NovaTec NovaDrier ND-7 User manual

U.S. Patent No.

US

6,584,701 B1

Document: ND IM 3 JAN 2017

NovaDrier

™MEMBRANE DRYER

for Plastics

MODELS: ND-7, ND-25, ND-50, ND-75,

ND-100, ND-150, ND-200

©NOVATEC, Inc. 2017 All Rights Reserved

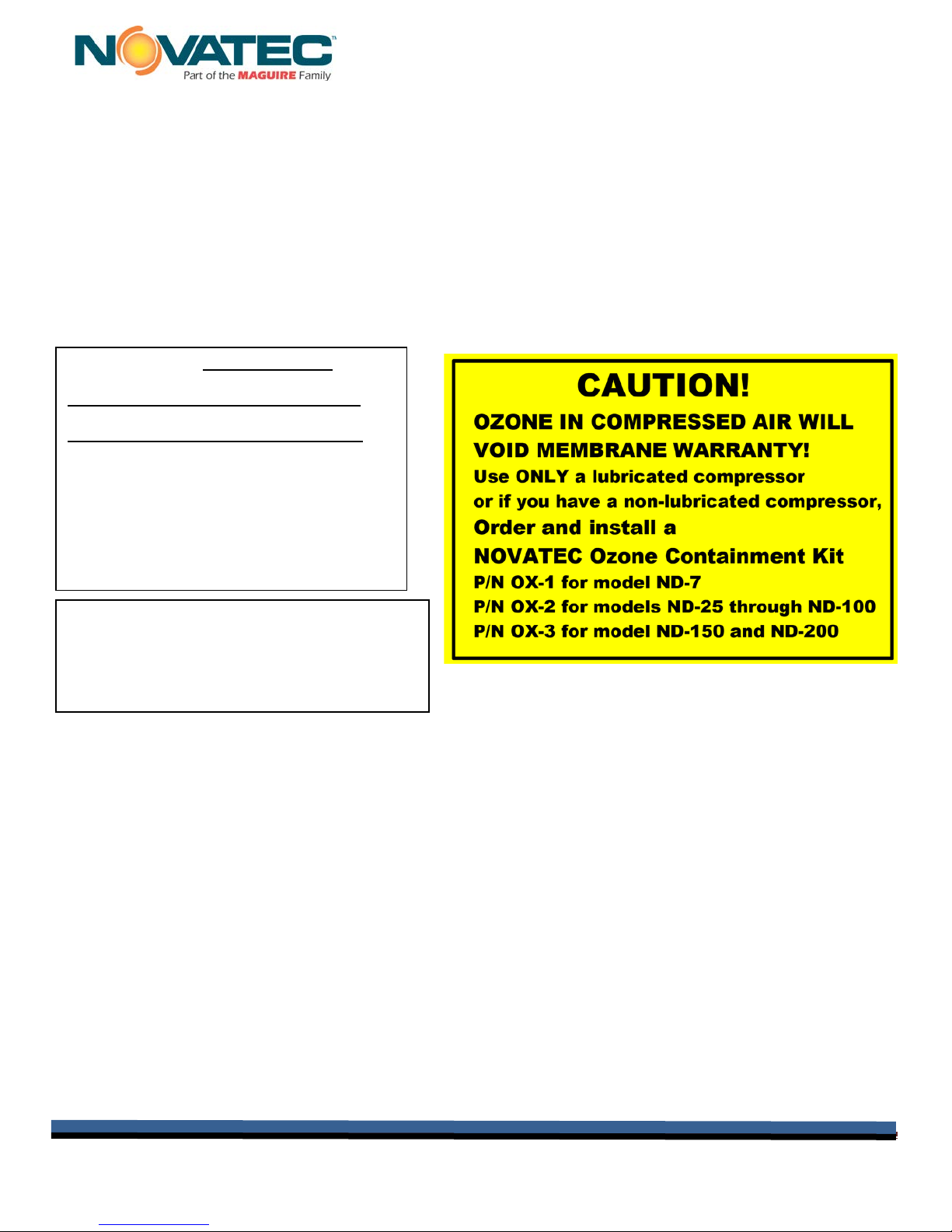

NOTE:

See important

information

about air supply

on next page.

Instruction Manual ND IM 3 JAN 2017

Instruction Manual IM ND 3 JAN 2017 Page 2

NOTES:

Please record the following information,

which is specific to this piece of

equipment, in the space provided. Our

Parts/Service Department will need these

numbers to properly respond to any of

your requests.

Instruction Manual: ND IM 3 JAN 2017

Model #:___________________________

Serial #____________________________

DISCLAIMER: NOVATEC, Inc. shall not be liable for

errors contained in this Instruction Manual nor for

misinterpretation of information contained herein.

NOVATEC shall not, in any event, be held liable for any

special, indirect or consequential damages in

connection with performance or use of this information.

Instruction Manual ND IM 3 JAN 2017

Instruction Manual IM ND 3 JAN 2017 Page 3

Table of Contents

1-UNPACKING AND INSPECTION .....................................................................................................4

1.1 Unpacking...................................................................................................................................4

1.2 General Inspection & Mounting................................................................................................5

1.3 Clamp Ring Inspection..............................................................................................................6

2 SPECIFICATIONS.............................................................................................................................7

2.1 NovaDrier STANDARD COMPONENT Set Points....................................................................7

3 INSTALLATION.................................................................................................................................8

3.1 Mounting The Dryer...................................................................................................................8

3.2 Connecting Power......................................................................................................................8

3.3 Compressed Air .........................................................................................................................9

3.3.1 Compressed Air Requirements ..........................................................................................9

3.3.2 Connecting Compressed Air.............................................................................................10

3.3.3 Condensate Drains ............................................................................................................10

4 DESCRIPTION OF OPERATION ....................................................................................................11

5 INITIAL START-UP & OPERATION ...............................................................................................12

5.1 Turning The Dryer On..............................................................................................................12

5.4 Other Parameters.....................................................................................................................14

6 USING THE 7 DAY TIMER OPTION:..............................................................................................15

7 SETTING ENERGY SAVER OPTION ON ND-100 AND LARGER SIZES......................................16

8 UPDATING FIRMWARE..................................................................................................................17

9 TROUBLESHOOTING GUIDE........................................................................................................18

9.1 Dryer Fault Lights ....................................................................................................................18

9.2 Power Failure ...........................................................................................................................18

9.3 Troubleshooting Chart ............................................................................................................19

10 MAINTENANCE AND INSPECTION SCHEDULE ........................................................................20

10.1 Vendor Instructions...............................................................................................................22

10.1.1Compressed Air Inlet Filters ............................................................................................22

10.1.2 Round Re-Circulation Air Filter.......................................................................................23

10.1.3 Heater Housing Thermostat............................................................................................23

10.1.4 Spare Parts Notes............................................................................................................23

11 WARRANTY – NOVATEC, INC. - Effective Date 21 SEPT 2016 ................................................24

Instruction Manual ND IM 3 JAN 2017

Instruction Manual IM ND 3 JAN 2017 Page 4

1- UNPACKING AND INSPECTION

Congratulations, you have purchased the finest Dryer on the market from the finest dryer

manufacturer. It has a (2) year warranty (as long as you replace the filter elements regularly and

exercise good maintenance – see the warranty information in section 8). This manual will provide

you with proper procedures to insure that you will be completely satisfied with your purchase.

Please review this manual carefully.

1.1 Unpacking

Caution should be exercised to make sure the equipment is not damaged during handling. The

crate must be removed carefully. The machine must not be used to pry against when removing

the crate. The dryer is usually shipped completely assembled and requires no further assembly

prior to installation.

Remove crating carefully.

Do not pry against the dryer

or hopper.

Dryer is typically shipped fully

assembled, ready to be

installed.

Instruction Manual ND IM 3 JAN 2017

Instruction Manual IM ND 3 JAN 2017 Page 5

1.2 General Inspection & Mounting

When the unit is unpacked, make a visual inspection looking for missing parts or damage, which

may have occurred during shipment. Some parts, such as hoses, and hose clamps may be

packed inside the hopper as well as the instruction manual. It is important that all electrical and

piping connections should be checked for tightness because vibration during transit may cause

them to loosen.

Inside of the hopper door, the (2) perforated air diffuser tubes (upper & lower) should be

thoroughly cleaned to remove any dust, moisture or oil that may have accumulated during

shipment. The diffuser tubes must be reinstalled so they are properly aligned and secure. The

upper diffuser tube must be installed at the end of the vertical tube in the center of the hopper (it is

a friction fit) and should stick out from the end of this tube as follows:

NovaDrier Upper

Diffuser Tube

NovaDrier Lower

Diffuser Tube

Optional Short Run Diffuser Tube for use

when hopper is less than 100% full.

NOTE: NovaDriers should always be

run with a 100% full hopper- never

below 75% full.

This manual suits for next models

6

Table of contents

Other NovaTec Dryer manuals

Popular Dryer manuals by other brands

ffuuss

ffuuss eos user manual

KitchenAid

KitchenAid 53-3498 installation instructions

Schulthess

Schulthess Spirit topLine TW 8340 operating instructions

Whirlpool

Whirlpool LGR4624BW0 parts list

World Dryer

World Dryer AirMax D M5-972A manual

Alliance Laundry Systems

Alliance Laundry Systems ADEE9BSS user guide