~ 3~

NOVATEK-ELECTRO

ЕТ-485

This Operating Manual is intended to familiarize you with the design, the requirements for safety, operation and

maintenance procedures of the Protocol converter ET-485 and ET-485-24 (hereinafter referred to as the "device";

ET-485; the abbreviation ET-485-24 is used separately when the power characteristics are different).

The unit meets the requirements of the following:

EN 60947-1, EN 60947-6-2; EN 55011; IEC 61000-4-2.

1. DESIGNATION

ЕТ-485 is a microprocessor unit.

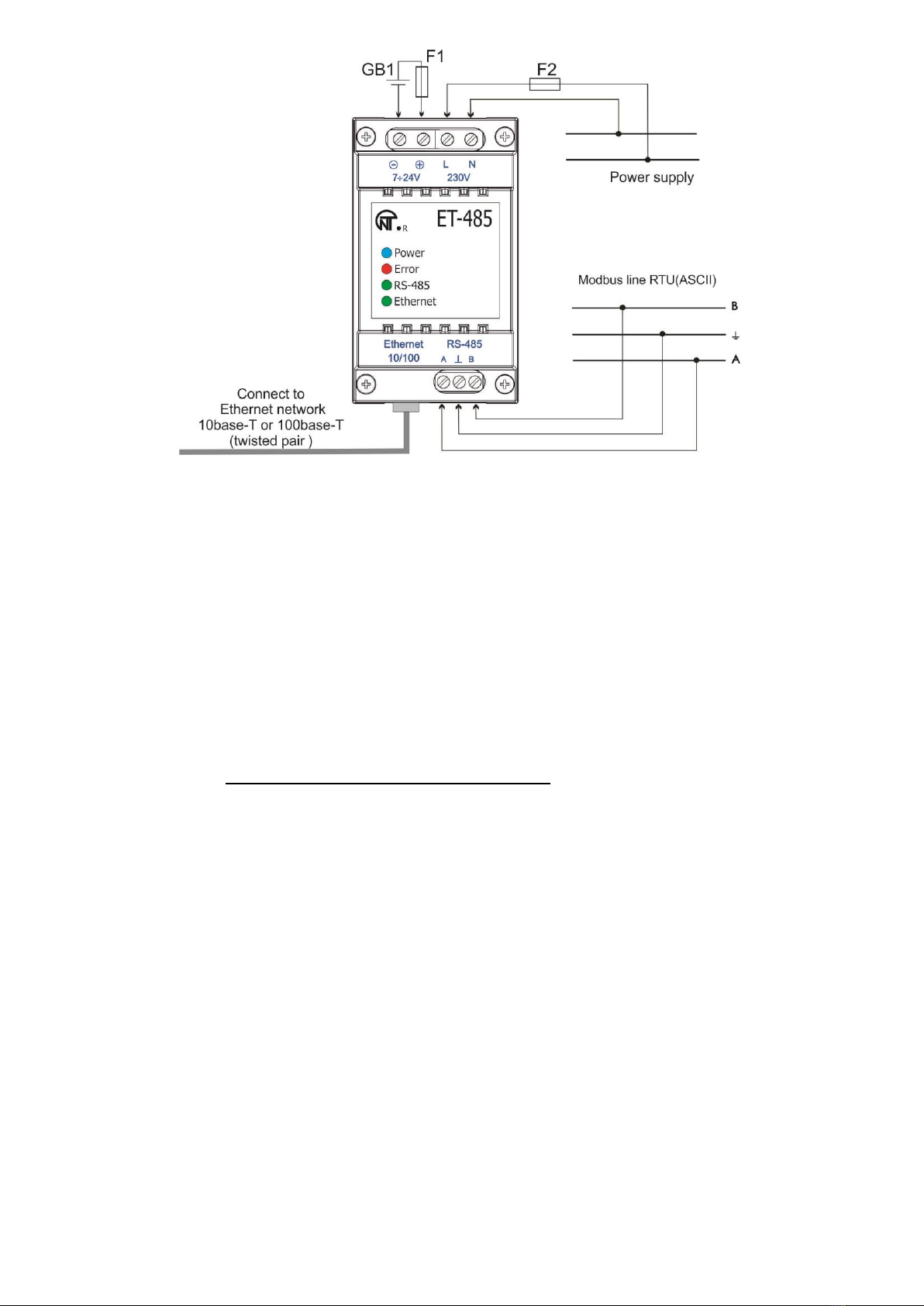

The unit is designed to provide data exchange between the equipment, connected to Ethernet 10BASE-T and

100BASE-T network, and the equipment, supplied with RS-485 interface and forming Modbus network. The

examples of network topology with application of ЕТ-485 are shown in appendix С.

In the RS-485 master mode, the unit redirects Modbus-queries from the clients in Ethernet network to the

devices in Modbus network and returns the answers from the devices to the clients. In the query redirection to

remote server mode, the unit maintains the connection to Modbus TCP server in Ethernet network and in addition

directs client queries to this server. In the RS-485 slave mode, the unit in addition accepts RS-485 queries from a

Modbus-client within Modbus network.

ЕТ-485 has:

flexible addressing within the Ethernet network (overloading MAC-address, static and dynamic IP-address);

different data transfer modes for Modbus network (RTU and ASCII with/without odd-even check, wide range

of transmission speeds, selectable delay;

adjustable redirection of queries;

security access (IP address filtration and/or access password for condition reading, for setting the unit, for

connection to Modbus network, and for recording/reading within Modbus network).

possibility to update the embedded software.

Changes in the ET-485 specifications and operation depending on version are described in appendix A.

Terms and abbreviations:

10Base-T –Ethernet standard for twisted pair communication with the speed of 10Mbit/s;

100Base-T –Ethernet standard for twisted pair communication with the speed of 100Mbit/s;

8P8C/RJ45 –is an unified socket for 10Base-T / 100Base-T network connections;

ACC - Active Connection to the Client, where connecting side acts as a server;

ASCII –is a table of standard codes for information interchange;

Client –is a device, which is addressing the other devices (server) with a request toperform certain functions;

DCRS - Data Collection Remote Server, to which ET-485 connects in the ACC mode

Ethernet –is a standard for packet network communication and transmitting data between units (e.g., PCs);

HTTP –is a protocol for transferring Web-pages and other data over "client-server " technology;

Indicator –is a LED element;

Internet –is a global routing system of units for storing and transferring data;

IP (protocol) –is a routable protocol for transferring data over Ethernet. It is a part of TCP/IP and used for

Internet;

IP (address) –is a node address, which is unique within a single network, operating over the IP protocol;

IPv4 –is a four byte IP-address;

MAC (address) –is an address, used for device authentication during Ethernet transmissions. It is usually

unique although qualified personnel can change it under certain circumstances.

MAC-48 –is a six byte MAC-address;

Modbus –is a standard and protocol for packet communication over the "client-server " technology for

industrial electronic units;

Modbus RTU –is a communication protocol of the unit for bite wise transfer of the package;

Modbus ASCII –is a communication protocol of the unit forthe transfer of package in the form of ASCII-symbols;

Modbus TCP –is a protocol for transferring Modbus packages under the TCP/IP standard;

Package –is a block of data to be transmitted between devices;

RS-485/EIA-485 –is a network standard for communicating units over the twisted pair;

Server –is a unit, which performs specific functions at the request of other units;

TCP/IP –is a standard and a set of protocols for transferring data along the networks with delivery

verification;

Twisted pair –is a pair of insulated conductors inside the cable, which are twisted together in order to reduce

the distortion of the transmitted signal;

Unit –is the ЕТ-485 Protocol converter;

WEB –is a system for accessing documents on the server, used in the Internet.

WEB-page –is a document, file, recourse, which is available on the Web-server;

WEB-browser –is a WEB-server client for accessing the WEB-pages, which is primarily using the HTTP

protocol.