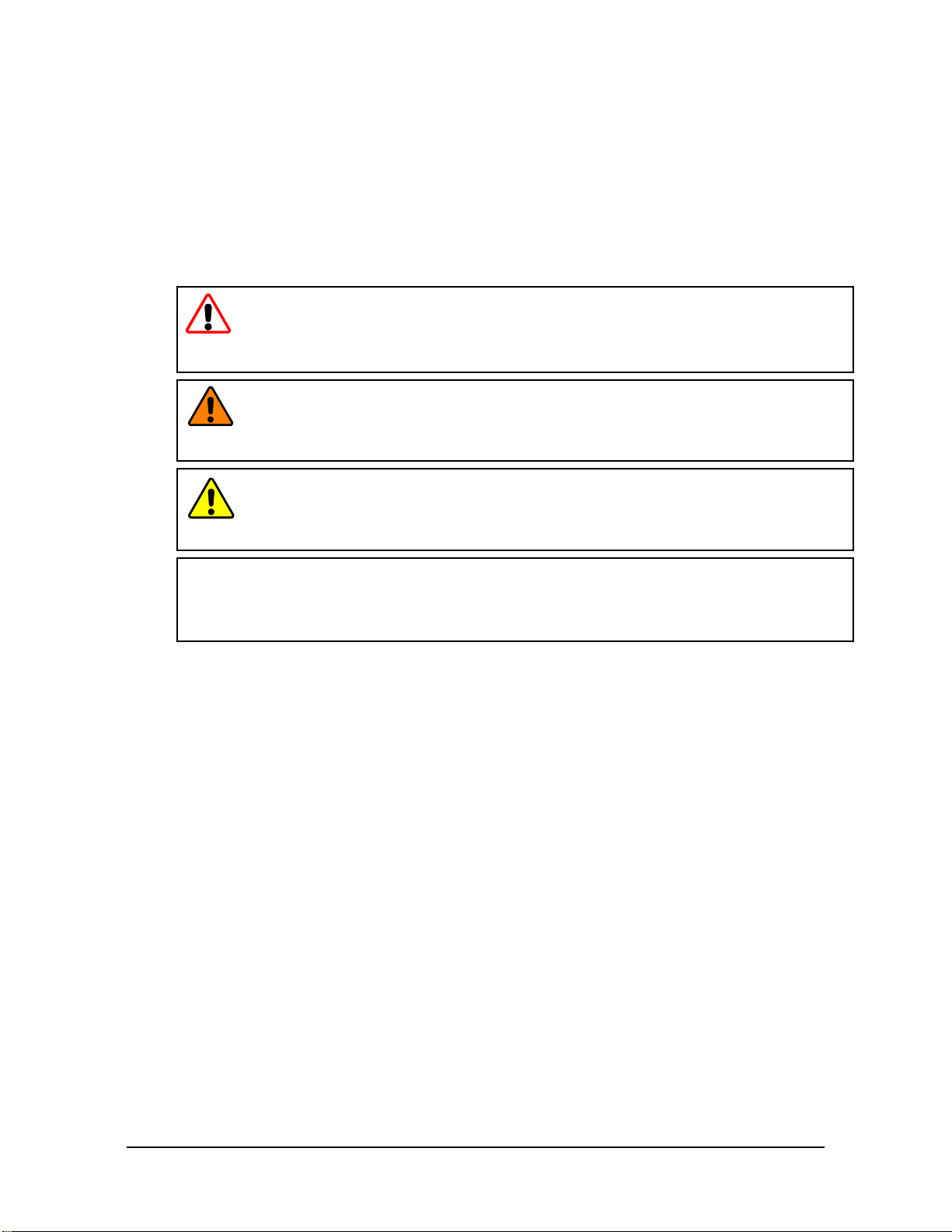

1. Safety

The safety section describes general safety guidelines to be followed with this product, explanations of the

notications found in this manual, and safety precautions that apply to the product. Product specic notications

are imbedded within the sections of this manual (where they apply).

1.1 ExplanationofNotications

These notications are used in all of ATI manuals and are not specic to this product. The user should heed

all notications from the robot manufacturer and/or the manufacturers of other components used in the

installation.

DANGER: Noticationofinformationorinstructionsthatifnotfollowedwillresultin

deathorseriousinjury.Thenoticationprovidesinformationaboutthenatureofthe

hazardous situation, the consequences of not avoiding the hazard, and the method for

avoiding the situation.

WARNING: Noticationofinformationorinstructionsthatifnotfollowedcouldresult

indeathorseriousinjury.Thenoticationprovidesinformationaboutthenatureofthe

hazardous situation, the consequences of not avoiding the hazard, and the method for

avoiding the situation.

CAUTION:Noticationofinformationorinstructionsthatifnotfollowedcouldresult

inmoderateinjuryorwillcausedamagetoequipment.Thenoticationprovides

information about the nature of the hazardous situation, the consequences of not

avoiding the hazard, and the method for avoiding the situation.

NOTICE: Noticationofspecicinformationorinstructionsaboutmaintaining,operating,

installing, or setting up the product that if not followed could result in damage to equipment. The

noticationcanemphasize,butisnotlimitedto:specicgreasetypes,bestoperatingpractices,

and maintenance tips.

1.2 General Safety Guidelines

The customer should verify that the sensor is rated for the maximum load and torque expected during

operation. Because static forces are less than the dynamic forces from the acceleration or declaration of the

robot, be aware of the dynamic loads caused by the robot.

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-11

1.3 Safety Precautions

CAUTION:Modifying or disassembly of the sensor could cause damage and void

the warranty. Use the supplied mounting interface plate and the provided tool side

mounting bolt pattern to mount the sensor to the robot and customer tooling to the

sensor. For more information, refer to the ATI customer drawings.

CAUTION:Probing openings in the sensor causes damage to the instrumentation.

Avoid prying into the openings of the sensor.

CAUTION:Do not overload the sensor. Exceeding the single-axis overload values of

the sensor causes irreparable damage.

CAUTION:The sensor should be protected from impact and shock loads that

exceed rated ranges during transportation as the impacts can damage the sensor’s

performance. For more information about rated ranges, refer to the appropriate sensor

manual in Table 2.1.

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-12

2. Product Overview

The Ethernet Axia Force/Torque (F/T) sensor measures six components of force and torque (Fx \ Fy \ Fz\ Tx\ Ty

\ Tz) and communicates this data to a device (such as a personal computer, robot, or PLC) that is compatible with

an Ethernet communication interface. The ATI Axia-series product line differs from the other (non-Axia) ATI F/T

sensor models. Thus, the Axia sensors have different options and available features. The Axia-series force/torque

sensors are available in several different payload and communication interface versions. This manual covers the

following topics for the Ethernet Axia interface version:

• Electrical specications and wire information for cables

• Initial set-up of a serial console for Ethernet communications

• Operation (LEDs, lter rates, sampling rates, and Status codes)

• Compatibility with the ATI Net F/T sensor UDP interface and Java demo application (for more

information, refer to Section 12—UDP Interface Using RDT, Section 7—Java® Demo Application, and

the 9620-05-NET F/T manual)

• Compatibility with parts of the ATI Net F/T web interface (for more information, Section 6—ATI

Ethernet Axia Webpages Interface and the 9620-05-NET F/T manual)

• ATI Ethernet Axia F/T sensor conguration through software interfaces: console interface through

Telnet, Common Gateway Interface (CGI), TCP interface, UDP (RDT) interface, and XML

• Troubleshooting guidance that relates to Ethernet Axia

For additional sensor information, such as installation on a robot, operation, and general troubleshooting, refer to

the appropriate ATI Axia F/T sensor manual listed in the following table:

Table 2.1—ATI Axia F/T Sensor Manual

ATI Axia Sensor Model RefertotheATIAxiaF/TSensorManualDocumentNumber(#):

Axia80 ATI F/T Axia80 Sensor Manual

(ATI Document #9620-05-B-Axia80)

Axia90 ATI F/T Axia90 Sensor Manual

(ATI Document #9620-05-B-Axia90)

Axia130 ATI F/T Axia130 Sensor Manual

(ATI Document #9620-05-B-Axia130)

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-13

3. Installation

WARNING: Performing maintenance or repair on the sensor when circuits (for example:

power, water, and air) are energized could result in death or serious injury. Discharge and

verify all energized circuits are de-energized in accordance with the customer’s safety

practices and policies.

CAUTION:Avoid damage to the sensor from electrostatic discharge. Ensure proper

grounding procedures are followed when handling the sensor or cables connected to the

sensor. Failure to follow proper grounding procedures could damage the sensor.

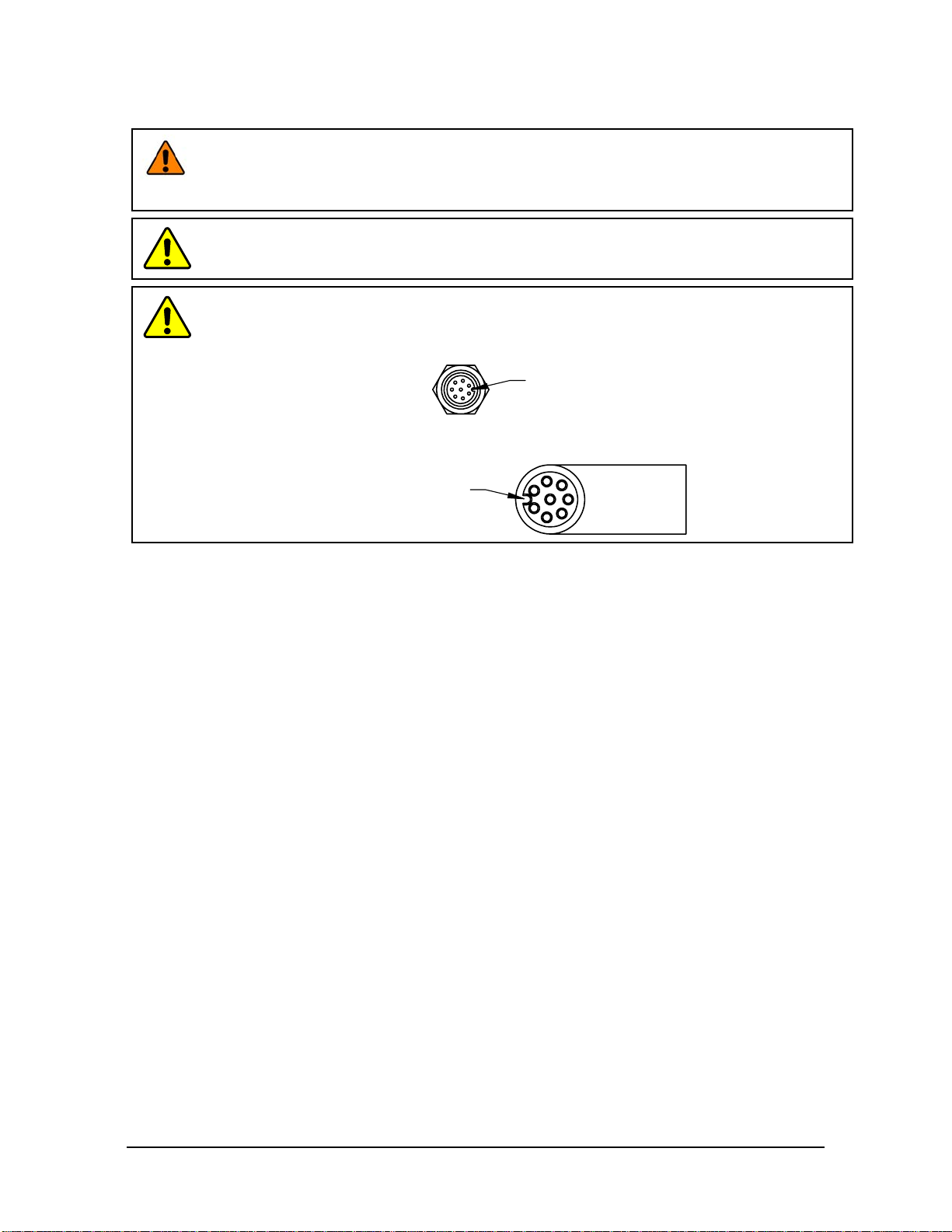

CAUTION:Do not apply excessive force to the sensor and cable connector during

installation, or damage will occur to the connectors. Align the keyway on the sensor and cable

connector during installation to avoid applying excessive force to the connectors.

Keyway on the

cable connector.

Keyway on the

sensor connector.

3.1 Installation of the Sensor to the Robot

For instructions on how to install the sensor to the robot, refer to the appropriate sensor manual in Table 2.1.

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-14

3.2 CableConguration

Cables can be congured a number of ways; however, the most common congurations are presented

in the following:

Figure3.1—Axia80/Axia90CableConguration

Axia F/T Sensor and

interface plate with

cable support bracket

(P-clip not shown in this view)

RJ45 Connector for Ethernet

(Branch 2)

Unterminated End for Power

(Branch 1)

6-pin Power and Ethernet Cable to the sensor

(ATI P/N 9105-C-ZC22-ZC28-X)

or

8-pin Power and Ethernet Cable to the sensor

(ATI P/N 9105-C-ZC27-ZC28-X)

Note: Cable lengths are shortened

in the figure for reference only.

Power and Ethernet cable

to the customer application

(ATI P/N 9105-C-ZC28-U-RJ45S-X)

Figure3.2—Axia130CableConguration

Axia130 sensor

sensor cable

(ATI P/N 9105-C-ZC28-ZC28-X-Z2)

Power and Ethernet cable

to the customer application

(ATI P/N 9105-C-ZC28-U-RJ45S-X)

Unterminated end for power

(branch 1)

RJ45 connector for Ethernet

Note: Cable lengths are shortened in the figure for reference only.

3.3 PinandWireAssignmentsforConnectors

CAUTION: Ensure the cable shield is properly grounded. Improper shielding on the

cables can cause communication errors and an inoperative Axia sensor.

The following section provides the pin assignment for the connector on the Axia sensor and applicable

connectors on the cables. For supply voltage ratings, refer to the following table or Section 14.1—Electrical

Specications. For additional cable technical specications, refer to Section 14.2—Cable Specications.

Table 3.1—Power Supply1

Power Source Voltage Power Consumption

Minimum Nominal Maximum Maximum

DC Power 12 V 24 V 30 V 1.5 W

Notes:

1. The power supply input is reverse polarity protected. If the power and ground to the power supply

inputs are plugged in reverse, then the reverse polarity protection stops the incorrectly wired supply

input from damaging or powering on the sensor.

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-15

3.3.1 PinAssignmentfortheAxiaF/TSensor

Signals and corresponding pin numbers for the Axia models are listed in the following sections.

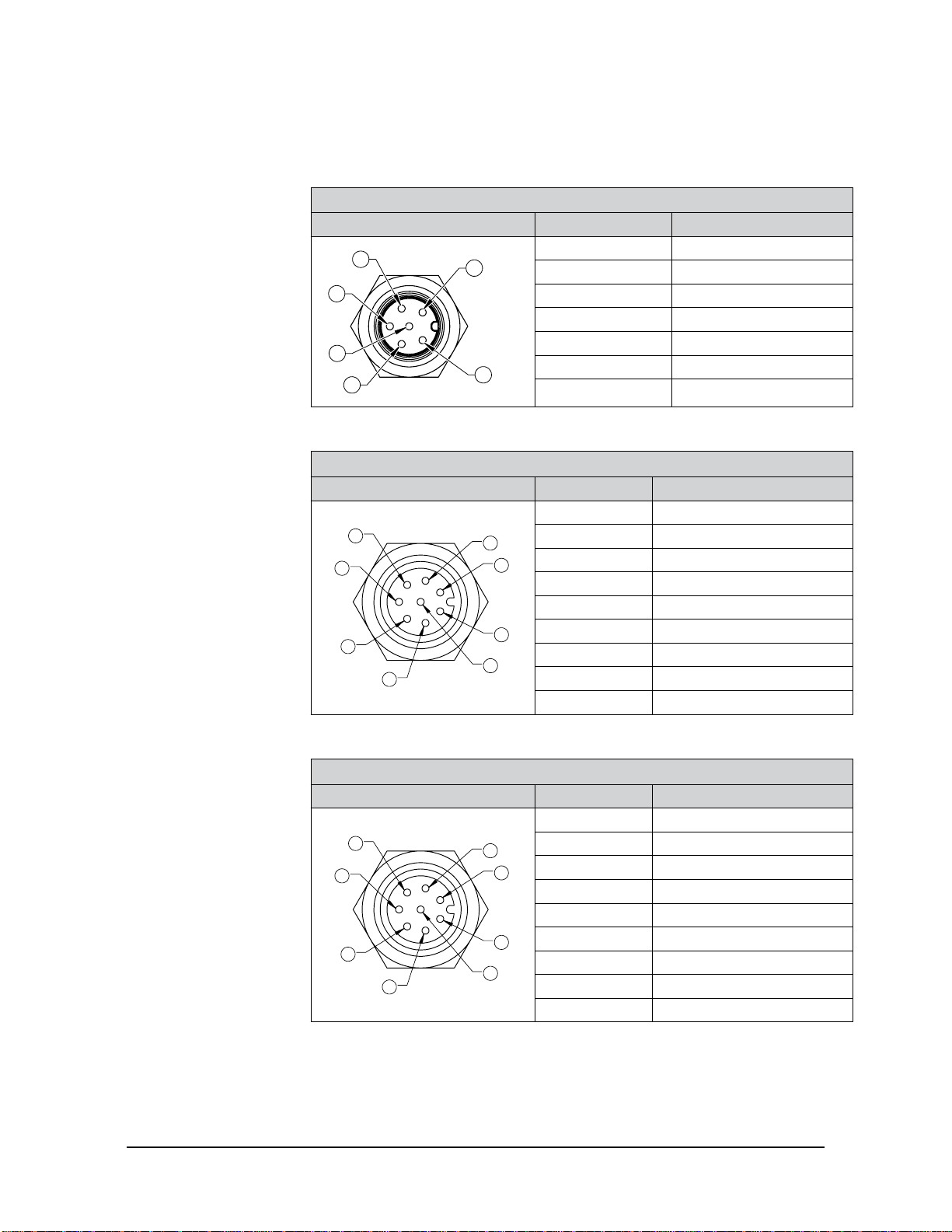

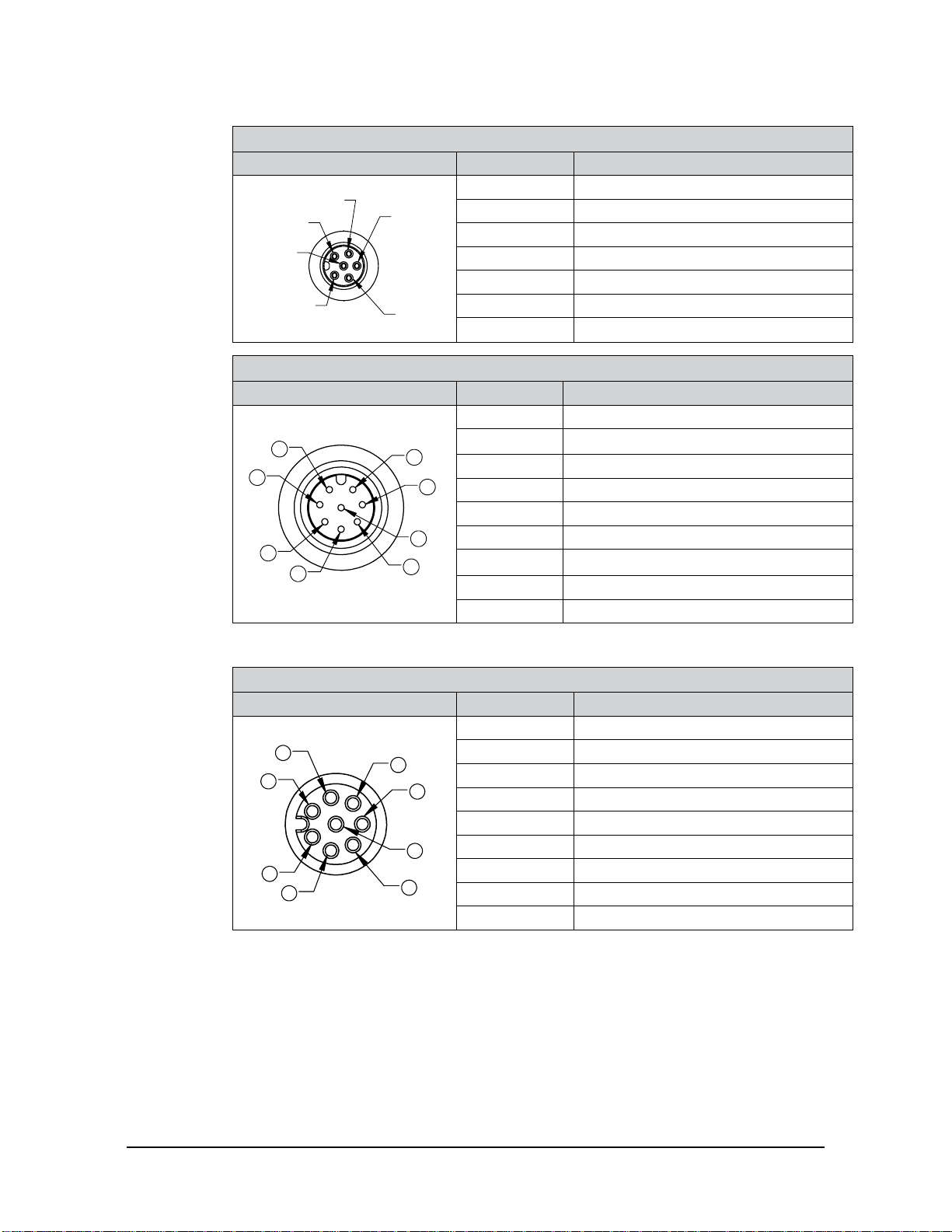

3.3.1.1 Axia80 6-Pin M8 Male Connector

Table 3.2—Axia80 Sensor Connector, M8, 6-pin, Male

Connector Schematic Pin Number Signal

1

2

6

3

4

5

1 Tx +

2 Tx -

3 Rx +

4 Rx -

5 V +

6 V - / 0 V / Ground

Shell Shield

3.3.1.2 Axia80 and Axia90 8-pin M8 Male Connector

Table 3.3—Axia80 and Axia90 Sensor Connector, M8, 8-pin, Male

Connector Schematic Pin Number Signal

1

6

2

8

4

5

3

7

1 Reserved

2 V +

3 V - / 0 V / Ground

4 Tx -

5 Rx +

6 Tx +

7 Reserved

8 Rx -

Shell Shield

3.3.1.3 Axia130 8-pin M12 Male Connector

Table 3.4—Axia130 Sensor Connector, M12, 8-pin, Male

Connector Schematic Pin Number Signal

1

6

2

8

4

5

3

7

1 Reserved

2 V +

3 V - / 0 V / Ground

4 Tx -

5 Rx +

6 Tx+

7 Reserved

8 Rx -

Shell Shield

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-16

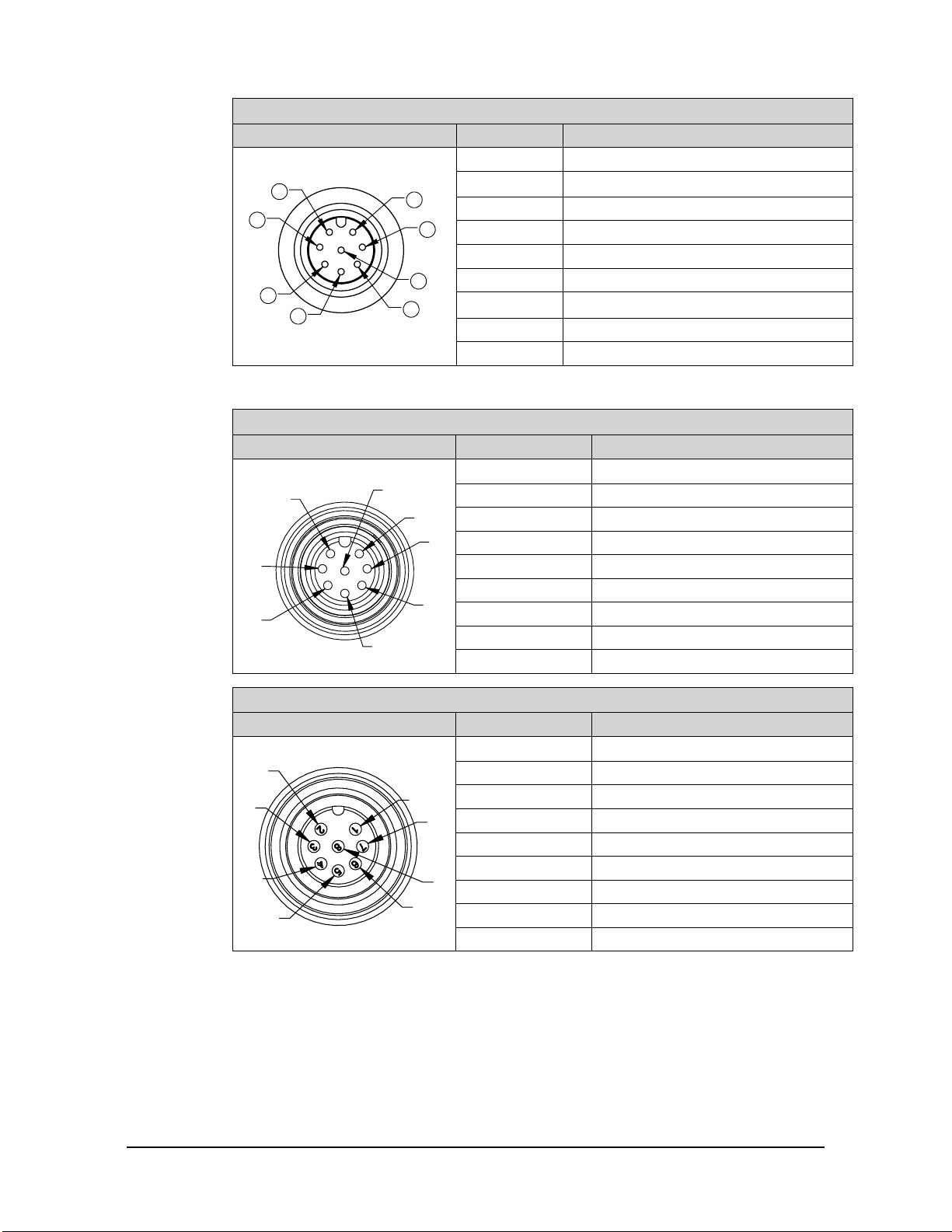

3.3.2 Axia80SensorCable(P/N9105-C-ZC22-ZC28-X)

Table 3.5—ZC22Connector,M8,6-pin,Female

Connector Schematic Pin Number Signal

1

2

3

4

5

6

1 Tx +

2 Tx -

3 Rx +

4 Rx -

5 V +

6 V - / 0 V / Ground

Shell Shield

Table 3.6—ZC28Connector,M12,8-pin,Male

Connector Schematic Pin Number Signal

1

2

3

456

7

8

1 Reserved

2 V +

3 V - / 0 V / Ground

4 Tx -

5 Rx +

6 Tx +

7 Reserved

8 Rx -

Shell Shield

3.3.3 Axia80andAxia90SensorCable(P/N9105-C-ZC27-ZC28-X)

Table 3.7—ZC27Connector,M8,8-pin,Female

Connector Schematic Pin Number Signal

1

2

34

5

7

8

6

1 Reserved

2 V +

3 V - / 0 V / Ground

4 Tx -

5 Rx +

6 Tx +

7 Reserved

8 Rx -

Shell Shield

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-17

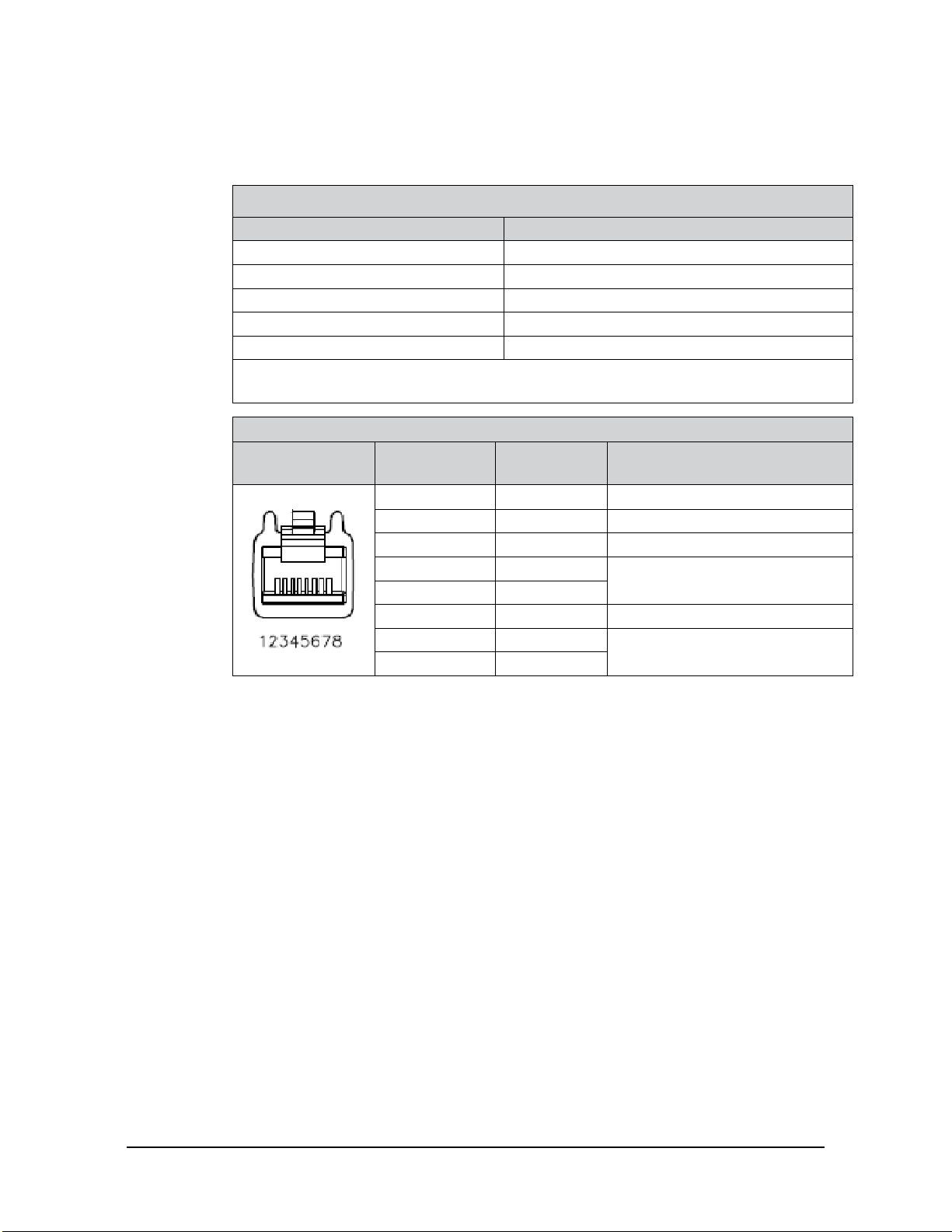

Table 3.8—ZC28Connector,M12,8-pin,Male

Connector Schematic Pin Number Signal

1

2

3

456

7

8

1 Reserved

2 V +

3 V - / 0 V / Ground

4 Tx -

5 Rx +

6 Tx +

7 Reserved

8 Rx -

Shell Shield

3.3.4 Axia130SensorCable(P/N9105-C-ZC28-ZC28-X)

Table 3.9—ZC28Connector,M12,8-pin,Female

Connector Schematic Pin Number Signal

12

3

4

5

6

7

8

1 Reserved

2 V +

3 V - / 0 V / Ground

4 Tx -

5 Rx +

6 Tx +

7 Reserved

8 Rx -

Shell Shield

Table 3.10—ZC28Connector,M12,8-pin,Male

Connector Schematic Pin Number Signal

3

4

1

2

56

7

8

1 Reserved

2 V +

3 V - / 0 V / Ground

4 Tx -

5 Rx +

6 Tx +

7 Reserved

8 Rx -

Shell Shield

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-18

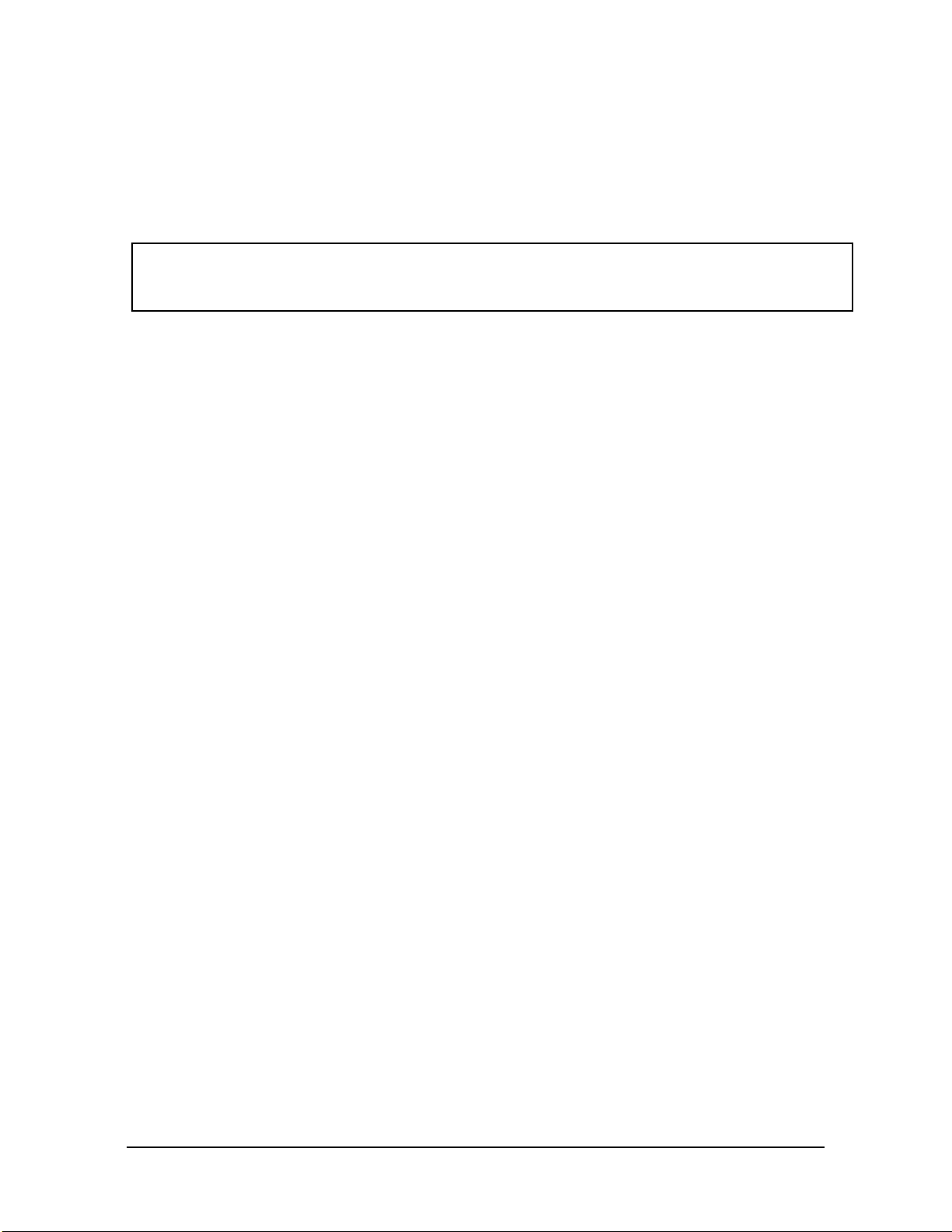

3.3.5 EthernetCable(P/N9105-C-ZC28-U-RJ45S-X)

This cable has (2) branches: an unterminated end for power and an RJ45 connection for Ethernet.

Both of these connections connect to the customer’s device. For the signals and corresponding pin

numbers/wire color, refer to the following sections.

Table 3.11—Branch1,UnterminatedEndForPower

WireJacketColor Signal

Braided Metal Shield Shield (Connect to Ground)

Brown V+

Brown/White V - / 0 V / Ground

Blue/White (TP1 +)1Reserved

Blue (TP1 -)1Reserved

Note:

1. Reserved-not used.

Table 3.12—Ethernet Connector, RJ45, 8-pin, Female

Connector

Schematic Pin Number Wire Color Signal

1 White/Orange Tx +

2 Orange Tx -

3 White/Green Rx +

4 - No Connection

5 -

6 Green Rx -

7 - No Connection

8 -

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-19

4. ConnectingThroughEthernet

Different methods for setting an IP address and how to congure a Windows® 7/8/10 operating system to connect

the sensor to the ATI Ethernet Axia sensor webpages, are covered in the following sections.

For a sensor to connect through Ethernet, a user must congure the IP address setting of the sensor. The sensor can

connect through Ethernet by one of the following options:

• Plug the end of the Ethernet cable into a port of an Ethernet switch that is connected to a computer.

NOTICE:

• If the computer does not have a spare Ethernet port, an additional port must be installed. Users

should contact their IT department for assistance.

4.1 IPAddressCongurationforEthernet

To apply new IP address settings, power cycle the sensor. New IP address settings are only loaded upon

power up. Congure an IP address for the Ethernet Axia sensor with one of the following methods:

Method 1: Set the IP address to a static value stored on the Communication Settings

webpage. (refer to Section 4.2—Connecting To the ATI Webpages Using a Windows

Computer steps 11 through 12)

Method 2: The DHCP server assigns an IP address. Enable this option in the Ethernet Axia’s

webpages (refer to Section 4.2—Connecting To the ATI Webpages Using a Windows

Computer steps 11 through 12). To use this method, a DHCP server must be present

in the network.

ATI ships the sensor with DHCP enabled and the static IP address set to 192.168.1.1. If the network does not

support DHCP, the network automatically uses the static IP address. If a LAN connection is absent during

power up, the network does not use DHCP. Users should contact their IT department for more information.

Manual, F/T Sensor, Ethernet Axia

Document #9620-05-C-Ethernet Axia-02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

C-20

4.2 ConnectingTotheATIWebpagesUsingaWindowsComputer

To initially access the ATI Ethernet Axia F/T webpages, congure the sensor to work on the network by

assigning an IP address and provide basic information about the network.

For the initial connection, directly connect the computer to the sensor and disconnect from LAN. The

sensor’s default IP address is 192.168.1.1. Temporarily change the computer’s Ethernet adapter to a static IP

address with the same rst three elds as the sensor, for example: 192.168.1.100.

NOTICE: If the computer has multiple connections to Ethernet, such as a LAN connection and a

wireless connection, select the LAN that will be connected to the Ethernet Axia sensor.

NOTICE: If the sensor’s static IP address has been changed and is no longer set to the default,

thecomputer’sEthernetadaptermustbesettoastaticIPaddresswiththesamerstthree

eldsastheNEWsensorIPaddress.Asanexample,192.168.1.100worksifthesensorisusing

the default IP address of 192.168.1.1.

1. Disconnect the Ethernet cable from the LAN port on the computer.

2. Open the computer’s Internet Protocol (TCP IP) Properties window:

• For Windows® 7/8/10 operating system, complete the following steps:

a. From the Start menu, select the Control Panel.

b. Click on the Network and Internet icon.

c. Click on the Network and Sharing Center icon.

d. Click on the View network status and tasks link.

e. Click on the Local Area Connection link.

f. A new window opens that displays the general settings for that local area connection link.

Click on the Properties button.

g. On the Networking tab, scroll down and select Internet Protocol Version 4 (TCP/IPv4)

connection item (refer to Figure 4.1).

h. Click on the Properties button (refer to Figure 4.1).

Figure4.1—Windows7/8/10NetworkingInformation

3. Record the values and settings shown in the properties window. Save these values so that the computer

can be returned to its original conguration.

Other manuals for ATI Axia80

1

This manual suits for next models

2

Table of contents

Other Novanta Accessories manuals