5.6 Supporting The Samples During Testing

Type of impact device Classification of samples

heavy medium-weight light-weight

D more than 5 kg 2 – 5 kg 0.05– 2 kg

When measuring hardness with HARTIP 1500, the following has to be noticed:

Despite the low mass of the impact body and low impact energy, a relatively large

impact force of short duration is generated when the impact body hits the measuring

surface. The max. impact force of impact device D is 900N.

For heavy samples of compact shape, no particular precautions are necessary.

Smaller and lighter samples or work pieces yield or flex under this force, producing L-

values which are too small and of excessively large variation. Even with big or heavy

work pieces it is possible for thin-wall regions or thinner protruding parts to yield upon

impact. Depending on the frequency of the resilient yielding action, the

measured L-value may be too small or too large. In many situations, potential

problems can be checked in the following manner:

a) Medium-weight samples and also heavier samples with protruding parts or

thin walls should be placed on a solid support in such a manner that they do not

move or flex during the test impact.

b) Light-weight samples should be rigidly “coupled” with a non-yielding support

such as a heavy base plate. Clamping in a vice is of no value, since the samples

become exposed to stress and because complete rigidity is never attained. As a rule,

the measured L-values would be too small and show excessive variations.

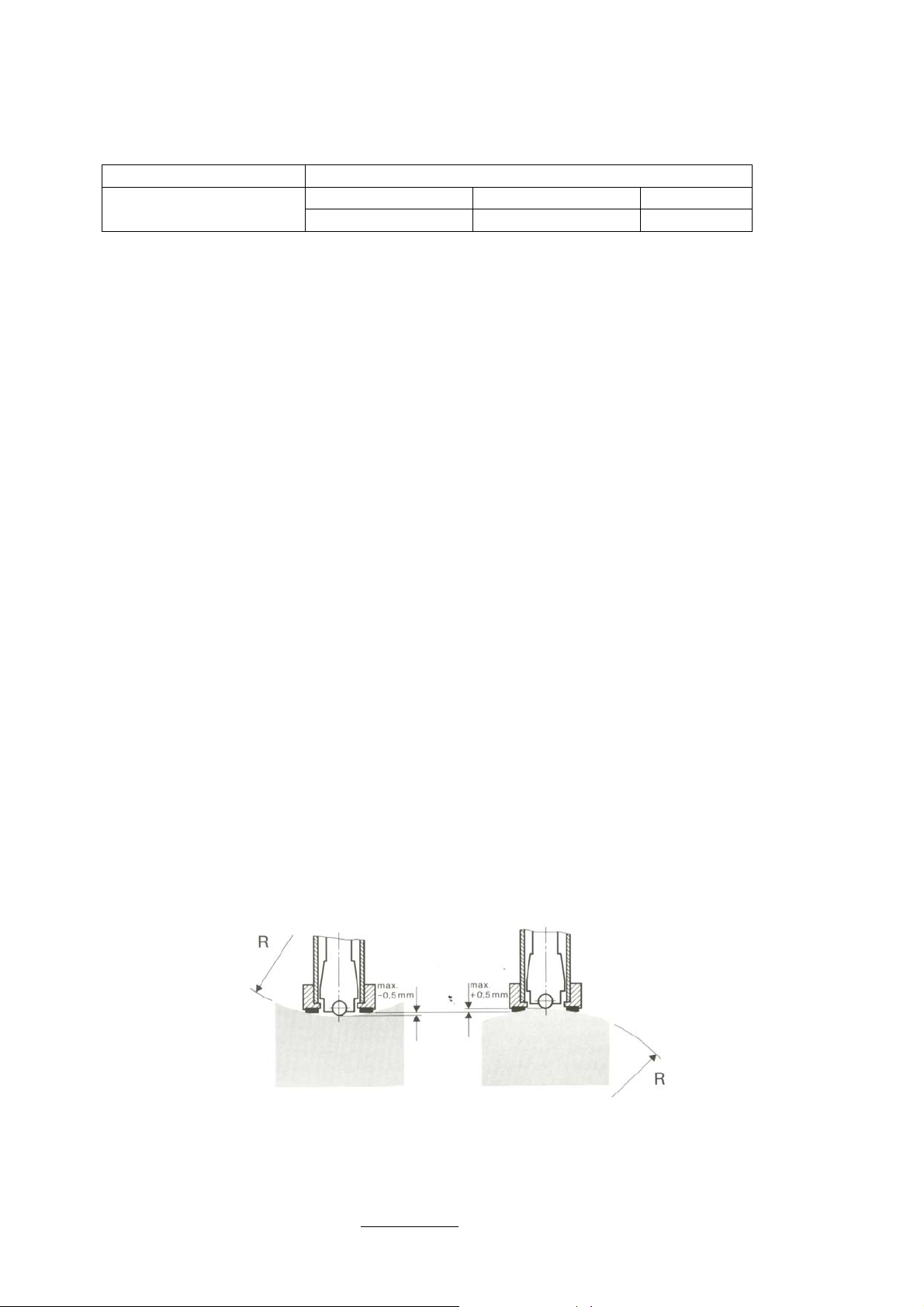

5.7 Samples With Curved Surfaces

Impact testers only work properly, if the impact body has a certain position in the

guide tube at the moment of impacting the test surface. In the normal position,

automatically present when testing flat and convex-cylindrical samples (such as

round samples), the spherical test tip is located exactly at the end of the guide tube.

However, when testing spherically or cylindrically shaped concave surfaces, the

impact body remains further within the guide tube or protrudes further therefore.

Thus, with such types of curved surfaces, it is to be observed that radii of curvature

do not drop below the values indicated in the following Fig.

Curved surfaces should always be tested with the small support ring.

Impact device types D Rmin=30mm

For impact devices D, special support rings are available to accommodate smaller

radii on convex or concave surface.

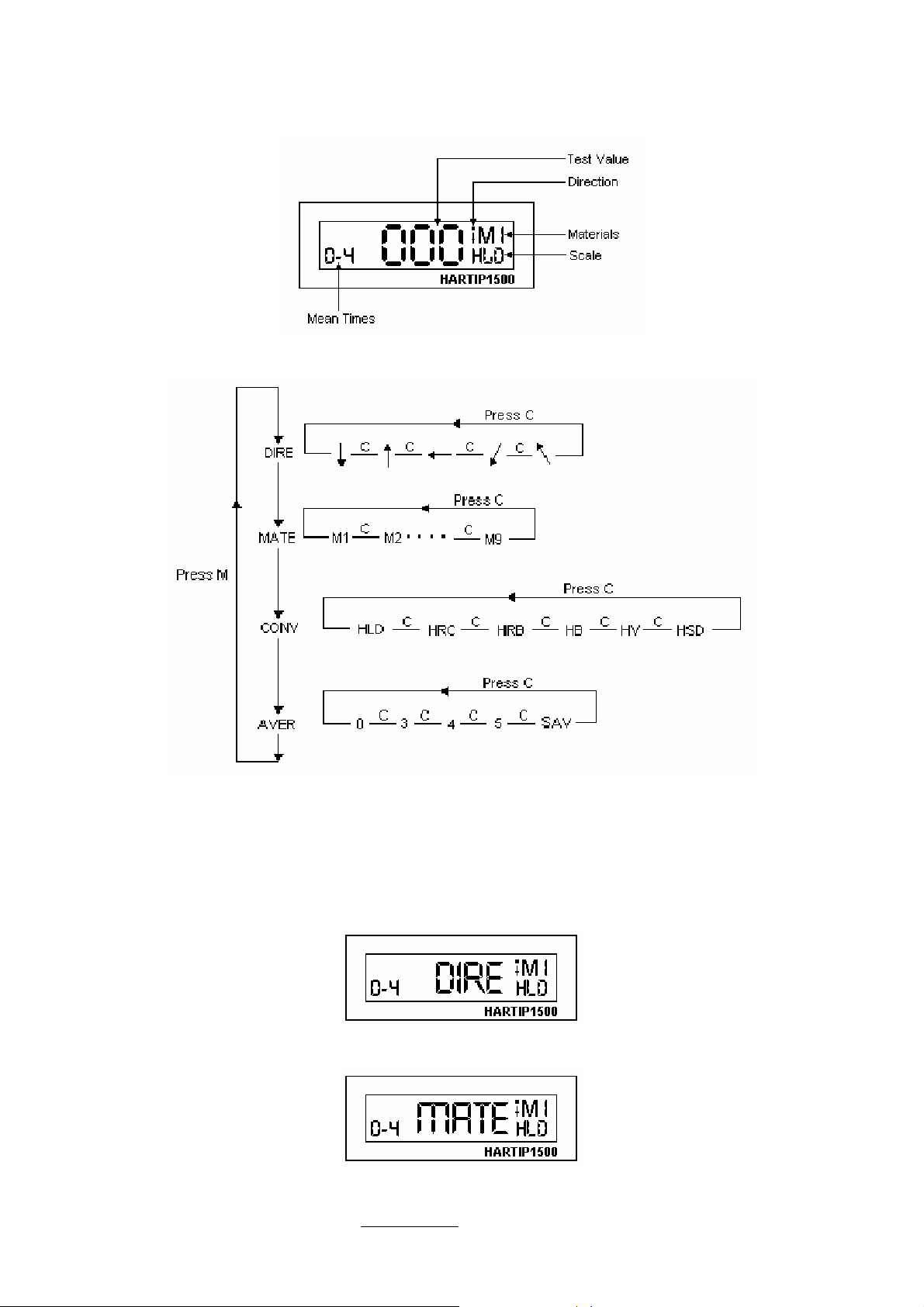

Operation

HARTIP-1500 Manual Rev:00 8 / 14