NWB & NWB-HC IM28 OCT 2014 Page 3

Instruction Manual NWB & NWB-HC IM 28 OCT 2014

Table of Contents

1.0 SALES AND SERVICE....................................................................................................4

2.0 SHIPPING AND INSPECTION.........................................................................................4

3.0 PRINCIPLE OF OPERATION ..........................................................................................5

4.0 PRODUCT FAMILIARIZATION........................................................................................6

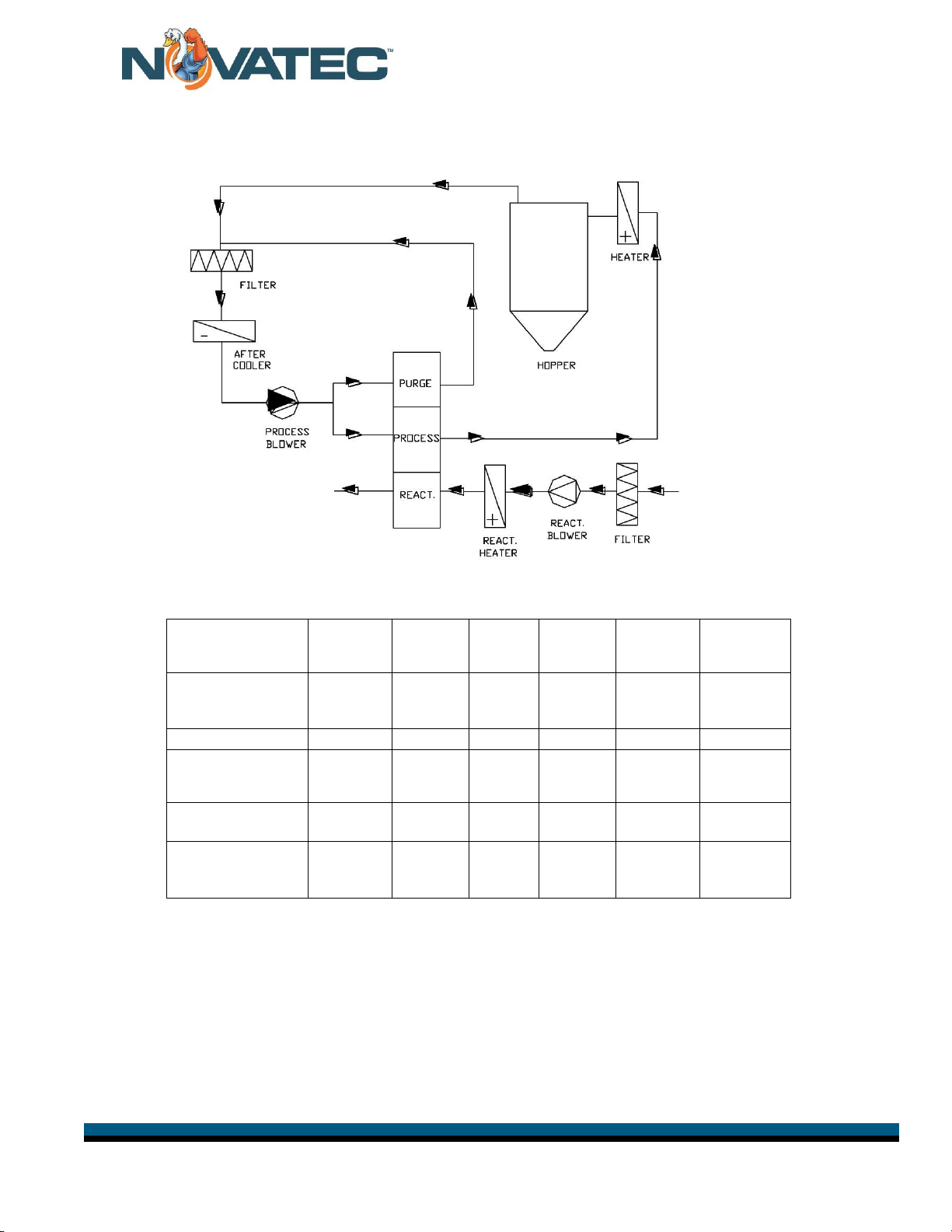

4.1 System Flow Diagram ......................................................................................................7

4.2 Specifications –NovaWheel™ Dryer...............................................................................7

5.0 INSTALLATION...............................................................................................................8

5.1 Location ...........................................................................................................................8

5.2 Customer Piping Connections..........................................................................................8

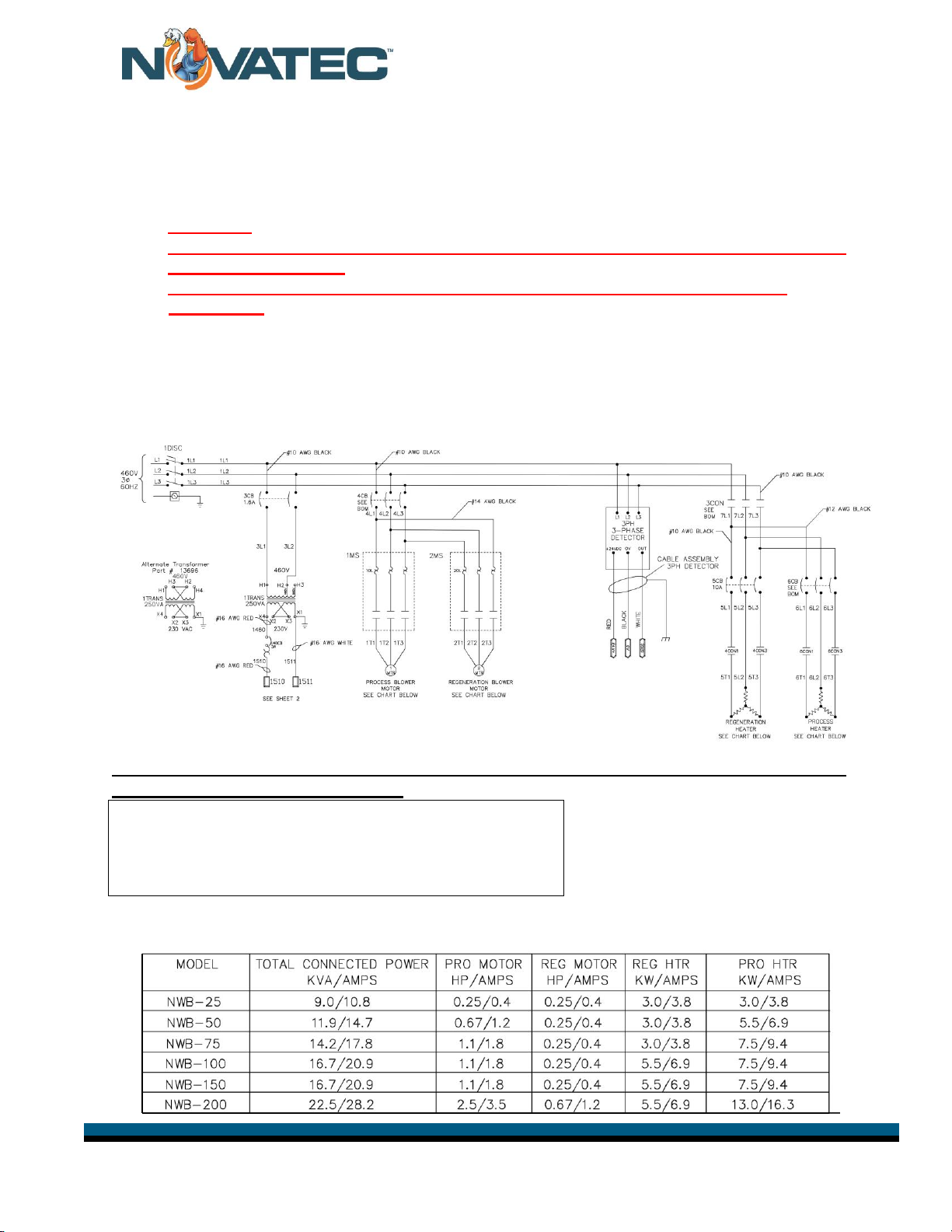

5.3 Electrical Connections......................................................................................................9

5.4 Cooling Coil Connection.................................................................................................10

6.0 FUNCTION CONTROLS................................................................................................11

6.1 Process Temperature Control (Drying Temperature).......................................................11

6.2 Regeneration Temperature Control.................................................................................11

6.3 Process & Regeneration Air Filter Pressure Switches (Ps).Error! Bookmark not defined.

6.4 Process Air Dew Point Monitor........................................................................................11

6.5 Intelligent Regeneration ..................................................................................................11

7.0 PRE-OPERATING SYSTEM CHECK.............................................................................12

7.1 Starting The Dryer...........................................................................................................12

7.2 Checking Electrical Phase...............................................................................................12

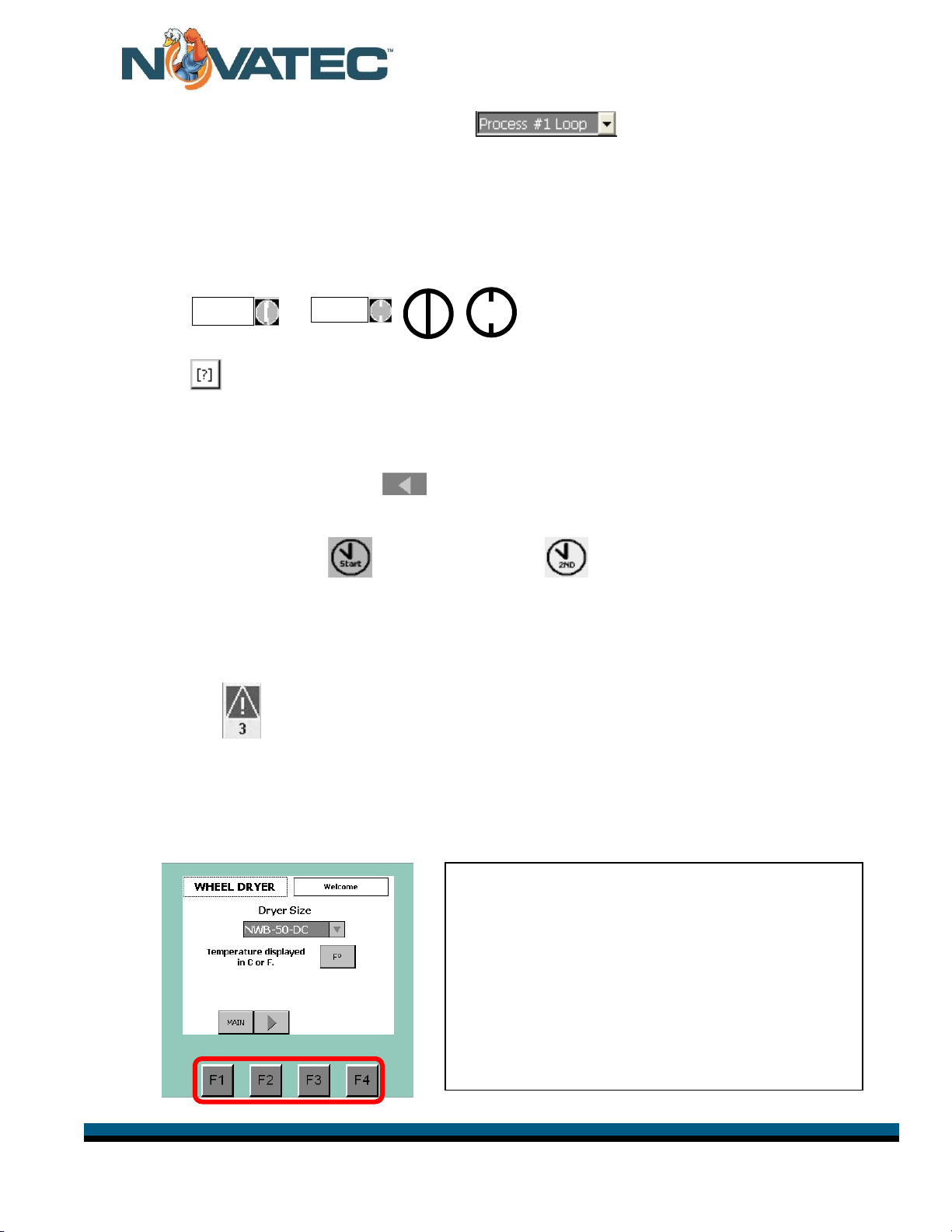

8.0 NovaTouch™ CONTROL..............................................................................................13

8.1 System Conventions: ......................................................................................................13

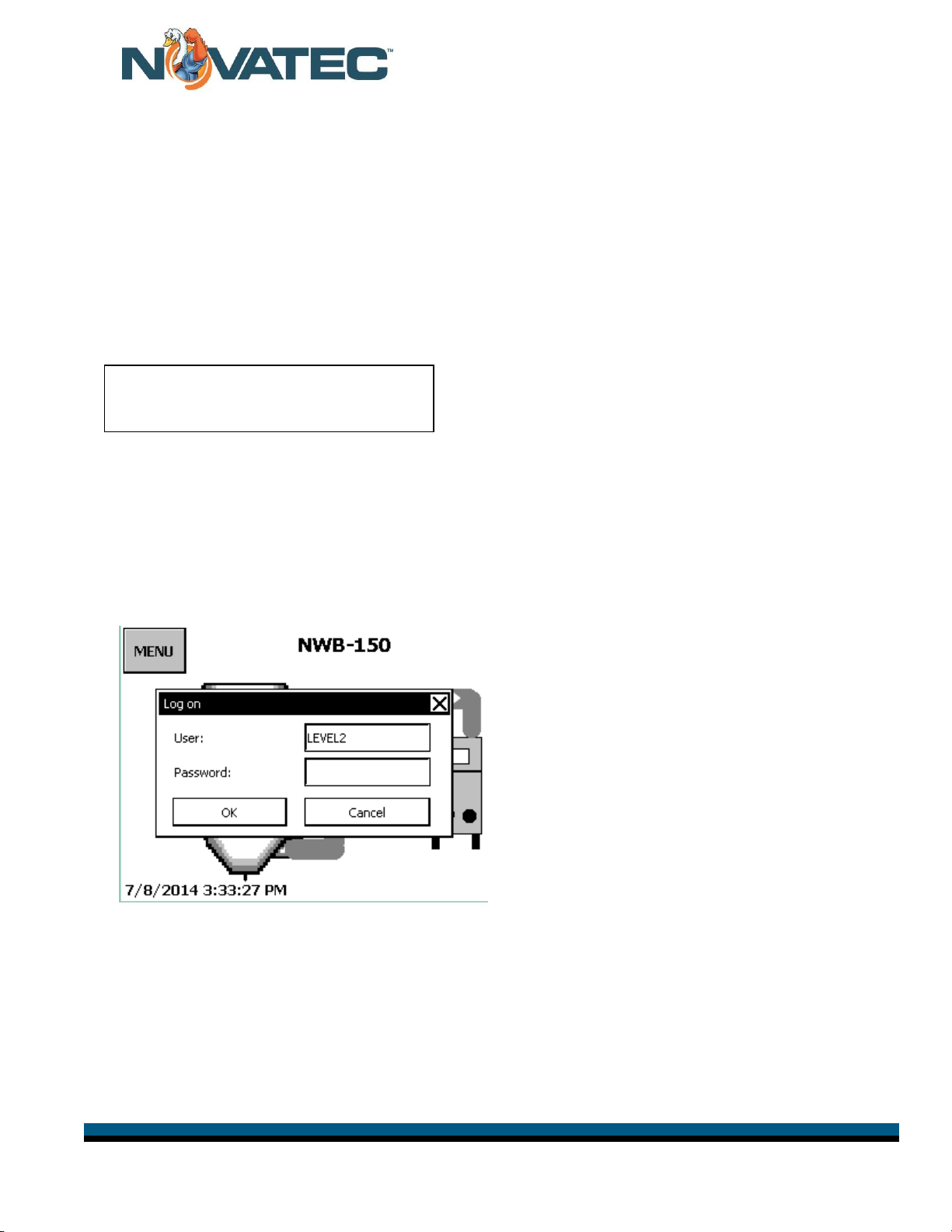

8.3 Explanation of Password Levels......................................................................................15

8.4 Initial Logon.....................................................................................................................15

9.1 Clock Setup......................................................................................................................16

9.2 Auto Start Setup...............................................................................................................16

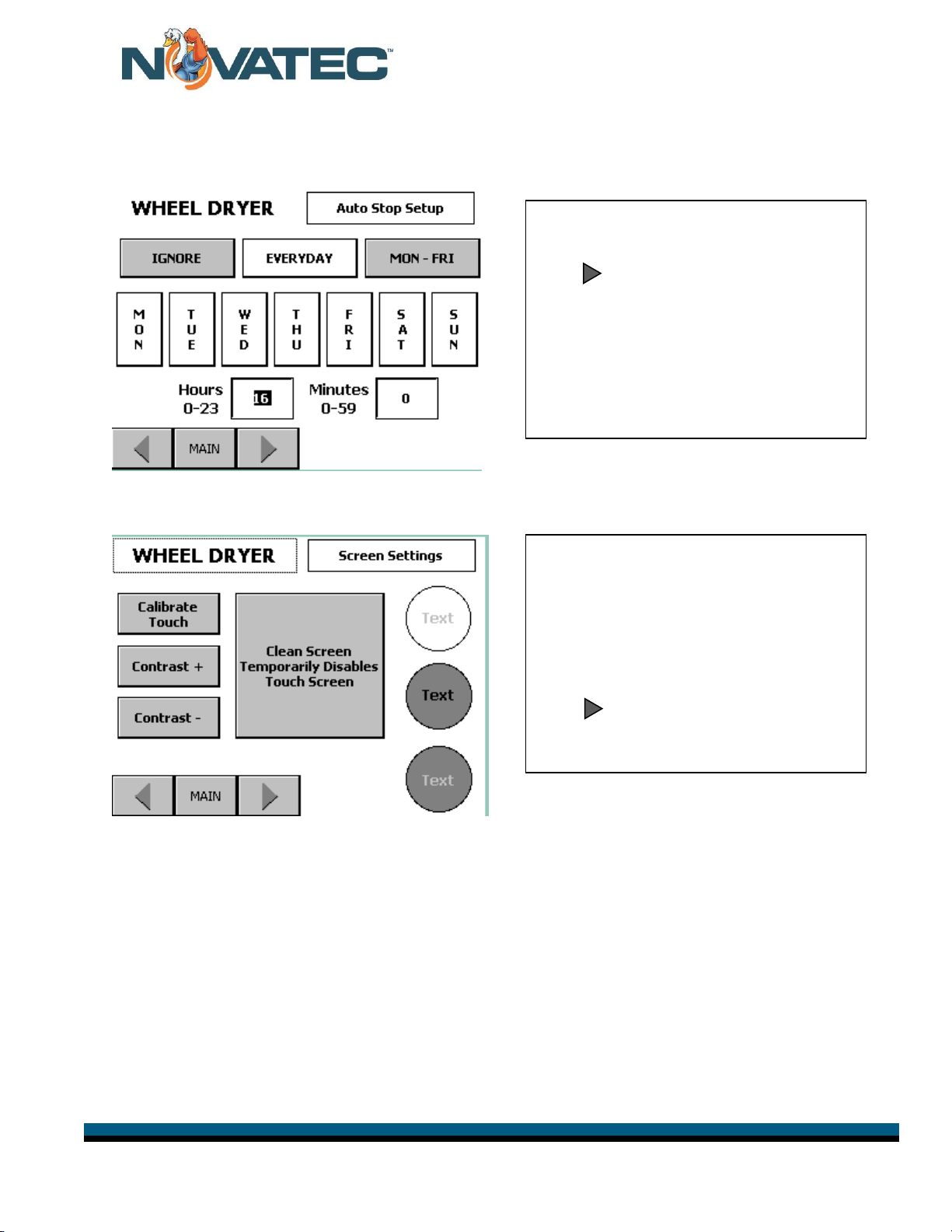

9.3 Auto Stop Setup...............................................................................................................17

9.4 Touch Screen Adjustments ..............................................................................................17

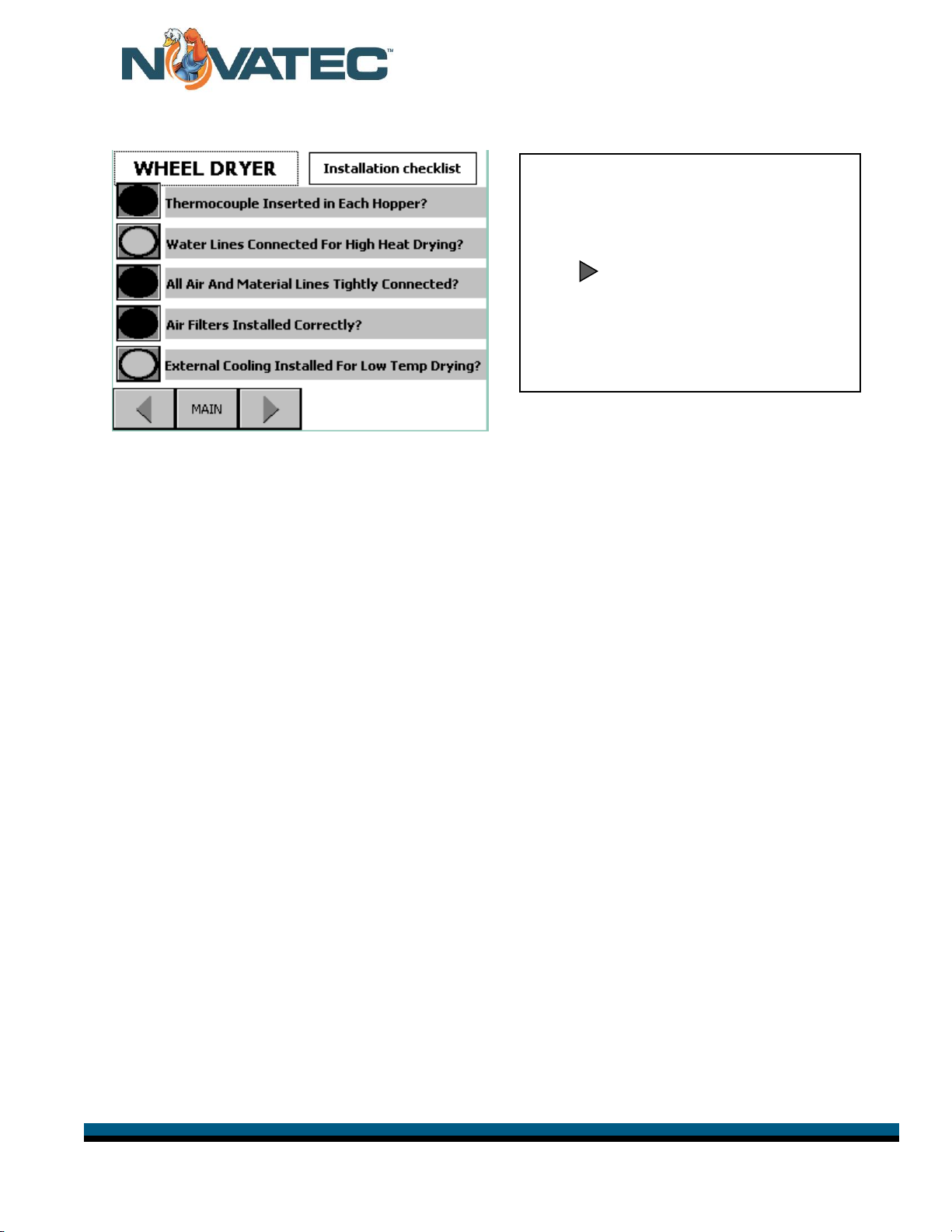

9.5 Installation Checklist.........................................................................................................18

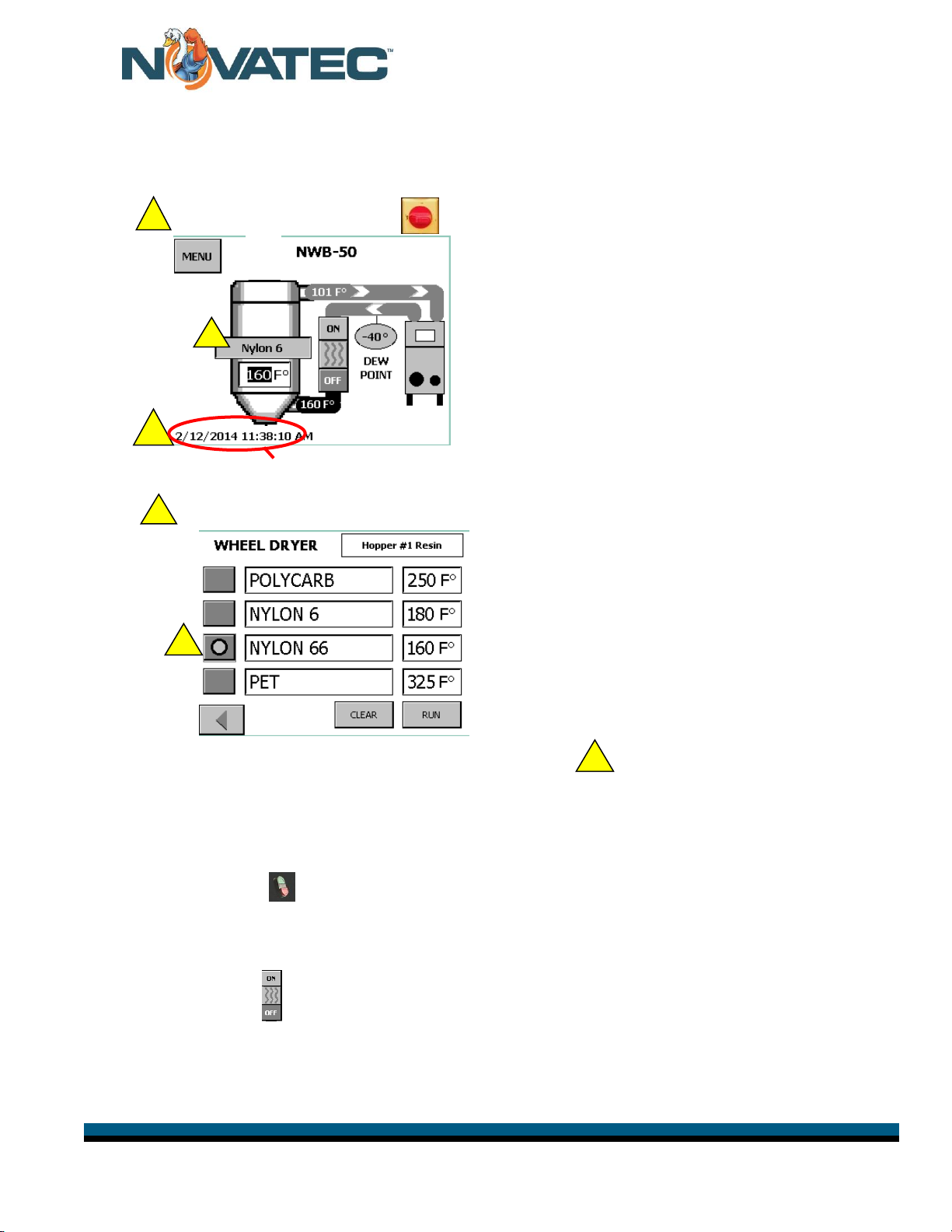

10.0 DRYING MATERIAL......................................................................................................19

11.0 ADVANCED FUNCTIONS..............................................................................................20

11.1 Advanced Functions And Options Screen (Level 2 or higher).........................................20

11.2 Dryer Alarms (Level 3) ...................................................................................................21

11.3 Dryer Status (Widely Used By processors).....................................................................21

12.0 MESSAGE SCREEN ALARMS .....................................................................................22

13.0 MAINTENANCE INSTRUCTIONS .................................................................................23

13.1 Suggested Maintenance Schedule*................................................................................23

13.2 Process and Regeneration Filters .................................................................................24

13.3 Draining Plasticizer........................................................................................................24

13.4 Chain and Sprockets.....................................................................................................25

13.5 Desiccant Rotor..............................................................................................................25

13.6 Motor Rotation Signal....................................................................................................26

13.7 Rotor Replacement .......................................................................................................26

13.8 Seal Replacement.........................................................................................................27

13.9 Drive Motor Replacement..............................................................................................27

13.10 Seal Replacement........................................................................................................28

13.11 Drive Motor Replacement............................................................................................28

13.12 Motor Rotation Signal..................................................................................................28

14.0 TROUBLE SHOOTING and ERROR MESSAGES.......................................................29

15.0 WARRANTY –NOVATEC, INC. - Effective Date 6-12-2012.........................................31