Novatest U5700 User manual

Novatest S.r.l.

[email protected]www.novatest.it

ZBL-U5600/U5700

Multichannel Ultrasonic Pile

Integrity Tester

Instruction Manual

Beijing ZBL Science & Technology Co., Ltd.

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

1

Contents

CONVENTIONS IN THIS MANUAL 0

CHAPTER 1 GENERAL 1

1.1 BRIEF INTRODUCTION

1

1.2 MAIN FUNCTIONS AND FEATURES

1

1.2.1 Main functions ............................1

1.2.2 Main Features ............................2

1.2.3 Relevant test specification .................3

1.3 MAIN TECHNICAL SPECIFICATIONS

3

1.4 PRECAUTIONS

5

1.5 DEVICE MAINTENANCE AND PRESERVATION

5

1.6 RESPONSIBILITY

7

CHAPTER 2 INSTRUMENT DESCRIPTION 9

2.1 INSTRUMENT COMPOSITION

9

2.1.1 Host ....................................9

2.1.2 Transducer..............................15

2.1.3 Counting device .........................17

2.1.4 Accessories .............................21

2.2 TEST PRINCIPLE

21

2.2.1 Cross-hole sonic logging for testing pipe

integrity 21

2.2.2 Ultrasonic-rebound combined method for

testing concrete strength ..........................23

2.2.3 Ultrasonic method for testing uncompacted area

and cavitation ....................................24

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

2

CHAPTER 3 COMMON MODULE DESCRIPTION 26

3.1 STARTUP INTERFACE

26

3.2 CONTROL INTRODUCTION

27

3.3 SOFT KEYBOARD

28

3.3.1 Character input ..........................28

3.3.2 Number input............................31

3.4 WAVEFORM DISPLAY AND OPERATION

33

3.4.1 Terminology .............................35

3.4.2 Dynamic waveform operation ..............37

3.4.3 Static waveform operation.................38

3.4.4 Magnify and display single-channel waveform40

3.5 FILE MANAGEMENT

41

3.5.1 OPERATING MODE

42

3.5.2 OPEN FILE

43

3.5.3 PROJECT AND FILE COPY

43

3.5.4 PROJECT AND FILE DELETION

43

3.5.5 PROJECT AND FILE UPLOAD

44

3.5.6 EXIT

44

3.6 ZERO SET

45

3.6.1 MANUAL ZERO SET

45

3.6.2 ACOUSTIC ZERO SET

45

3.7 RETEST

47

3.8 BATTERY LEVEL

48

3.9 SHUTDOWN

49

3.10 SYSTEM SETUP

50

3.10.1 GENERAL PARAMETER

51

3.10.2 INSTRUMENT INFORMATION

53

3.10.3 INTERNET PARAMETER

55

3.11 SOFTWARE UPDATE

57

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

3

CHAPTER 4 CROSS-HOLE SONIC LOGGING

SOFTWARE FOR TESTING PILE INTEGRITY 60

3.1 MAIN INTERFACE

60

3.2 PARAMETER SETUP

63

3.2.1 Basic parameter setup....................64

3.2.2 Advanced parameter .....................68

3.2.2.1 General parameter .......................68

3.2.2.2 Other parameters ........................72

3.3 DATA COLLECTION

77

3.3.1 Start sampling ...........................77

3.3.2 Stop sampling ...........................80

3.3.3 Retest ..................................80

3.3.4 Intensive test ............................81

3.3.5 Continued testing ........................81

3.3.6 Oblique test .............................82

3.3.7 Test next pile ............................88

3.4 VIEW SWITCHOVER

89

3.4.1 Bar graph ...............................89

3.4.2 Curve graph.............................91

3.4.3 Wave train graph ........................92

3.4.4 Data list ................................93

3.5 EXIT

94

CHAPTER 5 ULTRASONIC-REBOUND COMBINED

METHOD SOFTWARE FOR TESTING STRENGTH 95

5.1 MAIN INTERFACE

95

5.2 PARAMETER SETUP

97

5.2.1 Basic parameter .........................97

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

4

5.2.2 Advanced parameter ....................101

5.3 START TEST

107

5.3.1 Start sampling ..........................107

5.3.2 Stop sampling ..........................108

5.3.3 Retest .................................108

5.3.4 Test Next Object ........................108

5.4 ULTRASONIC DATA LIST AREA

109

5.5 SCHEMATIC GRAPH AREA

111

5.6 FILE MANAGEMENT

112

5.7 EXIT THE TEST

112

CHAPTER 6 ULTRASONIC TRANSMISSION METHOD

FOR TESTING DEFECT AND CAVITY TEST

SOFTWARE 113

6.1 MAIN INTERFACE

113

6.2 PARAMETER SETUP

114

6.2.1 Basic parameter ........................115

6.2.2 Advanced parameter ....................117

6.3 START TEST

121

6.3.1 Start sampling ..........................121

6.3.2 Stop sampling ..........................122

6.3.3 Retest .................................123

6.3.4 Test next object.........................123

6.4 ULTRASONIC DATA LIST AREA

123

6.5 DEFECTS SCHEMATIC GRAPH AREA

125

6.6 FILE MANAGEMENT

127

6.7 EXIT TEST

127

CHAPTER 7 ULTRASONIC METHOD FOR TESTING

CRACK DEPTH SOFTWARE 128

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

5

7.1 MAIN INTERFACE

128

7.2 PARAMETER SETUP

130

7.2.1 Basic parameter ........................131

7.2.2 Advanced parameter ....................133

7.3 START TEST

136

7.3.1 Start sampling ..........................136

7.3.2 Stop sampling ..........................137

7.3.3 Retest .................................138

7.3.4 Test the next crack ......................138

7.3.5 Test the next object .....................139

7.4 TEST POINT DATA LIST AREA

139

7.5 CRACK DATA LIST AREA

141

7.6 REGRESSION CURVE AREA

142

7.7 FILE MANAGEMENT

142

7.8 EXIT TEST

143

APPENDIX I RAPID OPERATION INSTRUCTION FOR

SITE TEST 144

F1.1 CROSS-HOLE SONIC LOGGING FOR TESTING PIPE

INTEGRITY

144

F1.1.1 Preparation before Test ..................144

F1.1.2 Test of New Foundation Piles .............150

F1.1.3 Data Processing ........................155

F1.1.4 Report Preparation ......................157

F1.2 ULTRASONIC-REBOUND COMBINED METHOD FOR

TESTING CONCRETE STRENGTH

159

F1.2.1 Preparation before test ..................159

F1.2.2 New object test .........................162

F1.2.3 Data processing ........................169

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

6

F1.2.4 Report formulation ......................171

F1.3 ULTRASONIC METHOD FOR TESTING UNCOMPACTED

AREA AND CAVITATIONS

172

F1.3.1 Preparation before test ..................172

F1.3.2 Ultrasonic test ..........................176

F1.3.3 Data processing ........................179

F1.3.4 Report formulation ......................181

F1.4 ULTRASONIC METHOD FOR TESTING CRACK DEPTH 181

F1.4.1 Preparation before test ..................181

F1.4.2 Ultrasonic test ..........................184

F1.4.3 Data processing ........................187

F1.4.4 Report formulation ......................189

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

Conventions in this manual

A. Word with gray background and black box is a button on the

interface (e.g., OK button).

B. All buttons on the device panel are shown with【】(e.g.,【OK】

button).

C. Word with white background and black box represent software

menu command in Windows, and “→” is a separator between

different menu levels. For example, File →Open means “Open”

the command under the “File” menu.

D. Words with grey background and without box represent the name

of options or menus on the screen. Such as Object option in

selection parameter setup.

E. Sign means special attention is needed here.

F. Besides descriptions in the manual, some prompt messages may

show automatically in the use of the software. Please operate

accordingly.

G. Software interfaces and pictures in this instruction manual are

only for reference. There will be changes with software upgrade

and improvement of products. No further notice is provided.

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

1

Chapter 1 General

1.1 Brief introduction

ZBL-U5600/U5700 multichannel ultrasound pile integrity tester

is a portable special instrument which uses ultrasonic transmission

method to test the integrity of concrete foundation pile; By adopting

multichannel self-transmitting and receiving circuit, this instrument

may test multiple profiles simultaneously; putting three or four

transducers in pipe may realize full combination test for three or six

profiles, which dramatically improves test efficiency and reduces the

work intensity of on-site tester.

1.2 Main functions and features

1.2.1 Main functions

1) Ultrasonic transmission method for testing the

integrity of foundation pile (called “pile test” for

short)

2) Ultrasonic-rebound combined method for testing

compressive strength of concrete (called “strength

test” for short);

3) Ultrasonic transmission method for testing defect

and cavity in structural member (called “defect test”

for short);

4) Ultrasonic flat-measured method for testing crack

depth of concrete surface (called “crack test” for

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

2

short);

1.2.2 Main Features

1) Multichannel self-transmitting and receiving full

combination ultrasonic test for foundation pile may

automatically and continuously collect and save

information such as depths, acoustic parameters and

waveforms of all test points on multiple profiles. With

steady and undistorted waveform, accurate interpretation of

acoustic parameter and excellent repeatability and

consistency, the on-site test speed may be dramatically

improved;

2) During the test, the test result is available and the graphic

distribution of abnormal points in each profile is shown at

any time. Meanwhile, wave train figure, curve graph and

data list of each profile may be shown;

3) During the test, sampling delay and amplification factor

may be adjusted at any time;

4) Radial transducer may be played back at any time without

any operations for repeating test;

5) With true color highlight LCD, waveform, wave speed and

amplitude of multiple tested profiles may be clearly

observed on site Data, curve, wave train figure and

schematic graph of pile integrity of all test points in all

profiles may be checked at any time, the quality of whole

pile in the test is very clear.

6) It adopts WinCE operation system with press screen and

user-friendly interface, which is simply, easy to learn and

convenient to operate;

7) With high-capacity SD card, there is no need to worry

about the storage space of test data;

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

3

8) Built in high-performance and capacity lithium battery may

satisfy fieldwork for long time.

9) Various USB ports may be used for data transmission or

software update within the instrument or external units

such as mouse or keyboard.

10) Test data of the same project is saved under the folder

created with the title of the project for easy and reliable

management.

1.2.3 Relevant test specification

1) Technical Code for Testing of Building Foundation Piles

(JGJ106)

2) Technical Specification for Pile Testing of Highway

Engineering(JTG/T F81-01)

3) Technical Specification for Testing of Foundation Piles of

Railway Engineering(TB 10218)

4) Guangdong Province Standard – Technical Code for Testing

Building Ground Foundation(DBJ15-60)

5) Technical Specification for Testing Building Foundation

Piles in Shenzhen(SJG09)

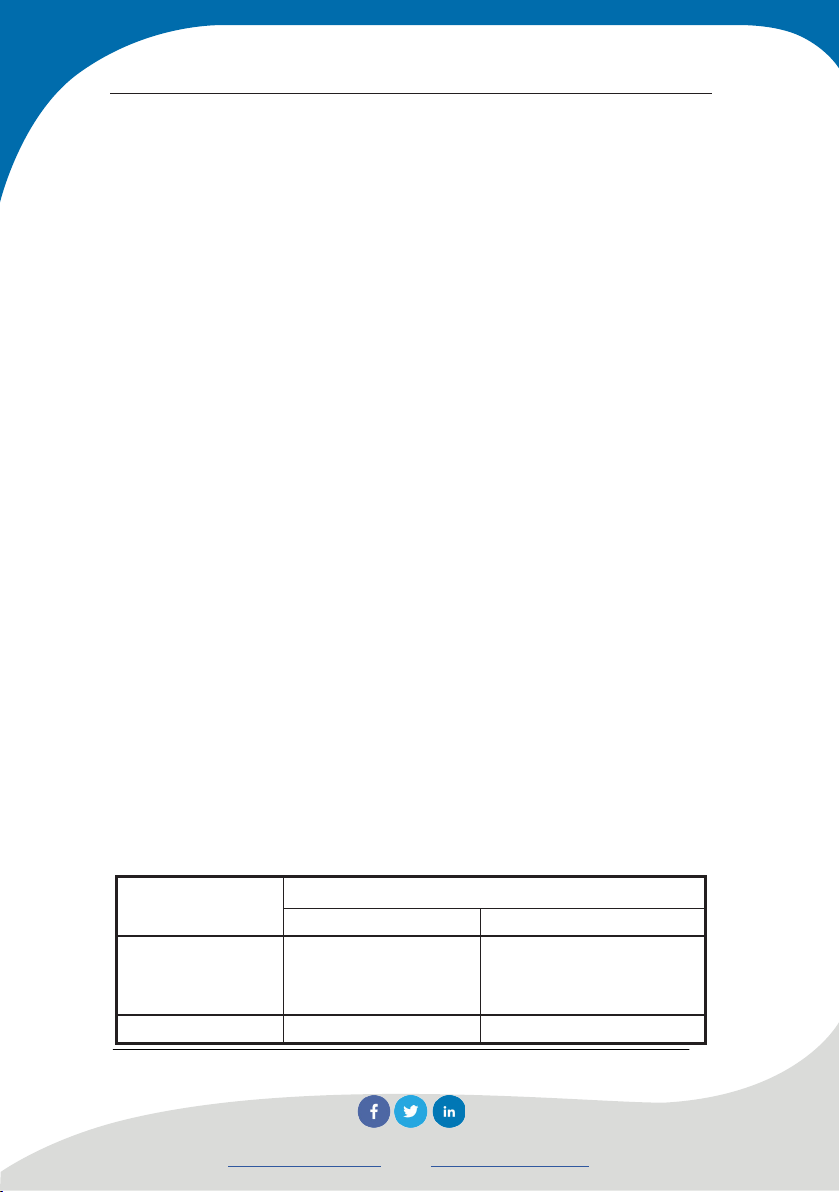

1.3 Main Technical Specifications

Table 1.1 Main technical specifications

Indicators

Item U5600 U5700

Number of

channels

Three channels,

individually

controllable

Four channels, individually

controllable

Number of profiles 3 6

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

4

under test

simultaneously

Testing and reading

precision of

acoustic time

0.025μs

Maximum system

dynamic range

154dB

Precision of gain

control

0.5dB

Amplitude

measurement error

≤1dB

Receiving

sensitivity

≤10μV

Sampling interval 0.025μs∼1638.4μs, optional multiple levels

Number of

waveform points

512、1024、2048、4096, optional multiple levels

Transmitting

voltage

65V、250V、500V、1000V, optional multiple levels

Testing and reading

range of acoustic

time

±1677ms

channel crosstalk ≤1/400

Frequency

bandwidth

2∼500kHz

Power supply mode AC: 220V±10%,DC: +12V

Operation time ≥8 hours

Total weight 2.5kg (including built-in lithium ion battery)

Whole volume 270 mm×220 mm×75 mm

Monitor 10.4 inch, highlight, true color LCD

Operating mode Press screen

Communication

interface USB port, Mini port and Bluetooth, etc.

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

5

1.4 Precautions

1. To make better use of the tester, please read this operation

manual carefully before use.

2. Requirements of operating environment:

Ambient temperature: 0℃~40 .℃

Relative humidity: <90%RH.

Don’t expose to direct sunlight for long term.

Corrosion protection: necessary precautions shall be

taken when used in damp, dusty or corrosive gas environment.

3. Requirements of storage environment

Ambient temperature: -20℃~+50 .℃

Relative humidity: <90%RH.

When not in use, please pack the device and store it

under ventilation, cool and dry environment. Don’t expose to

direct sunlight for long term.

If the device won’t be used for a long time, power on

and start up the device at regular intervals to have a check.

4. Avoid water ingress.

5. Anti-magnetism: avoid using the device under intense magnetic

field environment, such as near large electromagnet and

transformer.

6. Vibration-proof: prevent strenuous vibration and shock during

operation and transportation.

1.5 Device Maintenance and Preservation

1. Power supply: the instrument adopts special built-in

rechargeable lithium battery as power supply, please pay attention to

the battery indicator during the operation. Use external power supply

(AC power supply or external rechargeable battery) as soon as

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

6

possible if the battery is low, otherwise sudden power failure may

cause loss of test data or even system damage; make sure the external

power supply is AC220±10% V when supplied by AC power,

otherwise AC-DC power supply module or even instrument may be

damaged. The device must not be supplied by other batteries and

power sources.

NOTE: After the battery of the device is exhausted,

system data and time may be lost and require resetting after

startup.

2. Charging

When the matching AC-DC power supply module is charging for

internal battery, user only needs to insert the power plug into socket of

AC220±10% V and insert the DC output to the power plug of

instrument. When charging indicator on the instrument side panel is

red, it means the built-in battery of the instrument is charging; when

indictor turns into green, it means the battery is fully charged. (The

description above is the switch of indicator colors when in shutdown

mode and non-operating status)

NOTE: To ensure full charging, please keep continuous

charging for about 8 hours and at the meantime don’t charge the

device under the environment of above 60℃.

If the device won’t be used for a long time, the rechargeable

battery would discharge naturally, resulting in decreasing of battery

level. Re-charge the device before use. During the charging, the

instrument and the AC-DC power supply may be heated which is

normal, please keep good ventilation for the instrument, AC-DC

power supply and charger in order to dissipate heat.

NOTE: Don’t charge the device with other power

adapters; otherwise, the device might be damaged.

3. Rechargeable battery: the service life of rechargeable battery is

about 500 times of charging and discharging. When nearing the end of

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

7

service life, if the battery is found to operate abnormally (the battery

cannot be charged at all, cannot be fully charged or runs for a short

time after every full charging), the rechargeable battery might be

damaged or reach to the end of its service life. Please contact us to

replace new battery. Battery short circuit or near high temperature heat

source is prohibited.

4. Sensor: Since strong impact or vibration may result in sensor

performance reduction or damage, sensor dropping from height or

beneath weight shall be avoided.

5. After every use, the device shall be cleaned properly, to

prevent water, mud and etc. from entering into the connector, thus

resulting in performance reduction or damage of the device.

NOTE: Don’t put the device or its accessories into

water or wipe them with wet cloth!

Don’t rinse the device or its accessories with organic

solvents!

Please wipe the host and socket with soft clean and dry cloth!

Please clean socket with clean and soft brush.

6. Storage: when not in use, please pack the device and store it

under ventilation, cool, dry and room temperature environment.。If

the device won’t be used for a long time, power on and start up the

device at regular intervals to have a check.

1.6 Responsibility

The device is sophisticated detection equipment. Our company is

not responsible when the user commits one of the following acts or

other artificial destruction.

1. Violate the aforementioned operating or storage

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

8

environment requirements.

2. Abnormal operation.

3. Open the enclosure and dismantle any parts and components

without permission.

4. The device is seriously damaged by human or fortuitous

accidents.

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

9

Chapter 2 Instrument Description

2.1 Instrument Composition

U5600/U5700 multiple channel ultrasonic pile integrity tester is

composed of host, radial transducer, counting device (or depth

recorder) and accessories (including power adaptor and U disk, etc.).

2.1.1 Host

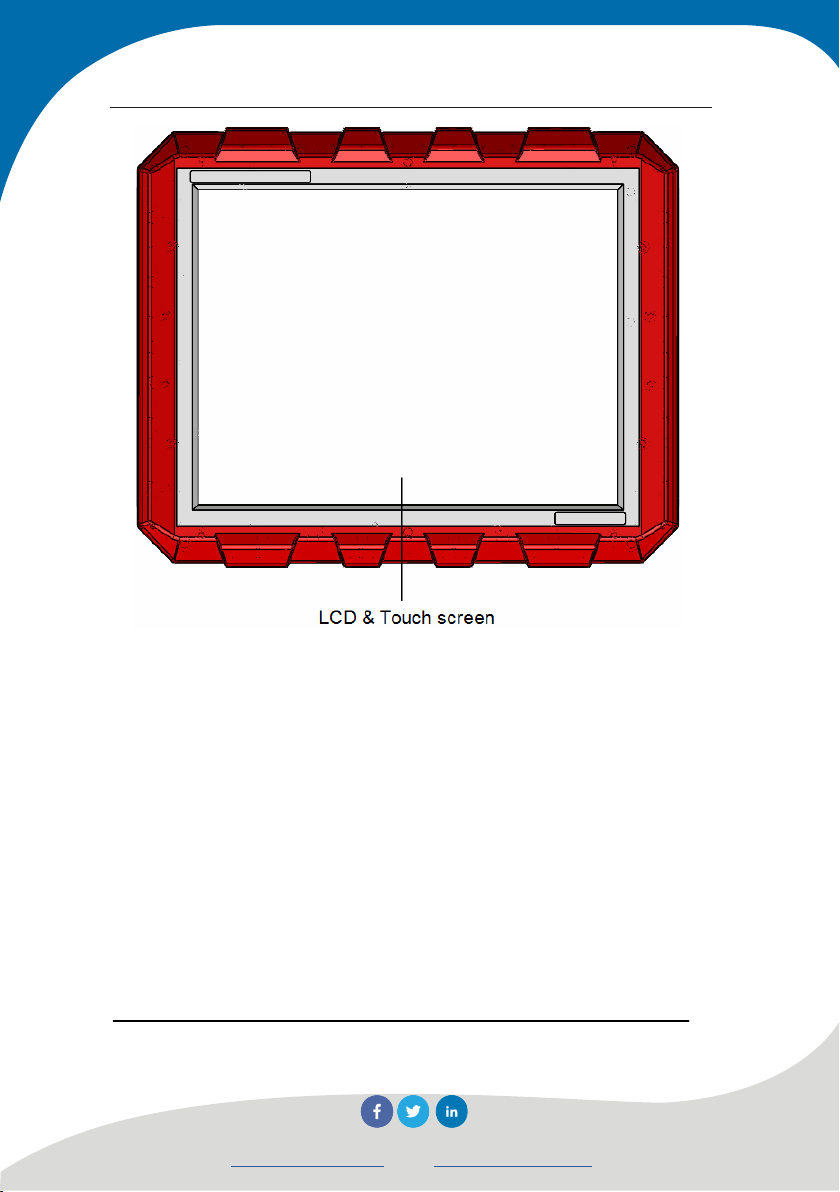

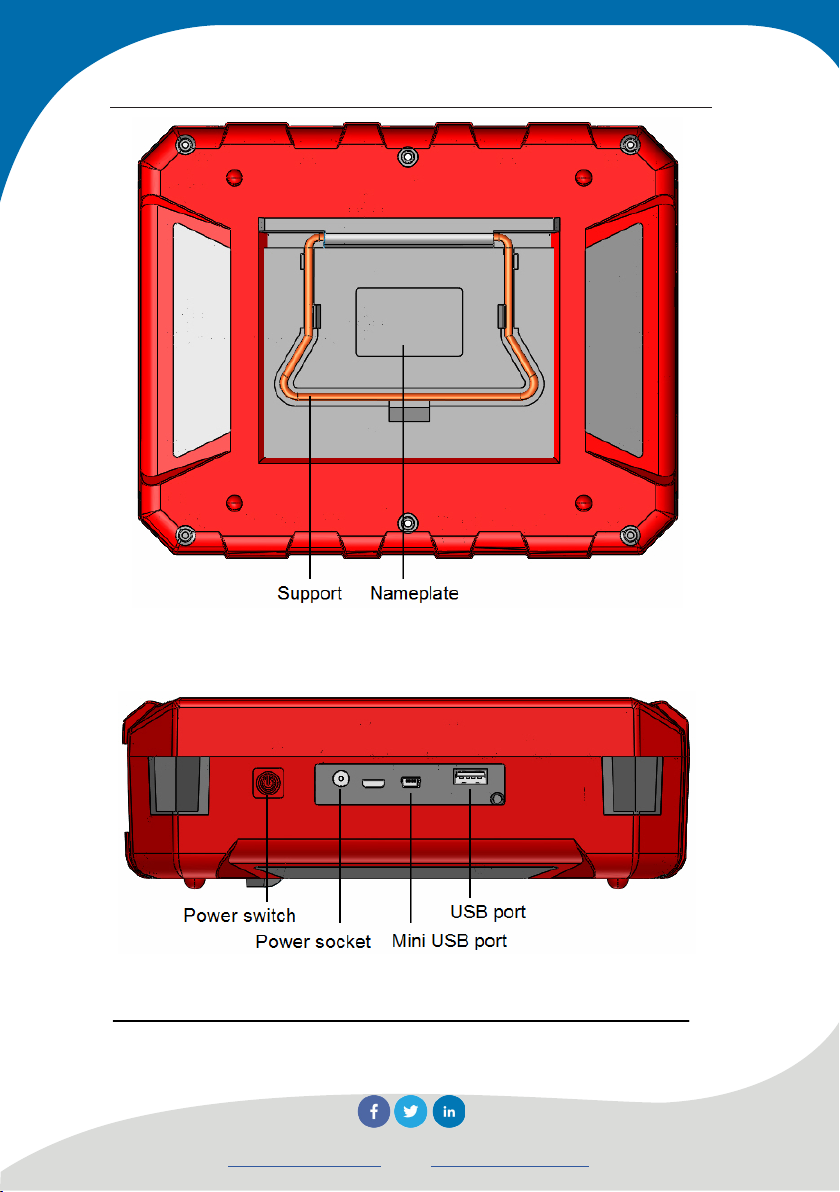

Picture of U5700 Multichannel Ultrasonic Pile Integrity Tester

appearance is shown in Figure 2.1.

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

10

a) Tthe obverse side

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

11

b) The reverse side

c) The left side

Novatest S.r.l.

[email protected]www.novatest.it

Manual for Multichannel Ultrasonic Pile Integrity Tester

12

d) Front

Figure 2.1 Picture of host appearance

NOTE: The pictures above are only for reference and

may be different from the actual instruments.

2.1.1.1 LCD and press screen

LCD is mounted on instrument panel and clings to press screen.

It is used to display operation interface and test data. Protective film

on press screen surface may effectively protect press screen, and be

replaced after damage.

2.1.1.2 Power switch

It is used to power on/off instrument, long press the button of

power switch for powering on instrument and long press again for

powering off instrument. During the startup, short press power switch

This manual suits for next models

1

Table of contents

Popular Test Equipment manuals by other brands

Bulut Makina

Bulut Makina HARTIP-1500 Operational manual

Gossen MetraWatt

Gossen MetraWatt METRATESTER 5+ operating instructions

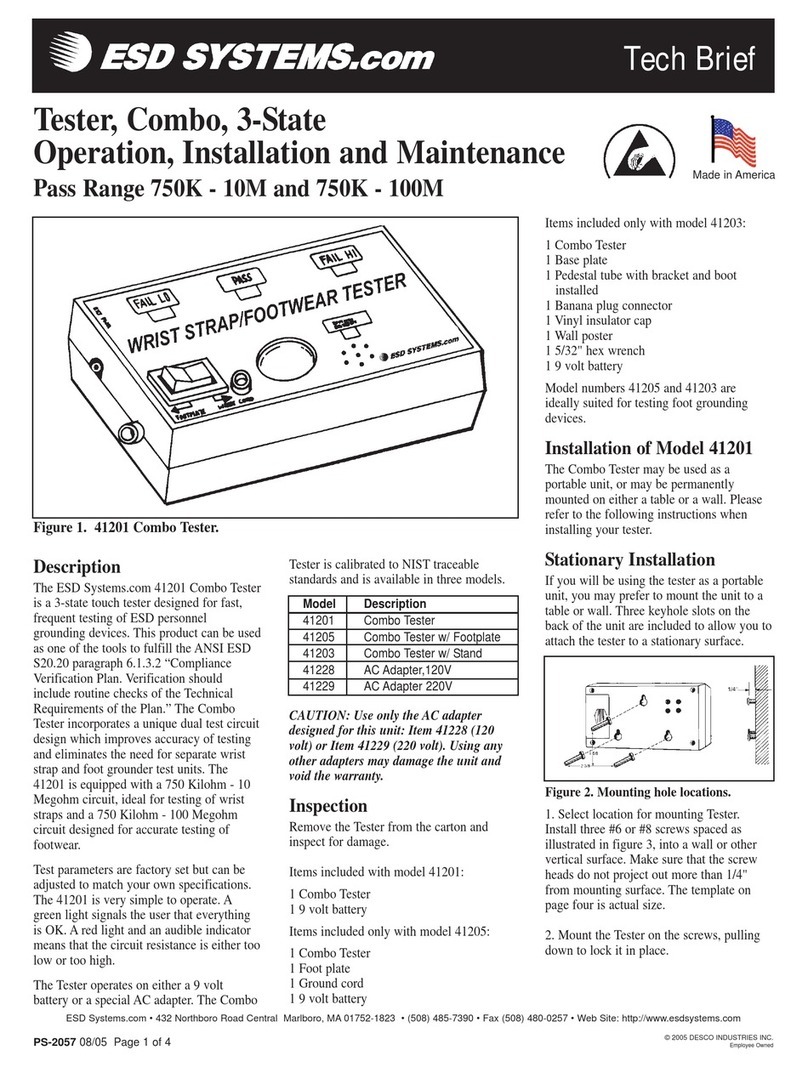

ESD SYSTEMS

ESD SYSTEMS 41201 Operation installation and maintenance

Rigol

Rigol DS1000Z-E Series Service guide

GW Instek

GW Instek GRF-1300 USER MANUAL and TEXT BOOK

Leader

Leader LBO-516 instruction manual