NovaWheel Instruction Manual 3 Document#: IM NW400-2000_10-07-08

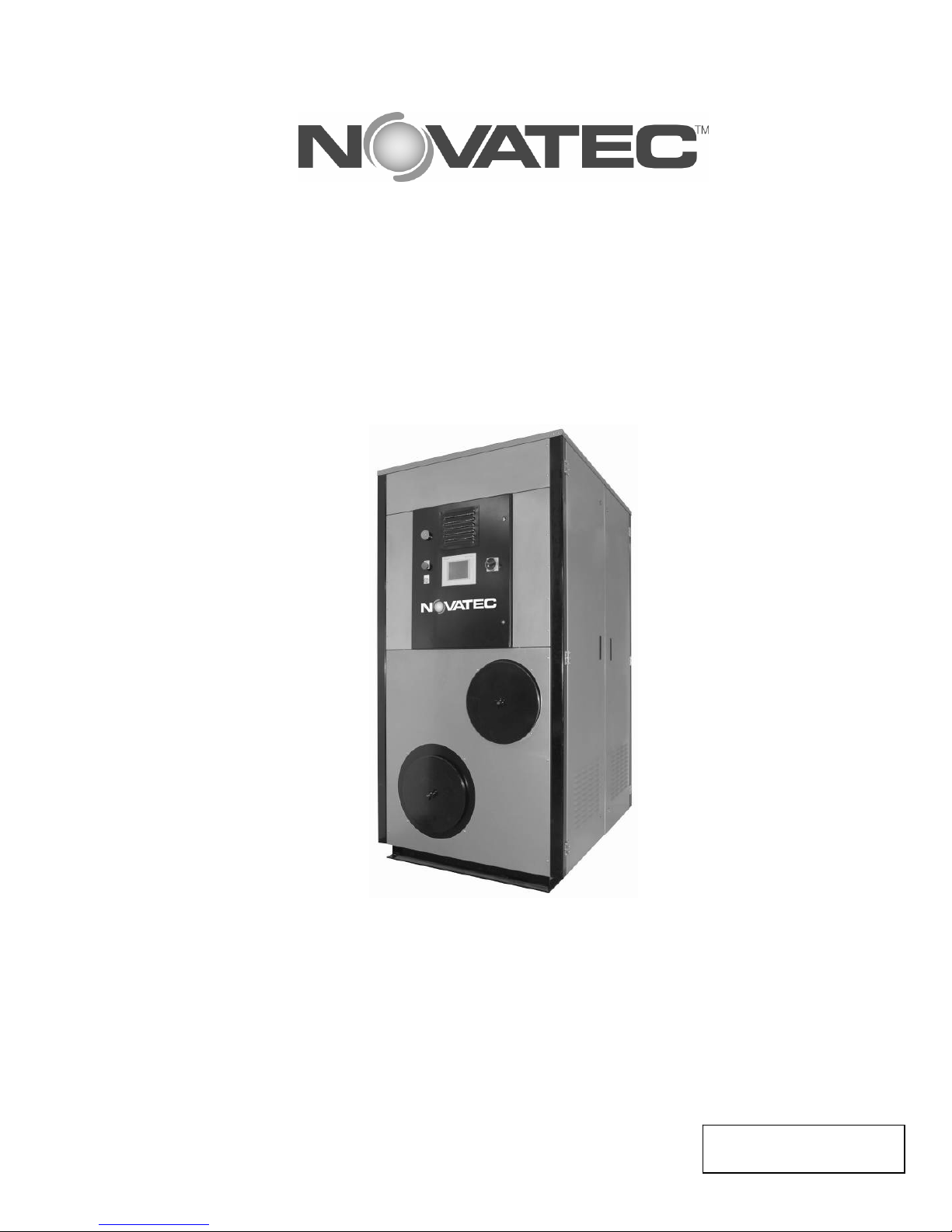

NW Series NovaWheel Dryer

INSTRUCTION MANUAL

FOREWORD

This manual is dedicated to the principle that any engineered system will have many elements

contributing to the smooth operation of the systems, and that these must be understood in

order that installation and operation can proceed successfully. The electrical and mechanical

components in the NW Series dryers have been manufactured, selected and assembled with

care to give you excellent service. A wide range of NW series dryers have been introduced to

enable our valued customers to select the right model for their application. This NW series

dryer has been designed for use in closed loop resin drying systems. All components of your

NW series dryers have been carefully engineered and manufactured and have been

thoroughly inspected for quality, function and performance. Before installing this system,

please read this manual, review the diagrams and the safety information. This should save

valuable installation and operation time later and will help insure safe operation and long life.

1. SALES AND SERVICE

NOVATEC maintains qualified sales, engineering, and service personnel to assist in any

way possible. If you have any questions concerning the types of equipment which

NOVATEC manufactures that might improve your process, or any questions concerning

service, we urge you to contact us.

2. SHIPPING AND INSPECTION

Although NOVATEC uses reputed carriers to deliver products, it has no control over the

products once it leaves the manufacturing facility. Upon receiving the products, thoroughly

inspect all equipment inside and out for damage that may have occurred during shipment. If

any damage is found, a claim should be filed immediately with your carrier.

NOVATEC thoroughly tests and inspects all products before shipment. You are to make the

piping, and electrical connections for final installation and commissioning. If there any

problems, shut down the equipment and contact the NOVATEC Technical Service

Department..