Novar NRC86 User manual

KMB systems, s.r.o.

Dr. M. Horákové 559, 460 06 Liberec 7, Czech Republic

tel. 420 485 130 314, fax 420 482 736 896

email : [email protected], internet : www.kmb.cz

10/2013

Remote Controlled Target PF and Remote Controlled

Outputs Compensation Systems Based on Novar Line

Po er Factor Controllers

NOVAR-1xxx NRC Po er Factor Controller

NRC 86 Remote Controller

Firmware v. 1.8 ( Novar ) / 1.0 ( NRC86 )

Operating Manual

Novar-NRC KMB systems

2

LIST OF CONTENTS

1. APPLICATION.................................................................. 4

1.1 Remote Controlled Target Po er Factor Compensation Systems ..................................................4

1.2 Remote Controlled Outputs Compensation Systems .......................................................................4

1.3 History of Firm are Versions ..............................................................................................................4

1.4 Manual Structure...................................................................................................................................4

2. THE „NOVAR1XXX NRC“ SPECIAL VERSION POWER

FACTOR CONTROLLERS...................................................... 6

2.1 Operation ...............................................................................................................................................6

2.1.1 Remote Controlled Power Factor (Cosinus) Mode – the „RCC“ Mode...........................................6

2.1.2 Remote Controlled Outputs – the „I/O“ Mode.................................................................................8

2.2 Parameters 01(07) – Target PF for Metering Rate 1(2) / Actual Remote Controlled Target PF......8

2.2.1 Parameter 01..................................................................................................................................8

2.2.2 Parameter 07..................................................................................................................................8

2.3 Parameters 30 – Alarm Setting, 40 – Alarm Status ............................................................................9

2.3.1 Alarm No. 6 – Undercurrent Alarm with Adjustable Limit or Alarm by Import with Adjustable Limit

and Fixed Outputs Release at Export..............................................................................................................9

2.3.1.1 Undercurrent Alarm with Adjustable Limit..................................................................................9

2.3.1.2 Alarm by Import with Adjustable Limit and Fixed Outputs Release at Export............................9

2.3.2 Alarm No. 15 – Remote Control Failure .......................................................................................10

2.4 Parameters 50, 51, 52 – Instrument Address, Communication Rate and Communication

Protocol / NRC86 response timeout...............................................................................................................11

2.5 Parameter 53 – Remote Control Mode ..............................................................................................11

2.6 Parameters 80,81 – Remote Controlled Target PFs and Remote Controlled PF Serial Number .13

3. NRC 86 REMOTE CONTROLLER................................. 14

3.1 Description ..........................................................................................................................................14

3.2 Operation .............................................................................................................................................15

3.2.1 Remote Controlled Power Factor (Cosinus) Mode – the „RCC“ Mode.........................................15

3.2.2 Remote Controlled Outputs – the „I/O“ Mode...............................................................................15

3.2.3 Manual Mode................................................................................................................................15

3.3 NRC86 Remote Controller Parameters .............................................................................................15

3.3.1 Parameter 01 – Remote Control Mode ........................................................................................15

3.3.2 Parameter 02 – Remote Controlled PF Serial Number................................................................16

3.3.3 Parameter 05 – Number of Processed Outputs (in I/O mode) .....................................................17

3.3.4 Parameter 06 – Daisy-Chain Communication Mode („Cascade“) ................................................17

3.3.5 Parameters 10, 11, 22 – Instrument Address, Communication Rate and Communication Protocol17

Novar-NRC KMB systems

3

3.3.6 Parameter 20 – Alarm Status.......................................................................................................17

3.3.7 Parameter 21 – Instrument Failure Status ...................................................................................17

3.3.8 Parameter 30 – Logic Inputs Status.............................................................................................18

3.4 Installation ...........................................................................................................................................18

3.4.1 Power Supply ...............................................................................................................................18

3.4.1.1 24 VDC Power Supply Version................................................................................................18

3.4.1.2 230 VAC Power Supply Version ..............................................................................................18

3.4.1.3 Protection.................................................................................................................................18

3.4.2 Logic Outputs...............................................................................................................................18

3.4.3 Logic Inputs..................................................................................................................................19

3.4.4 Communication Interface .............................................................................................................19

4. PUTTING IN OPERATION..............................................20

4.1 Remote Controlled Target PF Compensation Systems ..................................................................20

4.2 Remote Controlled Outputs Compensation Systems .....................................................................21

5. CONNECTION EXAMPLES............................................23

6. NRC86 REMOTE CONTROLLER TECHNICAL

SPECIFICATIONS..................................................................26

7. MAINTENANCE, TROUBLESHOOTING .......................27

Novar-NRC KMB systems

4

1. Application

1.1 Remote Controlled Target Power Factor Compensation Systems

When connecting major sources to medium voltage network, a remote control of reactive power is

often required. One possibility is to control target power factor using pulse signals from distributor (eg,

transmitted via a GPRS modem). Such equipped compensation systems can be implemented using

the Novar1xxx NRC power factor controller and the NRC86 remote controller.

1.2 Remote Controlled Outputs Compensation Systems

Alternatively, the NRC86 controller in combination with the Novar1xxx NRC power factor controller can

be used for remote controlled outputs compensation systems.

In practice, there may be cases where compensation capacitors must be placed at great distance from

the measuring current transformer (CT). Since the maximum length of the wires to the CT is limited

due to the limited maximum loop impedance, in some cases the power factor controller cannot be

installed in a switchboard with capacitors but at the measurement point near the CT. In such cases, it

is necessary to install a multi-core power cable connecting the controller with capacitor contactors. If,

for technical or other reasons, this solution is impossible and there exists a suitable communication

channel (cable or other media) between the points, the NRC86 remote controller can be used for

driving the capacitor contactors.

1.3 History of Firmware ersions

Novar 1xxx NRC

version date of release note

1.3 10/2010 - basic version

1.4 8/2011 - THDI alarm replaced with adjustable current limit undercurrent

alarm ( parameters 30, 40)

1.5 11/2011 - RCC/IO communication error fixed

1.6 09/2012 - combined RCC and I/O operation and multiple NRC86 units

performance support added

1.7 04/2013 - “Alarm by import with adjustable limit and fixed outputs release at

export" function added

1.8 10/2013 - PF display error at undercurrent alarm activation correction

NRC 86

version date of release note

0.1 10/2010 - basic version

0.2 01/2011 - „I/O“-mode for two NRC86 units added

0.3 04/2011 - general I/O device feature added

1.0 09/2012 - combined RCC and I/O operation and multiple NRC86 units

performance support added

1.4 Manual Structure

This Operating Manual describes the NRC86 remote controller and the Novar1xxx NRC controller’s

specific features only. At least basic knowledge of Novar line power factor controllers is necessary for

understanding it.

Novar-NRC KMB systems

5

Detailed description of the Novar power factor controllers can be found on the manufacturers website

at www.kmbsystems.eu .

Novar-NRC KMB systems

6

2. The „Novar1xxx NRC“ Special Version Po er Factor

Controllers

The „NRC“ special version is available for following Novar power factor controller (PFC) models :

1106, 1114, 1206, 1214 ( marking example : Novar1214 NRC). The 1414 and 1312 models can be

delivered with limited functionality only – see below.

The PFCs are equipped with a RS-485 communication interface and with the special version firmware

„0E“ that allow, in combination with the NRC86 remote controller, either a remote controlled power

factor operation mode or a remote controller outputs operation mode .

From point of view of hardware and installation, the „NRC“-version PFCs don’t differ from standard

PFC models (with exception of models Novar1414 NRC and Novar1312 NRC, see below) and detailed

description can be found at the standard Novar1xxx operation manual. The only difference is their

firmware – they are equipped with special version firmware „0E“. The PFCs are marked with the „0E“

code :

• on the panel of the controller at initial phase after supply voltage is applied. When the

firmware version is displayed the first two characters of displayed string „0E1.3“ stands for

special firmware version 0E, and the last two stands for basic firmware version 1.3.

• at firmware window of the product label on the rear panel of the controller. For example

marking „1.3/OE“ means basic firmware version 1.3 and the character after a slash mean

special version „0E“

The only limitation of this firmware version is that the Modbus communication protocol is not

supported. All of other features are the same as the standard version.

The Novar1414 NRC and the Novar 1312 NRC models differ, moreover, from the standard models by

not allowing automatic connection detection and automatic sections’ powers recognition. Therefore,

the type of connection (parameter No. 16) and individual sections’ power sizes (parameter No. 25)

must be entered manually.

2.1 Operation

2.1.1 Remote Controlled Po er Factor (Cosinus) Mode – the „RCC“ Mode

The Novar1xxx NRC PFC (or several PFCs) is connected to the NRC86 remote controller through a

RS-485 communication link. Using additional parameters of the „0E“ special firmware the PFC can be

set up to the RCC mode (Remote Controlled Cosϕ). After being set, the PFC periodically reads serial

number of remote controlled PF value in range 1 ÷ 5 from the NRC86 unit.

In the PFC it is possible to preset five PF values corresponding to the remote controlled PF serial

numbers. Default values are –0.95 / -0.97 / 1.00 / 0.97 / 0.95 , but they can be freely changed.

According this setting the PFC keeps preset target PF value that is dynamically controlled by the

remote controlled PF serial number from the NRC86 unit ( standard target PF value in parameter 01

has no meaning in this mode).

Simultaneously, other NRC86 units (up to six, i.e. seven units in total) in function of remote controlled

outputs (see below) can be connected to the communication link too.

Novar-NRC KMB systems

7

Tab. 2.1 : Novar 1xxx NRC Additional and Affected Parameters

# name range step

default comment

1

(7)

target PF for

metering rate 1

(2)

actual remote

controlled

target PF

0.80 L ÷ 0.80 C

„EX.XX“ format indicates

remote controlled target PF

value in the „RCC“-mode

0.01 0.98 L in the „RCC“-mode (see par. 53), depending

on the metering rate 2 parameter setting and

state, the actual value of target PF is defined

by setting of the „remote controlled target

PF“ (par. 80) and by actual state of the

„remote controlled PF serial number“ (par.

81)

6 metering rate 2

enable/disable

0 – 1 – E — 0 hen the metering rate 2 parameter enabled

(value "1" or "E") and the "RCC"-mode (par.

53) enabled, PF control is carried out by the

„remote controlled target PF“ hen the

metering rate 2 just active only (i. e. hen

digital input activated or active po er export

occurs ); for metering rate 1, the PF is

controlled by the target PF for metering rate

1 (par. 01), regardless to the „remote

controlled target PF“ value

30 alarm setting 0 / indication only / actuation

only / indication and actuation

— indication and

actuation

from

undercurrent,

voltage signal

absence or

section error

1... undercurrent

…

14 … external alarm

15 ... NRC86 connection loss

Alarm No. 15 is activated when no response

from the NRC86 unit occurs during approx. 20

seconds. The alarm actuation function is

intended mainly for the „I/O“-mode.

40 alarm

instantaneous

condition

„0“ indicates passive state, „1“ indicates active

state. Alarm numbering according par. 30.

50 instrument

address

1 ÷ 255 1 1 In the„RCC“- and a the„I/O“-mode the preset

value has no meaning. The fixed address 200

is used for communication ith the NRC86

unit.

51 communication

rate

4800 – 9600 – 19200 Bd — 9600 In the„RCC“- and a the„I/O“-mode the value

must correspond to that of the NRC86 unit

52 communication

protocol

NRC86

response

timeout

KMB(P0)

0 – 1 – 2 – 3 – 8 sec

- KMB(P0)

0 sec

Modbus-RTU protocol cannot be set.

In the„RCC“- and a the„I/O“-mode (par. 53)

the parameter defines the NRC86 unit

response timeout in seconds.

53 remote control

mode

-(=off) / IO / IO. / RCC / RCC.

/ RCCP

- -(=off) - … remote control mode s itched off -

comm. interface available for standard

remote monitoring (protocol KMB only)

- IO … „I/O“-mode only ( ith up to 7 NRC86s)

- IO. … „I/O“-mode ith actual PFC state

broadcast

- RCC … „RCC“-mode ith optional

simultaneous „I/O“-mode ( ith up to 6

additional NRC86s)

- RCC. … „RCC“-mode ith actual PFC state

broadcast

- RCCP … „RCCP“-mode (passive)

80 remote

controlled

target PF No. 1

÷ 5 ( in

„RCC“-mode )

0.80 L ÷ 0.80 C

0.01 1. = 0.95 C

2. = 0.97 C

3. = 1.00

4. = 0.97 L

5. = 0.95 L

individual remote controlled target PF values

EC1÷

÷÷

÷EC5 corresponding to remote

controlled PF serial number (par. 81) can be

set in a side branch

81 remote

controlled PF

serial number

( in „RCC“-

mode )

1 ÷ 5

1 3 the value is periodically read from the NRC86

unit

- slo ly flashing dec. point indicates off-line

state; the value displayed corresponds to the

last read value

- slo ly flashing dec. point indicates default

state 3 ( at long time off-line state )

Novar-NRC KMB systems

8

2.1.2 Remote Controlled Outputs – the „I/O“ Mode

The Novar1xxx NRC PFC is connected to the NRC86 remote controller (optionally to more of such

controllers) through a RS-485 communication link. Capacitor (or choke) contactors are not connected

to the PFC outputs but to corresponding outputs of the NRC86 controller(s).

Using additional parameters of the „0E“ special firmware the PFC can be set up to the I/O mode

(Input/Output). Then the PFC output state is periodically transmitted to the NRC86 controller(s) and its

outputs state „copies“ the PFC outputs state. The outputs refresh speed is between 3 ÷ 10 times per

second if a transparent communication medium ( i.e. a medium with no transmission delay) is used (it

depends on preset communication rate and remote control mode). If usual metallic cable is used

maximum distance between the PFC and the NRC86 unit is up to 1 km, but it can be nearly unlimited

for suitable wireless media.

Up to seven NRC86 units can be connected. At each of the units you can set how many outputs to

process (i.e. how many of its outputs are controlled by the PFC outputs); then other outputs of the

PFC are processed by other NRC86 units. By this you can control outputs which are spatially spread

within reach of the communication line.

Desired remote controlled mode ( either the „RCC“ or the „I/O“ ) can be set using additional

parameters according Tab. 2.1°. Essential matters that differ from standard version are bolded.

Significant parameters detailed description follows.

2.2 Parameters 01(07) – Target PF for Metering Rate 1(2) / Actual Remote

Controlled Target PF

2.2.1 Parameter 01

If the remote control mode (par. 53) is switched off or if the metering rate 2 control (par. 06) is

enabled, parameter 01 has usual meaning, i.e. preset target PF value ( for metering rate 1).

If any of RCC modes is set and the metering rate 2 control is disabled simultaneously, the target

PF is remote controlled by external NRC86 unit. In such case an actual value of remote controlled PF

with preceding „E“ character is displayed in parameter 01 ( for example E0

E0E0

E0.97

9797

97 ). This value cannot

be edited in parameter 01; it is defined by preset value of remote controlled target PF in parameter 80,

corresponding to actual state of remote controlled PF serial number. This serial number ( in range 1 ÷

5 ) is periodically read from theNRC86 unit and its value can be checked in parameter 81.

Thus the PFC controls PF to one of preset values in parameter 80. Usual value of parameter 01, i.e.

standard target PF value for metering rate 1, has no meaning in the RCC mode and it is not displayed.

But, if the metering rate 2 control (par. 06) is enabled, the parameter 01 has usual meaning - preset

target PF value ( for metering rate 1). Then, if the metering rate 2 is inactive actually, the parameter 01

target PF is used for PF control and the remote controlled target PF value is ignored.

2.2.2 Parameter 07

The standard meaning of this parameter is target PF for metering rate 2 (the second tariff). If the

metering rate control (parameter 06) is disabled its value has no meaning.

If the metering rate 2 control is enabled and the RCC mode is off, target PF is defined by the

parameter 01 or 07 according actual state of the metering rate 2 control value.

Novar-NRC KMB systems

9

If the metering rate 2 control is enabled and any of the RCC-modes is set simultaneously, the

target PF is remote controlled by external NRC86 unit only hen the metering rate 2 (tariff 2) just

active. In such case, the actual value of remote controlled PF with preceding „E“ character is

displayed in parameter 07 ( in the same way as in the parameter 01 when the metering rate 2 control

disabled). The parameter 01 has in such case its usual meaning, i.e. preset target PF value for tariff 1.

Thus, if the tariff 2 just inactive, the PF is controlled by the parameter 01 value and the remote

controlled target PF value is ignored.

The tariff2 value is evaluated in the usual way: either by state dig. input (1) or export (E).

2.3 Parameters 30 – Alarm Setting, 40 – Alarm Status

2.3.1 Alarm No. 6 – Undercurrent Alarm ith Adjustable Limit or Alarm by Import ith

Adjustable Limit and Fixed Outputs Release at Export

At standard Novar 1xxx controllers, the alarm No. 6 is controlled by THDI value.

At the Novar 1xxx NRC controllers, the alarm is not evaluated. The alarm No. 6 has one of following

meanings depending on its setting :

2.3.1.1 Undercurrent Alarm with Adjustable Limit

This is in fact enhanced undercurrent alarm. Behaviour of the alarm corresponds to the alarm No. 1

(thus, it is controlled by Ieff value); furthermore, the undercurrent limit value in “per mille”(ppt, range 0

÷ 200 ppt) of nominal current (5A/1A according parameter 13 setting) can be set in parameter 33.

For this alarm behaviour, the alarm No. 1 must be set in the same way as the alarm No. 6.

The limit value setup example : CT ratio (par. 12,13 ) is set to 500/5A. We intend to set the

undercurrent limit to 15A. Nominal current corresponds to the CT primary value, i.e. 500A, one ppt of

this is 0.5A. So we set the parametr 33 to 15 / 0.5 = 30.

2.3.1.2 Alarm by Import with Adjustable Limit and Fixed Outputs Release at Export

For this alarm functionality, the actuation function of the alarm No. 1 must be (unlike the function

described above) switched off (usual value 0

00

0) and the actuation function of the alarm No. 6 must be

switched on (usual value 2

22

2), simultaneously. Then :

• The alarm No. 6 is triggered as soon as fifteen minute average value of the active current

Iact is either positive (=import), or it is negative, but its absolute value is below the preset limit

in “per mille”(ppt, range 0 ÷ 200 ppt) of nominal current (5A/1A according parameter 13

setting) in parameter 33. During the check a hysteresis of /-1mA is applied.

• When the actuation is triggered all of the fixed sections are set to their preset states. The

controller goes on operation with the remaining ones. If all of the sections are fixed the power

factor control is suppressed.

• As soon as the fifteen minute average value of the active current Iact gets negative (=export)

and its absolute value exceeds the preset limit in the parameter 33, the alarm gets inactive.

At the same time, all of the sections preset as fixed ones are released for the control process,

i.e. they are considered as standard control sections.

• This alarm function setting is indicated by slowly flashing decimal points at the sections

pressed as fixed at the parameter 26, that denotes their conditional behaviour

Novar-NRC KMB systems

10

Note 1 : The fifteen minute average value of the active current Iact is not displayed, you can check

the actual value of the active current Iact only. So you must take in mind appriopriate delay in the

alarm activation and deactivation when checking its behaviour.

Note 2 : When this alarm is set , the undercurrent alarm (No. 1) is, as noted above, switched off,

necessarily. Therefore, the controller uses all of the sections but the fixed ones even if the measured

current drops to minimum. If you need the controller to set firmly defined combination of all the

sections when the alarm is activated, it is necessary to set as fixed all of the sections, not just those

that are to be fixed on, but the remaining sections as fixed off, as well.

The limit value setup example : Usually, it is necessary to set the current limit according required

active power threshold. CT ratio (par. 12,13 ) is set to 500/5A, type of measurement voltage (par. 15)

is phase-neutral ( U=LN

U=LNU=LN

U=LN), nominal voltage UNOM (par. 18) is 230 V. We intend to set the undercurrent

limit to correspond to the -5kW (export) of three-phase active power. Corresponding phase power is

-5 / 3 = -1.67 kW = -1670 W. As nominal voltage is 230V, corresponding phase current is 1670 / 230 =

-7.25 A (for phase-phase voltage, it must still be divided by √3). As one ppt of the current range is (as

in previous example) 0.5A, we set the parameter 33 to 7.25 / 0.5 =~ 15.

2.3.2 Alarm No. 15 – Remote Control Failure

For remote control mode state checking, alarm No. 15 was added :

Tab. 2.2 : Remote Control Failure Alarm

# condition description minimum delay

of

activation /

deactivation

actuation

15

remote

control

failure

loss of connection with the NRC86

unit/units ( some of the unit response

is incorrect or missing at all )

20 / 1 seconds disconnection of all

sections

As default, the remote control failure alarm is switched off and it is possible to switch it on if advisable.

If no remote controlled outputs connected the actuation function is not interesting; it is intended

especially for emergency disconnection of remote controlled outputs. When temporary interruption of

the connection between the PFC and the NRC86 unit/units appears, the situation will look as follows :

1. Approximately after 20 seconds of communication link fault the PFC disconnects all of

outputs step by step and it will stay in standby mode until the connection is restored.

2. The NRC86 remote controller(s) in the I/O mode disconnects (simultaneously) all of its

outputs after approx. 30 seconds of the communication link fault duration.

3. After the connection is restored, the PFC returns back to to control mode and the NRC86

controller(s) outputs starts to copy the PFCs outputs state to its outputs again.

So it is ensured that no premature switching of more outputs on will occur and the reconnection delay

time preset in the PFC will be kept

Novar-NRC KMB systems

11

2.4 Parameters 50, 51, 52 – Instrument Address, Communication Rate and

Communication Protocol / NRC86 response timeout

Parameter 50 specifies the instrument address for remote control and monitoring of the PFC with the

Retis ot the Envis program. But this function cannot be used in a remote control mode because the

communication link is reserved for connection with the NRC86 unit(s). So the parameter value has no

meaning in this mode (the PFC uses fixed addresses 200 and higher for communication with the

NRC86(s) ).

The communication rate ( parameter 51) must be set identically as the communication rate of the

NRC86 unit(s). It is recommended to use default value 9.6 kBd or, according local conditions ( cable

length, interference level, … ), it is possible to increase it if applicable. In the RCC mode the set value

is not critical, in the I/O mode the higher value can bring better performance.

Parameter 52 setting is relevant only when any remote control mode ( either the RCC or the I/O) is

activated in parameter 53. In such case it doesn’t specify the communication protocol as usual but it

defines maximum wait time for response from the NRC86 unit(s). For default value 0 the NRC86

response timeout is approx. 0.3 sec – this setting is suitable for transparent communication links ( that

have no transmission delay).

For non-transparent communication media (with transmission delay) such like radiomodems,

GSM/GPRS modems, LAN etc., it is necessary to set this parameter value to maximum wait time for

response from the NRC86 i seconds ( in range 1 – 2 – 3 – 5 – 8 ).

If the remote control mode is switched off the parameter 52 has its usual meaning – the type of

communication protocol. But as the „NRC“-version PFCs don’t support the Modbus protocol the value

is fixed to P0 (= KMB protocol ).

2.5 Parameter 53 – Remote Control Mode

With this parameter you can activate the so-called remote control mode. In this mode, the PFC

cooperates with a NRC86 control unit (or more units) interconnected with a serial interface. The

interface is used to full capacity during remote control mode and therefore remote monitoring and

control of the PFC with the Retis or the Envis program is not possible.

Tab. 2.3 : Parameter 53 – Remote Control Mode Setting Options

setting description note

--

----

--

remote control mode is switched off communication interface can be used for

PFC remote monitoring & control (Retis,

Envis)

i0

i0i0

i0

I/O mode only with up to 7 NRC86 units number of the units connected defined by

their setting

i0

i0i0

i0. I/O mode and actual PFC state

broadcast

actual PFC state is simultaneously

transmitted to the NRC86

rCC

rCCrCC

rCC

RCC active mode driven by the 1st

NRC86 unit and optional simultaneous

I/O mode with up to 6 additional NRC86

units

to be set at the „master“ PFC only

rCC

rCCrCC

rCC. RCC active mode with actual PFC state

broadcast

actual PFC state is simultaneously

transmitted to the NRC86

rCCP

rCCPrCCP

rCCP RCC passive mode to be set at the „slave“ PFCs

Novar-NRC KMB systems

12

In principle, one of two remote control modes can be activated - either the I/O or the RCC mode :

• RCC mode

The RCC mode (Remote Controlled Cosϕ) is designated for remote control of target power

factor value. Simultaneously, a remote controlled outputs can be driven by additional NRC86

units.

Basic RCC-mode, so called active, must be set at one of PFCs only connected to the NRC86

unit(s); this PFC then behaves as “master”, that means it controls data interchange on the

communication link; during this, actual states of the PFC outputs are transferred to additional

NRC86 units in case of simultaneous remote outputs control. If more PFCs connected to the

NRC86 unit, all of others must be set as „slaves“, that means to passive RCC-mode marked

as RCCP.

As soon as the mode is set, the master PFC starts to send commands to the NRC86 unit(s).

The unit (with address of 200 if more units connected) receives them, processes them and

sends confirmation back to the master PFC. The master PFC receives and processes the

NRC86 confirmation and this loop is repeated forever. The slave PFCs listen to

communication and receives the NRC86(s) answers (confirmations) only.

The (first) NRC86 confirmation contains so called remote controlled PF serial number - its

value can be checked parameter 81. According this value and remote controlled target PF

values preset in parameter 80 it evaluates actual target PF, displays it in parameter 01 and

controls the PF according its value.

If the first NRC86 unit respectively set and more units (up to six ) connected in “cascade”, the

response of the previous unit is always received by the next unit with address higher by one

and such units operate as remote controlled outputs as described below.

• I/O mode

The I/O mode (Inputs/Outputs) is determined for remote controlled outputs only. In this

mode, up to seven NRC86 remote controllers can be connected to a single PFC.

The data interchange between the PFC and the NRC86(s) runs in the same way as in the

RCC mode with one difference only – target power factor is not controlled by the NRC86, but

actual state of the PFC outputs is transmitted to the NRC86 unit(s) and so the PFC state

outputs are “copied” to the unit outputs.

So called daisy chain communication can be set at the NRC86 unit. If set , the unit passes

each command to the next unit with address higher by one after processing it. At the last unit

in the cascade the daisy-chain communication must be switched off.

Next, a number of processed outputs can be set at each unit. It specifies how many of PFC

outputs to be received and “copied” to the unit outputs. At the next unit in the cascade you

can set number of processed outputs similarly; then remaining PFC outputs are processed,

i.e. those starting from the first PFC output not processed by the previous unit. Maximum

number of the units in cascade is 7.

Example : The 1st unit setting : address=200, daisy-chain comm =on, No. of processed

outputs=6; the 2nd unit setting : address=201, daisy-chain comm =on, No. of processed

outputs=4; the 3rd unit setting : address=202, daisy-chain comm =off, No. of processed

outputs=7. Then, at the 1st unit 1÷6 outputs, the PFC 1÷6 outputs will appear; the 2nd unit

1÷4 outputs will copy the PFC ouputs No. 7÷10; and finally, at the outputs 1÷7 of the 3rd

unit, the PFC outputs No.11 and higher will appear (up to 17, or to the PFC maximum

output).

Novar-NRC KMB systems

13

In both of the remote control modes, actual state of the master PFC broadcast can be activated.

These options are identified with additional decimal point. When set, the PFC broadcasts its complete

actual state (all measured quantities actual values, outputs state etc.) during communication with the

NRC86 unit(s). Then, these values can be listed and viewed on the NRC86 unit (the first unit only in

case of the unit cascade) display in the same way as on the PFC display. It can be helpful during

installation or it can be optionally used for the PFC actual state monitoring by a third-party system

(program).

But if not necessary it is recommended to use remote control mode without PFC actual state

broadcast during common power factor compensation operation. At this setting, the remote control

commands are essentially shorter and due to this the data interchange is faster and more reliable.

Then actual PF value and the PFC alarm state only can be checked on the NRC86 display.

2.6 Parameters 80,81 – Remote Controlled Target PFs and Remote

Controlled PF Serial Number

These parameters are relevant only when any of the RCC mode is active. Otherwise they are not

displayed.

In the RCC mode , co called serial number of remote controlled PF is periodically transferred from the

(first) NRC86 unit to the PFC (or multiple PFCs). Its range is 1 ÷ 5 and actual value is displayed in

parameter 81with identification string „ECn“; for example, if its value is 2, the ECn2

ECn2ECn2

ECn2 string is

displayed.

If connection between the PFC and the NRC86 unit is interrupted, the PFC keeps last correctly read

value from the (first) NRC86 unit for approx. 30 seconds and during this indicates with slowly flashing

decimal point that the displayed vale is not actual. If the connection is not restored during approx. 1

minute, the serial number of remote controlled PF is set automatically to its default value 3. This state

is indicated with quickly (approx. three times per second) flashing decimal point.

The parameter is set to this default value automatically after the PFC startup and keeps it until

receives first actual value from the NRC86 unit.

In side branch of parameter 80 you can set five remote controlled target PFs EC-1

EC-1EC-1

EC-1 through EC-5

EC-5EC-5

EC-5,

corresponding to remote controlled PF serial number value. The PF range is the same as parameter

01 has, but it is not possible to set the value in angle degrees. Default values are –0.95 / -0.97 / 1.00 /

0.97 / 0.95 .

According this setting and actual value of remote controlled PF serial number, the PFC selects

corresponding PF from preset values EC

ECEC

EC-1

-1-1

-1 through EC-5

EC-5EC-5

EC-5, displays it in parameter 01 ( with

preceding “E” character) and uses it as actual target PF.

Novar-NRC KMB systems

14

3. NRC 86 Remote Controller

The unit is designed for power factor compensation systems either with remote controlled PF or with

remote controlled outputs. The unit operates in combination with special version of Novar power factor

controller – Novar1xxx NRC.

The unit is available in various modifications. Typical models are :

Tab. 3.1 : NRC86 Remote Controller Typical Models

model configuration typical use

NRC86-85 24VDC

• 8 inputs 24 V DC

• 5 relay outputs, up to 400 V AC

• aux. voltage 24 V DC

remote controlled PF

NRC86-07 230VAC

• 7 relay outputs, up to 400 V AC

• aux. voltage 100 ÷ 300 V AC

remote controlled

outputs

3.1 Description

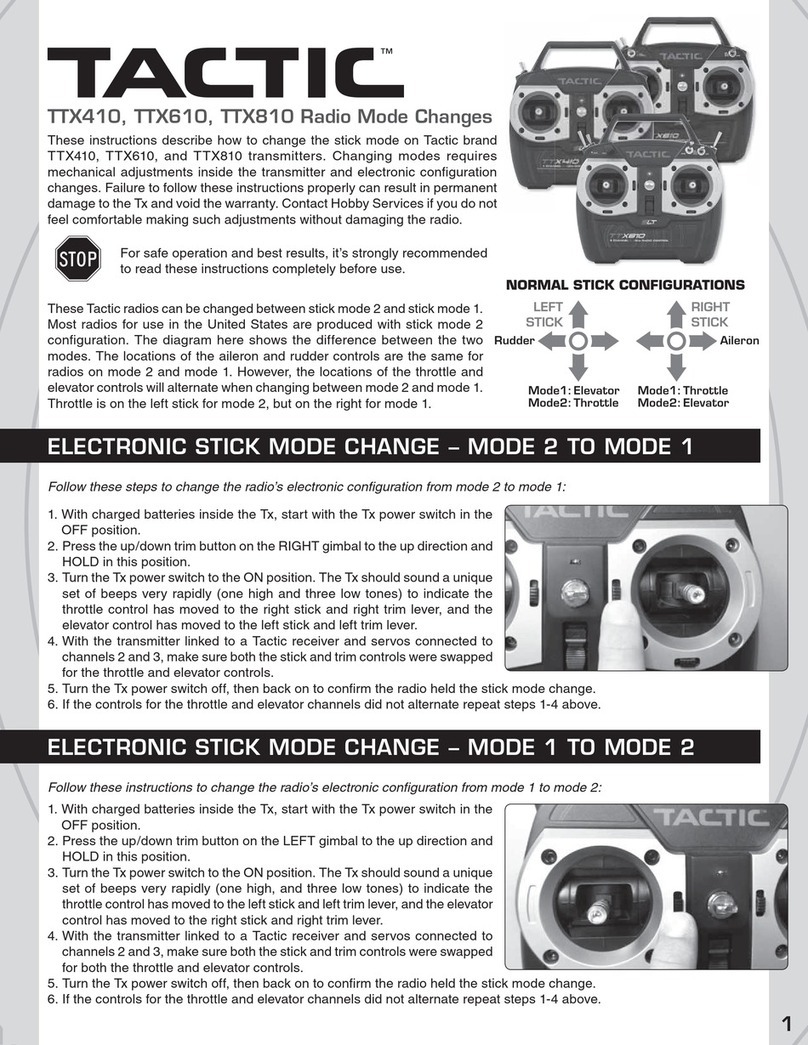

The front panel consists of a numeric display, indication LEDs and control keys.

Fig. 3.1 : NRC 86 Remote Controller

RemoteController

71 2 3 4 5 6 8

20:

21: Fail state

30: Input state

Alarmstate1: Mode

2: RCC number

10: Comm. addr

11: Comm. rate

12: Comm. protocol

Rx

Tx

0 97

.

The unit design is based on the Novar1007D PFC hardware; therefore indication elements and

manipulation is the same or similar. Detailed description can be found at the PFC operating manual.

Indication LED meaning corresponds to the PFC. There are additional LEDs Rx and Tx indicating

receiving and transmitting bytes from / to communication link.

You can list through actual values and unit parameters using the ▲, ▼ buttons. For into/off a side

branch or for parameters editing, use the ► button. Following operations can be made in the same

way as with a Novar line PFC :

• actual PF value display, refreshed periodically from connected PFC; if actual PFC state

broadcast is set, not only the PF value, but all actual values measured by the PFC can be

displayed

• listing through parameters and editing them

• disabling or enabling of parameter editing

• manual control of the unit outputs in Manual mode

Novar-NRC KMB systems

15

3.2 Operation

3.2.1 Remote Controlled Po er Factor (Cosinus) Mode – the „RCC“ Mode

Up to five pulse signals can be connected to the NRC86 unit. A pulse of correct duration on one of

inputs 1÷5 is evaluated as target PF serial number request. The unit saves the number into its

memory and confirms by switching of appropriate output on ( this signal is transmitted back to the

supervising system for checking ).

The Novar1xxx NRC PFC (or several PFCs) periodically reads the target PF serial number from the

unit and uses appropriate preset target PF for compensation.

The instrument address (parameter 10) must be set to 200. If other NRC86 units for remote controlled

outputs connected too, the daisy-chain communication option (parameter 6 ) must be set at all of the

units in the cascade but the last one. The other units’ addresses in the cascade must be increasing by

one, i.e. 201, 202 etc.

3.2.2 Remote Controlled Outputs – the „I/O“ Mode

For such applications the NRC86-07 unit model is suitable. It has 7 outputs (and no input). For

compensation systems with more than 7 outputs, two NRC86-07 units are necessary. Optionally you

can use up to 7 units in cascade if you need to spread remote outputs spatially.

The unit is installed in a PF compensation capacitor ( or choke) switchboard. It must be interconnected

with distant Novar1xxx NRC PFC using a communication link. The capacitor (or choke) contactors

must be connected to the NRC86 unit outputs; the PFC outputs stay unconnected.

The address (parameter 10) of the first unit must be set to 200. If other NRC86 units connected, the

daisy-chain communication option (parameter 6 ) must be set at all of the units in the cascade but the

last one and their addresses must increase by one, i.e. 201, 202 etc.

With the parameter 5 the number of processed outputs in the unit can be set. The parameter is preset

to the maximum number of outputs of the unit, but it can be decreased to “N” – then, the unit outputs

O1 ÷ ON will follow the PFC outputs’ state starting from the first output that is not processed by the

previous unit.

Example : The 1st unit (address 200) is set to 4 processed outputs; the 2nd unit (address=201) is set to

6 processed outputs. Then, at the 1st unit O1÷O4 outputs the PFC 1÷4 outputs will appear and the 2nd

unit O1÷O6 outputs will copy the PFC ouputs No. 5÷10. The daisy-chain communication must be

activated at the 1st unit and deactivated at the 2nd unit.

3.2.3 Manual Mode

In the Manual mode, the NRC86 unit goes on receiving commands and answering to them, but the

unit outputs stay unchanged - they can be changed manually only in the same way as a Novar PFC

outputs.

3.3 NRC86 Remote Controller Parameters

3.3.1 Parameter 01 – Remote Control Mode

The remote control mode of the NRC86 unit is displayed in the parameter – it can be eitheri0

i0i0

i0

(remote controlled outputs) or rCC

rCCrCC

rCC (remote controlled PF).

Novar-NRC KMB systems

16

The parameter value is controlled and refreshed with each command received from a Novar1xxx NRC

PFC, it is not necessary to set it manually. In case of power failure, the last valid value of the

parameter is stored in the unit memory and automatically loaded after the power restoration.

For testing purposes, the parameter value can be set manually too. But, for this it is necessary to

switch the remote control mode off firstly or simply disconnect the communication link temporarily.

3.3.2 Parameter 02 – Remote Controlled PF Serial Number

This parameter is relevant in the RCC mode only. In other modes it is not displayed.

The remote controlled PF serial number can have value in range 1 ÷ 5. If since last unit powerup or

the unit initialisation at least one PF control request had come ( i.e. a valid pulse signal had appeared

at one of I1 ÷ I5 inputs ), the decimal point of displayed parameter value is dark.

The last valid parameter value is stored into the unit memory and automatically uploaded after the unit

powerup. The fact that the parameter value was reloaded from the unit memory is indicated with

flashing decimal point of displayed parameter value. The same indication is activated after manual

editing of the parameter value.

The decimal point gets dark as soon as the first valid PF control request on I1 ÷ I5 inputs appears.

Tab. 3.2 : NRC86 Remote Controller Parameters

# name range step

default comment

1 remote control

mode

IO / RCC - IO set by PFC commands; manual setting for

testing purposes possible only when cooperating

PFC remote control mode is switched off or if

communication link is disconnected

2 remote

controlled PF

serial number (

in „RCC“-mode )

1 ÷ 5 1 3 relevant in the RCC-mode only ; not displayed in

the I/O mode

5 outputs

processed

0 ÷ MAX 1 MAX relevant in the I/O mode only; in the RCC mode

automatically 0, parameter not displayed

6 daisy-chain

communication

mode

0 (off) / 1 (on) - 0 in case of cascade of units must be set on at all

of the units but the last one

10 instrument

address 1 ÷ 254 1 200 for cooperation with a Novar1xxx NRC PFC in

remote control mode must be set to 200 (or

higher in case of units cascade)

11 communication

rate 4800 – 9600 – 19200 Bd - 9600 Bd must correspond to cooperating Novar1xxx NRC

PFC setting

12 communication

protocol

KMB(P0) / Modbus-RTU(P1) - KMB(P0) for cooperation with a Novar1xxx NRC PFC in

remote control mode must be set to P0 (KMB)

20 alarm status -- / E / C - - set by the NRC86 unit ; indicates type of alarm :

E … external alarm (= indicates cooperating

Novar1xxx NRC PFC alarm active state)

C … communication out of order (no Novar1xxx

NRC PFC commands received)

21 instrument

failure status

indicates E-00 for failure-free state

30 logic inputs

status

I1÷I8 logic inputs state :

i … 0 ( passive )

I… 1 (active )

Novar-NRC KMB systems

17

3.3.3 Parameter 05 – Number of Processed Outputs (in I/O mode)

The parameter is relevant in I/O mode only (it is not displayed in RCC mode). It defines how many of

the unit outputs starting from O1 output will be used as remote controlled outputs.

As default, the parameter is preset to the maximum outputs of the unit type. If decreased other outputs

will stay unused.

In case of cascade of more units in the I/O mode, PFC outputs’ states starting from the first output not

processed by previous unit are copied to the next unit outputs starting from its output O1.

3.3.4 Parameter 06 – Daisy-Chain Communication Mode („Cascade“)

If more than one NRC86 units connected to a PFC all of the units but the last one must be set to the

daisy-chain communication mode (i.e. set to 1

11

1).

This mode must be switched off at the last unit in the cascade , i.e. set to 0

00

0.

3.3.5 Parameters 10, 11, 22 – Instrument Address, Communication Rate and

Communication Protocol

The address (parameter 10) of the first NRC86 unit cooperating with a Novar1xxx NRC PFC in remote

control mode must be set to value 200. In case of more NRC86 units in “cascade” every next unit

address must by higher by one than the previous unit address, i.e. 201, 202, etc.

The communication rate (parameter 11) must be set identically as the supervisory Novar1xxx NRC

PFC. It is recommended to use default value 9.6 kBd or, according local conditions ( cable length,

interference level, … ), it is possible to increase it if applicable. In the RCC mode the set value si not

critical, in the I/O mode the higher value can bring better performance.

Parameter 12, i.e. communication protocol, must be set to KMB protocol, i.e. P0

P0P0

P0.

3.3.6 Parameter 20 – Alarm Status

This parameter value is driven by a NRC86 unit itself. If the Alarm LED-diode flashes, the cause of

the alarm can be identified by the parameter value :

• E

EE

E … indicates supervisory Novar1xxx NRC PFC in alarm state

• C

CC

C … indicates missing or incorrect commands from supervisory Novar1xxx NRC PFC (

probably communication link failure )

3.3.7 Parameter 21 – Instrument Failure Status

The unit carries out self-diagnostic tests in regular intervals during its operation. You can check the

diagnostics’ results in this parameter.

It shows E-00

E-00 E-00

E-00 if no errors have occurred. If the value is other than zero, the unit has identified an

error. Such a condition does not necessarily mean the unit is out of operation — in such an event the

unit supplier must be contacted and told about the identification value of the type of error shown.

Using this value, a specialist will then decide about the method of solving the problem.

Novar-NRC KMB systems

18

3.3.8 Parameter 30 – Logic Inputs Status

For logic inputs status and functionality checking actual state of all logic inputs I1 ÷ I8 is displayed in

the parameter. The inputs states are displayed in order from left to right (the leftmost is I1 , the

rightmost I8). Character representation is as follows :

i

ii

i … 0 ( passive )

I

II

I… 1 ( active )

3.4 Installation

The NRC86 unit is designed for mounting on a DIN-35 bar. Maximum cross section area of connection

wires is 2.5 square millimetres.

Examples of unit wiring are shown below.

3.4.1 Po er Supply

The unit requires supply voltage in the range as declared in technical specifications table for its

operation.

The power supply terminals are galvanically isolated from other unit circuits.

3.4.1.1 24 DC Power Supply ersion

Direct auxiliary voltage connects to terminals 17 (+) and 18 (-). The marked polarity of connection is

recommended only, in fact it is free.

Power supply voltage needs to be externally protected ( see chapter Protection below ).

3.4.1.2 230 AC Power Supply ersion

Alternating auxiliary voltage connects to terminals 16 (L) and 18 (N).

Power supply voltage needs to be externally protected ( see chapter Protection below ).

3.4.1.3 Protection

Article 6.12.2.1 in the EN 61010-1 standard requires that instrument must have a disconnecting device

in the power supply circuit (a switch — see installation diagram). It must be located at the instrument’s

immediate proximity and easily accessible by the operator. The disconnecting device must be marked

as such. A circuit breaker for nominal current of 1 amp makes a suitable disconnecting device, its

function and working positions, however, must be clearly marked (symbols “0” for power off and “I” for

power on in accordance with EN 61010–1).

3.4.2 Logic Outputs

The NRC86 unit can have up to 7 output relays (depending on unit model).

The relays’ contacts go to terminals 20 ÷ 26 ( O1 ÷ O7 ). The relays’ common contacts are connected

to terminal 19 ( OC).

The relays’ output contacts are internally wired with varistors.

Novar-NRC KMB systems

19

3.4.3 Logic Inputs

The NRC86 unit can have up to 8 galvanically isolated logic inputs (depending on unit model).

The inputs are passive – a voltage of appropriate level ( specified in technical parameters, see below )

must be applied. For direct voltage inputs the applied voltage polarity is free. The input voltages must

be connected to terminals 29 ÷ 36 ( I1 ÷ I8 ), the inputs’ common pole to terminal 28 ( IC ).

3.4.4 Communication Interface

The NRC86 units are equipped with galvanically isolated communication interface in compliance with

RS-485 specification for interconnection with supervisory Novar1xxx NRC PFC ( or with other

instruments in general use).

Signal-to-pin configuration for RS-485 type line is shown in Tab. 3.2.

Table 3.2: communication line signal configuration

signal

terminal

TR

1

DATA A 2

DATA B 3

GND/C 4

The interface allows connecting up to 32 instruments at a distance up to about 1 kilometre.

Recommended cable is shielded twisted metallic double pair. Use one pair for DATA A and DATA B

signals and the second pair for GND/C signal interconnection.

RS-485 line requires impedance termination of the final nodes by installing terminating resistors for

communication distances of a few tens of metres and longer. Terminating resistors matching the

cable’s wave impedance are connected between terminals DATA A and DATA B. The unit has a built-

in terminating resistor of 330 ohms. It is connected between DATA B-signal (terminal 3) and TR-

terminal (1) inside the unit. To install the resistor, simply interconnect terminals DATA A (2) and TR

(1).

If the communication cable is hundreds of meters long and in environments with electromagnetic

noise it is suitable to use shielded cable. The shielding connects to the PE (protection earth) wire at

one end of the cable.

Novar-NRC KMB systems

20

4. Putting in Operation

4.1 Remote Controlled Target PF Compensation Systems

For remote controlled power factor the NRC86-85 24 VDC remote controller is needed. If remote

controlled outputs using additional NRC86 units in cascade necessary too it is better to use the

NRC86-07 230 VAC models with 7 outputs each for this task.

One or more (up to 32) Novar1xxx NRC PFCs can be connected to.

Commissioning procedure step-by-step :

1. Install the Novar1xxx NRC PFC (or multiple PFCs) according its Operation Manual.

2. Install the NRC86 units according the Installation chapter of this manual.

3. Interconnect the NRC86 units and the PFC(s) with a communication link. Install terminating

resistors on the link ends. Switch the units’ power supply on and set the communication link

parameters No. 10, 11 a 12 according the specification above, i.e. the first unit ( which runs in

the RCC mode) address to 200 and the next units to 201, 202, 203 etc., step-by-step.

4. Set daisy-chain communication mode ( parameter 6 to 1) at all of the units but the last one

and the last unit to 0.

5. Set number of processed outputs ( parameter 5 ) at all units operating as remote controlled

outputs.

6. Power up the PFC (or PFCs). Check communication rate ( p. 51), eventually set to

correspond to the NRC86 unit setting. In the parameter 30, clear the section failure alarm (

No. 12 to „0“ ) and set the remote control failure alarm No. 15 to value „S“or to „2“.

7. In the „master” PFC, set the RCC-mode in parameter 53. The PFC will start transmitting

commands and the NRC86 unit should answer. Now set the NRC86 response timeout in

parameter 52. For transparent communication links set the value to 0. For non-transparent

links set the value (in seconds) that corresponds to maximum transmission delay of the

communication loop. Check the remote control function :

• The Rx and Tx LED-diodes of the NRC86 units must flashing synchronously to the

running communication. In the parameter 01 of the first unit, the RCC mode must be

displayed, optionally installed other units should indicate the I/O mode. At the first

unit one of unit outputs O1 ÷ O5 corresponding to serial number of remote

controlled PF in parameter 02 must be switched on, optional other units should copy

the PFC outputs’ states on their outputs. The units should not indicate any alarm, or

the external alarm only can be active ( the alarm of supervisory PFC, transmitted to

the unit)

• The PFC(s) should not indicate the remote control failure alarm. In the parameter

81, the serial number of remote controlled PF corresponding to that of the NRC86

unit should be. In parameter 01, appropriate remote controlled target PF value with

preceding „E“-character must appear.

8. In case of multiple PFCs connected, all other PFCs but the „master” one must be set to the

passive remote controlled PF mode, i.e. the parameter 53 to value RCCP. Parameter 52

must be set to the same value as the „master” PFC is set.

This manual suits for next models

1

Table of contents